How important is the manifold??

#1

Thread Starter

IRS 4 Life

iTrader: (12)

Joined: Feb 2001

Posts: 2,634

Likes: 2

From: Sicklerville, South Jersey!!

How important is the manifold??

Ok so I feel like a total NOOB asking, I know the manifold design is important but HOW important is what I’m really asking. Both times when I Had Demetrious and Steve Kahn tune my car they both made comment that my Manifold was robbing some power from my setup. I’ve had my FD since 97, slowly built it up over the years, I was stupid and felt that I could piece together a Single setup and save a lot of money. I successfully put it together but I’m wondering how much I left power on the table.

(Flame Suit On)

I’m running one of the early OBX manifolds; I Re-welded every weld, and Installed Gussets to help stabilize the manifold. I’m running the T04S from the real XS-engineering kit. Now the OBX manifold wasn’t designed to fit a 1.15 hot side so I have a 1 /2 spacer on the turbo flange to clear the shock tower. Custom 3” DP strait through to a blitz nurspec. Tial 46 vented to the atmosphere. Judge Ito Built Motor. The car Has made 465 @ 22psi on a dynapack Dyno and run 10.96

Obviously I’m craving more power, Ill never try to compete with the Ernie’s of the world, and nor do I have the finances to play at that level.

So long story I’m seriously contemplating adding an extra set of 1600’s and running E85. I have been toying with changing turbos, but as above I’m wondering if just changing manifolds, fuel and re-tuning could net out a substantial amount of ponies, and save a couple thousand in the process. Yes I know I’m sounding cheap again but id rather explore the limits of what I have.

So for those of who build manifolds, how restrictive is the manifold I have in comparison to whats avail. Is it worth upgrading just the manifold or is it time to just jump in with a new setup.

Thansk for any ideas/ oponions.B4 anyone says it I could build my own manifold, I have the fab skills and ability to but I’m tired of trying to be a engineer and fabricator. Id rather pay for the power this time around…

(Flame Suit On)

I’m running one of the early OBX manifolds; I Re-welded every weld, and Installed Gussets to help stabilize the manifold. I’m running the T04S from the real XS-engineering kit. Now the OBX manifold wasn’t designed to fit a 1.15 hot side so I have a 1 /2 spacer on the turbo flange to clear the shock tower. Custom 3” DP strait through to a blitz nurspec. Tial 46 vented to the atmosphere. Judge Ito Built Motor. The car Has made 465 @ 22psi on a dynapack Dyno and run 10.96

Obviously I’m craving more power, Ill never try to compete with the Ernie’s of the world, and nor do I have the finances to play at that level.

So long story I’m seriously contemplating adding an extra set of 1600’s and running E85. I have been toying with changing turbos, but as above I’m wondering if just changing manifolds, fuel and re-tuning could net out a substantial amount of ponies, and save a couple thousand in the process. Yes I know I’m sounding cheap again but id rather explore the limits of what I have.

So for those of who build manifolds, how restrictive is the manifold I have in comparison to whats avail. Is it worth upgrading just the manifold or is it time to just jump in with a new setup.

Thansk for any ideas/ oponions.B4 anyone says it I could build my own manifold, I have the fab skills and ability to but I’m tired of trying to be a engineer and fabricator. Id rather pay for the power this time around…

#2

Changing turbo is going to give you more power than changing the manifold. From what I have seen on our dyno the manifold doesnt make that much of a difference in terms of power. It will help spool more than anything else.

#3

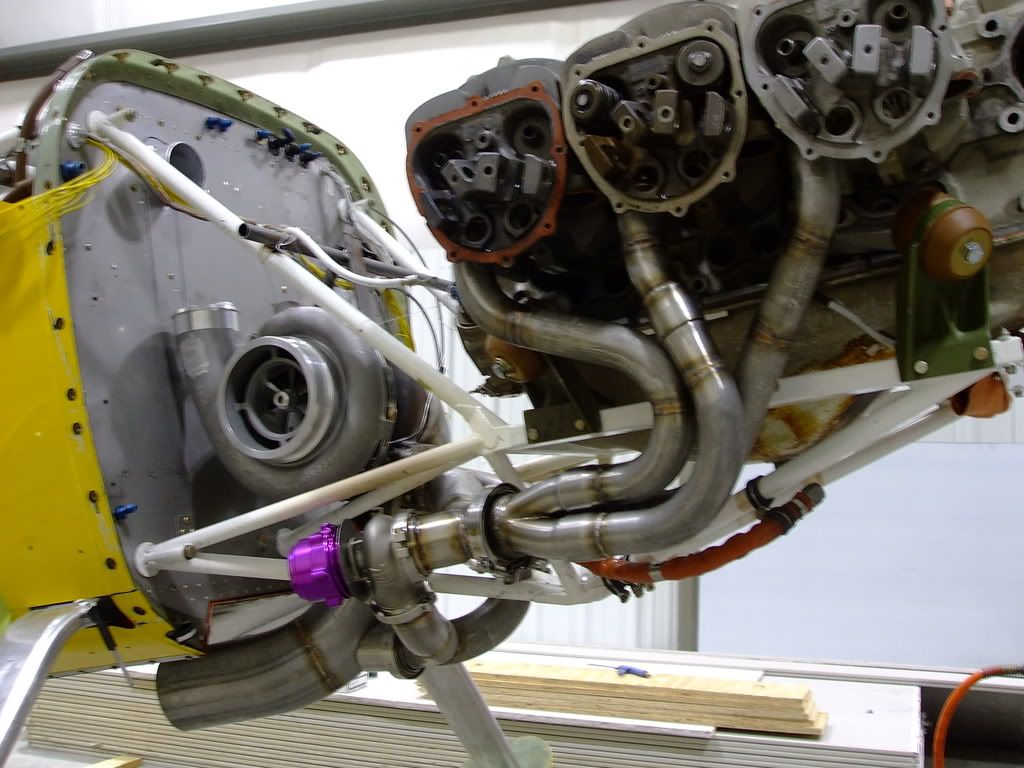

OK here is what I know and this is the kind of manifold you should run if you want to make the best power. Note the lengths of the runners and the collector design. The wall thickness of the manifold should be more than .065" so the turbo weight does not add any stress. This is first class and anything else is crap. If you need more photos just send me a pm.

Or you can give twinsturbo.com a call.

Or you can give twinsturbo.com a call.

Last edited by JEROME; 10-31-08 at 01:23 PM.

#4

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

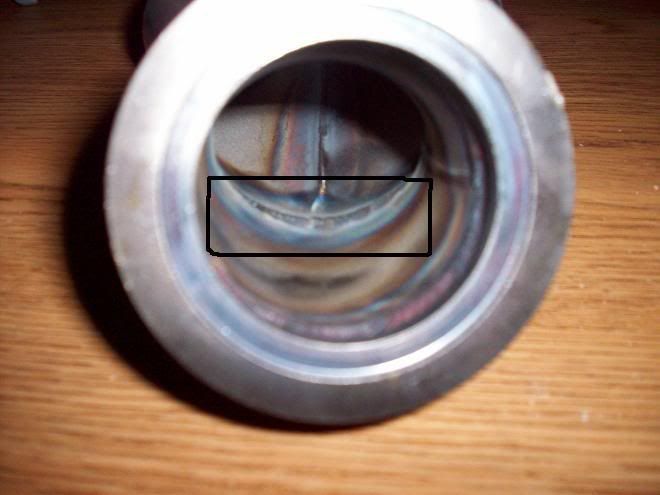

While the welds are nice and there are some nice finishing touches on that manifold, the wategate runner placement is terrible. This will effect spool and boost control.

Then again, few manifolds have ideal wastegate runner placement (mine included).

Then again, few manifolds have ideal wastegate runner placement (mine included).

#6

Aaron was referring to the first manifold you posted. Not the Twins Turbo rx7 manifold. The wastegate runner placement on the Twins Turbo manifold is perfect.

Trending Topics

#8

Not too long for a track only- record setting race car

I'm of a similar opinion to Jason - I've found it will effect spool characteristics more then ultimate power output if the turbo is kept the same.

I'm of a similar opinion to Jason - I've found it will effect spool characteristics more then ultimate power output if the turbo is kept the same.

#10

#11

I have always found long manifolds, take alot longer to spool and make their power much higher.

Short manifolds make alot of boost early and dont keep it going up top.

Id rather have a long runner manifold, and focus on a quality roller bearing turbo, so that you get early spool and good top end.

BUT on most street cars, choose the right turbo, and your 99% the way. Most important part of the manifold, is the WG pipe is put in the right place, and is big enough, and the gate is big enough. Ive seen people talk about exhaust flow direction etc. and in theory it makes alot of sense, but in practice, ive seen manifolds that in theory(and according to alot of e-professionals) should not work, end up working faultlessly.

Short manifolds make alot of boost early and dont keep it going up top.

Id rather have a long runner manifold, and focus on a quality roller bearing turbo, so that you get early spool and good top end.

BUT on most street cars, choose the right turbo, and your 99% the way. Most important part of the manifold, is the WG pipe is put in the right place, and is big enough, and the gate is big enough. Ive seen people talk about exhaust flow direction etc. and in theory it makes alot of sense, but in practice, ive seen manifolds that in theory(and according to alot of e-professionals) should not work, end up working faultlessly.

#13

There is NOT one thing wrong with the waste gate set up on the pictures of that first manifold. Its gorgeous in fabrication, but the T4 flange ports aren't shaped quite right (could be ported) and there could be a bit of straight coming out from the exhaust ports. Other then those nitpicks, great manifold. Waste gate placement should be done near high pressures zones, like near the TURBINE INLET (first choice) and or on the outside radius of a bend (second choice, if choice 1 isn't possible). Closer to the turbine, the better. So if you can get it close to the turbine, then having it on the outside of a radius isn't important anymore. Not to mention having holes in the outside of a radius causes turbulence's which can hurt spool up slightly. Its all give and take, better boost control or better spool up. If your control is good enough, then concentrate on spool up characteristics.

~Mike............

~Mike............

#14

I have always found long manifolds, take alot longer to spool and make their power much higher.

Short manifolds make alot of boost early and dont keep it going up top.

Id rather have a long runner manifold, and focus on a quality roller bearing turbo, so that you get early spool and good top end.

BUT on most street cars, choose the right turbo, and your 99% the way. Most important part of the manifold, is the WG pipe is put in the right place, and is big enough, and the gate is big enough. Ive seen people talk about exhaust flow direction etc. and in theory it makes alot of sense, but in practice, ive seen manifolds that in theory(and according to alot of e-professionals) should not work, end up working faultlessly.

Short manifolds make alot of boost early and dont keep it going up top.

Id rather have a long runner manifold, and focus on a quality roller bearing turbo, so that you get early spool and good top end.

BUT on most street cars, choose the right turbo, and your 99% the way. Most important part of the manifold, is the WG pipe is put in the right place, and is big enough, and the gate is big enough. Ive seen people talk about exhaust flow direction etc. and in theory it makes alot of sense, but in practice, ive seen manifolds that in theory(and according to alot of e-professionals) should not work, end up working faultlessly.

there could be a bit of straight coming out from the exhaust ports. Waste gate placement should be done near high pressures zones, like near the TURBINE INLET. Closer to the turbine, the better. Not to mention having holes in the outside of a radius causes turbulence's which can hurt spool up slightly.

~Mike............

~Mike............

I'm 100% in agreement.

Last edited by crispeed; 11-01-08 at 02:42 PM.

#15

what are peoples thoughts on runner diameter, are you better off having it a touch on the smaller side or a touch on the larger side? also is it important to keep the wastegate runners flowing in the same direction as the turbine runners?

cheers

Lance

cheers

Lance

Last edited by cach22; 11-03-08 at 06:47 AM.

#16

Smaller runners = quicker spool up and hotter manifold and turbine temps. Also, with smaller runners the more criticle your wastegate placement is and harder to control boost. Bigger runners is the exact opposite. Larger, the slower spool and more room for wastegate runner placement, slightly cooler manifold temps.

Wastegate flow should be in the direction of flow, but again, the closer to the turbine the less criticle it is and can be place perpendicluar to flow and still function correctly. AGAIN, its all give and take and compromises.

~Mike...............

Wastegate flow should be in the direction of flow, but again, the closer to the turbine the less criticle it is and can be place perpendicluar to flow and still function correctly. AGAIN, its all give and take and compromises.

~Mike...............

#17

Smaller runners = quicker spool up and hotter manifold and turbine temps. Also, with smaller runners the more criticle your wastegate placement is and harder to control boost. Bigger runners is the exact opposite. Larger, the slower spool and more room for wastegate runner placement, slightly cooler manifold temps.

Wastegate flow should be in the direction of flow, but again, the closer to the turbine the less criticle it is and can be place perpendicluar to flow and still function correctly. AGAIN, its all give and take and compromises.

~Mike...............

Wastegate flow should be in the direction of flow, but again, the closer to the turbine the less criticle it is and can be place perpendicluar to flow and still function correctly. AGAIN, its all give and take and compromises.

~Mike...............

cheers

Lance

Thread

Thread Starter

Forum

Replies

Last Post

[For Sale] Scratch & Dent, Used, and Open-Box Sale!

SakeBomb Garage

Vendor Classifieds

5

08-09-18 05:54 PM

Turblown

Group Buy & Product Dev. FD RX-7

7

03-21-18 11:19 AM