Sensors/instrumentation

#1

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

Sensors/instrumentation

our engines are really small

they make a ton of power when turbo'd

we are much closer to disaster than we think.

400 rwhp, that's 460 flywheel.... from 1.3 liters is considered middle of the road on the rotary power food chain.

it may be middle of the road but it is stratospheric in the real world.

for instance,

Camaro ZL1 supercharged titanium rodded makes 580 flywheel from 6.1 liters

Shelby GT500 4 valve supercharged makes 662 flywheel from 5.8 liters

both of these 2013 power-trains are pumped to the max for competitive reasons and the engineering post dates our FD by 20 years.

an additional sobering consideration is that the rotary has no cooling benefit as a 4 cycle where every other TDC is a non power event. the rotary is a 2 cycle.

given the prodigious power output of the turbo rotary...

we need to know what's going on.

the vital and necessary link between the engine and our understanding of it's operating specifics is the sensor.

instrumentation makes up for genius, and that's what this thread is about.

do instrumentation right and you may be able to remove your engine builder from speed dial.

properly fixtured, there is no reason to lose a motor.

let's talk sensors and instrumentation...

what do you run?

what would you like to run?

what is essential?

what specific brands are you happy with?

what specific brands have not worked for you?

what would you like to see ECUs offer calibrated click-on settings for?

since all single turbo setups make significantly more power than stock the important subject of instrumentation transcends the ECU Section and rightly belongs here, in the Single Turbo Section.

here's my current setup:

WIDEBAND

i run the NGK AFX. i have previously run 3 other WBs. i had a Techedge that worked well, an FJO that did not match up to the dyno, i then tried an Ecotrons that used the new Bosch 4.9 sensor. it did not line up w the dyno and it may have been a calibration problem so the jury is out. i finally took Luke's advice and switched to the NGK AFX and all is well. it is important to have accurate AFRs as my ViPEC V88 does do auto tune and of course it needs good input data. one of the benefits of the AFX is it reads very well in the "rich" area where many tune at 500 and above.

calibration is always a MAJOR issue on all WBs. how is your WB as to calibration?

what do you run and is it accurate? the manufacturers would like to get a sense of which brands have market share so they can offer brand specific calibration.

PRESSURE SENSORS

i use four.

fuel pressure...essential IMO

oil pressure

Auxiliary Injection pressure

Exhaust Back Pressure (EBP). that's between the engine and turbo

the problem i have had is i had an accumulation of pressure sensors and they all had different calibration numbers. Honeywell makes the good ones. recently Honeywell has introduced the PX2 line. the PX2 replaces all other Honeywell pressure sensors and is available in just about any configuration. i just bought four 0-150 psi sensors so i can use one calibration table. the PX2 is also available in metric/BAR. since they are +/- 2% across the range i will use the 0-150 for all four apps. the 10 BAR would work well if you are metric. $84 each.

if you look at your adj fuel pressure regulator and see a small dial (analog) you need to tell your engine you are sorry and lose the gauge and add a digital pressure sensor... your regulator should look like this...

if you do that you will have this:

you then relate it to this:

which will allow you to answer an important question...

what's my fuel pressure at 8000 RPM?

26,522/10,000 X 14.22 - 14.7= 23.0 PSI boost

40 static pressure + 23 boost = 63 Fuel pressure at 8000

recorded pressure 63.5

all is well

all is well w the fuel pump, the fuel pump sock, the connecting hose, the fuel pump filter, the regulator.

if you have the little gauge screwed into your FPR you can't answer any of those questions. if you have a fuel pressure gauge in your cockpit i challenge you to read it at 8000 rpm.

the Power FC/Datalogit can deliver the data for the price of a sensor... lots cheaper than a new motor.

here's another fuel pressure view from a newer ECU... my V88

i do have similar pressure plots for Oil, AI system pressure and EMP.

KNOCK

given the obvious huge combustion chamber pressures and heat that the turbo'd rotary runs knock is a key item. there exists numerous views as to the value of knock data.

my friend who makes a bit more than 1000 rwhp says knock is a complete waste of time. by the time you experience it your motor is gone.

well yah at 1000 hp. most of us don't operate in that crazy world.

i have always considered the OE generated knock readings as reported thru my Datalogit to be very helpful. if the tune is good knock should drop under boost to around the 10 area. if not, you'd best be looking for answers. further, i had occasion to test 5 OE knock sensors and they all checked out similarly. simply put, the FD OE setup combined w the Datalogit is excellent and helpful.

one of our members (Richard Green "JZG") from New Zealand has shared some excellent info on his dyno tuning process. his 2300 pound Mazda makes around 6-700 hp and has run 9.1 at over 150. it is a pretty simple build w a BW S475 and a pre turbo water AI setup. they tune 100% off knock. while the ECU is a ViPEC, it is the less featured V44. they purchased a ViPEC KnockBlock separate module and use it in conjunction w the ViPEC Knock Amplifier kit which uses headphones.

they tune til the start of noise and that's it. i recently purchased the ViPEC Knock Amp Kit and Luke uses it at Beyond Redline. we have had it for a few months and Luke says it has changed the way he tunes. nuff said.

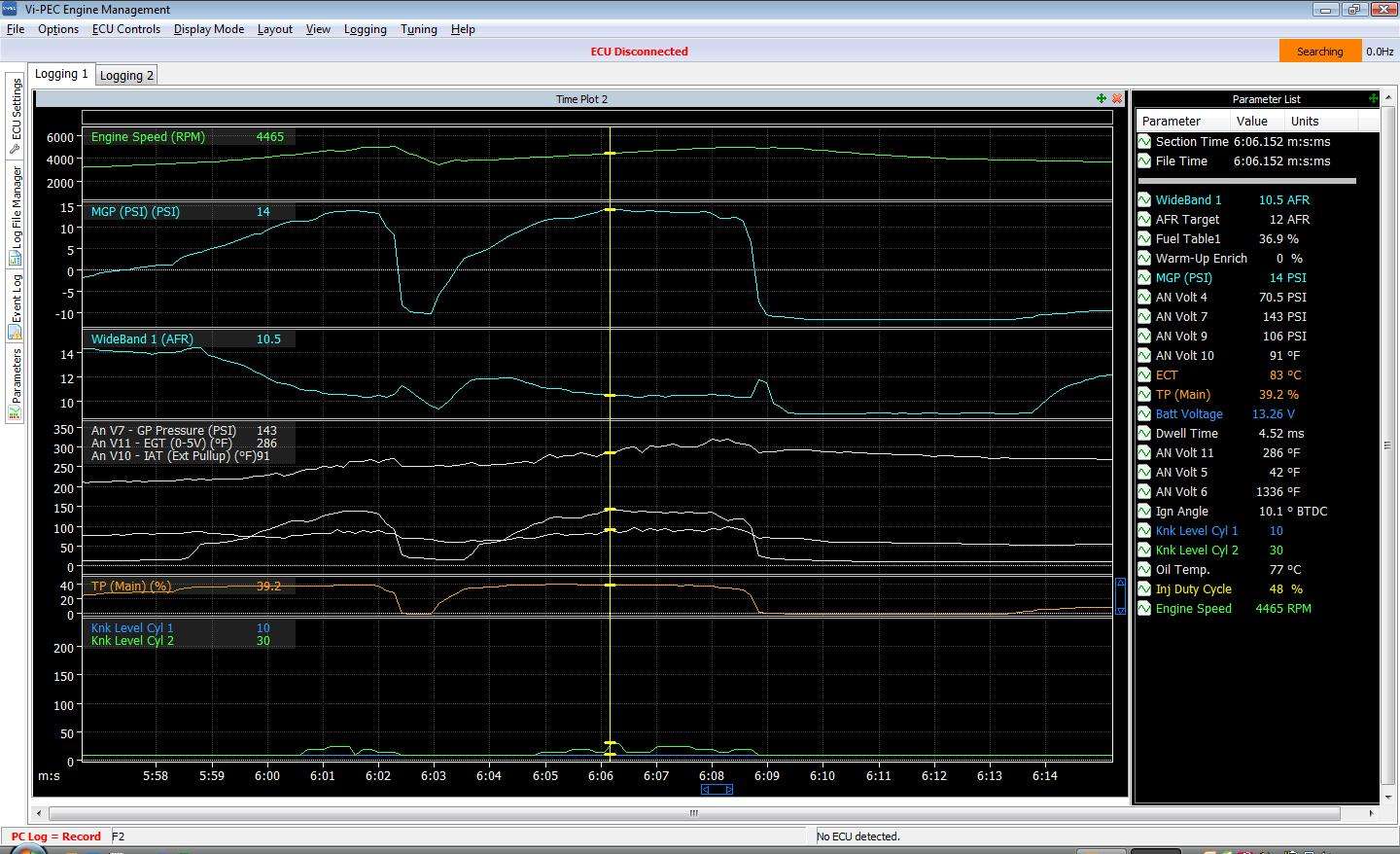

the internal knock system in my V88 recently paid for itself... here's the money plot:

the knock occurred due to my two AI fuel injectors being corroded. no AI delivery. i would not have known of the problem until i would have had motor damage. thank you knock sensors.

numerous newer ECUs do include a knock sensing and offer re-active response. (just like OE!)

when i re-fixtured my car last year i picked up a couple of the new style Bosch sensors from the RX8. the V88 has two channels so i log both the front and rear rotors. the response, also, is rotor specific.

i am going to end post one here but will return w the rest of my sensors...

i do hope that many of you will join the thread and share what has worked and not worked along w what you would like to add going forward.

howard

they make a ton of power when turbo'd

we are much closer to disaster than we think.

400 rwhp, that's 460 flywheel.... from 1.3 liters is considered middle of the road on the rotary power food chain.

it may be middle of the road but it is stratospheric in the real world.

for instance,

Camaro ZL1 supercharged titanium rodded makes 580 flywheel from 6.1 liters

Shelby GT500 4 valve supercharged makes 662 flywheel from 5.8 liters

both of these 2013 power-trains are pumped to the max for competitive reasons and the engineering post dates our FD by 20 years.

an additional sobering consideration is that the rotary has no cooling benefit as a 4 cycle where every other TDC is a non power event. the rotary is a 2 cycle.

given the prodigious power output of the turbo rotary...

we need to know what's going on.

the vital and necessary link between the engine and our understanding of it's operating specifics is the sensor.

instrumentation makes up for genius, and that's what this thread is about.

do instrumentation right and you may be able to remove your engine builder from speed dial.

properly fixtured, there is no reason to lose a motor.

let's talk sensors and instrumentation...

what do you run?

what would you like to run?

what is essential?

what specific brands are you happy with?

what specific brands have not worked for you?

what would you like to see ECUs offer calibrated click-on settings for?

since all single turbo setups make significantly more power than stock the important subject of instrumentation transcends the ECU Section and rightly belongs here, in the Single Turbo Section.

here's my current setup:

WIDEBAND

i run the NGK AFX. i have previously run 3 other WBs. i had a Techedge that worked well, an FJO that did not match up to the dyno, i then tried an Ecotrons that used the new Bosch 4.9 sensor. it did not line up w the dyno and it may have been a calibration problem so the jury is out. i finally took Luke's advice and switched to the NGK AFX and all is well. it is important to have accurate AFRs as my ViPEC V88 does do auto tune and of course it needs good input data. one of the benefits of the AFX is it reads very well in the "rich" area where many tune at 500 and above.

calibration is always a MAJOR issue on all WBs. how is your WB as to calibration?

what do you run and is it accurate? the manufacturers would like to get a sense of which brands have market share so they can offer brand specific calibration.

PRESSURE SENSORS

i use four.

fuel pressure...essential IMO

oil pressure

Auxiliary Injection pressure

Exhaust Back Pressure (EBP). that's between the engine and turbo

the problem i have had is i had an accumulation of pressure sensors and they all had different calibration numbers. Honeywell makes the good ones. recently Honeywell has introduced the PX2 line. the PX2 replaces all other Honeywell pressure sensors and is available in just about any configuration. i just bought four 0-150 psi sensors so i can use one calibration table. the PX2 is also available in metric/BAR. since they are +/- 2% across the range i will use the 0-150 for all four apps. the 10 BAR would work well if you are metric. $84 each.

if you look at your adj fuel pressure regulator and see a small dial (analog) you need to tell your engine you are sorry and lose the gauge and add a digital pressure sensor... your regulator should look like this...

if you do that you will have this:

you then relate it to this:

which will allow you to answer an important question...

what's my fuel pressure at 8000 RPM?

26,522/10,000 X 14.22 - 14.7= 23.0 PSI boost

40 static pressure + 23 boost = 63 Fuel pressure at 8000

recorded pressure 63.5

all is well

all is well w the fuel pump, the fuel pump sock, the connecting hose, the fuel pump filter, the regulator.

if you have the little gauge screwed into your FPR you can't answer any of those questions. if you have a fuel pressure gauge in your cockpit i challenge you to read it at 8000 rpm.

the Power FC/Datalogit can deliver the data for the price of a sensor... lots cheaper than a new motor.

here's another fuel pressure view from a newer ECU... my V88

i do have similar pressure plots for Oil, AI system pressure and EMP.

KNOCK

given the obvious huge combustion chamber pressures and heat that the turbo'd rotary runs knock is a key item. there exists numerous views as to the value of knock data.

my friend who makes a bit more than 1000 rwhp says knock is a complete waste of time. by the time you experience it your motor is gone.

well yah at 1000 hp. most of us don't operate in that crazy world.

i have always considered the OE generated knock readings as reported thru my Datalogit to be very helpful. if the tune is good knock should drop under boost to around the 10 area. if not, you'd best be looking for answers. further, i had occasion to test 5 OE knock sensors and they all checked out similarly. simply put, the FD OE setup combined w the Datalogit is excellent and helpful.

one of our members (Richard Green "JZG") from New Zealand has shared some excellent info on his dyno tuning process. his 2300 pound Mazda makes around 6-700 hp and has run 9.1 at over 150. it is a pretty simple build w a BW S475 and a pre turbo water AI setup. they tune 100% off knock. while the ECU is a ViPEC, it is the less featured V44. they purchased a ViPEC KnockBlock separate module and use it in conjunction w the ViPEC Knock Amplifier kit which uses headphones.

they tune til the start of noise and that's it. i recently purchased the ViPEC Knock Amp Kit and Luke uses it at Beyond Redline. we have had it for a few months and Luke says it has changed the way he tunes. nuff said.

the internal knock system in my V88 recently paid for itself... here's the money plot:

the knock occurred due to my two AI fuel injectors being corroded. no AI delivery. i would not have known of the problem until i would have had motor damage. thank you knock sensors.

numerous newer ECUs do include a knock sensing and offer re-active response. (just like OE!)

when i re-fixtured my car last year i picked up a couple of the new style Bosch sensors from the RX8. the V88 has two channels so i log both the front and rear rotors. the response, also, is rotor specific.

i am going to end post one here but will return w the rest of my sensors...

i do hope that many of you will join the thread and share what has worked and not worked along w what you would like to add going forward.

howard

Last edited by Howard Coleman; 05-30-13 at 08:53 AM.

#3

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

instrumentation is all about data... here's how my setup is starting to deliver.

thank you ViPEC V88 for providing the capability

i made an initial run w my Alkycontrol AI system yesterday (3rd gear on the road). i knew it would be pig rich before the run but needed to establish a base from which to re-tune for the right AFR.

i am running 25% water and 75% methanol thru two nozzles... an M10 630 CC/Min and an M15 945 CC/Min. flow rates are at 100 psi net of boost.

water is a part of the equation for two reasons.... water has 8087 cooling BTUs per gallon V (all) gasoline at 900 or methanol at 3340. water doesn't cool the charge air but does its thing in the combustion chamber. you can see a small amount of water goes a long way as to delivering cooling BTUs.

i said the water is there for two reasons... methanol may be a bit edgy at some fraction when mixed w gas. i think a portion of water in the combustion chamber may help. "may" i have a suspicion that a 75/25 mix may be the ultimate AI ratio.

let's get into the data from the run...

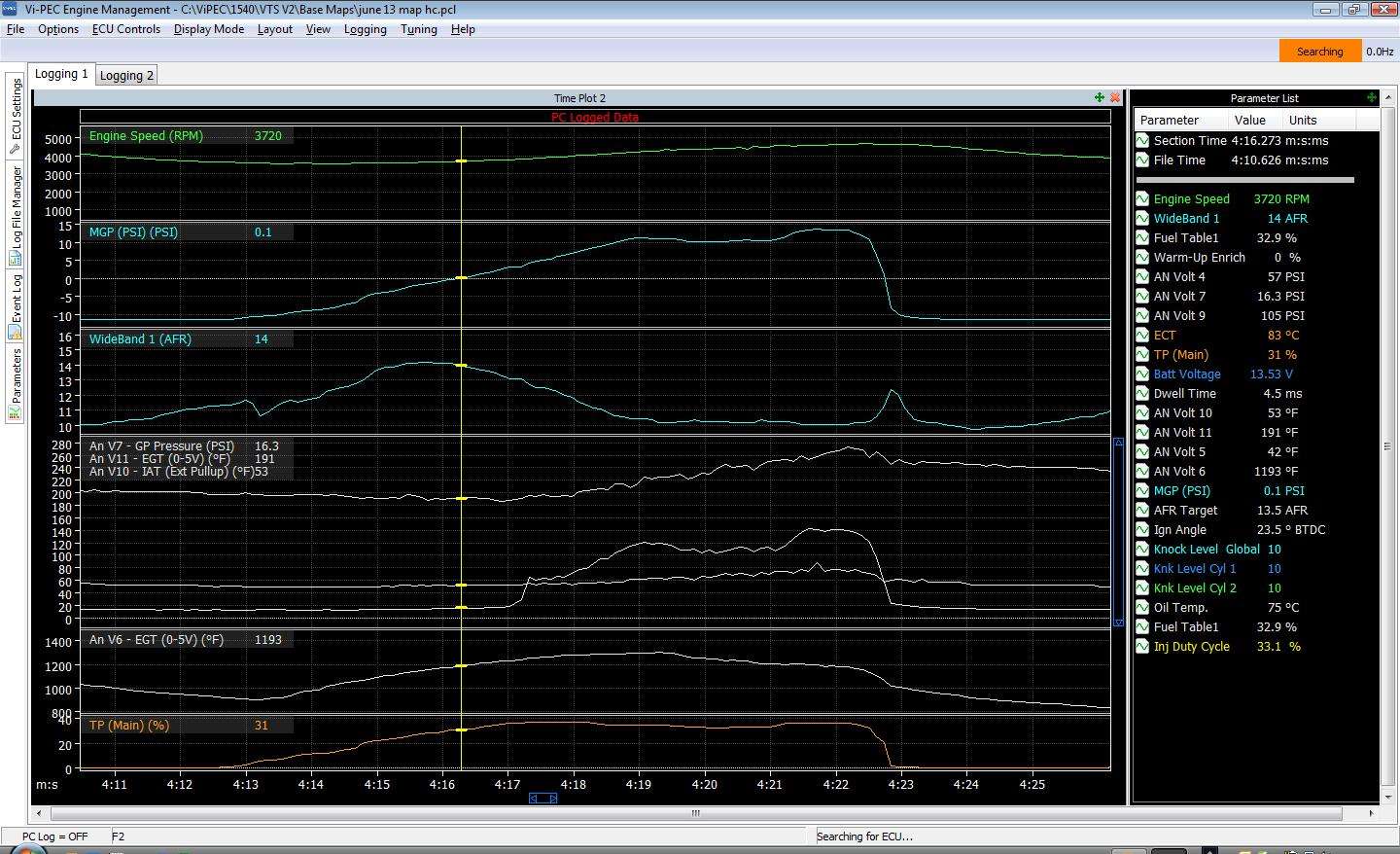

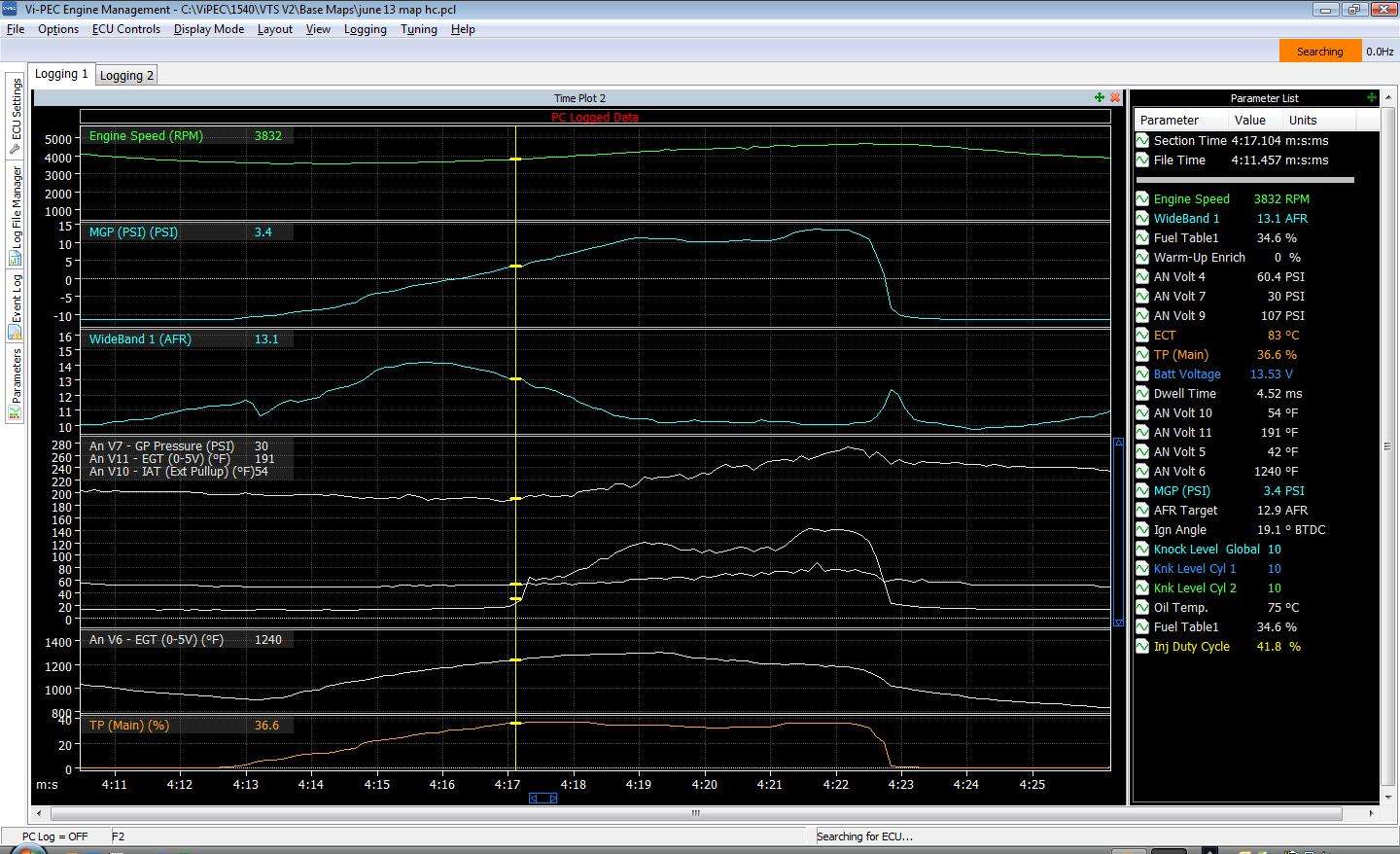

capture one is boost threshold.

3rd gear, roll into the throttle just to get the AI working... around 31% throttle. boost off the spring. the objective of this pull is just to get the AI working and start to adjust the fuel map.

RPM 3770

Boost zero

AFR 14

AN V7 (AI system pressure // ALL my Pressure readings w the exception of boost are absolute so you need to subtract 14.7 to get to the pressure we use... Gauge pressure) so the reading is 16.3 minus 14.7 or pretty much zero) AI pump is off at this point.

AN V11 191 F this is the charge air temp between the turbo and intercooler as measured by a Type K thermocouple (think EGT) accurate to the degree and mS.

AN V10 53 F charge air temperature after the intercooler at the stock FD location under the UIM as measured by a Type K thermocouple.

AN V6 EGT pre turbo 1193F rear rotor, front not currently working

TP 31% throttle position sensor

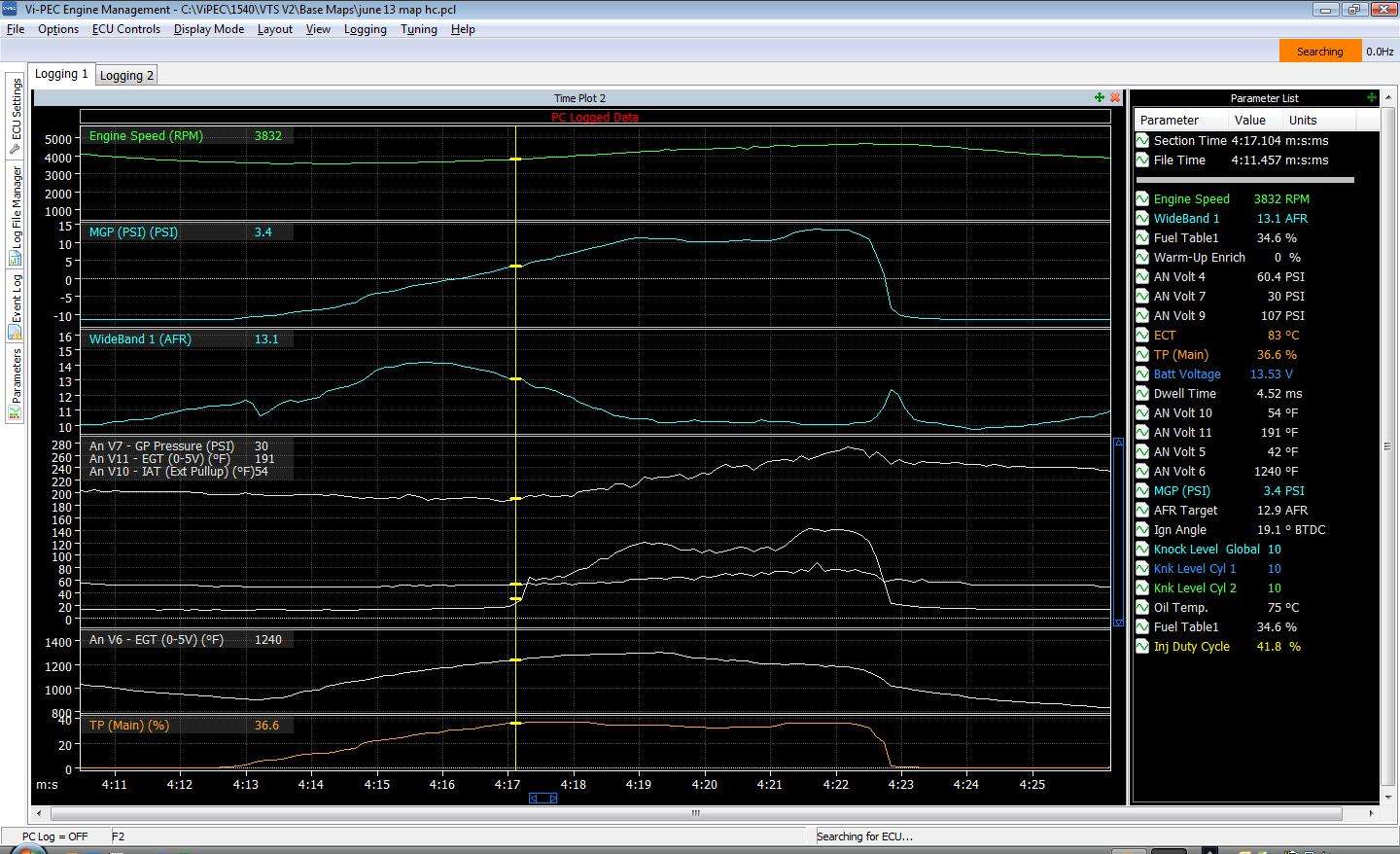

capture two

start of AI delivery

about 100 rpm later w around 3 psi of boost we see 30 psi AI pressure, minus the 14.7 is about 15 psi gauge pressure... timing has dropped (see ignition angle on left) from 23.5 to 19.1 and EGT has risen from 1193 to 1240.

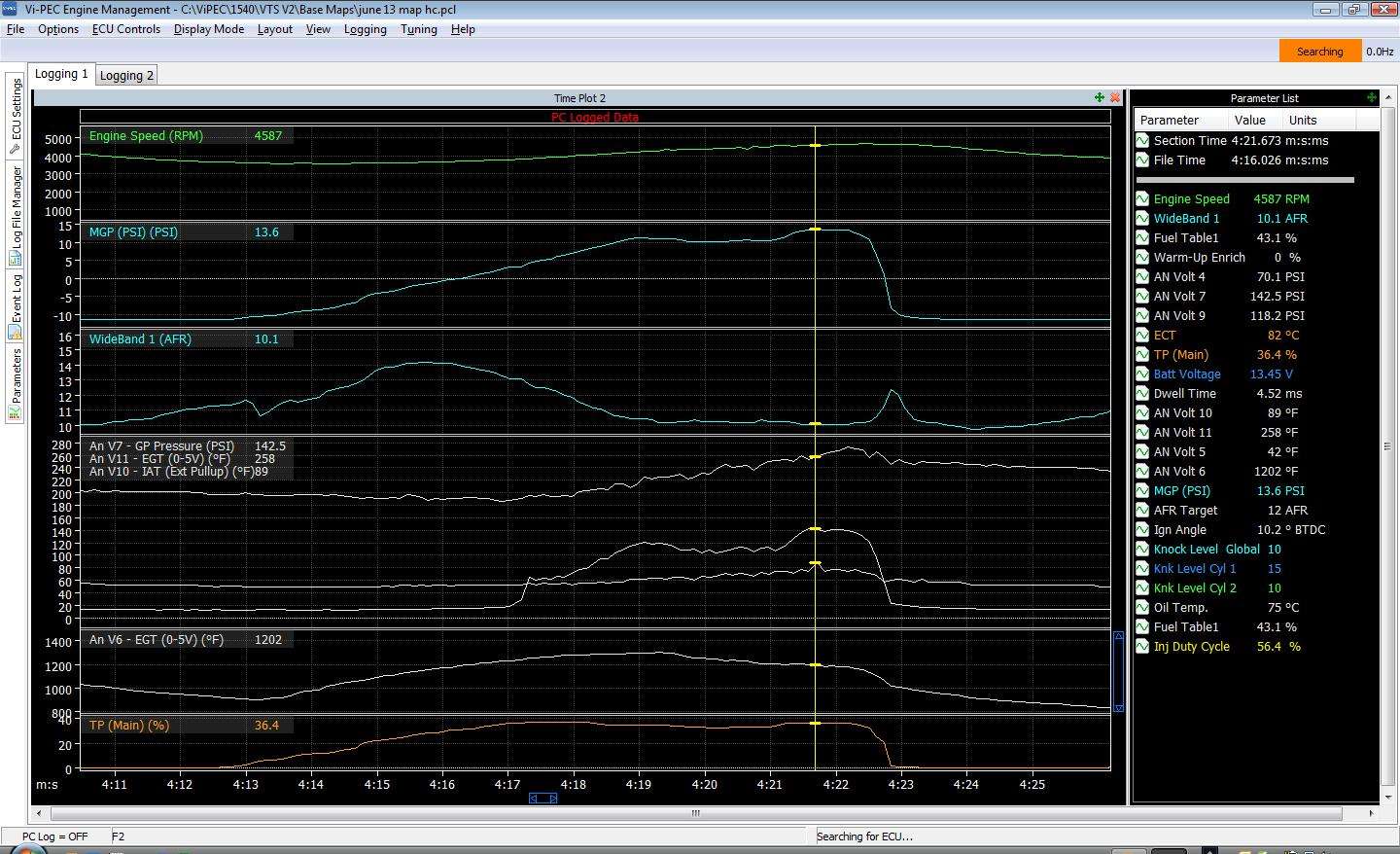

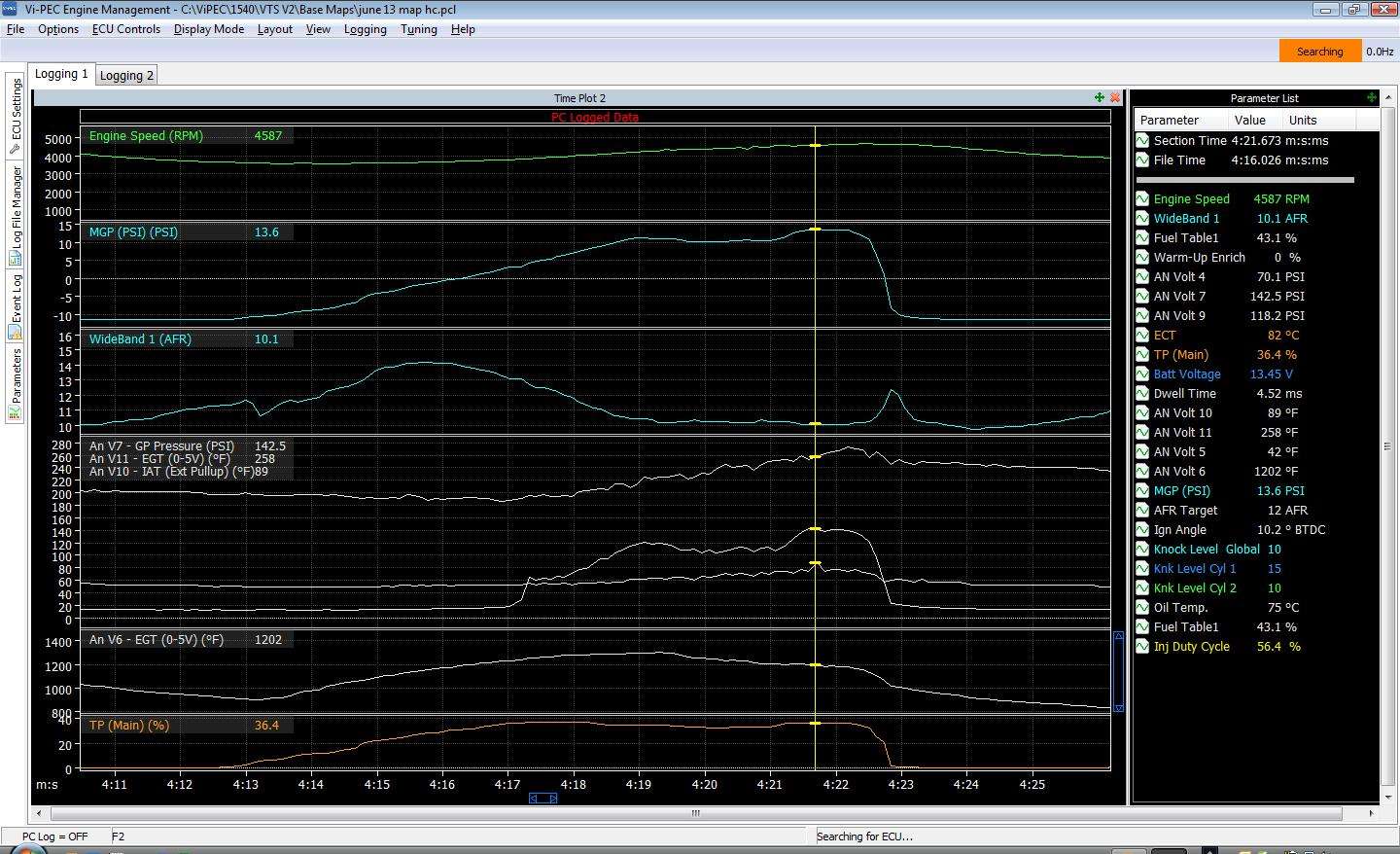

capture three

top of the run boostwise at 13.6 psi

RPM 4587

Boost 13.6

AFR 10.1 pig rich untuned for the meth at this point

AN V7 AI pressure 142.5 absolute, 127.8 gauge pressure (this is not full pressure BTW)

AN V11 258 F charge air from turbo.... at higher boost expect over 300

AN V10 89 F charge air at stock FD location

AN V6 EGT 1202F

Throttle 36.4%

at this point the engine was blubbering rich.

and now it gets really fun. i went thru this process in 2004 w my Alkycontrol system w the M10 and M15 nozzles.

the process, as most know, simply is the removal of base fuel umtil the desired AFR is attained.

back in the stone ages of 2004 the hot setup was to have an Excel program and do a bunch of cutting and pasting.

now it is as simple as click on the "Mixture Map."

each cell has the average AFR from the log, the target AFR that is set by the user, the number of samples and the amount of variance from the desired target.

more data after making the adjustments. no cut and paste, just a click and the fuel map is ready to rip.

howard

thank you ViPEC V88 for providing the capability

i made an initial run w my Alkycontrol AI system yesterday (3rd gear on the road). i knew it would be pig rich before the run but needed to establish a base from which to re-tune for the right AFR.

i am running 25% water and 75% methanol thru two nozzles... an M10 630 CC/Min and an M15 945 CC/Min. flow rates are at 100 psi net of boost.

water is a part of the equation for two reasons.... water has 8087 cooling BTUs per gallon V (all) gasoline at 900 or methanol at 3340. water doesn't cool the charge air but does its thing in the combustion chamber. you can see a small amount of water goes a long way as to delivering cooling BTUs.

i said the water is there for two reasons... methanol may be a bit edgy at some fraction when mixed w gas. i think a portion of water in the combustion chamber may help. "may" i have a suspicion that a 75/25 mix may be the ultimate AI ratio.

let's get into the data from the run...

capture one is boost threshold.

3rd gear, roll into the throttle just to get the AI working... around 31% throttle. boost off the spring. the objective of this pull is just to get the AI working and start to adjust the fuel map.

RPM 3770

Boost zero

AFR 14

AN V7 (AI system pressure // ALL my Pressure readings w the exception of boost are absolute so you need to subtract 14.7 to get to the pressure we use... Gauge pressure) so the reading is 16.3 minus 14.7 or pretty much zero) AI pump is off at this point.

AN V11 191 F this is the charge air temp between the turbo and intercooler as measured by a Type K thermocouple (think EGT) accurate to the degree and mS.

AN V10 53 F charge air temperature after the intercooler at the stock FD location under the UIM as measured by a Type K thermocouple.

AN V6 EGT pre turbo 1193F rear rotor, front not currently working

TP 31% throttle position sensor

capture two

start of AI delivery

about 100 rpm later w around 3 psi of boost we see 30 psi AI pressure, minus the 14.7 is about 15 psi gauge pressure... timing has dropped (see ignition angle on left) from 23.5 to 19.1 and EGT has risen from 1193 to 1240.

capture three

top of the run boostwise at 13.6 psi

RPM 4587

Boost 13.6

AFR 10.1 pig rich untuned for the meth at this point

AN V7 AI pressure 142.5 absolute, 127.8 gauge pressure (this is not full pressure BTW)

AN V11 258 F charge air from turbo.... at higher boost expect over 300

AN V10 89 F charge air at stock FD location

AN V6 EGT 1202F

Throttle 36.4%

at this point the engine was blubbering rich.

and now it gets really fun. i went thru this process in 2004 w my Alkycontrol system w the M10 and M15 nozzles.

the process, as most know, simply is the removal of base fuel umtil the desired AFR is attained.

back in the stone ages of 2004 the hot setup was to have an Excel program and do a bunch of cutting and pasting.

now it is as simple as click on the "Mixture Map."

each cell has the average AFR from the log, the target AFR that is set by the user, the number of samples and the amount of variance from the desired target.

more data after making the adjustments. no cut and paste, just a click and the fuel map is ready to rip.

howard

#5

I'd worry less about your brand of sensor and more about how you setup your limits. Having an accurate oil pressure sensor is great but if the only way it'll trigger anything is if it falls below some number then you're not doing a lot with it. If your limit is set to 10 psi because you dip down to 15 at idle, then you're engine will be dead before that ever gets triggered if you're at redline. Even if you get lucky and your engine doesn't die immediately, it will definitely shorten the life of the bearings. If you want to be baller, setup a temp vs rpm vs pressure table and then tell your limit to trigger if you're more than X% off.

After spending enough hours watching screens with all sorts of fancy gauges on them I can definitely tell you that it's easy to miss something, especially in transient conditions; your limits on the other hand, they don't miss a thing. I trust them a lot more than I do my eyesight and reaction time.

After spending enough hours watching screens with all sorts of fancy gauges on them I can definitely tell you that it's easy to miss something, especially in transient conditions; your limits on the other hand, they don't miss a thing. I trust them a lot more than I do my eyesight and reaction time.

#6

Howard, have you considered combustion chamber pressure analysis like Barry Bordes uses? I think he is using the "LCS" system here: TFX Engine Technology - Products & Features

I'm not sure what the actual dollar amount is.

I think it would be very helpful if you could calculate peak combustion chamber pressure amount & location in crank angle degrees, burn %, indicated mean effective pressure & std deviation thereof. For example, what peak IMEP are you reaching? I would think over 25 bar for really high horsepower setups. Also, what is the effect of water/meth injection on combustion stability, measured by std. deviation of IMEP? Also I would expect your ignition delay (time it takes from spark timing to 10% mass burn) is significantly affected.

I'm not sure what the actual dollar amount is.

I think it would be very helpful if you could calculate peak combustion chamber pressure amount & location in crank angle degrees, burn %, indicated mean effective pressure & std deviation thereof. For example, what peak IMEP are you reaching? I would think over 25 bar for really high horsepower setups. Also, what is the effect of water/meth injection on combustion stability, measured by std. deviation of IMEP? Also I would expect your ignition delay (time it takes from spark timing to 10% mass burn) is significantly affected.

#7

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

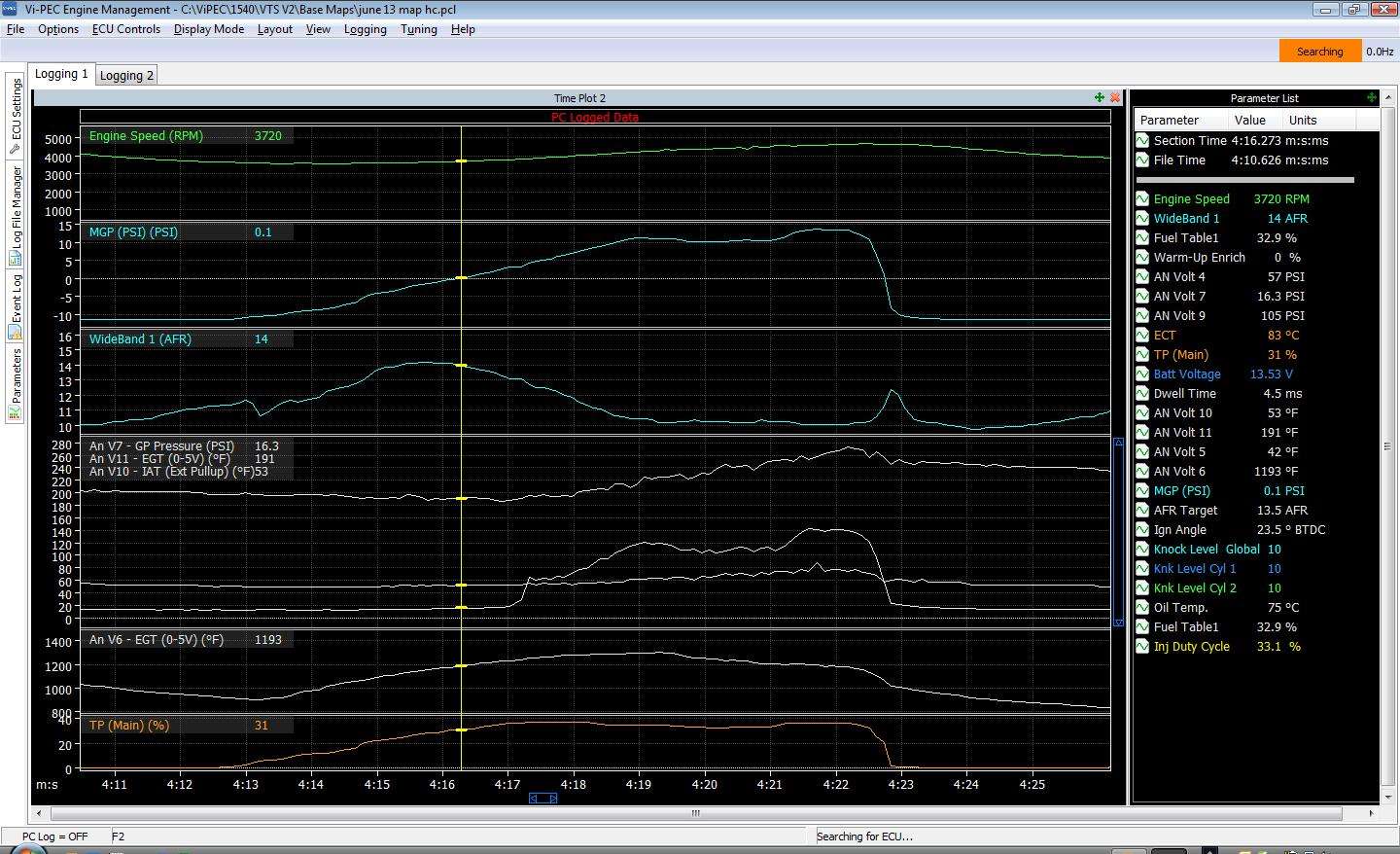

a combo of rain and building 4 motors ATM delayed run two a couple of days. the primary diff was a bit leaner fuel map and i also did a bit in 4th gear...

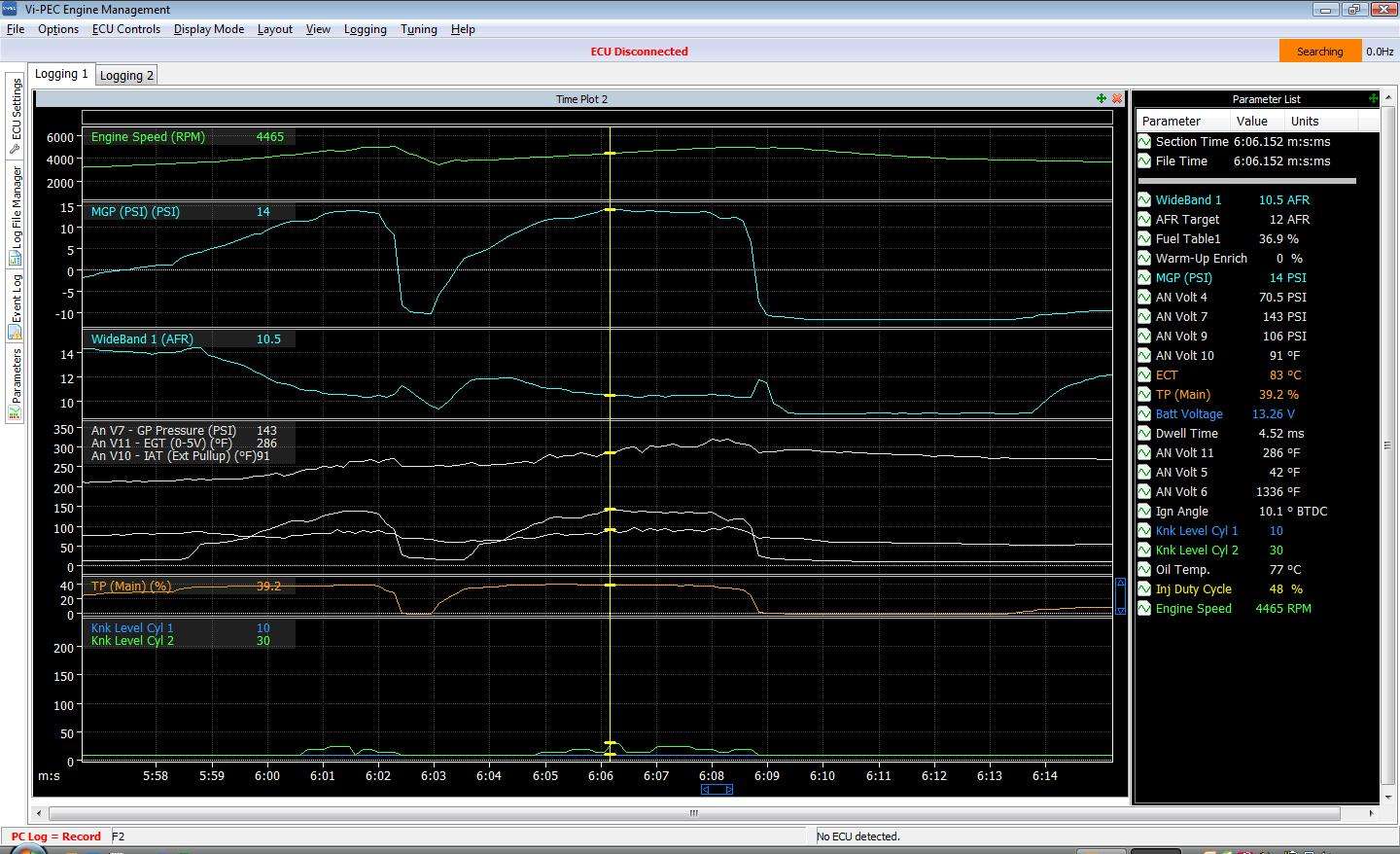

here's a capture of the top of the run boost-wise:

whereas the engine was blubbering during the prior day's run it is now firing cleanly yet still way too rich. even though the boost is high 13s the car is flying at high 30s% throttle. it will be a handful at full throttle just off the wastegate spring at around mid 11 AFR.

the AI pressure, listed as AN 7 GP Pressure, is 143 psi. since it is absolute, remove 14.7 and remove the boost, 14 to get net pressure of 114. the square root is 1.069. nozzles pass 1575 CC/Min at 100 so i am getting 1683 CC/Min into the motor. since i am 25% water and 75% meth:

420 CC/Min water

1263 CC/Min Methanol

i am liking the V88 internal knock system.... notice almost flatline knock until boost and then a small number in boost. what i like is that it seems able to report very small quantities of knock. sneaking up on knock is key.

notice temp of the air exiting the BW S363... 286 degrees F. IAT at the stock UIM location is 91 F.

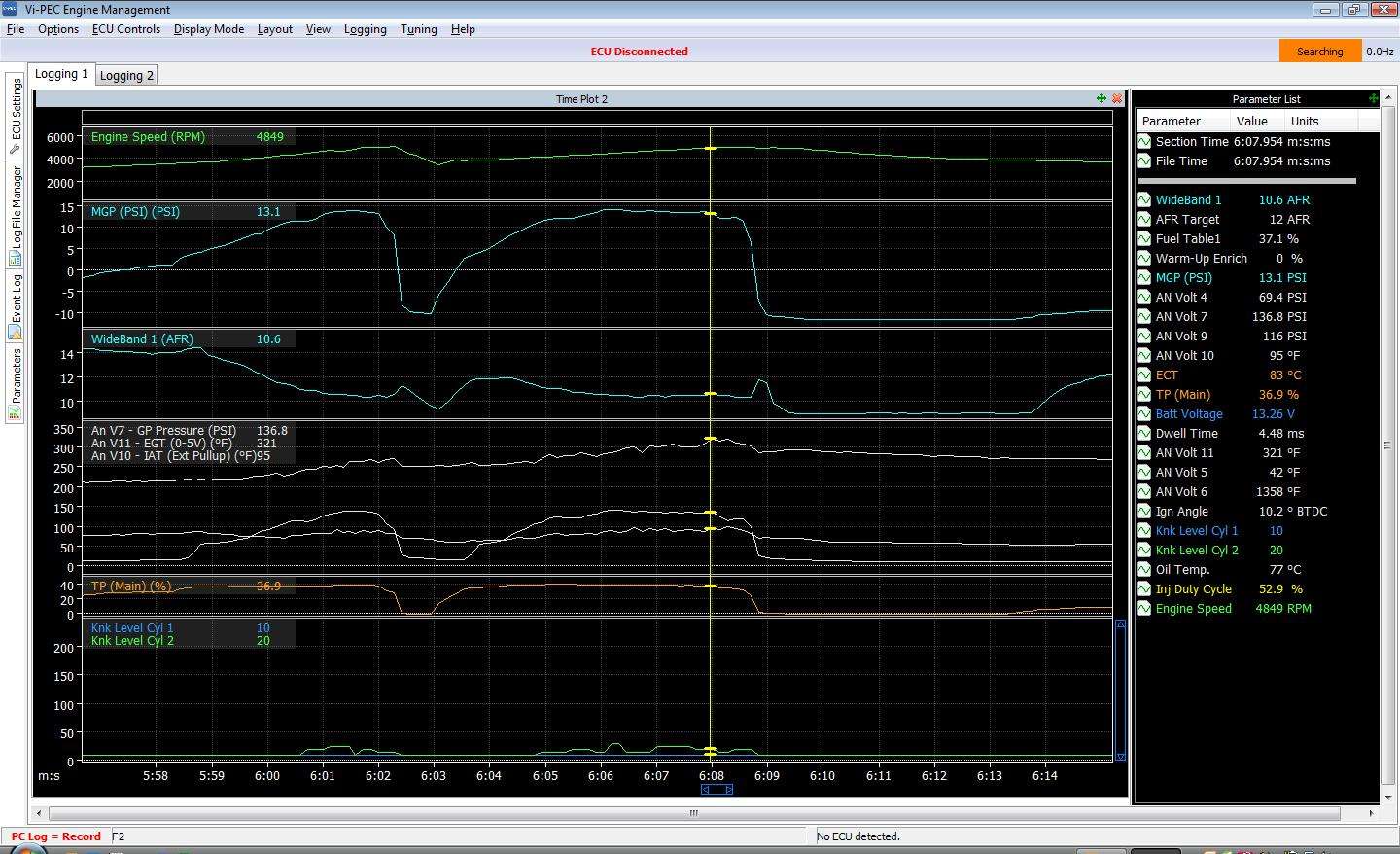

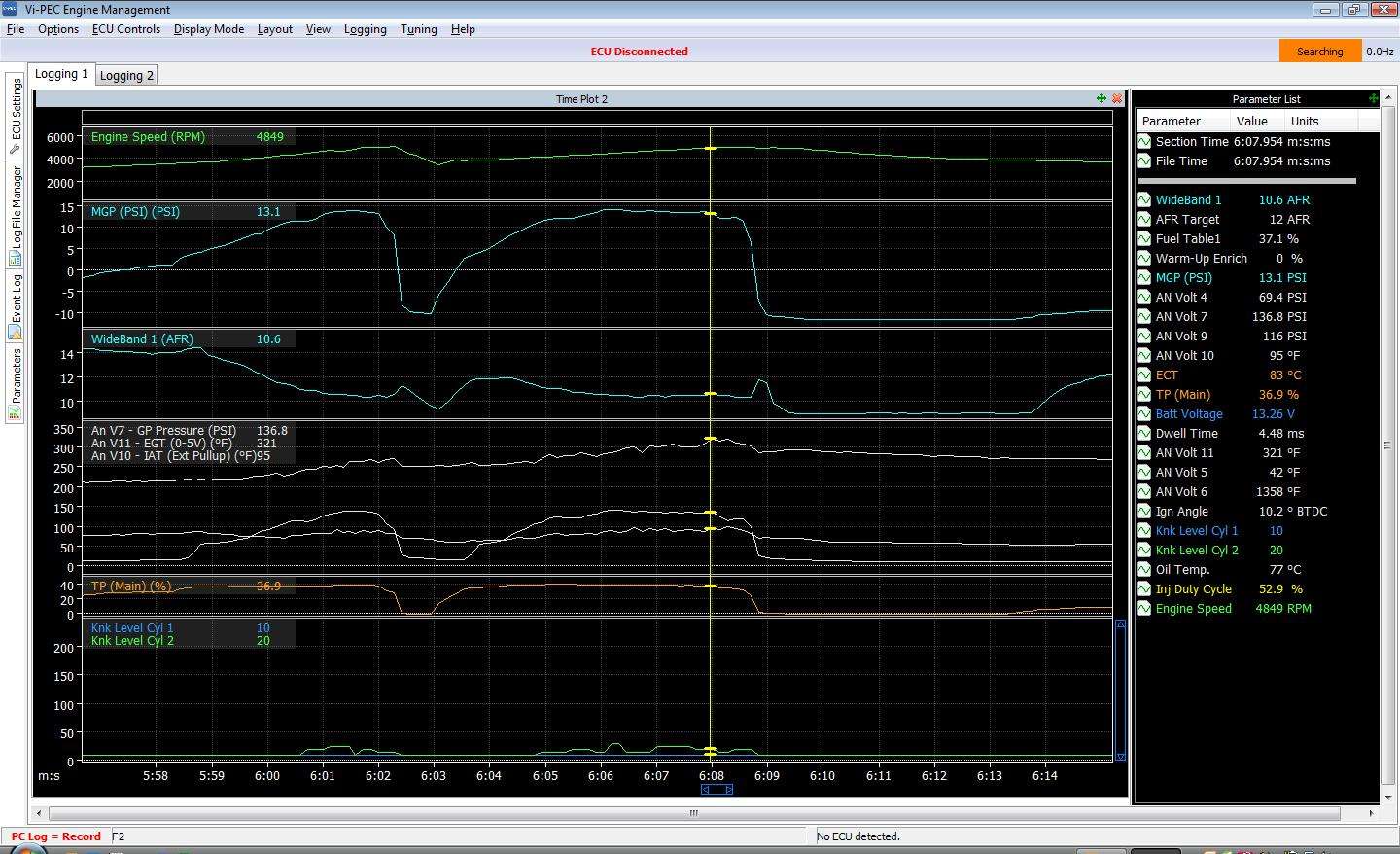

here's the end of the run in fourth...

the interesting thing to me is that it appears that the charge air temp exiting the turbo rises cumulatively. while the boost is 13.1 V 14 in the preceding capture the temp is now 321F!

also of note to me is how well the Alkycontrol AI system manages output w changing MAP. notice the pressure change between 3rd and fourth.

and now the fun part... time to call in the Mixture Map and do some tuning...

it looks like i am rich by over a point where it counts. this is getting interesting.

stay tuned, while i tune.

oh and "Howard, have you considered..." i am a few years overdue and job one ATM is just getting it running and dyno'd. maybe then but i have the feeling that 'then" is a ways down the path. Barry's pressure project is certainly interesting.

howard

here's a capture of the top of the run boost-wise:

whereas the engine was blubbering during the prior day's run it is now firing cleanly yet still way too rich. even though the boost is high 13s the car is flying at high 30s% throttle. it will be a handful at full throttle just off the wastegate spring at around mid 11 AFR.

the AI pressure, listed as AN 7 GP Pressure, is 143 psi. since it is absolute, remove 14.7 and remove the boost, 14 to get net pressure of 114. the square root is 1.069. nozzles pass 1575 CC/Min at 100 so i am getting 1683 CC/Min into the motor. since i am 25% water and 75% meth:

420 CC/Min water

1263 CC/Min Methanol

i am liking the V88 internal knock system.... notice almost flatline knock until boost and then a small number in boost. what i like is that it seems able to report very small quantities of knock. sneaking up on knock is key.

notice temp of the air exiting the BW S363... 286 degrees F. IAT at the stock UIM location is 91 F.

here's the end of the run in fourth...

the interesting thing to me is that it appears that the charge air temp exiting the turbo rises cumulatively. while the boost is 13.1 V 14 in the preceding capture the temp is now 321F!

also of note to me is how well the Alkycontrol AI system manages output w changing MAP. notice the pressure change between 3rd and fourth.

and now the fun part... time to call in the Mixture Map and do some tuning...

it looks like i am rich by over a point where it counts. this is getting interesting.

stay tuned, while i tune.

oh and "Howard, have you considered..." i am a few years overdue and job one ATM is just getting it running and dyno'd. maybe then but i have the feeling that 'then" is a ways down the path. Barry's pressure project is certainly interesting.

howard

Trending Topics

#8

Here is the list of instrumentation that I am implementing on my build. I am using the Megasquirt MS3-Pro ecu with a MS GPIO box for extra I/O.

Gauges:

- Tachometer | OEM

- Speedometer | OEM

- Odometer | OEM

- Fuel level | OEM

- Coolant temperature

- Oil pressure

- Oil temperature

- Boost pressure

- Wideband AFR

ECU inputs:

- Throttle position

- Crank angle (hall sensor)

- Coolant temperature

- Air intake temperature

- Oil pressure

- Oil temperature

- Fuel pressure

- Manifold pressure

- Wideband oxygen sensor

- EGT sensor (x2)

- Knock sensor (x2)

- Water injection flow

- Water injection tank low level switch

- Vehicle speed

- Barometric pressure (maybe)

- Ethanol content sensor (maybe)

ECU outputs:

- Ignition coil (x4)

- Fuel injector (x4)

- Boost control solenoid

- Idle air control valve

- Cooling fan relay

- Water injection pump relay

- Water injection solenoid

- Low water level LED

- AFR/EGT event LED

- Knock event LED

- Water injection flow below-threshold LED

- Water injection flow enabled LED

Gauges:

- Tachometer | OEM

- Speedometer | OEM

- Odometer | OEM

- Fuel level | OEM

- Coolant temperature

- Oil pressure

- Oil temperature

- Boost pressure

- Wideband AFR

ECU inputs:

- Throttle position

- Crank angle (hall sensor)

- Coolant temperature

- Air intake temperature

- Oil pressure

- Oil temperature

- Fuel pressure

- Manifold pressure

- Wideband oxygen sensor

- EGT sensor (x2)

- Knock sensor (x2)

- Water injection flow

- Water injection tank low level switch

- Vehicle speed

- Barometric pressure (maybe)

- Ethanol content sensor (maybe)

ECU outputs:

- Ignition coil (x4)

- Fuel injector (x4)

- Boost control solenoid

- Idle air control valve

- Cooling fan relay

- Water injection pump relay

- Water injection solenoid

- Low water level LED

- AFR/EGT event LED

- Knock event LED

- Water injection flow below-threshold LED

- Water injection flow enabled LED