goodby resistors, hello Peak and Hold

#1

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,135

Likes: 563

From: Florence, Alabama

goodby resistors, hello Peak and Hold

The ubiquitous resistor in the typical Power FC modded FD secondary fuel injector circuit is a band-aid that needs to go.

Since replacing my resistors with an FJO (AEM also offers) Peak and Hold module I pull the same AFR w 17% less injector ontime. Further, the mountainous peak in my base fuel map at transition is a now a linear slope.

Since there are differing levels of understanding re this important issue let’s start at square one…

There are 2 types of fuel injectors.

High Resistance (10-17 ohms)

Most OEM, including the FD are High Resistance injectors, and are run on a linear voltage basis. At a given moment they are hit w 14.4 volts. Figuring 12 ohms resistance that results in a current of 1.2 Amps. The flow is constant until close.

Low Resistance (1 to 4 ohms)

Generally higher flow and non-OEM. They are directed in an entirely different manner….

National Semiconductor builds most of the driver chips that run fuel injectors… here’s what they have to say on the subject:

“The current required to open a (fuel injector) solenoid is several times greater than the current necessary to merely hold it open therefore the LM1949 by directly sensing the actual solenoid current initially saturates the driver until the ‘‘peak’’ injector current is four times that of the idle or ‘‘holding’’ current. This guarantees opening of the injector. The current is then automatically reduced to the sufficient holding level for the duration of the input pulse. In this way the total power consumed by the system is dramatically reduced. Also a higher degree of correlation of fuel to the input voltage pulse (or duty cycle) is achieved since opening and closing delays of the solenoid will be reduced.”

So instead of the single voltage flow operation of the High Resistance injector, an initial flow four times that of the flow necessary to hold it open initiates fuel flow within the Low Resistance Injector.

Further, according to National Semi, who makes the drivers in the Power FC…

“Note that for large currents above one amp IR drops within the component leads or printed circuit board may create substantial errors unless appropriate care is taken…”

Bad things can happen to the components inside the Power FC if you run the fuel injectors substantially above one amp.

That’s why most of us have 10 ohm resistors in our secondary (Low Resistance) fuel injector circuits. 14.4 V / 12 ohms = 1.2 Amps. 1.2 Amps is O K as to protecting the Power FC circuits.

Fine. So we aren’t burning up our PFC, but what have we done?

We are attempting to run an injector designed to be Peak and Hold directed in a Saturated linear manner.

We solved the ECU protection at a cost of speaking Chinese to an Anglophile.

How’s that work?

Not as good as you might think.

There’s the theory and the real world observations.

Since installing my 850/1600s I have always had to build a mountain of injector ontime Ms in my base fuel map to maintain constant AFRs. I have consulted loads of people and have been all over the map messing with lag time, transition timing etc.

the mountain remained. Oh well, my AFRs were constant. But what a way to run a railroad.

Then I bumped into the Peak and Hold Convertor Module products. AEM and FJO make such a product. I found a helpful person at FJO and bought the unit.

Running an unchanged base fuel map I went PIG RICH at transition. After dialing down the Ms I now have a linear base fuel map.

And NO RESISTORS.

That’s when things got really interesting.

I had way too much fuel dialed into my map. By my calculations somewhere around 15%!!!! That’s right, I dialed down my fuel and maintained the same AFR as before.

That tells me that resistor-runners can accomplish a number of positive things w a switch to a Peak and Hold Module.

a rationalized fuel map at transition

increased fuel delivery

to quote RC Engineering:

there is more area under the curve w a Peak and Hold injector than a Saturated injector. Take both types, put them in the same fuel log, run them for the same Ms and you will get 8% more fuel w the Peak and Hold.

Perhaps more than 8%…. If you try and run a P&H injector Saturated you will probably get a lot less than the 8% drop quoted by RC. More like my 15% number.

Backing this up:

National Semi:

“a higher degree of correlation of fuel to the input voltage pulse (or duty cycle) is achieved since opening and closing delays of the solenoid will be reduced”

from Stealth 316:

Because the amps are higher in the Peak and Hold circuit, and because the P&H injectors are designed to act faster, the ECM decreases the duration of the pulse (that is, the amount of time the current is applied or the circuit is grounded) to compensate for the faster solenoid response. The ECM for Saturated injectors knows to use a slightly longer pulse duration.

EFI 101

“Your results are a direct consequence of the fact that putting a 10 ohm resistor in series with your injector limits the instantaneous injector current (no such thing as a perfect inductor), and the series resistance coupled with the parasitic coil resistance and the coil inductance, slows the magnetic field from forming in the injector.

This gives more injector "dead time", which means that for a considerable period of time, the injectors are on, but not flowing.”

EFI 101

“By putting a resistor inline with a low-impedance injector, you're limiting the current through the injector, and slowing down the opening time.”

And finally from FJO:

"I'm not surprised that you reduced your injector time to maintain the same

AFR. The difference depends on the peak current that the injector can draw

and the fuel pressure, while you were using a resistor.

Here's a non-tech explanation behind this:

A peak-n-hold injector (low impedance) is designed to draw more current

during the open cycle but requires less during the holding cycle. If the

current is not controlled and the injector is allowed to run saturated, it

will overheat.

The common way of adding a resistor in series with the injector will prevent

it from overheating, however it prevents the injector from reaching it's

peak current during an open cycle - which ultimately slows down its opening

time and makes it more sensitive to changes in fuel pressure and voltage.

The FJO driver allows the injector to hit its peak current, causing it to

open faster and more consistently. It then cuts back the current to the

minimum required to keep the injector open. This is lower than the current

regulated by a resistor. Because of this, when it is time to close, the

magnetic field in the injector will collapse faster and the injector will

close sooner and more consistently. This whole process results in the

injector opening and closing faster and more consistently.

Hope that helps explain it a bit. What you have seen is a common result in

cases where the "resistor box" was replaced. Another improvement is in the

idle stability. The faster closing time allows for shorter open times, which

is important if you are running large injectors."

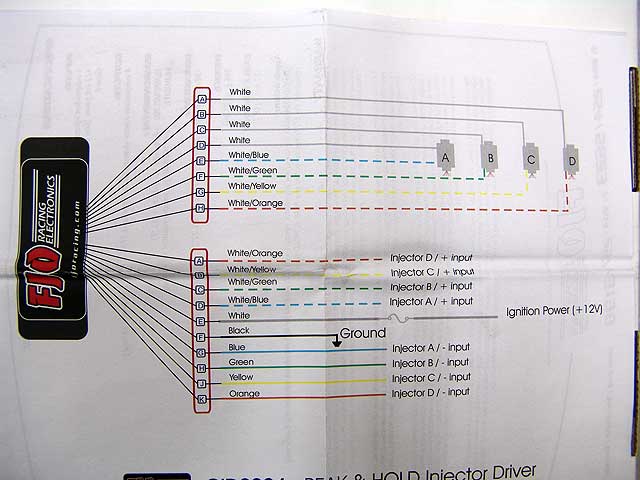

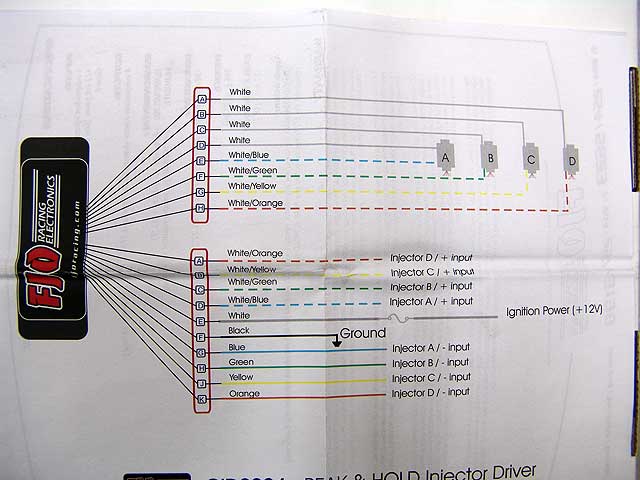

here's my FJO module before installation:

FJO's site:

http://www.fjoracing.com/products.php

2 models. the 4 injector model is approx $195. built to MilSpec.

a few dealers:

florida www.cyberauto.com

oregon www.horsepowerfreaks.com/buy/fjo

texas www.trickracingproducts.com i am working w Rick at Trick on other FJO rx7 products...

AEM

runs up to 10 injectors $349 retail.

http://www.aempower.com/ViewCategory.aspx?CategoryID=83

finally, those who are at the edge of their injectors deliverability might benefit greatly from an increased delivery from their current injectors.

any and all tech comments on this welcomed. i will be extensively dynoing july 15 and will no doubt have further data.

howard coleman

Since replacing my resistors with an FJO (AEM also offers) Peak and Hold module I pull the same AFR w 17% less injector ontime. Further, the mountainous peak in my base fuel map at transition is a now a linear slope.

Since there are differing levels of understanding re this important issue let’s start at square one…

There are 2 types of fuel injectors.

High Resistance (10-17 ohms)

Most OEM, including the FD are High Resistance injectors, and are run on a linear voltage basis. At a given moment they are hit w 14.4 volts. Figuring 12 ohms resistance that results in a current of 1.2 Amps. The flow is constant until close.

Low Resistance (1 to 4 ohms)

Generally higher flow and non-OEM. They are directed in an entirely different manner….

National Semiconductor builds most of the driver chips that run fuel injectors… here’s what they have to say on the subject:

“The current required to open a (fuel injector) solenoid is several times greater than the current necessary to merely hold it open therefore the LM1949 by directly sensing the actual solenoid current initially saturates the driver until the ‘‘peak’’ injector current is four times that of the idle or ‘‘holding’’ current. This guarantees opening of the injector. The current is then automatically reduced to the sufficient holding level for the duration of the input pulse. In this way the total power consumed by the system is dramatically reduced. Also a higher degree of correlation of fuel to the input voltage pulse (or duty cycle) is achieved since opening and closing delays of the solenoid will be reduced.”

So instead of the single voltage flow operation of the High Resistance injector, an initial flow four times that of the flow necessary to hold it open initiates fuel flow within the Low Resistance Injector.

Further, according to National Semi, who makes the drivers in the Power FC…

“Note that for large currents above one amp IR drops within the component leads or printed circuit board may create substantial errors unless appropriate care is taken…”

Bad things can happen to the components inside the Power FC if you run the fuel injectors substantially above one amp.

That’s why most of us have 10 ohm resistors in our secondary (Low Resistance) fuel injector circuits. 14.4 V / 12 ohms = 1.2 Amps. 1.2 Amps is O K as to protecting the Power FC circuits.

Fine. So we aren’t burning up our PFC, but what have we done?

We are attempting to run an injector designed to be Peak and Hold directed in a Saturated linear manner.

We solved the ECU protection at a cost of speaking Chinese to an Anglophile.

How’s that work?

Not as good as you might think.

There’s the theory and the real world observations.

Since installing my 850/1600s I have always had to build a mountain of injector ontime Ms in my base fuel map to maintain constant AFRs. I have consulted loads of people and have been all over the map messing with lag time, transition timing etc.

the mountain remained. Oh well, my AFRs were constant. But what a way to run a railroad.

Then I bumped into the Peak and Hold Convertor Module products. AEM and FJO make such a product. I found a helpful person at FJO and bought the unit.

Running an unchanged base fuel map I went PIG RICH at transition. After dialing down the Ms I now have a linear base fuel map.

And NO RESISTORS.

That’s when things got really interesting.

I had way too much fuel dialed into my map. By my calculations somewhere around 15%!!!! That’s right, I dialed down my fuel and maintained the same AFR as before.

That tells me that resistor-runners can accomplish a number of positive things w a switch to a Peak and Hold Module.

a rationalized fuel map at transition

increased fuel delivery

to quote RC Engineering:

there is more area under the curve w a Peak and Hold injector than a Saturated injector. Take both types, put them in the same fuel log, run them for the same Ms and you will get 8% more fuel w the Peak and Hold.

Perhaps more than 8%…. If you try and run a P&H injector Saturated you will probably get a lot less than the 8% drop quoted by RC. More like my 15% number.

Backing this up:

National Semi:

“a higher degree of correlation of fuel to the input voltage pulse (or duty cycle) is achieved since opening and closing delays of the solenoid will be reduced”

from Stealth 316:

Because the amps are higher in the Peak and Hold circuit, and because the P&H injectors are designed to act faster, the ECM decreases the duration of the pulse (that is, the amount of time the current is applied or the circuit is grounded) to compensate for the faster solenoid response. The ECM for Saturated injectors knows to use a slightly longer pulse duration.

EFI 101

“Your results are a direct consequence of the fact that putting a 10 ohm resistor in series with your injector limits the instantaneous injector current (no such thing as a perfect inductor), and the series resistance coupled with the parasitic coil resistance and the coil inductance, slows the magnetic field from forming in the injector.

This gives more injector "dead time", which means that for a considerable period of time, the injectors are on, but not flowing.”

EFI 101

“By putting a resistor inline with a low-impedance injector, you're limiting the current through the injector, and slowing down the opening time.”

And finally from FJO:

"I'm not surprised that you reduced your injector time to maintain the same

AFR. The difference depends on the peak current that the injector can draw

and the fuel pressure, while you were using a resistor.

Here's a non-tech explanation behind this:

A peak-n-hold injector (low impedance) is designed to draw more current

during the open cycle but requires less during the holding cycle. If the

current is not controlled and the injector is allowed to run saturated, it

will overheat.

The common way of adding a resistor in series with the injector will prevent

it from overheating, however it prevents the injector from reaching it's

peak current during an open cycle - which ultimately slows down its opening

time and makes it more sensitive to changes in fuel pressure and voltage.

The FJO driver allows the injector to hit its peak current, causing it to

open faster and more consistently. It then cuts back the current to the

minimum required to keep the injector open. This is lower than the current

regulated by a resistor. Because of this, when it is time to close, the

magnetic field in the injector will collapse faster and the injector will

close sooner and more consistently. This whole process results in the

injector opening and closing faster and more consistently.

Hope that helps explain it a bit. What you have seen is a common result in

cases where the "resistor box" was replaced. Another improvement is in the

idle stability. The faster closing time allows for shorter open times, which

is important if you are running large injectors."

here's my FJO module before installation:

FJO's site:

http://www.fjoracing.com/products.php

2 models. the 4 injector model is approx $195. built to MilSpec.

a few dealers:

florida www.cyberauto.com

oregon www.horsepowerfreaks.com/buy/fjo

texas www.trickracingproducts.com i am working w Rick at Trick on other FJO rx7 products...

AEM

runs up to 10 injectors $349 retail.

http://www.aempower.com/ViewCategory.aspx?CategoryID=83

finally, those who are at the edge of their injectors deliverability might benefit greatly from an increased delivery from their current injectors.

any and all tech comments on this welcomed. i will be extensively dynoing july 15 and will no doubt have further data.

howard coleman

#4

Very interesting data.

I was thinking this way after my tune last year. I had a PFC running 1200cc and 750cc RC engineering injectors. I used your normal Radio Shack ceramic 10 watt 10 ohm resisters (4). Now, I thought I would be good to about 400+whp with these injectors. I was having Steve Kan tune it and he stopped at 360 whp because he was seeing 85% duty cycle on the commander.

Another option I was thinking of trying is a resister pack from a Honda. Not sure if it is the same concept as the FJO, but they can be found in junk yards for next to nothing.

I was thinking this way after my tune last year. I had a PFC running 1200cc and 750cc RC engineering injectors. I used your normal Radio Shack ceramic 10 watt 10 ohm resisters (4). Now, I thought I would be good to about 400+whp with these injectors. I was having Steve Kan tune it and he stopped at 360 whp because he was seeing 85% duty cycle on the commander.

Another option I was thinking of trying is a resister pack from a Honda. Not sure if it is the same concept as the FJO, but they can be found in junk yards for next to nothing.

#5

A resistor pack from a Honda is going to give you the same effect as your Radio Shack resistors. FJO's driver box sounds like a good solution for PFC users that don't want to make the jump to a more capable standalone.

#6

The driver box is the way to go. Makes a huge difference with large injectors at very low turn on time especially during idle and low rpm/load operation.

Another very popular brand of (P-N-P) ECU presently in the piston world suffers from the very same problem when huge injectors are used. Just recently I was able to get idle mixture with 1600cc injectors down to 14:1 AFR where as before without the driver box it was in the mid 12's AFR and the low rpm/load operation improved by a whole bunch. It was like driving a complety new car.

Another very popular brand of (P-N-P) ECU presently in the piston world suffers from the very same problem when huge injectors are used. Just recently I was able to get idle mixture with 1600cc injectors down to 14:1 AFR where as before without the driver box it was in the mid 12's AFR and the low rpm/load operation improved by a whole bunch. It was like driving a complety new car.

#7

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,135

Likes: 563

From: Florence, Alabama

"Rick at Trick" checks in to tell me that his outfit is:

www.trickperformanceproducts.com /////////not trickracingproducts.

i will ask the moderator to correct the post.

hc

www.trickperformanceproducts.com /////////not trickracingproducts.

i will ask the moderator to correct the post.

hc

Trending Topics

#10

Now here's an explanation that makes sense.

I've been running 10 ohm 1/2 W resistors for a couple of years with no "issues" but now I see the obvious benefit here. I'll be changing over to this during the off season.

As always, thanks Howard!

I've been running 10 ohm 1/2 W resistors for a couple of years with no "issues" but now I see the obvious benefit here. I'll be changing over to this during the off season.

As always, thanks Howard!

#11

#12

I'm glad you did this. I'm trying to decide on which driver to go with. FJO is on top of that list, but I have no experience with there drivers only widebands, which seem to be good quality. The drivers are a very good price when compared to other manufactures as well.

#16

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,135

Likes: 563

From: Florence, Alabama

both the stock 550 primaries and the stock secondary 850s are high impedence and meant to run saturated.

your 1680 are low impedence and meant to run on a Peak and Hold direction.

i run the 850s as primaries and they run directly from the Power FC with no problem and no resistors.

where you and i need the Peak and Hold convertor module is the low impedence high flow secondaries.

hc

your 1680 are low impedence and meant to run on a Peak and Hold direction.

i run the 850s as primaries and they run directly from the Power FC with no problem and no resistors.

where you and i need the Peak and Hold convertor module is the low impedence high flow secondaries.

hc

#18

I haven't had any issues with the injector driver and it's pushing 750's and 1680's injectors.

#20

Howard,

Very nice and informative explanation. I am also running 850cc sidefeed injectors as the primaries. I can't get the idle AFRs any leaner then low 12- high 11s, any suggestions on a fix for this? I've been told that switching to top feed low impedence injectors will allow me to get to the 14s (where I want to be).

-Dan

Very nice and informative explanation. I am also running 850cc sidefeed injectors as the primaries. I can't get the idle AFRs any leaner then low 12- high 11s, any suggestions on a fix for this? I've been told that switching to top feed low impedence injectors will allow me to get to the 14s (where I want to be).

-Dan

#21

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,135

Likes: 563

From: Florence, Alabama

i think the Power FC has a minimum injector ontime (Ms) and no matter what you post in the base fuel map below the minimum it will not respond.

some have tuned around this by going to the lag settings which do subtract from base fuel and will lower the actual ontime. of course that changes the fuel map and also as i recall causes tip-in problems that may be hard to fix...

since we use very little fuel at idle, and we often run the bigger secondary as a primary, idle adjustment is challenging.

my guess is that the small ontime presents problems (fluctuating voltage and large nozzle size) for the ECU to tune so they have just set a higher minimum.

feedback of course appreciated here...

as to Crispeed's comments about running all 4 injectors Peak and hold... perhaps he is worried that if the box malfunctioned with right foot on the floor it would be better for the engine to receive no fuel as opposed to partial fuel and going bang.

or maybe if we run a Peak and Hold primary we could obtain a better idle.

i would love to understand the reasoning for running the primaries P&H. i'll bet i am not alone.

hc

some have tuned around this by going to the lag settings which do subtract from base fuel and will lower the actual ontime. of course that changes the fuel map and also as i recall causes tip-in problems that may be hard to fix...

since we use very little fuel at idle, and we often run the bigger secondary as a primary, idle adjustment is challenging.

my guess is that the small ontime presents problems (fluctuating voltage and large nozzle size) for the ECU to tune so they have just set a higher minimum.

feedback of course appreciated here...

as to Crispeed's comments about running all 4 injectors Peak and hold... perhaps he is worried that if the box malfunctioned with right foot on the floor it would be better for the engine to receive no fuel as opposed to partial fuel and going bang.

or maybe if we run a Peak and Hold primary we could obtain a better idle.

i would love to understand the reasoning for running the primaries P&H. i'll bet i am not alone.

hc

#22

The megasquirt (MSnS-E) has the capability to run peak-and-hold without a second box. Its done by adjusting the opening time and PW % variables in the "Basic Constants 1" menu, so you shoudlnt need to do anything else to it (assuming its working now)

#23

I installed one in my race car back in January of 2006 for all the reasons Howard has articulated above.

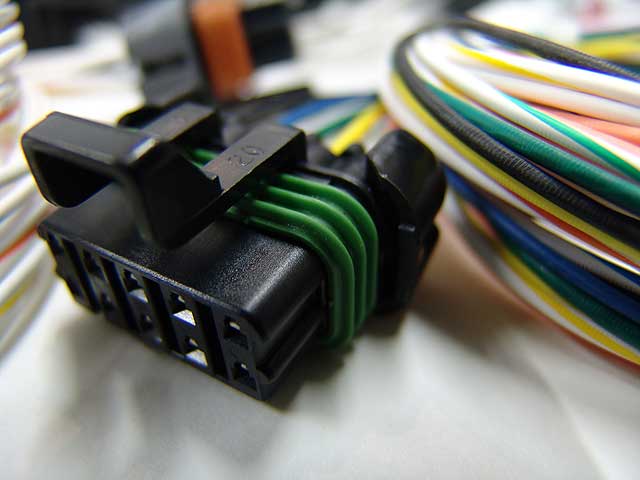

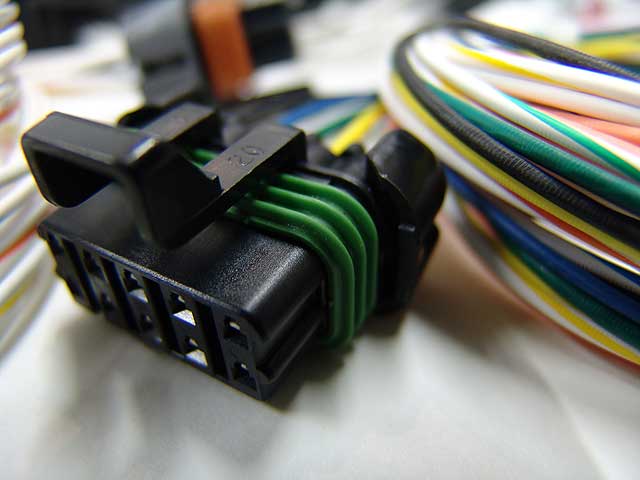

Here are a few more pics of the box that I took back in 2006 and forgot to post:

On a side note, my race car idles better than most street cars :-)

... but then again im an 'needs to idle perfect' freak.

Here are a few more pics of the box that I took back in 2006 and forgot to post:

On a side note, my race car idles better than most street cars :-)

... but then again im an 'needs to idle perfect' freak.

#24

Very interesting data.

I was thinking this way after my tune last year. I had a PFC running 1200cc and 750cc RC engineering injectors. I used your normal Radio Shack ceramic 10 watt 10 ohm resisters (4). Now, I thought I would be good to about 400+whp with these injectors. I was having Steve Kan tune it and he stopped at 360 whp because he was seeing 85% duty cycle on the commander.

Another option I was thinking of trying is a resister pack from a Honda. Not sure if it is the same concept as the FJO, but they can be found in junk yards for next to nothing.

I was thinking this way after my tune last year. I had a PFC running 1200cc and 750cc RC engineering injectors. I used your normal Radio Shack ceramic 10 watt 10 ohm resisters (4). Now, I thought I would be good to about 400+whp with these injectors. I was having Steve Kan tune it and he stopped at 360 whp because he was seeing 85% duty cycle on the commander.

Another option I was thinking of trying is a resister pack from a Honda. Not sure if it is the same concept as the FJO, but they can be found in junk yards for next to nothing.

I am going to try and get the same horse power as you with a twin setup.

#25

Howard, I understand what you are saying about using the FJO for the P&H Secondaries and the Power FC directly for the stock high impedence injectors , be they 550's or 850's. Is it a difficult install the FJO to only drive the secondaries? Sounded like the standard FJO install is pretty simple.