[For Sale] Billet CNC Merge Collector Series Turbo Manifolds - Group Pricing! Details inside.

#1

Thread Starter

Glease Manufacturing

iTrader: (5)

Joined: Jan 2012

Posts: 356

Likes: 1

From: Leamington, Ont

Billet CNC Merge Collector Series Turbo Manifolds - Group Pricing! Details inside.

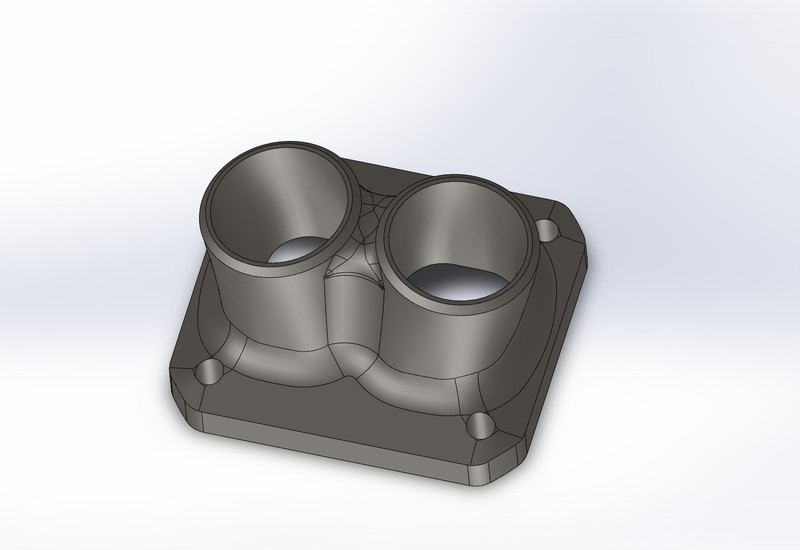

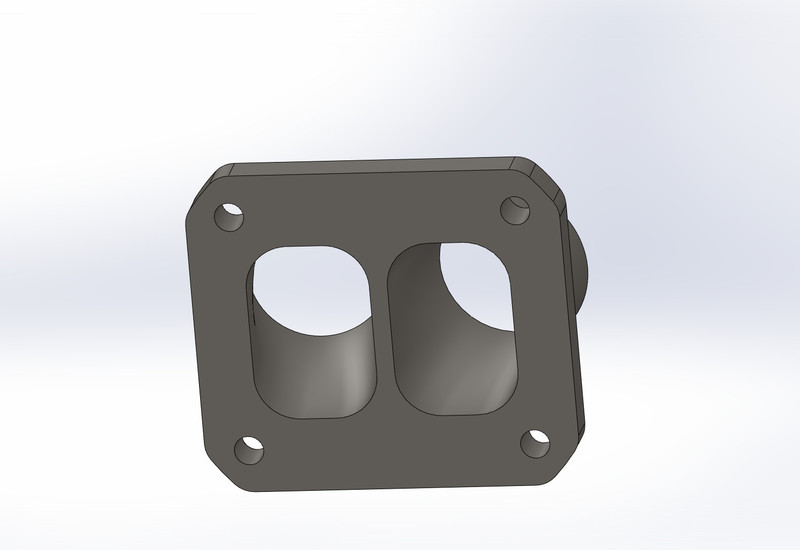

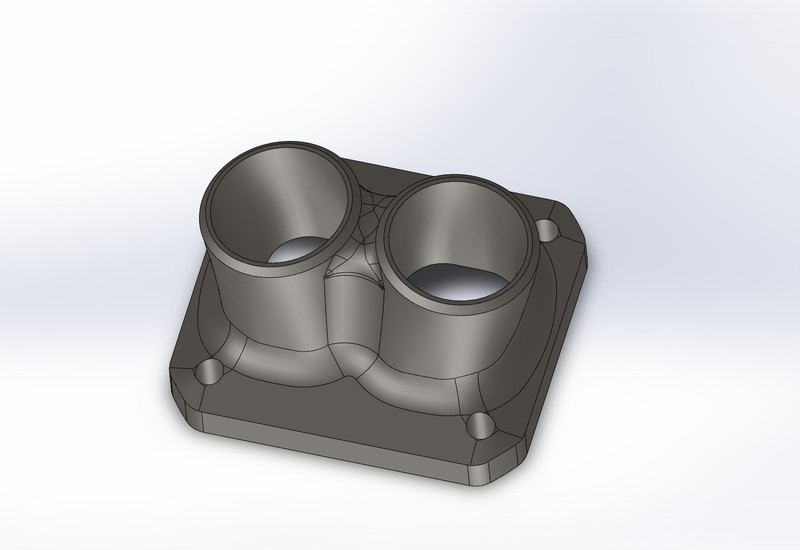

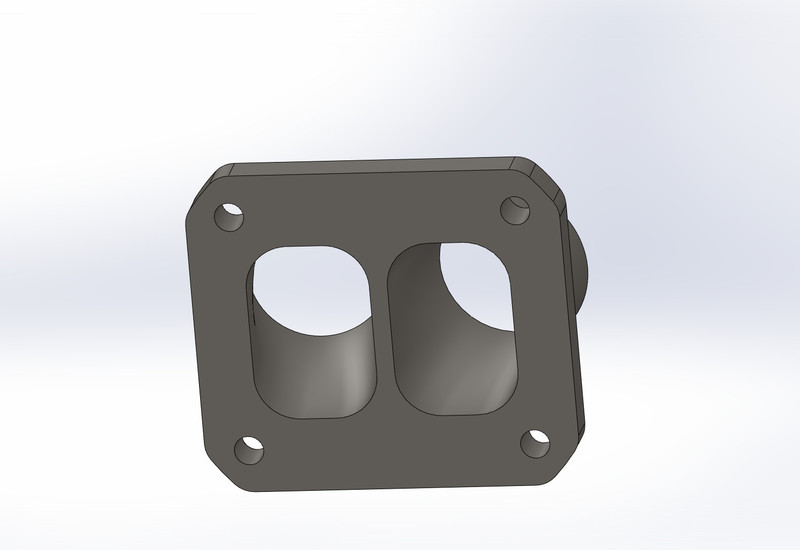

If you've been following our manifold at all, we have been working hard at getting these Billet Merge Collectors designed to our standards and ready for purchase. They're here! This will be by far the highest flowing long runner manifold you can buy. These are 3 weeks away from being complete, but we want to get the ball rolling as early as possible.

We're introducing them with a big discount in a group buy. Two spots are currently reserved, and we'd like to see 4 more minimum to achieve the discount.

Pricing is set to $350USD for the first batch on top of manifold pricing. That's only $1100.00USD for an entire Billet Series Manifold. People have been paying just less than that for the other popular option for years. The pricing will go up after the group buy. They are not available separately, only on our long runner manifolds. We have EFR and SX full turbo kits about to be released, and we'd be happy to quote you a kit if you'd like as well.

For ordering info, please email me - john@gleasemanufacturing.com

There Non-Billet Series manifolds are found here:

https://www.rx7club.com/vendor-class...npipe-1085128/

Machined from a solid block of 304 stainless on a 5 axis CNC, they flow better than ANY merge collector on the market. Typically the tubes of a fabricated merge collector are hand formed into the shape of the T4 flange, and welded into place. That's not terrible, but you're limited to the sizing of the pipe (1.625ID), these units are built much wider than a pipe could ever be, allowing a perfect transition to the turbo flange. Then, when you weld the inside to be able to port it smooth, you bring the collector to welding temp again. Every time that happens, 304 stainless looses strength, particularly in the HAZ (Heat Affected Zone), and that's almost always where you'll see a crack form from. The runners of a manifold are fine to build this way, as long as they're welded properly, but the merge collector takes too much heat too many times for a small part.

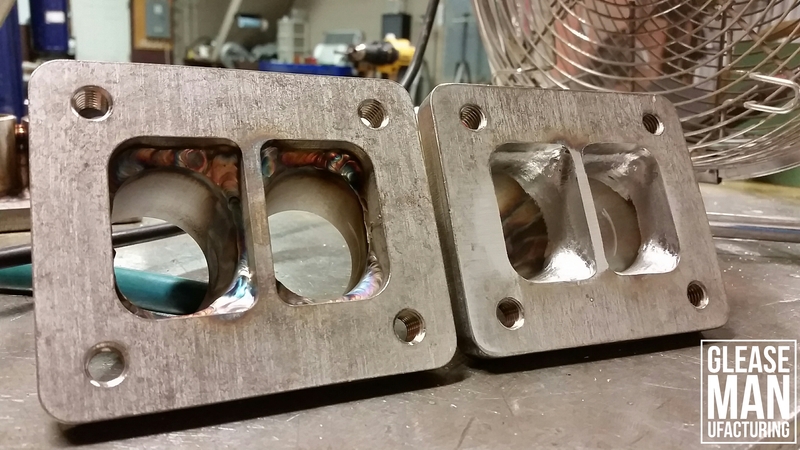

This isn't a sales gimmick, we're so sold out to this that we've changed our standard non-billet series manifolds to a CNC ported T4 flange that only requires one pass to weld, and has the porting already done perfectly by a CNC machine. The only difference is that the billet series will flow better due to not being restrained by pipe size. A more expensive piece to build, and we aren't changing the price at all.

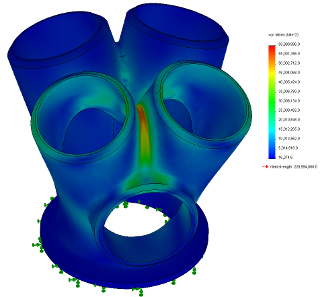

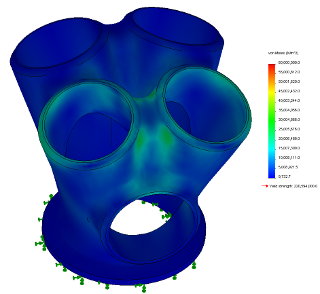

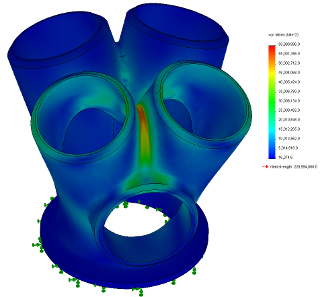

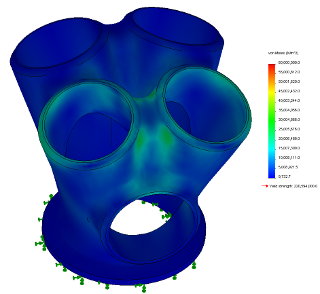

Here's a stress test taken from online, it shows the strength differences between a welded merge collector and a Billet piece. You can see the weak point is where the heat buildup from welding is. Even if welded properly, it's the reality.

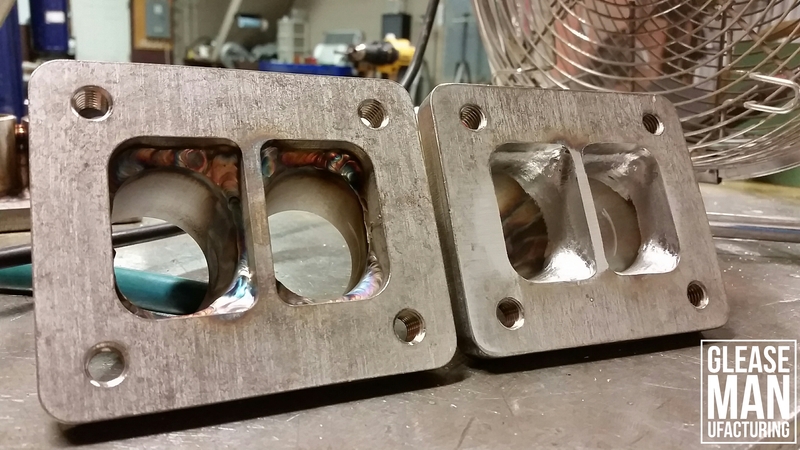

This is also taken from online, we do not sell or own this image, but these are the exact finish you'll see on these. The machine lines are in the same direction as the exhaust flow. Every detail has been worked out.

We're introducing them with a big discount in a group buy. Two spots are currently reserved, and we'd like to see 4 more minimum to achieve the discount.

Pricing is set to $350USD for the first batch on top of manifold pricing. That's only $1100.00USD for an entire Billet Series Manifold. People have been paying just less than that for the other popular option for years. The pricing will go up after the group buy. They are not available separately, only on our long runner manifolds. We have EFR and SX full turbo kits about to be released, and we'd be happy to quote you a kit if you'd like as well.

For ordering info, please email me - john@gleasemanufacturing.com

There Non-Billet Series manifolds are found here:

https://www.rx7club.com/vendor-class...npipe-1085128/

Machined from a solid block of 304 stainless on a 5 axis CNC, they flow better than ANY merge collector on the market. Typically the tubes of a fabricated merge collector are hand formed into the shape of the T4 flange, and welded into place. That's not terrible, but you're limited to the sizing of the pipe (1.625ID), these units are built much wider than a pipe could ever be, allowing a perfect transition to the turbo flange. Then, when you weld the inside to be able to port it smooth, you bring the collector to welding temp again. Every time that happens, 304 stainless looses strength, particularly in the HAZ (Heat Affected Zone), and that's almost always where you'll see a crack form from. The runners of a manifold are fine to build this way, as long as they're welded properly, but the merge collector takes too much heat too many times for a small part.

This isn't a sales gimmick, we're so sold out to this that we've changed our standard non-billet series manifolds to a CNC ported T4 flange that only requires one pass to weld, and has the porting already done perfectly by a CNC machine. The only difference is that the billet series will flow better due to not being restrained by pipe size. A more expensive piece to build, and we aren't changing the price at all.

Here's a stress test taken from online, it shows the strength differences between a welded merge collector and a Billet piece. You can see the weak point is where the heat buildup from welding is. Even if welded properly, it's the reality.

This is also taken from online, we do not sell or own this image, but these are the exact finish you'll see on these. The machine lines are in the same direction as the exhaust flow. Every detail has been worked out.

Last edited by Glease Man; 10-29-15 at 12:56 AM.

#3

Machined from a solid block of 304 stainless on a 5 axis CNC, they flow better than ANY merge collector on the market. Typically the tubes of a fabricated merge collector are hand formed into the shape of the T4 flange, and welded into place. That's not terrible, but you're limited to the sizing of the pipe (1.625ID), these units are built much wider than a pipe could ever be, allowing a perfect transition to the turbo flange. Then, when you weld the inside to be able to port it smooth, you bring the collector to welding temp again. Every time that happens, 304 stainless looses strength, particularly in the HAZ (Heat Affected Zone), and that's almost always where you'll see a crack form from. The runners of a manifold are fine to build this way, as long as they're welded properly, but the merge collector takes too much heat too many times for a small part.

#4

Thread Starter

Glease Manufacturing

iTrader: (5)

Joined: Jan 2012

Posts: 356

Likes: 1

From: Leamington, Ont

Good question, I see where you're going with this. The runners are still 1.612 ID like the pipe attached to it, but on the billet version you're able to transition it to the T4 flange size without squeezing them in a press. It's transitions right through the T4 flange at full ID, not squished pipe to fit and then the gaps welded shut.

Thread

Thread Starter

Forum

Replies

Last Post