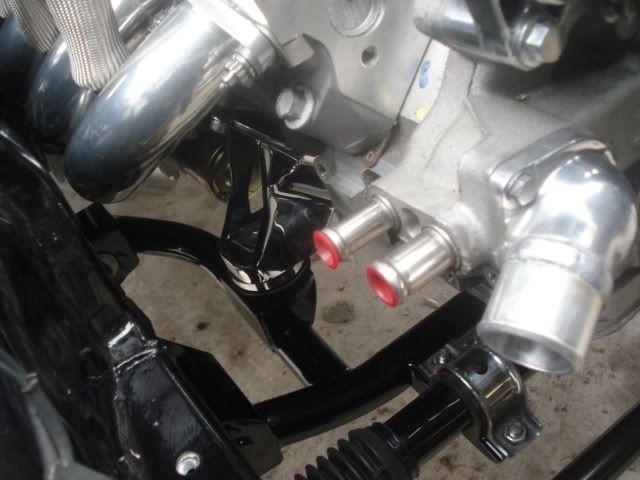

NEW JimLab/Dynotested Subframe

#2

It looks good....

Has anyone proven that these cars do not need the stiffness provided by the stock front subframe? There isn't that much support between the frame rails on the fronts of these cars to help with bending and flexing... granted a box rail design is generally a stiff on its own... I am just unaware if anyone has shown the additional support isn't needed.

At great risk for being flamed, I guess I will say forgive me if I am less than enthusiastic about this latest design... smaller, lighter, and minimalistc design does NOT mean better or even adequate when it comes to automotive designs if they are not engineered to be stronger or stiffer.

Perhaps this design has been engineered, and if so I would like to see the notes to explain the design work that went into this. If it is to be proven through testing that is ok too. It should be stated though.

Sorry if this comes across like an ***.... but I already own what seems to be a $500 paper weight due to excessive flexing which could eventually lead to fatigue failure depending on use. Shame on me for not looking further into the product before buying.

-Chris

Has anyone proven that these cars do not need the stiffness provided by the stock front subframe? There isn't that much support between the frame rails on the fronts of these cars to help with bending and flexing... granted a box rail design is generally a stiff on its own... I am just unaware if anyone has shown the additional support isn't needed.

At great risk for being flamed, I guess I will say forgive me if I am less than enthusiastic about this latest design... smaller, lighter, and minimalistc design does NOT mean better or even adequate when it comes to automotive designs if they are not engineered to be stronger or stiffer.

Perhaps this design has been engineered, and if so I would like to see the notes to explain the design work that went into this. If it is to be proven through testing that is ok too. It should be stated though.

Sorry if this comes across like an ***.... but I already own what seems to be a $500 paper weight due to excessive flexing which could eventually lead to fatigue failure depending on use. Shame on me for not looking further into the product before buying.

-Chris

#3

It looks good....

Has anyone proven that these cars do not need the stiffness provided by the stock front subframe? There isn't that much support between the frame rails on the fronts of these cars to help with bending and flexing... granted a box rail design is generally a stiff on its own... I am just unaware if anyone has shown the additional support isn't needed.

At great risk for being flamed, I guess I will say forgive me if I am less than enthusiastic about this latest design... smaller, lighter, and minimalistc design does NOT mean better or even adequate when it comes to automotive designs if they are not engineered to be stronger or stiffer.

Perhaps this design has been engineered, and if so I would like to see the notes to explain the design work that went into this. If it is to be proven through testing that is ok too.

-Chris

Has anyone proven that these cars do not need the stiffness provided by the stock front subframe? There isn't that much support between the frame rails on the fronts of these cars to help with bending and flexing... granted a box rail design is generally a stiff on its own... I am just unaware if anyone has shown the additional support isn't needed.

At great risk for being flamed, I guess I will say forgive me if I am less than enthusiastic about this latest design... smaller, lighter, and minimalistc design does NOT mean better or even adequate when it comes to automotive designs if they are not engineered to be stronger or stiffer.

Perhaps this design has been engineered, and if so I would like to see the notes to explain the design work that went into this. If it is to be proven through testing that is ok too.

-Chris

I asked the same question 3-4yrs ago about the stiffness lost due to the missing rear section, no one was interested in discussing it at the time, V8 conversions weren't common. The "H" shape of the stock subframe would be significantly stiffer than this design. Only some good FEA would prove out the design though.

Anytime cars are modified you take a risk, the bigger the mod the bigger the risk.

#5

While I would agree that seeing FEA on it would be nice, I do know that Jim is pretty thorough on his designs and concepts, and I would certainly expect that he had accounted for that.

It certainly is pretty.

It certainly is pretty.

#6

Best I can tell, no-one has checked to be confident that the FD doesn't actually rely on some stiffness that the stock front subframe provides to the car... and I'm not going to assume anything about new designs that are this integral to the car.

#7

This is my favorite design, especially since I plan on going LS7 or similar with a dry sump setup and this is the only one that will allow such an oil pan. I still look forward to hearing about high horsepower installs and how well this subframe stands up to the torture before I purchase.

Trending Topics

#9

sorry fellas I have not logged on since I posted the pics, so to answer your questions about this subframe I'm new at this V8 conversion and still working on finishing it up so no results or great info on my end , Jimlab would be the man to ask

#11

Remember, for Jim's purposes (cruising around the street and presumably smoking people in roll-on races), that won't matter. Jim doesn't track/roadrace, or autocross. Your application may vary.

#12

Of course if you aren't planning on getting into an accident we can switch back to the loss of stiffeness effect on handling

.

. Even if you aren't doing track days or auto-xes, a stiff structure allows the suspension to work and give the driver the feeling of control (makes the car feel solid also). I'd guess that the body would benefit from a stiffer subframe but it might be hard to quanitify the difference between stock and modified.

#13

One frame rail isn't going anywhere without the other when tied together by that subframe. The steel used for the mounting pads is considerably thicker than the stock stamped subframe and positively located by the dowel pins and secured by four 17mm studs. You'd have to bend the 1 3/4" 0.120"-wall cross tube before you could shift one frame rail without the other, and that tube is far more rigid than the stock subframe on every axis.

The front control arm boxes are the only ones that really matter, since they're the ones under load by the suspension. You'll notice that the front bushing in the lower control arm is larger and of different construction than the rear. Now you know the reason for that. The rear boxes provide alignment adjustment but aren't under significant load, so they don't need to be connected side to side. The side bars are also 1 3/4" 0.120"-wall tubing and very rigid.

You could easily bend a stock subframe long before this one failed. Or have you forgotten the bent subframe your friend sent me? Didn't that come off a car that didn't have much front end damage, and it appeared to be straight?

I'd guess that the body would benefit from a stiffer subframe but it might be hard to [quantify] the difference between stock and modified.

#14

Consider a cross-section through the horizontal plane of the stock subframe, it is a box section with a front, rear and side sections all tied together. Your subframe is missing the entire rear section. In addition to the rear section being gone the tubes are welded to another tube w/o any gusseting, that equals stress concentrations at the welds.

Do you think one little 1 3/4 cross bar is stronger than the 2 box sections with large radiuses on the stock subframe? Wall thickness isn't nearly as important as the distance between the walls.

Your subframe vs. stock analogous to a convertible vs. a coupe. No matter how much you brace the floor of the convertible it won't be stiffer than the box section body of a coupe.

#15

Why shouldn't I? If someone posted assumptions about the quality of construction of your battery boxes as if they were fact, wouldn't you be defensive?

No, it's not.

A "box", as you put it, resists compression from the sides, but is not a rigid structure in a vertical plane and can still twist, especially when made from cheap stamped steel. A cube resists compression from all sides and distortion or twisting in the vertical plane (think roll cage), and the stock subframe is obviously not a cube (it's just a square), and hence is not a coupe (cube) vs. a convertible ("U").

The only forces that the engine subframe has to resist during operation are the twisting of the engine, the lateral load of the steering rack, and the compressive load of the suspension, which is concentrated at the front as I explained previously. All are more than adequately supported with my subframe, and the frame rails and base of the firewall complete the "box" you're worried about. There would be only a minimal gain in chassis rigidity achieved by adding a rear cross-member to the cradle, and it would interfere with oil pan and exhaust clearance.

If you really believed in your analogy of the box, you'd advise everyone to install a strut tower brace, because they'd be completing the top front of the cube formed by the engine cradle, strut towers, frame rails and firewall, and yet we know that the FD performs just fine without one and handles crashes just fine without one. If you've seen many wrecked FDs (as I know you have), then you know that the front and rear strut tower braces are easily bent in a crash where the forces at work are far in excess of what the car experiences during normal operation. The stock subframe also distorts in a crash, as we've found out.

What you're forgetting is that there are already multiple K-members available from other sources that are very similar in design to mine and they have been in use at drag strips, road courses, and auto-x events. If there were a penalty in performance or strength associated with omitting the rear cross-member of the engine cradle, we'd know it by now.

As I explained before, the rear mounting points are not under the same load as the front and therefore additional bracing at the rear isn't required. My subframe is more rigid than any of the other K-members currently available (Hinson, Granny's, etc.), and none of them have had issues with deflection of the suspension under cornering.

I don't believe that Raceshop (Larry) has added significantly more rigidity to his cradle by adding so many cross-members (just cost and weight), because the cradle becomes part of the overall structure of the chassis (as described above) when attached and doesn't have to stand alone. If you were compressing the rear of my cradle unattached from the car, then sure, it would be more rigid with the rear boxed in, but that's not how it will be subjected to force in use on the car, and the multiple cross tubes just add a mental benefit... but limit the types of oil pans you can use without providing much (if any) real benefit in return.

Yep, and for a reason. The oil pan would object.

Consider a cross-section through the horizontal plane of the stock subframe, it is a box section with a front, rear and side sections all tied together. [edit] Your subframe vs. stock analogous to a convertible vs. a coupe.

A "box", as you put it, resists compression from the sides, but is not a rigid structure in a vertical plane and can still twist, especially when made from cheap stamped steel. A cube resists compression from all sides and distortion or twisting in the vertical plane (think roll cage), and the stock subframe is obviously not a cube (it's just a square), and hence is not a coupe (cube) vs. a convertible ("U").

The only forces that the engine subframe has to resist during operation are the twisting of the engine, the lateral load of the steering rack, and the compressive load of the suspension, which is concentrated at the front as I explained previously. All are more than adequately supported with my subframe, and the frame rails and base of the firewall complete the "box" you're worried about. There would be only a minimal gain in chassis rigidity achieved by adding a rear cross-member to the cradle, and it would interfere with oil pan and exhaust clearance.

If you really believed in your analogy of the box, you'd advise everyone to install a strut tower brace, because they'd be completing the top front of the cube formed by the engine cradle, strut towers, frame rails and firewall, and yet we know that the FD performs just fine without one and handles crashes just fine without one. If you've seen many wrecked FDs (as I know you have), then you know that the front and rear strut tower braces are easily bent in a crash where the forces at work are far in excess of what the car experiences during normal operation. The stock subframe also distorts in a crash, as we've found out.

What you're forgetting is that there are already multiple K-members available from other sources that are very similar in design to mine and they have been in use at drag strips, road courses, and auto-x events. If there were a penalty in performance or strength associated with omitting the rear cross-member of the engine cradle, we'd know it by now.

In addition to the rear section being gone the tubes are welded to another tube w/o any gusseting, that equals stress concentrations at the welds.

I don't believe that Raceshop (Larry) has added significantly more rigidity to his cradle by adding so many cross-members (just cost and weight), because the cradle becomes part of the overall structure of the chassis (as described above) when attached and doesn't have to stand alone. If you were compressing the rear of my cradle unattached from the car, then sure, it would be more rigid with the rear boxed in, but that's not how it will be subjected to force in use on the car, and the multiple cross tubes just add a mental benefit... but limit the types of oil pans you can use without providing much (if any) real benefit in return.

Your subframe is missing the entire rear section.

#18

The entire kit is $1250 shipped.

http://dynotested.com/product_info.p...products_id=30

I dunno what the price of JUST the subframe is, though.

http://dynotested.com/product_info.p...products_id=30

I dunno what the price of JUST the subframe is, though.

#20

Why shouldn't I? If someone posted assumptions about the quality of construction of your battery boxes as if they were fact, wouldn't you be defensive?

No, it's not.

A "box", as you put it, resists compression from the sides, but is not a rigid structure in a vertical plane and can still twist, especially when made from cheap stamped steel. A cube resists compression from all sides and distortion or twisting in the vertical plane (think roll cage), and the stock subframe is obviously not a cube (it's just a square), and hence is not a coupe (cube) vs. a convertible ("U").

The only forces that the engine subframe has to resist during operation are the twisting of the engine, the lateral load of the steering rack, and the compressive load of the suspension, which is concentrated at the front as I explained previously. All are more than adequately supported with my subframe, and the frame rails and base of the firewall complete the "box" you're worried about. There would be only a minimal gain in chassis rigidity achieved by adding a rear cross-member to the cradle, and it would interfere with oil pan and exhaust clearance.

If you really believed in your analogy of the box, you'd advise everyone to install a strut tower brace, because they'd be completing the top front of the cube formed by the engine cradle, strut towers, frame rails and firewall, and yet we know that the FD performs just fine without one and handles crashes just fine without one. If you've seen many wrecked FDs (as I know you have), then you know that the front and rear strut tower braces are easily bent in a crash where the forces at work are far in excess of what the car experiences during normal operation. The stock subframe also distorts in a crash, as we've found out.

What you're forgetting is that there are already multiple K-members available from other sources that are very similar in design to mine and they have been in use at drag strips, road courses, and auto-x events. If there were a penalty in performance or strength associated with omitting the rear cross-member of the engine cradle, we'd know it by now.

As I explained before, the rear mounting points are not under the same load as the front and therefore additional bracing at the rear isn't required. My subframe is more rigid than any of the other K-members currently available (Hinson, Granny's, etc.), and none of them have had issues with deflection of the suspension under cornering.

I don't believe that Raceshop (Larry) has added significantly more rigidity to his cradle by adding so many cross-members (just cost and weight), because the cradle becomes part of the overall structure of the chassis (as described above) when attached and doesn't have to stand alone. If you were compressing the rear of my cradle unattached from the car, then sure, it would be more rigid with the rear boxed in, but that's not how it will be subjected to force in use on the car, and the multiple cross tubes just add a mental benefit... but limit the types of oil pans you can use without providing much (if any) real benefit in return.

Yep, and for a reason. The oil pan would object.

No, it's not.

A "box", as you put it, resists compression from the sides, but is not a rigid structure in a vertical plane and can still twist, especially when made from cheap stamped steel. A cube resists compression from all sides and distortion or twisting in the vertical plane (think roll cage), and the stock subframe is obviously not a cube (it's just a square), and hence is not a coupe (cube) vs. a convertible ("U").

The only forces that the engine subframe has to resist during operation are the twisting of the engine, the lateral load of the steering rack, and the compressive load of the suspension, which is concentrated at the front as I explained previously. All are more than adequately supported with my subframe, and the frame rails and base of the firewall complete the "box" you're worried about. There would be only a minimal gain in chassis rigidity achieved by adding a rear cross-member to the cradle, and it would interfere with oil pan and exhaust clearance.

If you really believed in your analogy of the box, you'd advise everyone to install a strut tower brace, because they'd be completing the top front of the cube formed by the engine cradle, strut towers, frame rails and firewall, and yet we know that the FD performs just fine without one and handles crashes just fine without one. If you've seen many wrecked FDs (as I know you have), then you know that the front and rear strut tower braces are easily bent in a crash where the forces at work are far in excess of what the car experiences during normal operation. The stock subframe also distorts in a crash, as we've found out.

What you're forgetting is that there are already multiple K-members available from other sources that are very similar in design to mine and they have been in use at drag strips, road courses, and auto-x events. If there were a penalty in performance or strength associated with omitting the rear cross-member of the engine cradle, we'd know it by now.

As I explained before, the rear mounting points are not under the same load as the front and therefore additional bracing at the rear isn't required. My subframe is more rigid than any of the other K-members currently available (Hinson, Granny's, etc.), and none of them have had issues with deflection of the suspension under cornering.

I don't believe that Raceshop (Larry) has added significantly more rigidity to his cradle by adding so many cross-members (just cost and weight), because the cradle becomes part of the overall structure of the chassis (as described above) when attached and doesn't have to stand alone. If you were compressing the rear of my cradle unattached from the car, then sure, it would be more rigid with the rear boxed in, but that's not how it will be subjected to force in use on the car, and the multiple cross tubes just add a mental benefit... but limit the types of oil pans you can use without providing much (if any) real benefit in return.

Yep, and for a reason. The oil pan would object.

In an accident, specifically a head on accident when 1 frame rail gets hit the stock subframe is a very rigid structure that ties both rails together and keeps the bending in FRONT of the subframe. Of course it will bend but the load required to bend it will be much higher than yours.

A stock FD has 3 braces in the trans tunnel one on the rear shock towers and the optional R1 brace. If you remove them all could you tell the difference? Did Mazda waste time and money developing them? Probably not. So they do something, at what level is hard to quantify. BTW the stock R1 bar works only in tension by design.

Review the pic here. Front hit to a FD, damage stopped at the stock subframe. Your subframe would not transfer the load to the opposite frame rail nearly as well.

http://rides.webshots.com/photo/1072...34192742xYtjLm

Another thing to consider on your subframe design is the cantilevered steering rack mounts. I'd think about putting a gusset to help reduce the stress on the welds.

#21

Not that Jim needs a public defender here but in the pic you have shown, the damage did'nt even reach the subframe. How would it tranfer a load it has'nt even seen. Also, I own a fab shop and see nothing that needs reinforcement with regards to the steering rack mount, as is, IMO.

#22

Not that Jim needs a public defender here but in the pic you have shown, the damage did'nt even reach the subframe. How would it tranfer a load it has'nt even seen. Also, I own a fab shop and see nothing that needs reinforcement with regards to the steering rack mount, as is, IMO.

If you push on one end of a rod the force is directly and immediatly transferred to the other end of the rod. If the rod is a tube (like a frame rail) and bending/crushing the other end of the rod is "seeing" the load.

The damage didn't reach the subframe, maybe because to bend the subframe you'd have to apply a pretty large force.

I've got a few pics of another FD that was hit directly in the drivers frame rail at home. The subframe was bent, the drivers footwell and tunnel and crinkled, there was even a tiny little tear in the drivers C pillar (or is it B?).

In your experience what is the load on a tie rod end? How much force does it take to move the wheel when the car is stopped.

#23

Sure, Jeff. Get back to me when you can explain how you determined that simply by looking at a picture.

#24

not that it matters... but "if" you do get into a wreck with a v8-fd and you do damage anything. your insurance company wont cover any of the damage bc its not the stock engine. and "if" you have special interest insurance on the car to cover the changes you have made what the heck does it matter if it doesnt stand up to the stress of a front end hit? if it gets back that far your car is totaled!!

#25

It's legal to install a different engine in the car as long as it's from a vehicle of the same year or newer and includes all of the required emissions equipment from the vehicle it came from. The car will still be insured as if it were a stock vehicle for book value. Any modifications over and above the book value of the car may be covered as long as the insurance company knows about them and they are documented with receipts, or at worst, you may have to pay extra for coverage for the additional equipment, but that's true of even rotary RX-7s.