wideband experience

#51

Meters like AEM or LC1 do have the option for sensor calibration, which is fussy IMHO and almost no one do the calibration, let us say once a month, resulting in inaccurate reading.

Just my 2p.

#52

Some companies use free-air calibrations as a selling point, others see it as a design flaw.

If you are planning to perform a free-air calibration, it would be best to remove the sensor from the exhaust piping and make sure it is in clean air (not inside a workshop full of exhaust gases). Calibrating with contaminated air would be counter-productive.

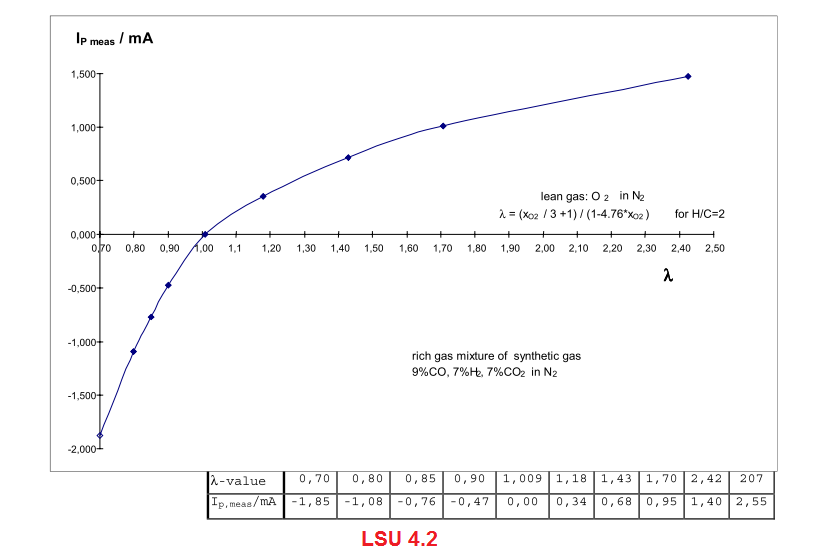

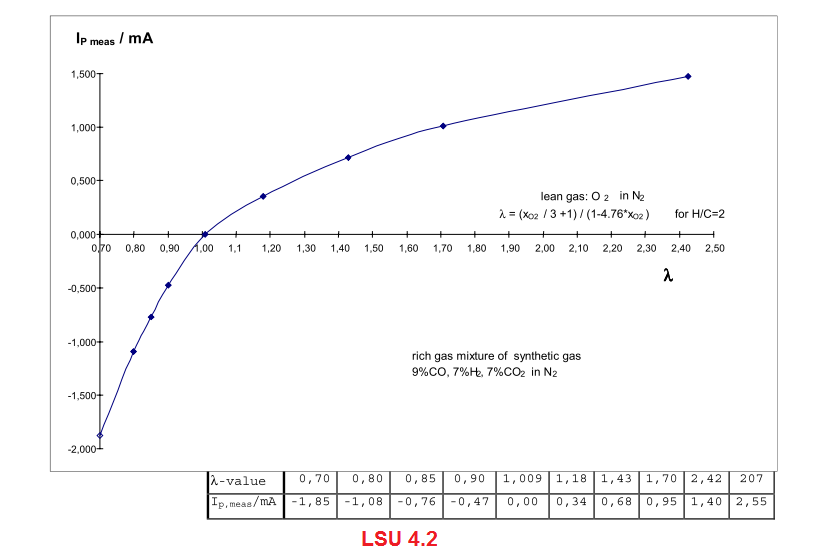

Arghx's chart depicting sensor current at different lambda values is very nice. Note that the rich regions we care about are on the far left side of the scale, and free air is on the far right side, and it's a non-linear curve. Unfortunately, our aftermarket controllers have to work with sensors and control chips that were designed to operate near Lambda = 1.0 for emissions purposes. It may be unwise to assume that every gauge will make identical measurements in the rich region of the curve. As has been mentioned, precise sensor temperature and pressure will skew the readings, so variables such as exhaust backpressure and O2 bung location can make it difficult to assume that every car will work well when running at a certain AFR.

Luckily, most engines I have seen tuned have a relatively wide margin for AFR vs best power. It's not uncommon to make the same power at X AFR and X +/-0.5 AFR. In other words, as long as my wideband measures the same mixture consistently regardless of temperature and pressure, I'm not incredibly concerned that it is within 0.1 AFR of my friend's wideband or some guy on the internet's dyno printout. Many gauges have more error in the wiring between the 0-5V analog output and the ECU or datalogger's input due to grounding offsets, but that's a rabbit hole we shouldn't travel through just yet.

From what I gather, high-dollar race teams purchase calibrated test gas that is used as a reference, and some of them are re-calibrating their setups each time they replace a wideband sensor or controller. This can be purchased from welding gas suppliers as a special order. Although I don't know exactly what AFR they target I suspect it is something more useful than stoich or free air.

If you are planning to perform a free-air calibration, it would be best to remove the sensor from the exhaust piping and make sure it is in clean air (not inside a workshop full of exhaust gases). Calibrating with contaminated air would be counter-productive.

Arghx's chart depicting sensor current at different lambda values is very nice. Note that the rich regions we care about are on the far left side of the scale, and free air is on the far right side, and it's a non-linear curve. Unfortunately, our aftermarket controllers have to work with sensors and control chips that were designed to operate near Lambda = 1.0 for emissions purposes. It may be unwise to assume that every gauge will make identical measurements in the rich region of the curve. As has been mentioned, precise sensor temperature and pressure will skew the readings, so variables such as exhaust backpressure and O2 bung location can make it difficult to assume that every car will work well when running at a certain AFR.

Luckily, most engines I have seen tuned have a relatively wide margin for AFR vs best power. It's not uncommon to make the same power at X AFR and X +/-0.5 AFR. In other words, as long as my wideband measures the same mixture consistently regardless of temperature and pressure, I'm not incredibly concerned that it is within 0.1 AFR of my friend's wideband or some guy on the internet's dyno printout. Many gauges have more error in the wiring between the 0-5V analog output and the ECU or datalogger's input due to grounding offsets, but that's a rabbit hole we shouldn't travel through just yet.

From what I gather, high-dollar race teams purchase calibrated test gas that is used as a reference, and some of them are re-calibrating their setups each time they replace a wideband sensor or controller. This can be purchased from welding gas suppliers as a special order. Although I don't know exactly what AFR they target I suspect it is something more useful than stoich or free air.

Last edited by scotty305; 04-24-12 at 02:55 AM.

#55

I ordered the ecotrons ALM wideband with the 4.9 sensor and will be testing it once I receive it. Reason I ordered it was I got tired of the bulky LM-2's and it has some nice connectors.

thewird

#56

Had a chance to test the Ecotrons wideband with the 4.9 sensor against an NGK Powerdex. This was tested in the same car at the same time and the sensors are only about 1" apart so it was a good test bed. Some interesting results to say the least.

Between about 11.3 and 13.0 AFR, the sensors would were reading 100% identical. It was beyond those ranges where things got interesting. When the Powerdex was reading 15+ AFR, the Ecotrons was reading almost 1 whole AFR leaner. Going to the opposite end, when the Powerdex was reading 11.0, the Ecotrons was reading somewhere around 10.6-10.8 (it was hard getting a stable an stable rich reading since I'm only partial boosting this car for now). Maybe tomorrow, I'll make it idle rich for an steady comparison.

Anyway, just figured I'd post my findings. The extreme lean differences between the 2 widebands makes me wonder which is the correct reading. The 4.9 is supposed to be more accurate in the lean range from the 4.2

thewird

Between about 11.3 and 13.0 AFR, the sensors would were reading 100% identical. It was beyond those ranges where things got interesting. When the Powerdex was reading 15+ AFR, the Ecotrons was reading almost 1 whole AFR leaner. Going to the opposite end, when the Powerdex was reading 11.0, the Ecotrons was reading somewhere around 10.6-10.8 (it was hard getting a stable an stable rich reading since I'm only partial boosting this car for now). Maybe tomorrow, I'll make it idle rich for an steady comparison.

Anyway, just figured I'd post my findings. The extreme lean differences between the 2 widebands makes me wonder which is the correct reading. The 4.9 is supposed to be more accurate in the lean range from the 4.2

thewird

#57

Here is an older but good thread on widebands and sensors.

https://www.rx7club.com/single-turbo...el-c16-607774/

Most of the posts on there are from real experience.

Anthony

https://www.rx7club.com/single-turbo...el-c16-607774/

Most of the posts on there are from real experience.

Anthony

#59

#60

this is a nice topic so I tought it would be better to revive it instead of making a new one..

I am sick and tired of my LM-2 and therefore I want to buy a decent instrument once and for all.

The 3 viable sensors are NTK L2H2, NTK lab grade 7ZB2 and LSU4.9

the sub 1000 usd price range controllers that I am targeting are:

NGK powerdex, the cheapest available at 250 usd. seems to be a nice unit and can work with both the NTK L2H2 sensor and the LSU4.9. It has only analog output, altough on forums it is said the units read about .5 afr point rich. also they do not use the CJ125 chip which the LSU4.9 requires to work well.

ALM Wideband. slightly more expensive at 259 usd for the gasoline version and 339 usd for the diesel version with the more robust LSU4.9D sensor. this one has analog and CAN output, which is nice when conncting to and aftermarket ecu or to a PC

ALM Wideband dual channel. seems to be a very nice unit for the price (600USD) as it also has analog input so one can see dual channel afr and dual channel EGT on one display. also works with LSU4.9

NEKO AF700 this one is about 4 times more expensive the then ones above, the reason for this that it uses the NTK 7ZB2 lab gade sensor which costs around 450-500 USD vs the 150 USD for a normal L2H2 sensor

now the main question is. how well does the LSU4.9 stand rotary exhaust conditions. the LSU4.2 sensors die within 10 minutes without heatsink, and even with heatsink their reaction speed becomes really slow after some use. the LSU 4.9 is reported to be much better but I want to ask if some people had succes with it. from what I read on the NTK sensors, it seems they are very robust and have no problems being installed without heatsink directly after turbo...

I am sick and tired of my LM-2 and therefore I want to buy a decent instrument once and for all.

The 3 viable sensors are NTK L2H2, NTK lab grade 7ZB2 and LSU4.9

the sub 1000 usd price range controllers that I am targeting are:

NGK powerdex, the cheapest available at 250 usd. seems to be a nice unit and can work with both the NTK L2H2 sensor and the LSU4.9. It has only analog output, altough on forums it is said the units read about .5 afr point rich. also they do not use the CJ125 chip which the LSU4.9 requires to work well.

ALM Wideband. slightly more expensive at 259 usd for the gasoline version and 339 usd for the diesel version with the more robust LSU4.9D sensor. this one has analog and CAN output, which is nice when conncting to and aftermarket ecu or to a PC

ALM Wideband dual channel. seems to be a very nice unit for the price (600USD) as it also has analog input so one can see dual channel afr and dual channel EGT on one display. also works with LSU4.9

NEKO AF700 this one is about 4 times more expensive the then ones above, the reason for this that it uses the NTK 7ZB2 lab gade sensor which costs around 450-500 USD vs the 150 USD for a normal L2H2 sensor

now the main question is. how well does the LSU4.9 stand rotary exhaust conditions. the LSU4.2 sensors die within 10 minutes without heatsink, and even with heatsink their reaction speed becomes really slow after some use. the LSU 4.9 is reported to be much better but I want to ask if some people had succes with it. from what I read on the NTK sensors, it seems they are very robust and have no problems being installed without heatsink directly after turbo...

#61

So I've used the LSU 4.2, 4.9, NGK 7ZB2, Denso production vehicle sensors and also emissions bench to calculate AFR in an engine dyno lab environment. I've also used the LSU 4.2 on various aftermarket widebands in cars.

The reason why the LSU 4.2 fails on Innovate products is because they have crappy heater control. The LSU 4.9 has a higher nominal rated temperature btw, and the LSU-ADV and other newer Bosch products are also available. The main difference is light off time. I've beaten the daylights out of all of those sensors, throwing very high exhaust temperatures at them in cars and on engine dynos. At first I thought that the Innovate widebands were just smart enough to detect a problem, but the main explanation is poor heater control.

The reason for this is simple. There are a factory direct injected turbo applications running around with LSU 4.2 and many of these other sensors (late 90s Audi 1.8T engine was the original mass production application for that sensor). Modern turbo piston engines have exhaust temperatures as hot or hotter than an FD. I'm talking over 1000C (over 1850F) before the turbo with some temperature drop after that. There are also plenty of other aftermarket widebands that never seem to have catastrophic failure.

The reason why the LSU 4.2 fails on Innovate products is because they have crappy heater control. The LSU 4.9 has a higher nominal rated temperature btw, and the LSU-ADV and other newer Bosch products are also available. The main difference is light off time. I've beaten the daylights out of all of those sensors, throwing very high exhaust temperatures at them in cars and on engine dynos. At first I thought that the Innovate widebands were just smart enough to detect a problem, but the main explanation is poor heater control.

The reason for this is simple. There are a factory direct injected turbo applications running around with LSU 4.2 and many of these other sensors (late 90s Audi 1.8T engine was the original mass production application for that sensor). Modern turbo piston engines have exhaust temperatures as hot or hotter than an FD. I'm talking over 1000C (over 1850F) before the turbo with some temperature drop after that. There are also plenty of other aftermarket widebands that never seem to have catastrophic failure.

#64

ZT-2 works indeed quite good but it still work with the older lsu 4.2. I installed one in the a TII with the small disply in in the clock location, fits perfect and looks really stealth.. a bad thing to use it for is to trigger w/m injection as the output switches really slow causing a short time of injection at when the throttle is already closed

#66

I've been running an NGK AFX w/ NTK sensor with good results for a few years now. I've run well over 100 gallons of leaded race fuel on the original sensor with no issues. I check the calibration over few months and rarely requires any adjustment. My only complaint is the response is a little slow, IMO, and I do believe it reads a little leaner than actual.

I've had a few AEM UEGO's and they're an OK cheapo gauge. Response is quick but the sensor life is relatively short and I've had issues with the display going dim and being essentially unreadable during the day..

I've had a few AEM UEGO's and they're an OK cheapo gauge. Response is quick but the sensor life is relatively short and I've had issues with the display going dim and being essentially unreadable during the day..

#67

The Primary problem is it does not read accurate all the time. I will start up the car, let the sensor warm up or whatever (light on it goes out) and I start the car. Im pretty sure My idle isnt pinned to 8.5 AFR. Im also pretty sure under full decel (No fuel injection whatsoever) I have a higher AFR than 13. Sometimes it reads what I guess is correct. Like 12.5 AFR at idle, and 10.5 at WOT. 17+ at full decel.

I really don't know what to do about it. It cant be the sensor because as soon as I put in the new one it made no difference.