[For Sale] Turblown BorgWarner EFR IWG Cast Manifold Turbo kits

#1

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

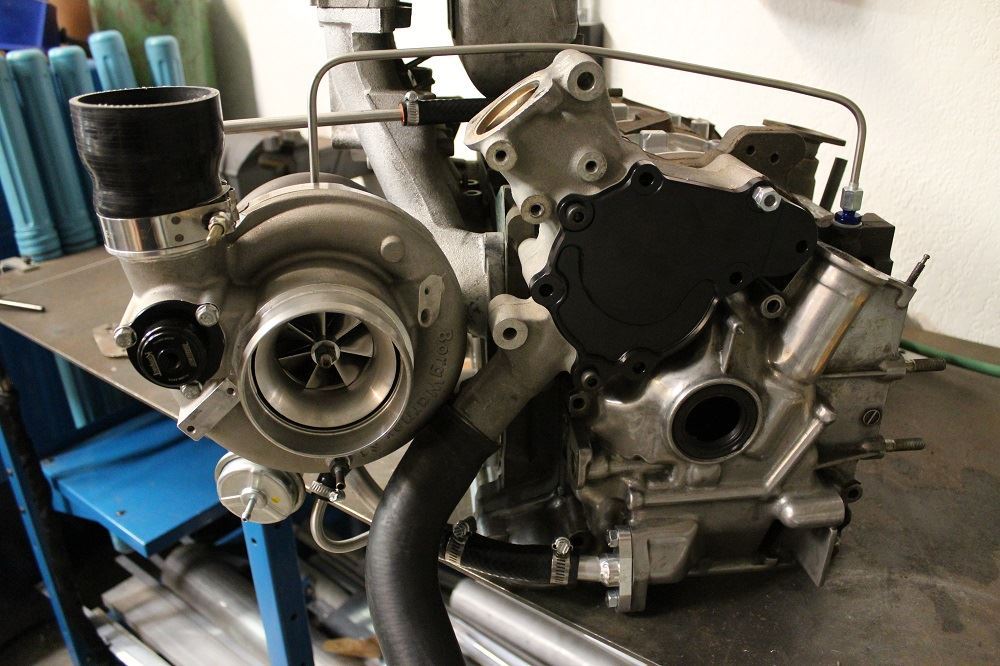

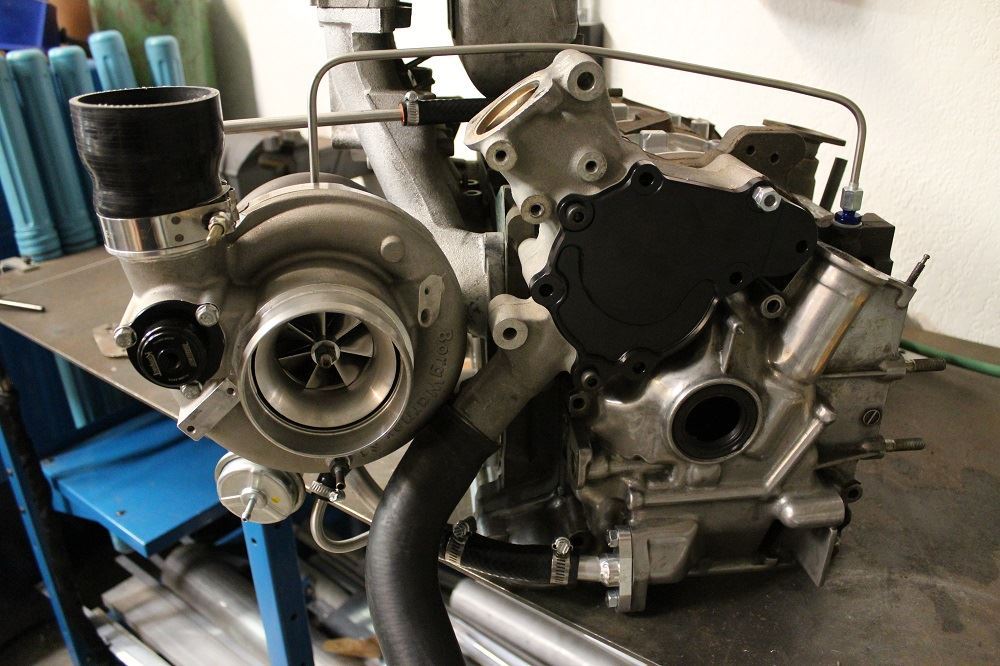

We have 9 Turblown BorgWarner EFR IWG Cast Manifold Turbo kits Available for sale for the FD & FC Chassis.

The Kit gives you the choice of three different size of the BorgWarner EFR IWG Series Turbo's:

EFR 7670 - $3,700.00

EFR 8374 - $3949.00

EFR 9180/9174 $4,149.00

The kit includes the following:

* Your choice of T4 EFR 7670 IWG,8374 IWG, 9174, or 9180 IWG turbocharger

* Stainless hard line turbo cooling lines( oil feed, coolant feed/return & Flexible oil compatible heat shielded oil return line) & hardware

* 304SS TIG welded & back purged Mandrel Bent 3" V-Band downpipe with single o2 sensor bung, vband clamp and 2 bolt gasket/hardware

* 347SS Investment Cast Tapered IWG turbo manifold

* Replacement WG actuator bracket Adapter for necessary placement

* Inconel T4 Turbo Gasket, and Inconel turbo manifold studs & nuts

* Rear turbo oil return block off plate

* K&N 3.5" or 4" air filter depending upon size of the turbo selected

* 2 feet of fire wrap heat sleeve

* FD heater core hardline replacement with new hose and clamps

Please contact our Sales Manager Shawn Christenson to place your order. 763-753-9939

http://www.turbosource.com/BorgWarne...s-fd3siwg-.htm

The Turblown Rx7 EFR IWG Turbo System is designed to deliver the fastest boost response possible while decreasing as many failure points as possible. At the heart of this turbo system is a Ball Bearing BorgWarner EFR(Engineered For Racing) Turbochargers. These Internal Waste-Gate EFR turbochargers also feature Built In Recirc Blow Off Valves, & 3 Port Boost Control Solenoids built into the compressor cover. All of these features in one package reduce the complexity of your turbo system.The turbo is also positioned as low and as far back as possible for extra stealth and a low center of gravity

The internal waste-gate configuration offers considerably less noise than open dump tubes. This is more desirable for street and track cars with decibel limits. Furthermore one does not have to worry about melting your external wastegate lines, or blowing your waste-gate diaphragms( common on road course driven cars with external wastegates). The internal wastegate is also a divorced unit, with two separate runners leading up to one single 42mm waste-gate valve. This is the best internal waste-gate design of any turbocharger. This turbo system is a true twin-scroll unit. It completely separates the exhaust pulses between the two rotors. This separation not only makes more power, but increases boost response. The internal 42mm waste-gate has been proven to properly control boost pressure on a 13b without any creep at medium boost levels( see attached charts of 11-12 psi). This turbo system comes standard with the medium waste-gate canister. Boost pressures lower than 12psi require exhaust restriction( A Catalytic converter, 2.5" exhaust system, or a re stricter insert) on 8374 and 9180 turbo systems. 7670 turbo systems generally maintain lower boost pressures much easier( 7 to 9 psi). A TurboSmart EFR IWG dual port actuator is recommended for those who wish to run both low( 10-12psi, and very high boost pressures with the OE EFR solenoid.

Every single piece of this turbo system is designed for the highest reliability and performance that money can buy. As of 10/17/15 this turbo systems will now include our new 347SS investment cast EFR IWG T4 manifold. This manifold comes standard with twin 1/8 NPT exhaust gas temperature or exhaust manifold back pressure ports( plugs included).

At the heart of the system is a your choice of an EFR 7670, 8374 or 9180 T4 .92 Internal Waste-gate Turbocharger.. The 7670 will deliver the fastest boost response, and lowest boost threshold, and is perfect for a 350 to 400rwhp street, or AutoX car. The 7670 will make over 450rwhp at high boost pressures. The 8374 will deliver a very wide power-band that will work well for road-course driven cars, or higher powered street cars(450-550rwhp selection). The 9180 will provide the highest level of IWG power with its 68mm compressor wheel and 80mm turbine wheel. One should choose the 9180 for 550 to 630+rwhp range.

This turbo system Does Require Supporting Modifications such as an aftermarket ECU, intercooler, clutch, fuel, & ignition upgrades to reach it's full potential.

Turblown Engineeing offers a Lifetime Limited Warranty for the original purchaser on the turbo manifold and downpipe. The turbo is under BorgWarner's One Year limited warranty.

This turbo system Fits Both Left and Right Hand Drive FD3S 93-2002 Rx-7s. It also accommodates the Pineapple Racing Idler Pulley, US-Spec, J-spec, 13BRE, Projay Typhoon & Xcessive FD3S Manufacturing( requires grinding to fit 8374/9180) intake Manifolds. This turbo system does clear the OEM FD3S airpump. 8374 and 9180 turbochargers require a custom tension-er bracket and light trimming to the airpump( see photos). 7670 require zero modifcations. This system also fits the FC3S chassis using RE/REW swaps. 7670 version will fit S4/S5 13BT engine/chassis with zero modifications. The 8374/9180 will fit the FC3S S4/S5 OEM 13BT with a little bit of grinding on the OEM LIM(to clear the bigger compressor cover vband clamp & water line-see photos). Inconel turbine housing shield recommended for the FC3S engine because of close proximity of turbine housing to lower intake manifold.

Default downpipe size is 3". Choose 3.5" if ultimate, power, and boost response are desired. Please note you might experience boost creep with the 3.5" downpipe, especially if used with a full 3.5" or 4" exhaust system. 3" downpipe usually runs around 11psi as your base pressure. FD3S downpipes bolt right up to stock location midpipe/cat. FC3S downpipes do not bolt up to OEM midpipe; they are left blank to fit to your midpipe

S5 FC3S cars require the use of the S4 waterpump housing or cutting/welding as the lower radiator section interferes with placement of the 8374 or 9180 compressor cover. 8374 & 9180 FC cars require an electric fan for turbo inlet duct clearance, V-mounts may or may not fit with this kit on an FC. Our race EWP is another option. Turbo inlet duct( not included) will be require and a tight fit on the 7670 FC cars with stock fan shroud.

OEM A/C line compatible with all models.

The turbo and manifold can be installed together before being placed in the engine bay. Installation does not require the engine to be removed, jacked up, or any studs pulled. This is the easiest single turbo to install that we have ever seen.

Read our Blog about the developments in the EFR IWG technology!

The Kit gives you the choice of three different size of the BorgWarner EFR IWG Series Turbo's:

EFR 7670 - $3,700.00

EFR 8374 - $3949.00

EFR 9180/9174 $4,149.00

The kit includes the following:

* Your choice of T4 EFR 7670 IWG,8374 IWG, 9174, or 9180 IWG turbocharger

* Stainless hard line turbo cooling lines( oil feed, coolant feed/return & Flexible oil compatible heat shielded oil return line) & hardware

* 304SS TIG welded & back purged Mandrel Bent 3" V-Band downpipe with single o2 sensor bung, vband clamp and 2 bolt gasket/hardware

* 347SS Investment Cast Tapered IWG turbo manifold

* Replacement WG actuator bracket Adapter for necessary placement

* Inconel T4 Turbo Gasket, and Inconel turbo manifold studs & nuts

* Rear turbo oil return block off plate

* K&N 3.5" or 4" air filter depending upon size of the turbo selected

* 2 feet of fire wrap heat sleeve

* FD heater core hardline replacement with new hose and clamps

Please contact our Sales Manager Shawn Christenson to place your order. 763-753-9939

http://www.turbosource.com/BorgWarne...s-fd3siwg-.htm

The Turblown Rx7 EFR IWG Turbo System is designed to deliver the fastest boost response possible while decreasing as many failure points as possible. At the heart of this turbo system is a Ball Bearing BorgWarner EFR(Engineered For Racing) Turbochargers. These Internal Waste-Gate EFR turbochargers also feature Built In Recirc Blow Off Valves, & 3 Port Boost Control Solenoids built into the compressor cover. All of these features in one package reduce the complexity of your turbo system.The turbo is also positioned as low and as far back as possible for extra stealth and a low center of gravity

The internal waste-gate configuration offers considerably less noise than open dump tubes. This is more desirable for street and track cars with decibel limits. Furthermore one does not have to worry about melting your external wastegate lines, or blowing your waste-gate diaphragms( common on road course driven cars with external wastegates). The internal wastegate is also a divorced unit, with two separate runners leading up to one single 42mm waste-gate valve. This is the best internal waste-gate design of any turbocharger. This turbo system is a true twin-scroll unit. It completely separates the exhaust pulses between the two rotors. This separation not only makes more power, but increases boost response. The internal 42mm waste-gate has been proven to properly control boost pressure on a 13b without any creep at medium boost levels( see attached charts of 11-12 psi). This turbo system comes standard with the medium waste-gate canister. Boost pressures lower than 12psi require exhaust restriction( A Catalytic converter, 2.5" exhaust system, or a re stricter insert) on 8374 and 9180 turbo systems. 7670 turbo systems generally maintain lower boost pressures much easier( 7 to 9 psi). A TurboSmart EFR IWG dual port actuator is recommended for those who wish to run both low( 10-12psi, and very high boost pressures with the OE EFR solenoid.

Every single piece of this turbo system is designed for the highest reliability and performance that money can buy. As of 10/17/15 this turbo systems will now include our new 347SS investment cast EFR IWG T4 manifold. This manifold comes standard with twin 1/8 NPT exhaust gas temperature or exhaust manifold back pressure ports( plugs included).

At the heart of the system is a your choice of an EFR 7670, 8374 or 9180 T4 .92 Internal Waste-gate Turbocharger.. The 7670 will deliver the fastest boost response, and lowest boost threshold, and is perfect for a 350 to 400rwhp street, or AutoX car. The 7670 will make over 450rwhp at high boost pressures. The 8374 will deliver a very wide power-band that will work well for road-course driven cars, or higher powered street cars(450-550rwhp selection). The 9180 will provide the highest level of IWG power with its 68mm compressor wheel and 80mm turbine wheel. One should choose the 9180 for 550 to 630+rwhp range.

This turbo system Does Require Supporting Modifications such as an aftermarket ECU, intercooler, clutch, fuel, & ignition upgrades to reach it's full potential.

Turblown Engineeing offers a Lifetime Limited Warranty for the original purchaser on the turbo manifold and downpipe. The turbo is under BorgWarner's One Year limited warranty.

This turbo system Fits Both Left and Right Hand Drive FD3S 93-2002 Rx-7s. It also accommodates the Pineapple Racing Idler Pulley, US-Spec, J-spec, 13BRE, Projay Typhoon & Xcessive FD3S Manufacturing( requires grinding to fit 8374/9180) intake Manifolds. This turbo system does clear the OEM FD3S airpump. 8374 and 9180 turbochargers require a custom tension-er bracket and light trimming to the airpump( see photos). 7670 require zero modifcations. This system also fits the FC3S chassis using RE/REW swaps. 7670 version will fit S4/S5 13BT engine/chassis with zero modifications. The 8374/9180 will fit the FC3S S4/S5 OEM 13BT with a little bit of grinding on the OEM LIM(to clear the bigger compressor cover vband clamp & water line-see photos). Inconel turbine housing shield recommended for the FC3S engine because of close proximity of turbine housing to lower intake manifold.

Default downpipe size is 3". Choose 3.5" if ultimate, power, and boost response are desired. Please note you might experience boost creep with the 3.5" downpipe, especially if used with a full 3.5" or 4" exhaust system. 3" downpipe usually runs around 11psi as your base pressure. FD3S downpipes bolt right up to stock location midpipe/cat. FC3S downpipes do not bolt up to OEM midpipe; they are left blank to fit to your midpipe

S5 FC3S cars require the use of the S4 waterpump housing or cutting/welding as the lower radiator section interferes with placement of the 8374 or 9180 compressor cover. 8374 & 9180 FC cars require an electric fan for turbo inlet duct clearance, V-mounts may or may not fit with this kit on an FC. Our race EWP is another option. Turbo inlet duct( not included) will be require and a tight fit on the 7670 FC cars with stock fan shroud.

OEM A/C line compatible with all models.

The turbo and manifold can be installed together before being placed in the engine bay. Installation does not require the engine to be removed, jacked up, or any studs pulled. This is the easiest single turbo to install that we have ever seen.

Read our Blog about the developments in the EFR IWG technology!

Last edited by Turblown; 09-19-17 at 10:12 AM.

#3

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

#4

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

8 kits left to be sold!

#5

* Install the cast manifold on the engine with just 2 nuts top/bottom left/right (make sure its snug)

* Install all 4 inconel studs ( use red high heat lock tight for the studs going into the manifold. Double nut method to get them tight)

* Remove the wastegate actuator

* Remove the WG actuator bracket

* loosen 5/6 bolts on the turbine side of the turbo (leave the 6th tight preferably the one closest to the oil feed)

* loosen the compressor housing Vband

* install the T4 gasket

* install the blue oil feed fitting on the Front iron w/ the copper crush washer

* install the turbo onto the Cast manifold with 2 nuts (I like to use the bottom left and top right and make sure the nuts are relatively snug

* Loosen the 6th nut on the Turbine housing

* Clock the turbo until the oil feed line fits easily on both the turbo and the Iron fitting you will also need to move the compressor housing so it is in the correct place for your intercooler piping. ( Use the long end of the oil feed to go to the turbo and the short for the Iron fitting)

* Tighten the turbine housing bolt that is next to the oil feed line & the compressor housing Vband.

* Remove the oil feed line

* take the turbo off the cast manifold

* Tighten the rest of the 5 Turbine bolts

* install the OEM WG actuator bracket onto the new WG Adapter I sent you

* install the WG bracket/adapter assembly onto the turbo

* install the TurboSmart WG ( Read the Turbosmart instructions they are important when installing it)

* install the oil drain line

* remove the OEM BOV ( there is a rubber gasket inside remove that as well)

* Install the TurboSmart BOV

* install the Oil drain line. ( when you put the clamp over the shield and hose it makes it tight when installing the 2 bolts that go into the turbo to secure the flange to the turbo. I like to have the hose about 1/8th inch from the flange surface. Make sure to have the clamp TIGHT as well to suck it in as much as possible.)

* Flip Flop the Coolant caps on the turbo. (The cap that will be closest to the engine needs to be on the top. The Cap that will be facing the passenger side.)

* Install the Black coolant fittings with the Copper crush washer

* Install the O-Ring Flange onto the front cover.

* Take the cast manifold off the engine.

* Install the turbo onto the cast manifold. (use the Inconel washers & nuts w/ Anti-Seas)

* install the Turbo Assembly onto the engine. ( I recommend Anti-Seas on the Nuts)

* Slip the clamp over the oil drain line. Slip the oil drain line onto the flange that is installed on the front cover. (if you have the engine in the car already you need to jack up the car to get at it.)

* install the oil feed line back again.

* Install the Long SS coolant line hose with a elbo onto the passenger side of the car. The rubber line will go on the TOP coolant nipple that is on the water pump housing. (I suggest after you get it finger tight tighten the hose clams on the FD nipple/end of the SS line then tighten it on the turbo)

* install the Short SS coolant hose with a elbo onto the Engine side of the turbo. (Follow the same strategy with the long SS coolant line) * install the DP ( best to get the V-band flange slightly loose so it can be moved but not fall off. If you have studs on your mid-pipe you will need use a nut and bolt combo. If the DP is not lining up drastically you may need to loosen the nuts on the turbo to re position it on the manifold because there is a little bit of slop and a 1/4 inch movement is over a inch movement at the Vband flange on the turbo.)

* install your intercooler piping

* install your air filter.

* Install all 4 inconel studs ( use red high heat lock tight for the studs going into the manifold. Double nut method to get them tight)

* Remove the wastegate actuator

* Remove the WG actuator bracket

* loosen 5/6 bolts on the turbine side of the turbo (leave the 6th tight preferably the one closest to the oil feed)

* loosen the compressor housing Vband

* install the T4 gasket

* install the blue oil feed fitting on the Front iron w/ the copper crush washer

* install the turbo onto the Cast manifold with 2 nuts (I like to use the bottom left and top right and make sure the nuts are relatively snug

* Loosen the 6th nut on the Turbine housing

* Clock the turbo until the oil feed line fits easily on both the turbo and the Iron fitting you will also need to move the compressor housing so it is in the correct place for your intercooler piping. ( Use the long end of the oil feed to go to the turbo and the short for the Iron fitting)

* Tighten the turbine housing bolt that is next to the oil feed line & the compressor housing Vband.

* Remove the oil feed line

* take the turbo off the cast manifold

* Tighten the rest of the 5 Turbine bolts

* install the OEM WG actuator bracket onto the new WG Adapter I sent you

* install the WG bracket/adapter assembly onto the turbo

* install the TurboSmart WG ( Read the Turbosmart instructions they are important when installing it)

* install the oil drain line

* remove the OEM BOV ( there is a rubber gasket inside remove that as well)

* Install the TurboSmart BOV

* install the Oil drain line. ( when you put the clamp over the shield and hose it makes it tight when installing the 2 bolts that go into the turbo to secure the flange to the turbo. I like to have the hose about 1/8th inch from the flange surface. Make sure to have the clamp TIGHT as well to suck it in as much as possible.)

* Flip Flop the Coolant caps on the turbo. (The cap that will be closest to the engine needs to be on the top. The Cap that will be facing the passenger side.)

* Install the Black coolant fittings with the Copper crush washer

* Install the O-Ring Flange onto the front cover.

* Take the cast manifold off the engine.

* Install the turbo onto the cast manifold. (use the Inconel washers & nuts w/ Anti-Seas)

* install the Turbo Assembly onto the engine. ( I recommend Anti-Seas on the Nuts)

* Slip the clamp over the oil drain line. Slip the oil drain line onto the flange that is installed on the front cover. (if you have the engine in the car already you need to jack up the car to get at it.)

* install the oil feed line back again.

* Install the Long SS coolant line hose with a elbo onto the passenger side of the car. The rubber line will go on the TOP coolant nipple that is on the water pump housing. (I suggest after you get it finger tight tighten the hose clams on the FD nipple/end of the SS line then tighten it on the turbo)

* install the Short SS coolant hose with a elbo onto the Engine side of the turbo. (Follow the same strategy with the long SS coolant line) * install the DP ( best to get the V-band flange slightly loose so it can be moved but not fall off. If you have studs on your mid-pipe you will need use a nut and bolt combo. If the DP is not lining up drastically you may need to loosen the nuts on the turbo to re position it on the manifold because there is a little bit of slop and a 1/4 inch movement is over a inch movement at the Vband flange on the turbo.)

* install your intercooler piping

* install your air filter.

#6

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

Installation Video;

Trending Topics

#8

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

The clocking of the turbo flange plays a direct role in the clocking of the CHRA with an IWG turbo. The BW CHRA does not allow full 360 degree of WG bracket orientation If you do not use the CNC adapter( not a shim), the oil feed/return will be too far out of alignment for proper draining(BW states no more than 20 degrees). It ends up being like 25-27 degrees without the adapter.

#10

Its just an option under the turbo manifold. If you need one separately just call or email us.

The medium actuator( does not matter if its on a 7670 or 8374) cracks at 8.8 psi and is at full stroke( full WG open) at 20psi.

BorgWarner EFR Installation Guide | TurboSource

The medium actuator( does not matter if its on a 7670 or 8374) cracks at 8.8 psi and is at full stroke( full WG open) at 20psi.

BorgWarner EFR Installation Guide | TurboSource

#11

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

We have another batch of manifolds that I was just told are now finished. Just waiting on final inspection, and shipping. Of the 80 units, about 20 are already pre-sold.

Full kits have dropped in price by $300 from the first post...

We have the 7670 turbos in stock, and those are $3700 + freight. We've already finished 50 turbo kits worth of turbo cooling hardware, just making up some of the other parts like downpipes...

Full kits have dropped in price by $300 from the first post...

We have the 7670 turbos in stock, and those are $3700 + freight. We've already finished 50 turbo kits worth of turbo cooling hardware, just making up some of the other parts like downpipes...

#12

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

#13

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

9180 cast kit video at 30 psi

#17

Hey Dude can that downpipe work with the 8374 system from previous made manifold? I have your kit but I been trying to figure out 2 exhaust leak for over 1 year: 1st is where the downpipe bolts on the midpipe and 2nd leak is at the turbo discharge. At first I thought it was my SMB midpipe not sealing properly, so I brought a new Rx7 resonated midpipe same out come brought new metal gasket and Remflex to solve the issue same outcome still leaks at the midpipe section connection. Now at the turbo I a thin metal round gaskets same outcome finally I decide to buy a product that suppose to cure exhaust and it's like a putty type stuff and still it did not cure it. It appears that the new downpipe have flex section on it, do you think it have more flexibility than the older downpipe? Any input is gladly appreciated.

Khris

Khris

#19

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

10 7670 kits are in stock, EFR 9174 are in stock, all 8374 model back orders have shipped. Currently waiting on more 8374 units. 9180 still back ordered.

#20

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

30 8374 model kits in stock, 8 7670, 4 9174. 9180 still on back order.

#21

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

We have 12 of these turbo kits left in stock, once they are sold out. It will be another 100 days until we have more( casting time frame).

Here is the new link on our new website to the kits;

https://turbosource.com/collections/...g-turbo-system

Here is the new link on our new website to the kits;

https://turbosource.com/collections/...g-turbo-system

#22

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

9 left

#23

Thread Starter

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

I just heard from our casting company that 100 more of our IWG manifolds are done. These will be back in stock soon!

Full kits also available soon.

https://turbosource.com/collections/...urbo-kits-fd3s

Full kits also available soon.

https://turbosource.com/collections/...urbo-kits-fd3s