Garrett GTX3582R vs BorgWarner EFR 7670/8374

#51

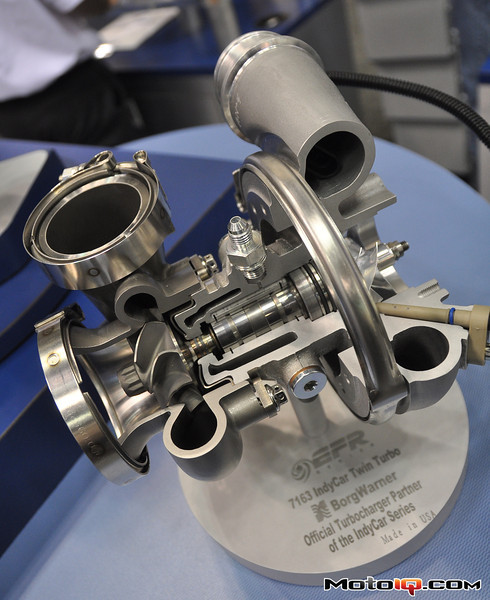

That is the standard Indy car turbo- EFR 7163 for twin turbo applications.

Honda was allowed to run a single EFR 9180 in single turbo configuration for the 2012 and 2013 seasons (also v-band exhaust inlet), but must now use the standard twin turbos.

Honda was allowed to run a single EFR 9180 in single turbo configuration for the 2012 and 2013 seasons (also v-band exhaust inlet), but must now use the standard twin turbos.

#53

Well, there appears to be an Indy car 9180 on Ebay currently and the exhaust manifold is welded directly to the exhaust housing.

http://www.ebay.com/itm/INDY-RACE-CAR-IRL-2012-DW12-DALLARA-BORG-WARNER-TURBOCHARGER-LEMANS-HOTROD-TURBO-/371162121834?pt=Race_Car_Parts&hash=item566afc866a&vxp=mtr

http://www.ebay.com/itm/INDY-RACE-CAR-IRL-2012-DW12-DALLARA-BORG-WARNER-TURBOCHARGER-LEMANS-HOTROD-TURBO-/371162121834?pt=Race_Car_Parts&hash=item566afc866a&vxp=mtr

#54

Well, again, I think a v-band inlet set-up is pretty key, and I doubt those treadstone housings could be adapted to it, so between that and the fact that low boost (<15 psi) may not be possible, it seems like the IWG route is out.

So, the choices would be:

8374 EWG w/ .86 Treadstone v-band housing

GTX3582E w/ 1.03 TiAL v-band housing

I'm not quite following the affect of an open-volute vs. twin-scroll w/ regard to heat and spool time. Am I reading that twin scroll is better for spool, but open-volute is better for heat and decent for spool provided that the manifold is designed such that the flow from the exhaust ports from each rotor aren't pointed at each other too badly? So a shortly manifold to a TiAL housing may not be ideal?

Garret actually makes a divided v-band inlet housing as well.

So, the choices would be:

8374 EWG w/ .86 Treadstone v-band housing

GTX3582E w/ 1.03 TiAL v-band housing

I'm not quite following the affect of an open-volute vs. twin-scroll w/ regard to heat and spool time. Am I reading that twin scroll is better for spool, but open-volute is better for heat and decent for spool provided that the manifold is designed such that the flow from the exhaust ports from each rotor aren't pointed at each other too badly? So a shortly manifold to a TiAL housing may not be ideal?

Garret actually makes a divided v-band inlet housing as well.

peter, i bolded what you said above in regards to the <15psi not being possible, and please know that my setup seems to have been an isolated case. Elliot has had several customers that have held 7psi til redline with no boost creep --i think 2 of whom had large streetport "race port" engines.

Elliot will still say that my setup had an ignition system issue, like a weak ignition coil (or something else with my engine setup) that was causing the boost to creep up, but i didn't do enough troubleshooting on it to completely rule anything out.

that being said, i AM selling my complete EFR kit, as you know, and anyone can search my posts and see that i did in fact have boost issues. however, 1. i had a large streetport engine, 2. i did no troubleshooting with ignition settings, and 3. the same setup held 10psi til redline for about 6 months (and 3 track events) with absolutely no issues.

also, along with what LOOKatme posted above, i think the importance of the internal wastegate for reliability/longevity is undervalued. i sold my turblown dual wastegate setup and switch to this IWG EFR setup to substantially simplify my setup. previously, i had a turblown long-runner dual 38mm manifold, two mvs 38mm wastegates, water lines running in series between the two wastegates and back to the engine, 2 vbands connecting the wastegates to the manifold, 2 vbands connecting the wastegate outlets to the downpipe recirc pipes, and 1 vband at the turbo discharge/downpipe. it took about 2 hours to remove the downpipe when i had an issue with one of the wastegate water lines leaking. (and that's just to remove the downpipe). changing wastegate springs, replacing block/turbo gaskets, etc. adds lots more time/work onto that. --and this is just the affect the turbo system complexity on work/time. there are so many pieces that there was much more "that could go wrong" on the track.

the EFR IWG system has one internal wastegate flapper, and one rod connecting it about 12" to an actuator. when i needed to take the turbo off to do anything (EFR setup) it took me 13 minutes (timed) to get the entire turbo/manifold setup off of the car.

#55

Brings us back to-

What is wrong with trimming and welding a divided EFR SS exhaust housing flange to a SS divided turbo manifold flange for a failure free connection and an optimal runner to exhaust wheel design for a rotary?

Not the right way to do it? Honda Indy program says otherwise

You trust the welds in a SS exhaust manifold still if you go V-band exhaust housing and you lose the divided housing.

What is wrong with trimming and welding a divided EFR SS exhaust housing flange to a SS divided turbo manifold flange for a failure free connection and an optimal runner to exhaust wheel design for a rotary?

Not the right way to do it? Honda Indy program says otherwise

You trust the welds in a SS exhaust manifold still if you go V-band exhaust housing and you lose the divided housing.

#56

^^^^

Thanks Jacob. I would definitely NOT be looking at a dual wastegate setup, for exactly the reasons you outline. When did single turbo setups start needing two gates? Seems like most of the setups for years only required one, and then all of a sudden everyone seems to need two.

The internal gate is great. I just really want a v-band inlet. It's really puzzling to me that this isn't available (is it harder to cast a circle than a square?!), and it actually seems to exist as a prototype at least (that's a Borg Warner booth at Sema).

P

Thanks Jacob. I would definitely NOT be looking at a dual wastegate setup, for exactly the reasons you outline. When did single turbo setups start needing two gates? Seems like most of the setups for years only required one, and then all of a sudden everyone seems to need two.

The internal gate is great. I just really want a v-band inlet. It's really puzzling to me that this isn't available (is it harder to cast a circle than a square?!), and it actually seems to exist as a prototype at least (that's a Borg Warner booth at Sema).

P

#57

That Indy turbo still looks like an external wastegate set-up.. pictured is an internal with v-band inlet.

There were two turbos used in Indy car as I stated.

Honda HPD used a single EFR 9180 in 2012 and 2013.

The rest of the teams used twin EFR 7163s.

Yes, it looks like Honda used the standard EWG 9180 exhaust housing cut and welded.

IWG is an option for a Indy car style cut and welded turbo exhaust housing/manifold.

There were two turbos used in Indy car as I stated.

Honda HPD used a single EFR 9180 in 2012 and 2013.

The rest of the teams used twin EFR 7163s.

Yes, it looks like Honda used the standard EWG 9180 exhaust housing cut and welded.

IWG is an option for a Indy car style cut and welded turbo exhaust housing/manifold.

#58

^^^^

Thanks Jacob. I would definitely NOT be looking at a dual wastegate setup, for exactly the reasons you outline. When did single turbo setups start needing two gates? Seems like most of the setups for years only required one, and then all of a sudden everyone seems to need two.

The internal gate is great. I just really want a v-band inlet. It's really puzzling to me that this isn't available (is it harder to case a circle than a square?!), and it actually seems to exist as a prototype at least (that's a Borg Warner booth at Sema).

P

Thanks Jacob. I would definitely NOT be looking at a dual wastegate setup, for exactly the reasons you outline. When did single turbo setups start needing two gates? Seems like most of the setups for years only required one, and then all of a sudden everyone seems to need two.

The internal gate is great. I just really want a v-band inlet. It's really puzzling to me that this isn't available (is it harder to case a circle than a square?!), and it actually seems to exist as a prototype at least (that's a Borg Warner booth at Sema).

P

peter, no problem.

i think a big issue with the vband inlet is that while they're great for racing and quick changing, they are still a vband and may never seal perfectly. i'm imagining starting up an FD in the cold winter and having an audible exhaust leak from the turbo inlet for a minute or two before it seals up. this may not be an issue, but i've previously had quite a bit of annoyance from vbands not sealing perfectly and creating noticeable/audible leaks. there's a reason 034motorsports sells "vband gaskets."

vbands also warp, and i imagine a large, hot vband like one you're describing will be likely to slightly warp and create a small leak(s). of course the square flanges warp too, but it helps with you have a 1/8" gasket helping seal (well, until it blows out too)

this could all differ from the experiences of others on this forum, but i have had very few vbands seal perfectly.

and blueTII is right, we trust the welds on the manifold, why not trust welding on an aftermarket high quality vband ring to an EFR inlet?

#59

Brings us back to-

What is wrong with trimming and welding a divided EFR SS exhaust housing flange to a SS divided turbo manifold flange for a failure free connection and an optimal runner to exhaust wheel design for a rotary?

Not the right way to do it? Honda Indy program says otherwise

You trust the welds in a SS exhaust manifold still if you go V-band exhaust housing and you lose the divided housing.

What is wrong with trimming and welding a divided EFR SS exhaust housing flange to a SS divided turbo manifold flange for a failure free connection and an optimal runner to exhaust wheel design for a rotary?

Not the right way to do it? Honda Indy program says otherwise

You trust the welds in a SS exhaust manifold still if you go V-band exhaust housing and you lose the divided housing.

Heck, why not just CNC a v-band flange, cut off the 4-bolt, and weld it on to the damned turbo like they should've done it in the first place (per attached). Then you can get things apart if you need to.

Last edited by ptrhahn; 10-14-14 at 02:03 PM.

#60

IMO one opens a whole other can of worms when machining a divided T4 flange into a V-band style connection.

Now there are differential pressures, temperatures and material expansion along the v-band flange that will affect the outer circular sealing path.

----------

Alternately, one could weld up a manifold that has dual v-bands before the turbo housing (like the Indy car manifold, but shaped for the rotary application).

Even then, forces from the two manifold runners' expansion acting on each other that could put strain on the v-band seals (note the Indy car manifold has a flex section).

If the v-band flanges were on straight parallel runners, these forces would likely be minimal.

-----------

Is there an advantage to being able to remove the turbo exhaust housing separate from the manifold?

On my EFR I was able to reach all of the CHRA bolts to exhaust housing with the turbo in the car and a standard closed end wrench.

Now there are differential pressures, temperatures and material expansion along the v-band flange that will affect the outer circular sealing path.

----------

Alternately, one could weld up a manifold that has dual v-bands before the turbo housing (like the Indy car manifold, but shaped for the rotary application).

Even then, forces from the two manifold runners' expansion acting on each other that could put strain on the v-band seals (note the Indy car manifold has a flex section).

If the v-band flanges were on straight parallel runners, these forces would likely be minimal.

-----------

Is there an advantage to being able to remove the turbo exhaust housing separate from the manifold?

On my EFR I was able to reach all of the CHRA bolts to exhaust housing with the turbo in the car and a standard closed end wrench.

#61

why not trust welding on an aftermarket high quality vband ring to an EFR inlet?

If you do this and want IWG I think you are stuck with the BW EFR 0.83AR T3 IWG exhaust housing.

I did just find a PDF where BW shows they offer-

V-band entry 0.90AR External WG T3 exhaust housing for up to the EFR 8374

12741009002

Is this the Treadstone housing?

http://www.google.com/url?sa=t&rct=j...77412846,d.b2U

If you do this and want IWG I think you are stuck with the BW EFR 0.83AR T3 IWG exhaust housing.

I did just find a PDF where BW shows they offer-

V-band entry 0.90AR External WG T3 exhaust housing for up to the EFR 8374

12741009002

Is this the Treadstone housing?

http://www.google.com/url?sa=t&rct=j...77412846,d.b2U

#62

Exactly! Nothing wrong with it at all--done properly. Use TIG with 310 (preferably) or 309 filler.

The following users liked this post:

ZekeO (12-12-20)

#63

I would run the turbo as designed, do whatever the manufacturer recommends, and if you have problems, modify from there. It's not going to be a catastrophic failure if you have a small exhaust leak or something.

#65

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

Based on previous experience it will be a long time with Tial for those products.

Another customer with our 8374 iwg kit holds a solid 13 psi with no intake or exhaust restriction.

Another customer with our 8374 iwg kit holds a solid 13 psi with no intake or exhaust restriction.

#66

Joined: Dec 2001

Posts: 7,090

Likes: 121

From: Twin Cities, MN

It appears I have found Vband inlet EFR turbine housings for the 8374/9180 in 1.0 a/r!

Working on getting more details and one in my hands etc... Pricing is same as the EWG version of the 9180 housing.

Working on getting more details and one in my hands etc... Pricing is same as the EWG version of the 9180 housing.

#69

The link below may be of some use to anyone looking for 8374 and smaller v-band housings

http://www.treadstoneperformance.com...rbine+Housings

http://www.treadstoneperformance.com...rbine+Housings

#71

To me the GTX3582 doesn't seem like a good turbo to compare against either of the Borgwarners .

I think a good comparison would be the gtx3576r vs efr7670. Very similar size wise at both ends but the gtx compressor map favors the 13b more in that 2..0 -2.5 pr range that most people run them at.

The gtx3576 should spool up well enough and be more suitable for a 400whp car .

Thoughts ?

I think a good comparison would be the gtx3576r vs efr7670. Very similar size wise at both ends but the gtx compressor map favors the 13b more in that 2..0 -2.5 pr range that most people run them at.

The gtx3576 should spool up well enough and be more suitable for a 400whp car .

Thoughts ?

#72

Reviving an old thread as I do my research on Turbo options for my stock internal 13BREW...

I see both the 7670 and 8374 are still on sale all over the place... it seems like they've been around for 10+ years! Any word on any updates to them? and are they still some of the best quick-response street turbos out there? Have Garrett's GTXs caught up??

I see both the 7670 and 8374 are still on sale all over the place... it seems like they've been around for 10+ years! Any word on any updates to them? and are they still some of the best quick-response street turbos out there? Have Garrett's GTXs caught up??

#73

There are some piston applications where the GTX are better than EFR with their little exhaust sides. Which is why EFRs are comming out with bigger compressors on their exhaust wheels (so basically making small exhaust wheel models).

But for the rotary the generous exhaust wheel to compressor diameter ratio of the original EFRs really spools well.

But for the rotary the generous exhaust wheel to compressor diameter ratio of the original EFRs really spools well.

#74

There are some piston applications where the GTX are better than EFR with their little exhaust sides. Which is why EFRs are comming out with bigger compressors on their exhaust wheels (so basically making small exhaust wheel models).

But for the rotary the generous exhaust wheel to compressor diameter ratio of the original EFRs really spools well.

But for the rotary the generous exhaust wheel to compressor diameter ratio of the original EFRs really spools well.

His "ideal ratio" of 1:1 for rotaries plays, because if you look at the turbos close to that ratio, those are the ones that are touted as the best to use on rotaries.

So would you then look for turbo that is say .75:1 for a piston engine? What might the factors be that would change the target? displacement? peak rpm? rpm of peak torque?

#75

Head design, cam profiles and operating rpm range play a huge role in how tolerant piston engines are to exhaust manifold pressure.

Something like 4g63 can handle a small exhaust side and make in redible powet where the same 2.0L k20 has to have a relatively huge exhaust side.

Something like 4g63 can handle a small exhaust side and make in redible powet where the same 2.0L k20 has to have a relatively huge exhaust side.

Thread

Thread Starter

Forum

Replies

Last Post

Turblown

Vendor Classifieds

12

10-17-20 03:25 PM

Turblown

Group Buy & Product Dev. FD RX-7

7

03-21-18 11:19 AM