boost creep or something else?

#1

im running a t61 with a 46mm tial gate. using the big yellow 10 psi spring.

under 3rd or 4th itll hold 10 psi till around 6k rpms where it will jump to 20 psi by 7200 rpms.

im running a greddy profec b 2. i tried with it off, and disconnected the hose from the valve and samething. im using the turbo compressor as source for wastegate to the side of it.

can 46mm be to small or do i have another problem? im running vacuum hoses and barbed fittings. there is a "t" plastic adapter from turbo compressor to ebc valve then to wastegate.

any help please?!

under 3rd or 4th itll hold 10 psi till around 6k rpms where it will jump to 20 psi by 7200 rpms.

im running a greddy profec b 2. i tried with it off, and disconnected the hose from the valve and samething. im using the turbo compressor as source for wastegate to the side of it.

can 46mm be to small or do i have another problem? im running vacuum hoses and barbed fittings. there is a "t" plastic adapter from turbo compressor to ebc valve then to wastegate.

any help please?!

#5

hks fd style manifold?

http://i187.photobucket.com/albums/x...0setup/172.jpg

http://i187.photobucket.com/albums/x...0setup/174.jpg

3" dp too

http://i187.photobucket.com/albums/x...0setup/172.jpg

http://i187.photobucket.com/albums/x...0setup/174.jpg

3" dp too

Trending Topics

#11

ok found something interesting.

found a few older logs on my 60-1 setup running with ebc on set for 15 psi

http://i187.photobucket.com/albums/x...628_100841.jpg

now this is my t61 rebuilt turbo same manifold and wastegaet setup with spring. running off of 10 psi spring

http://i187.photobucket.com/albums/x...920_174619.jpg

http://i187.photobucket.com/albums/x...920_174627.jpg

http://i187.photobucket.com/albums/x...920_174654.jpg

found a few older logs on my 60-1 setup running with ebc on set for 15 psi

http://i187.photobucket.com/albums/x...628_100841.jpg

now this is my t61 rebuilt turbo same manifold and wastegaet setup with spring. running off of 10 psi spring

http://i187.photobucket.com/albums/x...920_174619.jpg

http://i187.photobucket.com/albums/x...920_174627.jpg

http://i187.photobucket.com/albums/x...920_174654.jpg

#13

Joined: Dec 2001

Posts: 7,093

Likes: 122

From: Twin Cities, MN

The highest RPM your old setup goes to the boost pressure is the same as your new setup. Looks just like creep to me. Generally it only happens on well built engines, with big ports and big exhaust. We have a 2nd gen in the shop that doesn't creep one bit with an improperly built turbo manifold. The engine isn't that strong, even with BIG ports so its not a problem...

Why not just set the boost controller to 20psi and call it a day? You have the water injection...

Why not just set the boost controller to 20psi and call it a day? You have the water injection...

#15

ya well i wanted to run it at 20 psi but if i set the ebc to 20 psi wouldnt it just creep more to maybe 27 this time for example?

mine is just a moderate street port, nothing huge.

ive been thinking about switching the pressure source to maybe the intake manifold and see if that makes a difference which i doubt :/

mine is just a moderate street port, nothing huge.

ive been thinking about switching the pressure source to maybe the intake manifold and see if that makes a difference which i doubt :/

#17

Joined: Dec 2001

Posts: 7,093

Likes: 122

From: Twin Cities, MN

If you move to to the intake boost will usually go up 1.5 to 2psi.

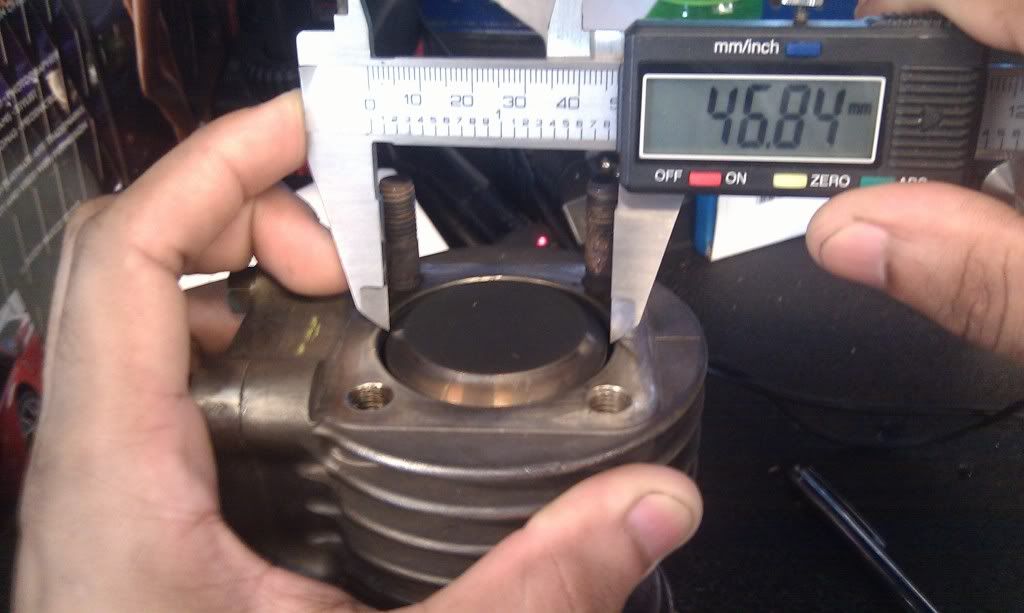

The inside diameter of the pipe looks to be the right size. That waste gate really necks down, I know the Tial 44's inlet size is near 40mm. You can either go up in wastegate size, or change the wastegate location on the turbo manifold.

The inside diameter of the pipe looks to be the right size. That waste gate really necks down, I know the Tial 44's inlet size is near 40mm. You can either go up in wastegate size, or change the wastegate location on the turbo manifold.

#18

ok, so far it isnt

a. ebc (was by passed completely and still "crreps")

b. pressure source hose, new 9/32" hose installed straight and same thing

c. doubt its the spring, new 10 psi yellow installed last yr

d. dont think its manifold, several people have used same manifold, bigger turbo n smaller gate and no creep, or not as bad as mine.

e. diaphragm? i was told by a tial support tech a leaking one wouldnt hold boost at all and just creep.

f. dp is only 3" so i dont think its too big

i appericate everyones help and putting in there 2cents, i really wanna figure this out.

a. ebc (was by passed completely and still "crreps")

b. pressure source hose, new 9/32" hose installed straight and same thing

c. doubt its the spring, new 10 psi yellow installed last yr

d. dont think its manifold, several people have used same manifold, bigger turbo n smaller gate and no creep, or not as bad as mine.

e. diaphragm? i was told by a tial support tech a leaking one wouldnt hold boost at all and just creep.

f. dp is only 3" so i dont think its too big

i appericate everyones help and putting in there 2cents, i really wanna figure this out.

Last edited by AlexG13B; 09-30-10 at 07:47 PM. Reason: mis spelled word

#19

i agree with turblown 10 psi is bypassing too much for the wastegate to handle. i ran a t67 at 15psi on a 44mm wg and never creeped. make sure ur wg boost hose is big enough and as short as possible.

#21

The easiest solution would be to use a stiffer spring on the gate. Try something at least 1 bar. Basically pick a spring pressure where the wastegate can flow enough so that boost will not creep in cold weather with no controller. A stiffer spring requires less wastegate flow.

If you have a creep problem with no boost controller, then the boost control will tend to be less predictable if you try the "just run higher boost with the same spring" route.

Here's my experience with the problem you are having. On my old motor I had an FC HKS log manifold, similar in runner design to the cheap ebay FC manifolds. I was using a brand new HKS 40mm gate with 10psi spring, no boost controller initially. In ambient temps above 55-60F it would never creep. This was with a street ported motor and 3" straight pipe to a 3" Racing Beat dual catback. When it got cold out it would creep to about 13psi.

When I rebuilt the motor I switched to a divided stainless manifold with Tial 44mm gate and 13psi spring. I've never had boost creep since then.

If you have a creep problem with no boost controller, then the boost control will tend to be less predictable if you try the "just run higher boost with the same spring" route.

Here's my experience with the problem you are having. On my old motor I had an FC HKS log manifold, similar in runner design to the cheap ebay FC manifolds. I was using a brand new HKS 40mm gate with 10psi spring, no boost controller initially. In ambient temps above 55-60F it would never creep. This was with a street ported motor and 3" straight pipe to a 3" Racing Beat dual catback. When it got cold out it would creep to about 13psi.

When I rebuilt the motor I switched to a divided stainless manifold with Tial 44mm gate and 13psi spring. I've never had boost creep since then.

#22

makes sense, ur the 3rd person who has told me to try a stiffer spring. guess i should order a small red spring to make it 13 psi.

The easiest solution would be to use a stiffer spring on the gate. Try something at least 1 bar. Basically pick a spring pressure where the wastegate can flow enough so that boost will not creep in cold weather with no controller. A stiffer spring requires less wastegate flow.

If you have a creep problem with no boost controller, then the boost control will tend to be less predictable if you try the "just run higher boost with the same spring" route.

Here's my experience with the problem you are having. On my old motor I had an FC HKS log manifold, similar in runner design to the cheap ebay FC manifolds. I was using a brand new HKS 40mm gate with 10psi spring, no boost controller initially. In ambient temps above 55-60F it would never creep. This was with a street ported motor and 3" straight pipe to a 3" Racing Beat dual catback. When it got cold out it would creep to about 13psi.

When I rebuilt the motor I switched to a divided stainless manifold with Tial 44mm gate and 13psi spring. I've never had boost creep since then.

If you have a creep problem with no boost controller, then the boost control will tend to be less predictable if you try the "just run higher boost with the same spring" route.

Here's my experience with the problem you are having. On my old motor I had an FC HKS log manifold, similar in runner design to the cheap ebay FC manifolds. I was using a brand new HKS 40mm gate with 10psi spring, no boost controller initially. In ambient temps above 55-60F it would never creep. This was with a street ported motor and 3" straight pipe to a 3" Racing Beat dual catback. When it got cold out it would creep to about 13psi.

When I rebuilt the motor I switched to a divided stainless manifold with Tial 44mm gate and 13psi spring. I've never had boost creep since then.

#23

update:

tried with ebc hooked up and set greddy profec b 2 to 115 set gain. 3rd gear hit 15 psi around 4300 rpms, held it till around 6300 rpms. then went up to 20 psi again by 6700.

tried with ebc hooked up and set greddy profec b 2 to 115 set gain. 3rd gear hit 15 psi around 4300 rpms, held it till around 6300 rpms. then went up to 20 psi again by 6700.