Efr 7670

#80

Ha, just realized we joined this site at the same time, lol. Anyways. What let go? Just finished installing mine last week. Using ALS seals and teflon coated coolant seals so hopefully they'll be more robust. What was in yours?

#81

Thread Starter

Joined: Aug 2004

Posts: 4,619

Likes: 120

From: Colorado Springs, CO

Oh yeah we did huh? lol

I was using ALS seals also. My exhaust ports were rectangular and the ends of the apex seals wore down as they went over the sides of the ports, while the middle did not. They wore down to the point that I lost compression enough to start the car. Oil and pull starting were the only ways to start it. I sent the seals back to Edgar and he said he was surprised it ran as long as it did considering the wear the housings put on the seals. He gave me a discount on another set of seals and I got a replacement engine so we'll see how this one does lol. This time I'm using ALS (or rather E&J) seals again, and the Pineapple HD kit and the rest is Atkins with their solid corner seals. Although I'm thinking I maybe should go with OEM corner seals this time. I had some chatter marks in my housings too. I was also thinking about using Goopy 1pc seals and using these E&J seals in another engine I'm going to build as a backup, but I'm not sure.

I was using ALS seals also. My exhaust ports were rectangular and the ends of the apex seals wore down as they went over the sides of the ports, while the middle did not. They wore down to the point that I lost compression enough to start the car. Oil and pull starting were the only ways to start it. I sent the seals back to Edgar and he said he was surprised it ran as long as it did considering the wear the housings put on the seals. He gave me a discount on another set of seals and I got a replacement engine so we'll see how this one does lol. This time I'm using ALS (or rather E&J) seals again, and the Pineapple HD kit and the rest is Atkins with their solid corner seals. Although I'm thinking I maybe should go with OEM corner seals this time. I had some chatter marks in my housings too. I was also thinking about using Goopy 1pc seals and using these E&J seals in another engine I'm going to build as a backup, but I'm not sure.

#84

My experience-

Too much boost on pump gas= detonation= very high EGTs= more apex seal sag/wear.

Even if its not breaking your engine detonation's higher EGTs will wear it our really fast.

Tune on 104, then pull or abuse your O2 sensor by running 5 gallons 116 with each tank of pump gas to save $$.

TEL in the leaded gas raises octane of non leaded gas far higher than the average by volume of the leaded/non-leaded mix.

On race gas even lean outs from component failure won't detonate, power just drops out.

Too much boost on pump gas= detonation= very high EGTs= more apex seal sag/wear.

Even if its not breaking your engine detonation's higher EGTs will wear it our really fast.

Tune on 104, then pull or abuse your O2 sensor by running 5 gallons 116 with each tank of pump gas to save $$.

TEL in the leaded gas raises octane of non leaded gas far higher than the average by volume of the leaded/non-leaded mix.

On race gas even lean outs from component failure won't detonate, power just drops out.

#85

My experience-

Too much boost on pump gas= detonation= very high EGTs= more apex seal sag/wear.

Even if its not breaking your engine detonation's higher EGTs will wear it our really fast.

Tune on 104, then pull or abuse your O2 sensor by running 5 gallons 116 with each tank of pump gas to save $$.

TEL in the leaded gas raises octane of non leaded gas far higher than the average by volume of the leaded/non-leaded mix.

On race gas even lean outs from component failure won't detonate, power just drops out.

Too much boost on pump gas= detonation= very high EGTs= more apex seal sag/wear.

Even if its not breaking your engine detonation's higher EGTs will wear it our really fast.

Tune on 104, then pull or abuse your O2 sensor by running 5 gallons 116 with each tank of pump gas to save $$.

TEL in the leaded gas raises octane of non leaded gas far higher than the average by volume of the leaded/non-leaded mix.

On race gas even lean outs from component failure won't detonate, power just drops out.

#86

Ah, nice. I haven't tried water/meth yet.

I pretty much use a stock closing line on the exhaust port as well.

just the top outer corners squared up more, but rebevelled/ surface height relieved like stock.

When I have run into detonation on pump gas it has worn a flat spot on the side of the apex seals where it runs over the (raised from heat) leading spark plug hole/boss.

I pretty much use a stock closing line on the exhaust port as well.

just the top outer corners squared up more, but rebevelled/ surface height relieved like stock.

When I have run into detonation on pump gas it has worn a flat spot on the side of the apex seals where it runs over the (raised from heat) leading spark plug hole/boss.

#87

Thread Starter

Joined: Aug 2004

Posts: 4,619

Likes: 120

From: Colorado Springs, CO

Thanks for your input! I have been told I'm boosting too high on pump gas, so even though I'll be keeping water injection, I believe I'm gonna drop the boost a bit. I don't trust my knock sensor anyway, but because I'm using delrin engine mounts, I'm not sure if it's causing my high knock readings or if it really was detonating. The readings will be fairly low until I just barely step on the gas, and from then on and higher my knock readings soar. My EGTs were fairly normal until I'd be on the highway for a while, then they'd peg as high as the gauge would read.

I see water/meth as somewhat of a double edged sword. You really need to run excess premix so it doesn't get washed off the housing walls, but for the first time that I've used water injection on the entire life of the engine, I finally didn't have scorch marks and cracks next to the spark plug holes. I still have my OMP and I put Valvoline 2 cycle through it, and I've been premixing the same stuff in the tank, about .5oz to every gallon. I'll be bumping that up to at least 1/1, maybe even a tad more than that.

I see water/meth as somewhat of a double edged sword. You really need to run excess premix so it doesn't get washed off the housing walls, but for the first time that I've used water injection on the entire life of the engine, I finally didn't have scorch marks and cracks next to the spark plug holes. I still have my OMP and I put Valvoline 2 cycle through it, and I've been premixing the same stuff in the tank, about .5oz to every gallon. I'll be bumping that up to at least 1/1, maybe even a tad more than that.

#88

Thanks for your input! I have been told I'm boosting too high on pump gas, so even though I'll be keeping water injection, I believe I'm gonna drop the boost a bit. I don't trust my knock sensor anyway, but because I'm using delrin engine mounts, I'm not sure if it's causing my high knock readings or if it really was detonating. The readings will be fairly low until I just barely step on the gas, and from then on and higher my knock readings soar. My EGTs were fairly normal until I'd be on the highway for a while, then they'd peg as high as the gauge would read.

I see water/meth as somewhat of a double edged sword. You really need to run excess premix so it doesn't get washed off the housing walls, but for the first time that I've used water injection on the entire life of the engine, I finally didn't have scorch marks and cracks next to the spark plug holes. I still have my OMP and I put Valvoline 2 cycle through it, and I've been premixing the same stuff in the tank, about .5oz to every gallon. I'll be bumping that up to at least 1/1, maybe even a tad more than that.

I see water/meth as somewhat of a double edged sword. You really need to run excess premix so it doesn't get washed off the housing walls, but for the first time that I've used water injection on the entire life of the engine, I finally didn't have scorch marks and cracks next to the spark plug holes. I still have my OMP and I put Valvoline 2 cycle through it, and I've been premixing the same stuff in the tank, about .5oz to every gallon. I'll be bumping that up to at least 1/1, maybe even a tad more than that.

#90

I think he was running mid 20's PSI. I don't think its your PSI, because you had good intake temps and your pressure ratio (3.13) is efficient according to the compressor map. The best boost level at our altitude would probably be around a pressure ratio of 2.8 or 21 PSI for that turbo. I think your timing might be the problem. I have your map and when I compare it to the one I am running, your timing is quit a bit retarded from mine, which typically means hotter exhaust temps, and I think mine is conservative.

#92

I'm almost absolutely positive you were over 400hp, and most likely over 400whp when running 20psi on that turbo.

We wanna see the motor apart!! Lookin' great.

Where do you get the motivation to keep going?

Are you switching turbos?

We wanna see the motor apart!! Lookin' great.

Where do you get the motivation to keep going?

Are you switching turbos?

#93

Thread Starter

Joined: Aug 2004

Posts: 4,619

Likes: 120

From: Colorado Springs, CO

I think he was running mid 20's PSI. I don't think its your PSI, because you had good intake temps and your pressure ratio (3.13) is efficient according to the compressor map. The best boost level at our altitude would probably be around a pressure ratio of 2.8 or 21 PSI for that turbo. I think your timing might be the problem. I have your map and when I compare it to the one I am running, your timing is quit a bit retarded from mine, which typically means hotter exhaust temps, and I think mine is conservative.

What is the difference between US and Australian dynos?

I doubt I hit 400, but anything is possible I guess. I'll post some pics of the internals one of these days. I haven't had much motivation actually. I've had more lately because this summer has been so nice and it seems like so many others are up and running and it drives me crazy lol. Plus I'm trying to finish it before I deploy again. I've been dating my gf for about a year and a half and spending most of my time with her. Otherwise I would've been doing all this last summer already. I'm not blaming her, I've enjoyed spending time with her. I'm just saying when I'm single about all I do is work on the car so I get a lot more done lol. I don't think I'll switch turbos until this one goes. Then I might do it.

#94

What is the difference between US and Australian dynos?

I think Australians commonly use Dyno Dynamics dynos which read lower.

For instance my local dyno is Dyno Dynamics and my car makes 300rwhp @ 10psi, 325rwhp @ 16psi and 330rwhp @ 18psi.

My car has previously dynoed

340 @ 12psi on DynoJet

340 @ 12psi on DynaPack

385 @ 14psi on DynaPack

Two Stock class "505hp" C6 Z06 made 370 and 380rwhp respectively on the local Dyno Dynamics.

You can set the Dyno Dynamics on "flywheel hp" and it will spit out DynoJet and DynaPack compatible numbers.

For example my Dyno Dynamics 330rwhp became 375hp in "flywheel" mode.

#95

I doubt I hit 400, but anything is possible I guess.

Could easily be over 400rwhp on DynoJet.

My car would have made over 400rwhp on a DynoJet at 16psi on my 57lbsmin peak 60-1 HiFi stock hybrid, but the runs were aborted due to BOV popping open.

The trend was 20hp over the 385rwhp runs though.

The 7670 flows 64lbsmin peak.

Could easily be over 400rwhp on DynoJet.

My car would have made over 400rwhp on a DynoJet at 16psi on my 57lbsmin peak 60-1 HiFi stock hybrid, but the runs were aborted due to BOV popping open.

The trend was 20hp over the 385rwhp runs though.

The 7670 flows 64lbsmin peak.

#96

Thread Starter

Joined: Aug 2004

Posts: 4,619

Likes: 120

From: Colorado Springs, CO

What is the difference between US and Australian dynos?

I think Australians commonly use Dyno Dynamics dynos which read lower.

For instance my local dyno is Dyno Dynamics and my car makes 300rwhp @ 10psi, 325rwhp @ 16psi and 330rwhp @ 18psi.

My car has previously dynoed

340 @ 12psi on DynoJet

340 @ 12psi on DynaPack

385 @ 14psi on DynaPack

Two Stock class "505hp" C6 Z06 made 370 and 380rwhp respectively on the local Dyno Dynamics.

You can set the Dyno Dynamics on "flywheel hp" and it will spit out DynoJet and DynaPack compatible numbers.

For example my Dyno Dynamics 330rwhp became 375hp in "flywheel" mode.

I doubt I hit 400, but anything is possible I guess.

Could easily be over 400rwhp on DynoJet.

My car would have made over 400rwhp on a DynoJet at 16psi on my 57lbsmin peak 60-1 HiFi stock hybrid, but the runs were aborted due to BOV popping open.

The trend was 20hp over the 385rwhp runs though.

The 7670 flows 64lbsmin peak.

Could easily be over 400rwhp on DynoJet.

My car would have made over 400rwhp on a DynoJet at 16psi on my 57lbsmin peak 60-1 HiFi stock hybrid, but the runs were aborted due to BOV popping open.

The trend was 20hp over the 385rwhp runs though.

The 7670 flows 64lbsmin peak.

Here are some pics as Terrence requested.

#97

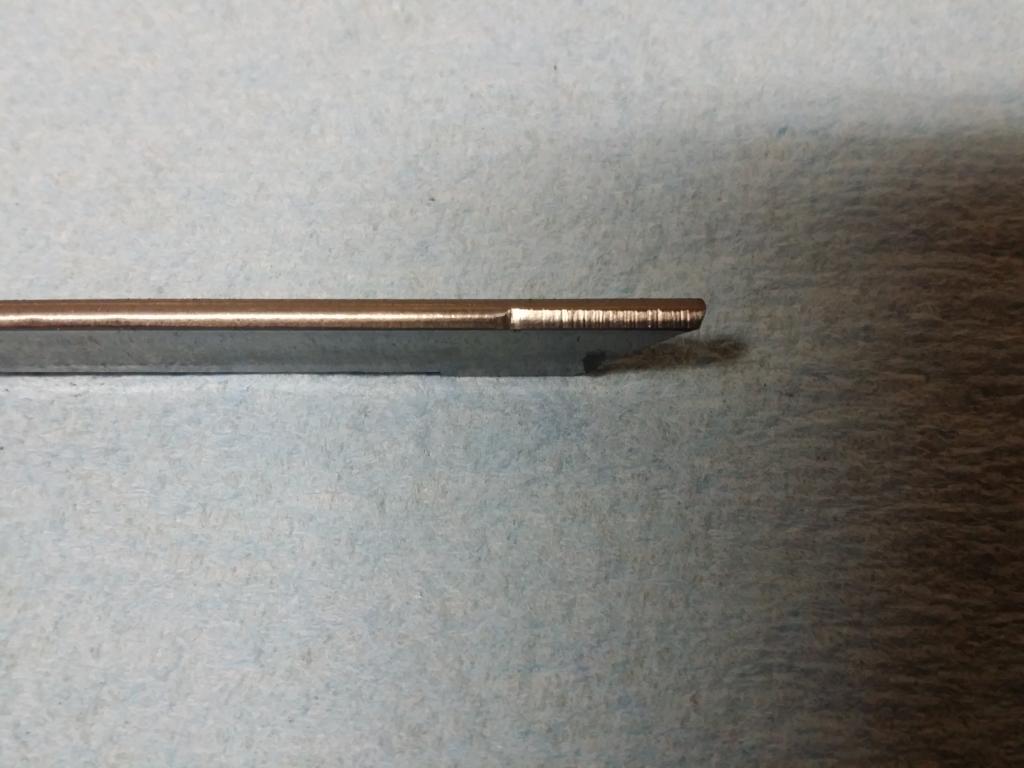

That exhaust port is indeed horrible, but it is not what wore the apex seals.

Note that the apex seal is worn where it is in continuous contact with the rotor housing.

It appears that the chrome has flaked off the rotor housing adjacent to the exhaust port. The seal is riding on the sheet metal insert in that area of wear on the apex seal.

----------------------

Side rant-

Also, the apex seal material is not compatible with the chrome rotor housing material.

Note the chatter marks on the entire rotor housing surface. The chatter will greatly increase wear on the rotor housing, apex seal, rotor slot as well as greatly increased change of "spitback" (Mazda's term) induced preignition/misfire as the apex seal crosses the rotor housing minor axis.

I ran RA Classic seals and RA SuperSeals in 2mm and 3mm (among other aftermarket seals) with similar results.

With OEM 2mm or 3mm seals the engine runs better, lasts longer and when you take it apart it is evident why. Smooth housing surfaces with very little wear.

Note I have managed to break all types of apex seals with crap pump gas and detonation as well.

With 3mm seals (OEM or aftermarket) my experience is that its about 50/50 whether the cornerseals, apex seals or housings crack first. I don't see the benefit of a "stronger" aftermarket 3mm seal.

My experience with 2mm seals (OEM and aftermarket) is that they are indeed the weakest link with detonation. More broken apex seals from detonation, but less detonation induced engine damage overall (engine doesn't run long while detonating).

Note that the apex seal is worn where it is in continuous contact with the rotor housing.

It appears that the chrome has flaked off the rotor housing adjacent to the exhaust port. The seal is riding on the sheet metal insert in that area of wear on the apex seal.

----------------------

Side rant-

Also, the apex seal material is not compatible with the chrome rotor housing material.

Note the chatter marks on the entire rotor housing surface. The chatter will greatly increase wear on the rotor housing, apex seal, rotor slot as well as greatly increased change of "spitback" (Mazda's term) induced preignition/misfire as the apex seal crosses the rotor housing minor axis.

I ran RA Classic seals and RA SuperSeals in 2mm and 3mm (among other aftermarket seals) with similar results.

With OEM 2mm or 3mm seals the engine runs better, lasts longer and when you take it apart it is evident why. Smooth housing surfaces with very little wear.

Note I have managed to break all types of apex seals with crap pump gas and detonation as well.

With 3mm seals (OEM or aftermarket) my experience is that its about 50/50 whether the cornerseals, apex seals or housings crack first. I don't see the benefit of a "stronger" aftermarket 3mm seal.

My experience with 2mm seals (OEM and aftermarket) is that they are indeed the weakest link with detonation. More broken apex seals from detonation, but less detonation induced engine damage overall (engine doesn't run long while detonating).

#100

Thread Starter

Joined: Aug 2004

Posts: 4,619

Likes: 120

From: Colorado Springs, CO

That exhaust port is indeed horrible, but it is not what wore the apex seals.

Note that the apex seal is worn where it is in continuous contact with the rotor housing.

It appears that the chrome has flaked off the rotor housing adjacent to the exhaust port. The seal is riding on the sheet metal insert in that area of wear on the apex seal.

----------------------

Side rant-

Also, the apex seal material is not compatible with the chrome rotor housing material.

Note the chatter marks on the entire rotor housing surface. The chatter will greatly increase wear on the rotor housing, apex seal, rotor slot as well as greatly increased change of "spitback" (Mazda's term) induced preignition/misfire as the apex seal crosses the rotor housing minor axis.

I ran RA Classic seals and RA SuperSeals in 2mm and 3mm (among other aftermarket seals) with similar results.

With OEM 2mm or 3mm seals the engine runs better, lasts longer and when you take it apart it is evident why. Smooth housing surfaces with very little wear.

Note I have managed to break all types of apex seals with crap pump gas and detonation as well.

With 3mm seals (OEM or aftermarket) my experience is that its about 50/50 whether the cornerseals, apex seals or housings crack first. I don't see the benefit of a "stronger" aftermarket 3mm seal.

My experience with 2mm seals (OEM and aftermarket) is that they are indeed the weakest link with detonation. More broken apex seals from detonation, but less detonation induced engine damage overall (engine doesn't run long while detonating).

Note that the apex seal is worn where it is in continuous contact with the rotor housing.

It appears that the chrome has flaked off the rotor housing adjacent to the exhaust port. The seal is riding on the sheet metal insert in that area of wear on the apex seal.

----------------------

Side rant-

Also, the apex seal material is not compatible with the chrome rotor housing material.

Note the chatter marks on the entire rotor housing surface. The chatter will greatly increase wear on the rotor housing, apex seal, rotor slot as well as greatly increased change of "spitback" (Mazda's term) induced preignition/misfire as the apex seal crosses the rotor housing minor axis.

I ran RA Classic seals and RA SuperSeals in 2mm and 3mm (among other aftermarket seals) with similar results.

With OEM 2mm or 3mm seals the engine runs better, lasts longer and when you take it apart it is evident why. Smooth housing surfaces with very little wear.

Note I have managed to break all types of apex seals with crap pump gas and detonation as well.

With 3mm seals (OEM or aftermarket) my experience is that its about 50/50 whether the cornerseals, apex seals or housings crack first. I don't see the benefit of a "stronger" aftermarket 3mm seal.

My experience with 2mm seals (OEM and aftermarket) is that they are indeed the weakest link with detonation. More broken apex seals from detonation, but less detonation induced engine damage overall (engine doesn't run long while detonating).

My only fear with OEM seals is the reputation of breaking and taking out housing, turbo, rotor...if not for that I'd definitely get some.

I've never even thought about going 3mm. I'm planning to always stick with 2mm.

It was probably around May or June 2012. I put the engine together in July. I got them from you lol. I sent the seals to Edgar and he said he was surprised the engine lasted more than 1000 or 2000 miles the way the seals were worn lol. He gave me a discount on another set.

)

)