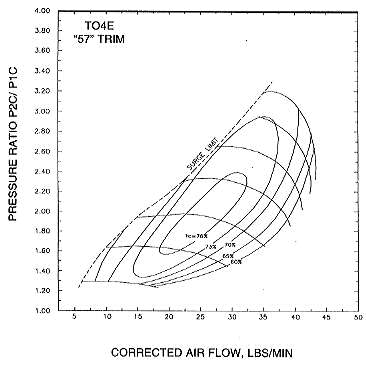

what do you think of this compressor map

Trending Topics

#8

Compressor efficiency drops off pretty steadily after 1 bar.

Assuming that 1 hp = 1 lbs/m, you'll be around 380hp in the 78% efficiency range (sweet spot).

However, you can MAX this turbo to mid-high 400hp on the flywheel at 2 bar of boost.

500hp to the wheels or flywheel? I seriously doubt you'll hit 500hp at the wheels with this turbo.

It shouldn't make tons of heat unless you push that turbo way out of it's efficiency range (< 75%).

Looks like a pretty good street n strip turbo.

I bet it would act great in an auto-x trac or small road track. An all around good turbo.

It's hard to tell spool characteristics without turbine information and the turbine housing spec.

J

Assuming that 1 hp = 1 lbs/m, you'll be around 380hp in the 78% efficiency range (sweet spot).

However, you can MAX this turbo to mid-high 400hp on the flywheel at 2 bar of boost.

500hp to the wheels or flywheel? I seriously doubt you'll hit 500hp at the wheels with this turbo.

It shouldn't make tons of heat unless you push that turbo way out of it's efficiency range (< 75%).

Looks like a pretty good street n strip turbo.

I bet it would act great in an auto-x trac or small road track. An all around good turbo.

It's hard to tell spool characteristics without turbine information and the turbine housing spec.

J

#9

AJatx, do you mean 10hp = 1 lbs/min? This is a topic I brought up a little while ago and not many would touch it with a 10 foot pole. Considering our typical pressure levels (~2.0-2.5), it appeared than anything under a T-66 compressor was too small to be kept in its highest efficiency level for 400-450 rwhp.

#10

Rotary Freak

Joined: Jan 2002

Posts: 1,640

Likes: 0

From: l.a.

btwn, 50 to 58 lbs/min. he's still w/in 72-74% efficiency, this is still great efficiency. when choosing a compressor, the trick is to be to the right of peak efficiency. the drop off in efficiency isn't that great, but you'll get much better spool because the compressor is smaller. if you were to get a turbo that had peak efficiency at 60lbs/min., it would be huge and very laggy. at 500 crank hp this turbo will still be very happy and it'll offer much less lag than a bigger one. even 500whp isn't a problem as long as he keeps his backpressure and intake air temps under control.

#11

Originally posted by fdracer

btwn, 50 to 58 lbs/min. he's still w/in 72-74% efficiency, this is still great efficiency. when choosing a compressor, the trick is to be to the right of peak efficiency. the drop off in efficiency isn't that great, but you'll get much better spool because the compressor is smaller. if you were to get a turbo that had peak efficiency at 60lbs/min., it would be huge and very laggy. at 500 crank hp this turbo will still be very happy and it'll offer much less lag than a bigger one. even 500whp isn't a problem as long as he keeps his backpressure and intake air temps under control.

btwn, 50 to 58 lbs/min. he's still w/in 72-74% efficiency, this is still great efficiency. when choosing a compressor, the trick is to be to the right of peak efficiency. the drop off in efficiency isn't that great, but you'll get much better spool because the compressor is smaller. if you were to get a turbo that had peak efficiency at 60lbs/min., it would be huge and very laggy. at 500 crank hp this turbo will still be very happy and it'll offer much less lag than a bigger one. even 500whp isn't a problem as long as he keeps his backpressure and intake air temps under control.

#14

Thread Starter

Eats, Sleeps, Dreams Rotary

iTrader: (61)

Joined: Aug 2001

Posts: 3,103

Likes: 1

From: Nago Okinawa

I went to a turbo shop in Dallas. I was planning on getting the GT4088 after they tracked down the part number they found the 4088 is not made any more.

but the Borg&Warner S300 was the direct replacement in there cross ref book.

so they had them fax us a compressor map. I already had a 4088 comp map and its almost the same. but the 4088 was a little larger.

here is the GT4088 comp map

http://www.limitengineering.com/catalog.pdf

its on page 21

but the Borg&Warner S300 was the direct replacement in there cross ref book.

so they had them fax us a compressor map. I already had a 4088 comp map and its almost the same. but the 4088 was a little larger.

here is the GT4088 comp map

http://www.limitengineering.com/catalog.pdf

its on page 21

#16

For a basic explanation ...... Read it like it was a plateau map for geography class.. The smaller plateaus towards the middle are higher efficiency the very middle/top one being the most efficient. You want to size your turbo so that when you are at peak efficiency for the longest amount of time during your powerband. IE - your turbo is doing its best work when you want it to. Boot pressure in ATM is on the left (2 = 2atms) and compressor flow is on the right (Lbs/min) That number is basically how much air your turbo is moving/compressing in relation to your exhaust gases at a certain boost level. I *THINK* I got that right - somebody correct me if I'm wrong. -JinX

Oh yeah - so you figure out how much HP you want - then figure out how many lbs of boost you need to run to get there and find a turbo that is at peak efficiency for that boost level. Talk to Kenku for a more detailed explanation - he has a much better grasp than I do. (So do other people on this board, I just happen to know him personally)

Oh yeah - so you figure out how much HP you want - then figure out how many lbs of boost you need to run to get there and find a turbo that is at peak efficiency for that boost level. Talk to Kenku for a more detailed explanation - he has a much better grasp than I do. (So do other people on this board, I just happen to know him personally)

Last edited by JinXed; 05-08-03 at 02:58 PM.

#20

Thread Starter

Eats, Sleeps, Dreams Rotary

iTrader: (61)

Joined: Aug 2001

Posts: 3,103

Likes: 1

From: Nago Okinawa

here is a few pics of my S300

http://www.teamfc3s.org/forum/showth...threadid=13243

http://rx7.cyberosity.com/87GTR/pics/2003/05102003/

http://www.teamfc3s.org/forum/showth...threadid=13243

http://rx7.cyberosity.com/87GTR/pics/2003/05102003/

#22

Full Member

Joined: Sep 2002

Posts: 86

Likes: 0

From: Sweden

Originally posted by 87GTR

wankelman

do you have your car up and running? IM going to be installing the S300 tomorrow. getting a downpipe made for it.

wankelman

do you have your car up and running? IM going to be installing the S300 tomorrow. getting a downpipe made for it.

What manifold are you going to use, and what A/R do you have on the compressor and turbine?

#23

We've got the BorgWarner S300 running on 87GTR's car. Fortunately, the compressor is kick butt. Unfortunately, the turbine housing is too large in both of our opinions. We opted for the 1.15 A/R but I'm unsure of the actual dimensions of the turbine. Even using two bridgeport cuts in the outer end plates on the motor, it's still taking too long to get moving. It's equivalent to a 5500rpm to 8500rpm power-band like on a high-powered race car only and leaves little to be desired on the street.

Hopefully, we can find a different turbine setup for this and go to one trim size smaller.

We managed to get the turbo to fit nicely in the engine bay with a couple of spacers here and there. We had the exhaust made today and used a 4" to 3" reducer and it worked pretty well. But, at the end of the day, it gets into boost too late in the RPM band. We're going to find out what options we have tomorrow.

Updates soon.

B

Hopefully, we can find a different turbine setup for this and go to one trim size smaller.

We managed to get the turbo to fit nicely in the engine bay with a couple of spacers here and there. We had the exhaust made today and used a 4" to 3" reducer and it worked pretty well. But, at the end of the day, it gets into boost too late in the RPM band. We're going to find out what options we have tomorrow.

Updates soon.

B