Ceramic coated turbine housing + heat blanket=decreased longevity?

#52

Thread Starter

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

My turbo is both oil and water cooled, so I'm not concerned about any oil coking issues.

#53

This is a great thread GoodFella. Im glad someone decided to ask the question. My buddys and I were just talking about this the other night. So I should be okay with just the ceramic coating?

If you guys need ceramic coating done I would recommend getting a hold of GoodfellaFD3s (Rich) or Gotham. I had my dp, hot side and manifold done and it looks great.

Pics of the coating in my build up thread.

https://www.rx7club.com/single-turbo-rx-7s-23/gotham-racing-gt42r-buildup-650-hp-720511/

If you guys need ceramic coating done I would recommend getting a hold of GoodfellaFD3s (Rich) or Gotham. I had my dp, hot side and manifold done and it looks great.

Pics of the coating in my build up thread.

https://www.rx7club.com/single-turbo-rx-7s-23/gotham-racing-gt42r-buildup-650-hp-720511/

#54

Thread Starter

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

Thanks for the props man

I'd recommend running the heat blanket too, the ceramic coating helps but the heat blanket made a big difference on top of it.

I'd recommend running the heat blanket too, the ceramic coating helps but the heat blanket made a big difference on top of it.

#57

The price varies ofcouse depending on your setup. I will tell you that the Turbine housing cover cost around $300 if it is one he already has a mold for. Mine is a .96 Tangential. A friend of mine did the complete exhaust as well, and he said he spooled up about 400 rpm sooner. I will not have a comparison on my car because everything is new. Check out the pics of my downpipe/wastegate/manifold covers.

Last edited by gilesr6; 03-09-08 at 12:10 PM.

#58

Just finished reading the thread. I have always thought that heat wrap help keep under hood temps down as well as keep internal temps stable.

As far as ceramic coating flaking I thought this was not an issue until I read other threads. Reading this was great because it has put my thought of making sure that a good ceramic coating with a heat wrap will help our cars.

As far as what people do with race apps. this is OK if you are planning to do a tear down after each race or every few months. We as enthuses do not plan on tearing down the car as much. We are looking for longevity.

With that said a good ceramic coating with a heat blanket we should have no worries if we run proper cool down.

As far as ceramic coating flaking I thought this was not an issue until I read other threads. Reading this was great because it has put my thought of making sure that a good ceramic coating with a heat wrap will help our cars.

As far as what people do with race apps. this is OK if you are planning to do a tear down after each race or every few months. We as enthuses do not plan on tearing down the car as much. We are looking for longevity.

With that said a good ceramic coating with a heat blanket we should have no worries if we run proper cool down.

#59

kevin, if you want your stuff properly ceramic coated (3600 degrees), let me know.

To update, I ended up installing the blanket recently on coated turbine housing. Under hood temps definitely went down, the jury is still out on potential after-effects. Based on the massive reduction in under hood temps, I think it was a good decision.

To update, I ended up installing the blanket recently on coated turbine housing. Under hood temps definitely went down, the jury is still out on potential after-effects. Based on the massive reduction in under hood temps, I think it was a good decision.

Also thanks for your info on the apex fuel pump. I am sourcing one right know at a decent price. Trying to stay under $400. for it.

#62

^ Scott, we were just talking about this last night!

I think that the turbo cooling issues would be more of a problem on oil cooled turbos with insufficient cool-down. Don't drop the hammer and then shut the car off 10 seconds after you slow down, as obvious as that may sound.

If you look at all the OEM designs across multiple manufacturers, you will notice a few common things:

1) OEM turbo setups usually last far longer than almost any aftermarket setup we all may be running. Figure a minimum 80-100k miles trouble-free on most cars, whether it's a larger diesel turbo or a smaller 4 cylinder gas engine type of deal. Even though people drive these stock applications easier than we may drive our modified cars, the typical driver doesn't know or care about cooling down their turbo. The fact that these turbos survive so long indicates to me that clearly the OEM's are doing something right.

2) Factory turbo systems are designed to keep heat in to a point at least. This is absolutely vital on an emissions-controlled production car because the catalytic converter(s) needs to warm up as quickly as possible. Many of them use thick cast iron manifolds, in part because cast iron retains heat very well. Even though these exhaust systems hold in a ton of heat the turbos still last a very long time relative to the 20-30k most people seem to get out of an aftermarket turbo (depending on the setup).

3) just about all of the OEM setups have heatshields around the turbine housing and the exhaust manifolds. Besides being there for looks, this is to keep underhood temps down and protect wires etc. These shields are hardly as thick as a turbo blanket, but they do trap in heat.

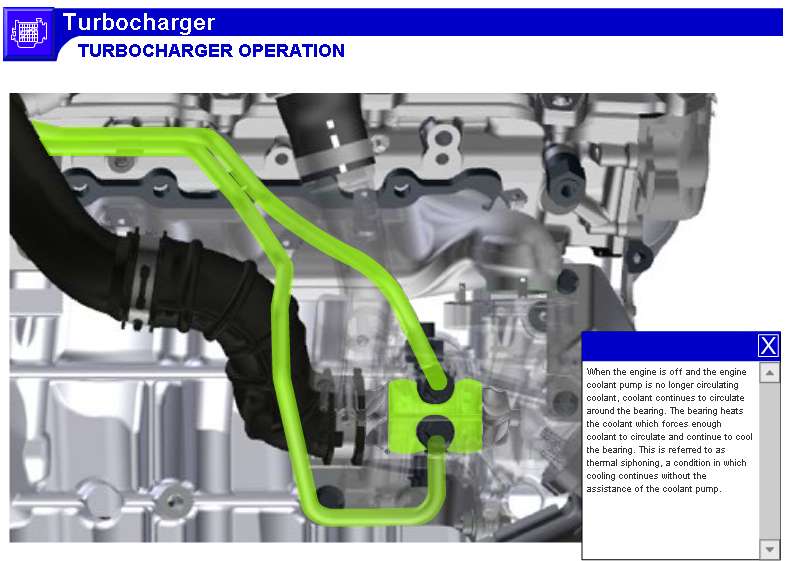

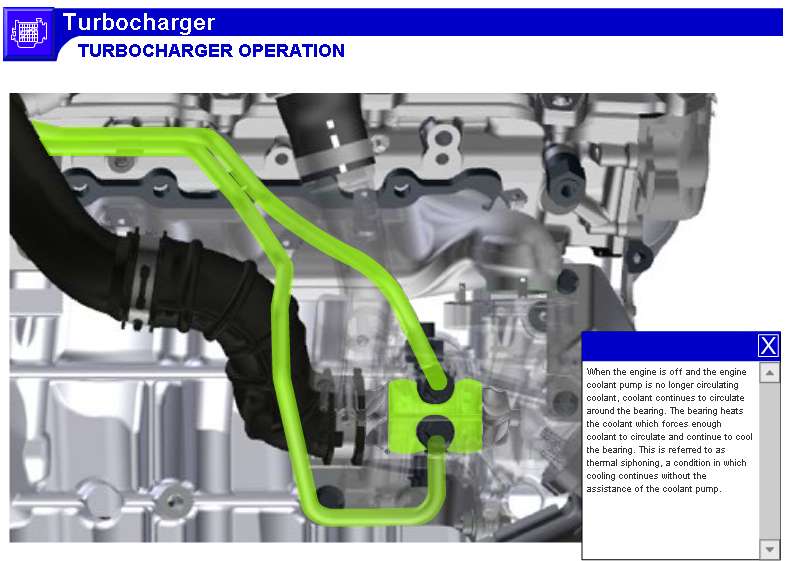

3) passenger vehicles use water cooled turbos from the factory. When the engine shuts off, heat exchange continues between the bearings and the coolant. As the coolant increases in temperature from the heat exchange, its expansion forces circulation to continue. The cool-down process is thus continued after shutdown.

Ford explains this very well in their discussion of the twin-turbo Taurus SHO ("Ecoboost" engine"):

Remember that there are multiple heat transfer processes at work here:

-- forced convection between the oil and the bearings

-- forced convection between the coolant and the bearings (on water cooled turbos)

-- conduction between the bearings and the rest of the turbo CHRA that it is physically connected to

-- radiation of heat from the bearings into the atmosphere

Even if the heat is not able to radiate as well due to various insulators (turbo blanket etc), the forced convection of the oil and coolant still plays a big role. And the cooler your oil and water temps tend to be, the better those fluids will cool your turbo (based on the overall concepts of Newton's Law of Cooling). So the long answer, like so many things in engineering is... it depends.

The short answer is, since less heat can radiate away from the turbo and bearings you need better heat exchange through fluids. Water cooling helps a lot, and but if you're a brokeass like me with an oil-cooled turbo (like me) you do have to be more careful about cooling down. But if you think about it, rarely do people do some hard boosting and then shut the car off without at least driving it easy while pulling into a neighborhood or a parking lot. So maybe it's not that big of a deal.

I think that the turbo cooling issues would be more of a problem on oil cooled turbos with insufficient cool-down. Don't drop the hammer and then shut the car off 10 seconds after you slow down, as obvious as that may sound.

If you look at all the OEM designs across multiple manufacturers, you will notice a few common things:

1) OEM turbo setups usually last far longer than almost any aftermarket setup we all may be running. Figure a minimum 80-100k miles trouble-free on most cars, whether it's a larger diesel turbo or a smaller 4 cylinder gas engine type of deal. Even though people drive these stock applications easier than we may drive our modified cars, the typical driver doesn't know or care about cooling down their turbo. The fact that these turbos survive so long indicates to me that clearly the OEM's are doing something right.

2) Factory turbo systems are designed to keep heat in to a point at least. This is absolutely vital on an emissions-controlled production car because the catalytic converter(s) needs to warm up as quickly as possible. Many of them use thick cast iron manifolds, in part because cast iron retains heat very well. Even though these exhaust systems hold in a ton of heat the turbos still last a very long time relative to the 20-30k most people seem to get out of an aftermarket turbo (depending on the setup).

3) just about all of the OEM setups have heatshields around the turbine housing and the exhaust manifolds. Besides being there for looks, this is to keep underhood temps down and protect wires etc. These shields are hardly as thick as a turbo blanket, but they do trap in heat.

3) passenger vehicles use water cooled turbos from the factory. When the engine shuts off, heat exchange continues between the bearings and the coolant. As the coolant increases in temperature from the heat exchange, its expansion forces circulation to continue. The cool-down process is thus continued after shutdown.

Ford explains this very well in their discussion of the twin-turbo Taurus SHO ("Ecoboost" engine"):

Remember that there are multiple heat transfer processes at work here:

-- forced convection between the oil and the bearings

-- forced convection between the coolant and the bearings (on water cooled turbos)

-- conduction between the bearings and the rest of the turbo CHRA that it is physically connected to

-- radiation of heat from the bearings into the atmosphere

Even if the heat is not able to radiate as well due to various insulators (turbo blanket etc), the forced convection of the oil and coolant still plays a big role. And the cooler your oil and water temps tend to be, the better those fluids will cool your turbo (based on the overall concepts of Newton's Law of Cooling). So the long answer, like so many things in engineering is... it depends.

The short answer is, since less heat can radiate away from the turbo and bearings you need better heat exchange through fluids. Water cooling helps a lot, and but if you're a brokeass like me with an oil-cooled turbo (like me) you do have to be more careful about cooling down. But if you think about it, rarely do people do some hard boosting and then shut the car off without at least driving it easy while pulling into a neighborhood or a parking lot. So maybe it's not that big of a deal.

#63

Thread Starter

Joined: Mar 2001

Posts: 30,580

Likes: 567

From: FL-->NJ/NYC again!

The coating that I had on from A Spec (which is vastly inferior to the coating my guy uses btw [sorry sean]) crumbled to nothingness under the heat blanket.

Due to the retarded complexity involved in R&Ring the turbine housings from the CHRA (I'd rather chop off both testes than do it again) I opted to leave it as-is, although I did send my long runner manifold and 4 inch downpipe back off to be stripped of the old coating and recoated with the good stuff

Due to the retarded complexity involved in R&Ring the turbine housings from the CHRA (I'd rather chop off both testes than do it again) I opted to leave it as-is, although I did send my long runner manifold and 4 inch downpipe back off to be stripped of the old coating and recoated with the good stuff

Thread

Thread Starter

Forum

Replies

Last Post

tiger18

3rd Generation Specific (1993-2002)

9

09-03-15 08:27 PM