Flange port matching??

#1

HI,

I got this Flange for my manifold. Its set up on the Manilfold fine:

This is the flange in place:

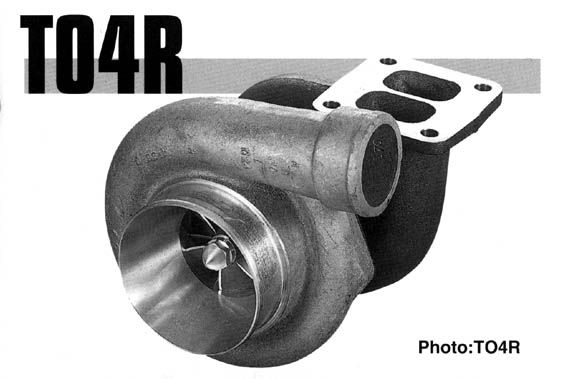

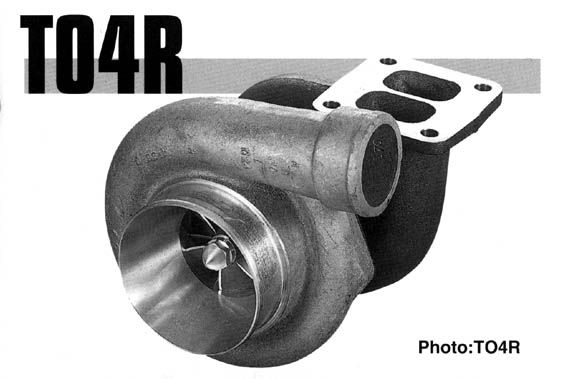

I got my TO4R from the Store.....this is the flange. The exhaust inlet holes seem small even compared to the gasket:

Now I did see a couple of T66s and To4Rs and the exhaust inlet where big as big as the picture of the flange provided.

The A/R were constant of 1.00. I am not sure of the trim though. Does it have anything to do with the wheel trim? Will this flange cause too much back pressure? Will this housing spool like crazy? will it be restrictive? Just really curious to know. in my books, big holes = Lag, small holes = spool. but considering that comparing apples with apples, the hole on the other T4 flanges I seen for the same a/r is way bigger then mine. Your input is as always appreciated.

Thanks for reading this far.

Best of Regards.

George

I got this Flange for my manifold. Its set up on the Manilfold fine:

This is the flange in place:

I got my TO4R from the Store.....this is the flange. The exhaust inlet holes seem small even compared to the gasket:

Now I did see a couple of T66s and To4Rs and the exhaust inlet where big as big as the picture of the flange provided.

The A/R were constant of 1.00. I am not sure of the trim though. Does it have anything to do with the wheel trim? Will this flange cause too much back pressure? Will this housing spool like crazy? will it be restrictive? Just really curious to know. in my books, big holes = Lag, small holes = spool. but considering that comparing apples with apples, the hole on the other T4 flanges I seen for the same a/r is way bigger then mine. Your input is as always appreciated.

Thanks for reading this far.

Best of Regards.

George

#3

That would be more restrictive than better spooling because of so much air just hitting the flat metal which would cause some turbulence.

If you have enough metal on the housing, you should port match it at the opening edges so there's a smooth transition. The opening will then narrow and cause the air to speed up as it enters the housing after the opening.

If you have enough metal on the housing, you should port match it at the opening edges so there's a smooth transition. The opening will then narrow and cause the air to speed up as it enters the housing after the opening.

#5

well it should be a garrett T4 Flange...

Port matching is a bit of a problem I think since the passage itself is restricted.... ever met that kind of foot print?

Thanks for your quick replies

George

Port matching is a bit of a problem I think since the passage itself is restricted.... ever met that kind of foot print?

Thanks for your quick replies

George

#7

Two things going on here. 1st, your manifold/turbine flange looks like it was made for thin wall tubbing to be inserted into the flange and not welded on top of the runners. This is fairly common, and not what should be used on a thick walled rotary manifold were the flange gets welded on top of the runners. Those inlet holes look too big. Check the dimensions of the flange here:

http://www.t3flange.com/t4flangesplit.gif

2nd, thats one strange T4 turbine. Who makes it? Its inlet/valute opening is really small looking. I'd personally get a better turbine if it is indeed smaller then the dimensions that I just gave you. The flange drawing I gave you should be the same inlet/valute opening as the manifold flange AND the flange on the turbine itself. Check both witht the supplied drawing and get back to us.

~Mike..................

http://www.t3flange.com/t4flangesplit.gif

2nd, thats one strange T4 turbine. Who makes it? Its inlet/valute opening is really small looking. I'd personally get a better turbine if it is indeed smaller then the dimensions that I just gave you. The flange drawing I gave you should be the same inlet/valute opening as the manifold flange AND the flange on the turbine itself. Check both witht the supplied drawing and get back to us.

~Mike..................

Trending Topics

#10

these are my measurements....sorry for the metric... but i will muck it up in imperial  the ones I edited are different, the other are the same.

the ones I edited are different, the other are the same.

this is a similar pic I found of the flange.....

these are the markings on the housing Rear(V Band Side):

front (CHRA side):

Thanks... look forward for your replies

George

the ones I edited are different, the other are the same.

the ones I edited are different, the other are the same.

this is a similar pic I found of the flange.....

these are the markings on the housing Rear(V Band Side):

front (CHRA side):

Thanks... look forward for your replies

George

#12

George,

The flange measurements you gave are of your manifold flange, or the actual turbine flange? Also, your sure all the other measurements are the same correct?

For refferance, 1" (1 inch) = 25.4mm

So your 23mm= .906"

27mm=1.063"

6mm=.236"

~Mike............

The flange measurements you gave are of your manifold flange, or the actual turbine flange? Also, your sure all the other measurements are the same correct?

For refferance, 1" (1 inch) = 25.4mm

So your 23mm= .906"

27mm=1.063"

6mm=.236"

~Mike............

#13

yep!!! they tally perfectly. I measured them in inches and mm.

the 'hole' dimensions are off the turbine.... the manifold is perfectly in sync with your diagram

I am really lost

Thanks Mike

G

the 'hole' dimensions are off the turbine.... the manifold is perfectly in sync with your diagram

I am really lost

Thanks Mike

G

#14

George,

You have one weird turbine. The inlets are definately way WAY small. Were did you buy it from, and you have no idea who manufactured it? Garrett, Master Power, Turbonetics, etc.? I'd order a Garrett or Turbonetics turbine for it if I were you. All you need to know is the turbine wheel trim and what A/R you want to run. At the very least contact the seller and find out what the heck is going on and explain that the inlet is no were near what it should be.

~Mike................

You have one weird turbine. The inlets are definately way WAY small. Were did you buy it from, and you have no idea who manufactured it? Garrett, Master Power, Turbonetics, etc.? I'd order a Garrett or Turbonetics turbine for it if I were you. All you need to know is the turbine wheel trim and what A/R you want to run. At the very least contact the seller and find out what the heck is going on and explain that the inlet is no were near what it should be.

~Mike................