4" Complete Exhaust System Build

#28

interesting how more and more are trying the 4" route. i will be going 4 inch as well but will be welding mine up myself as i wanted certain stipulations for it. as far as sound the only thing people have been doing is a straight through design muffler and a couple extra

resonators...sure that worked for my protege giving it a nice deep tone but with the results others have got from the straight through design i will be going a different route. it will be v-banded 409 stainless with the actual muffler a flowmaster 50HD series 4in dual 3 out. there will

be a couple removable resonator sections as well to play with but we will see after its on the car. i have all the piping muffler and resonators just tring to find time to do it unfortunatlly once completed i will make my own thread with pics and vid/sound. good luck with it get some

video sound clips posted when done.

i like how that second pic is of the welds on the magnaflow muffler factory welds not thiers.....oh well

z

resonators...sure that worked for my protege giving it a nice deep tone but with the results others have got from the straight through design i will be going a different route. it will be v-banded 409 stainless with the actual muffler a flowmaster 50HD series 4in dual 3 out. there will

be a couple removable resonator sections as well to play with but we will see after its on the car. i have all the piping muffler and resonators just tring to find time to do it unfortunatlly once completed i will make my own thread with pics and vid/sound. good luck with it get some

video sound clips posted when done.

i like how that second pic is of the welds on the magnaflow muffler factory welds not thiers.....oh well

z

#33

This 9" thick intercooler core that I'm running has been mocked and scorned for the past 8 years since I've owned the car. I will tell you this, each of the core's tube and fin are in graduating sizes. This thing runs cooler than any ebay special out there. Yes it runs well. The jig would be something I would do when I'm finished. I would offer it not to get rich, but to help the rx7 community. I'm not on this forum as a vendor because I have no intrest in selling parts. I'm simply here to share my experiences and spare others from wasting there time and money. If anyone can benifit from my errors, then that enough payment.

I knew it was going to be one of those strange deep cores. I forget who did the testing but they concluded that any core longer than 18" doesn't yield much more heat exchange. They also found that cores thicker than 3.5" was the same story. I'm not sure if they figured any figures with multiple cores but I'm sure that will make a difference.

Also, in reference to the "jig" to be made. Every turbo kit is going to need to have a different downpipe route. Unless you're going to market these for the factory twins I see easy fitment issues.

Also, in reference to the "jig" to be made. Every turbo kit is going to need to have a different downpipe route. Unless you're going to market these for the factory twins I see easy fitment issues.

#35

Thank for the support. The heat shield is something that I made for sheet aluminum the attached wit DEI Reflect-A-Cool matting. I ended up going crazy with this stuff. I did the entire trasmission tunnel and firewall because I did not want to shake and bake.

#36

My turbo setup uses a 1.15 back housing, so 4.0" is what the engineer calculated will give the best result. I've run the 3.0" system before and I'm ready to step up to the next level. I will have tons of photos to share with everyone. Boost is not the end all. My current tubo flows more volume of air at lower boost than my previous T66 BB P-Trim Turbonetics Turbo with the .85 AR on the exhaust housing did at higher boost. My goal is to move as much volume of air as possible and not be hell bent of big boost numbers.

Last edited by JEROME; 07-29-08 at 12:15 AM.

#38

Thank you to all for the reading my post. On Saterday 08/09/08 @10 am the build of 1 mean 4" exhaust system will start. Please stand by. I will start with a layout of all the raw materials.

#39

Hey Jerome, it would be a good Idea if you made this downpipe back, so that way anybody can purchase it and just make their own custom downpipe to mate with it. Basically it will start at the midpipe back...

#45

#46

lol.. i was thinking about buying a cheap set to do it to.. i use spray tint that hobby town usa has, i use it all the time on different cars, here is how it looks on my bmw, should look good on that to. you can make the tint almost pitch black if you spary enough coats and still not loose much lighting, probably nothing with leds.

#47

Wow! I thought I was the only one who owns a bmw m3 and a fd3s. That looks like a great idea. I need to inform the board that TRUST exhaust systems are not 100% 85mm like they claim. I have proof and will upload it all for the world to see. Yes, they make a nice exhaust system, but it is choaking the turbo more than I ever thought. No more deception, the truth shall set my turbo FREE.

#49

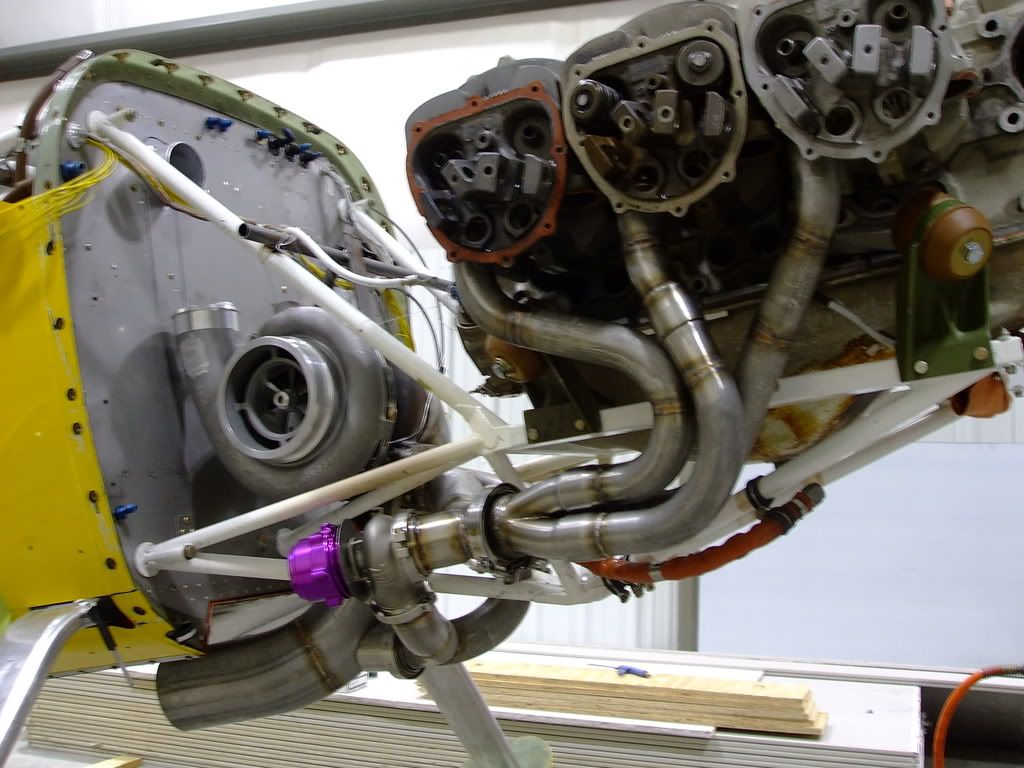

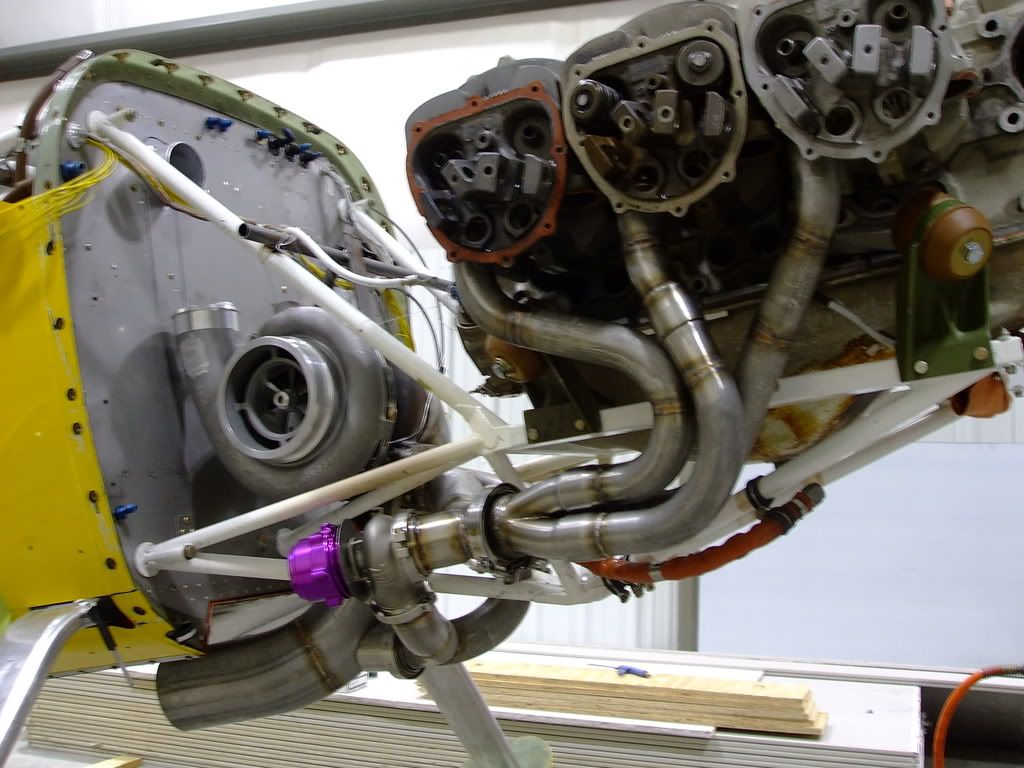

And now for the moment that we all been waiting for. The engineer stated with the downpipe tonight. The weld are the best I've ever seen on four wheels. Only thing that comes close is my friends racing plane. See for yourself.

#50

Downpipe Complete.

The wait is over. The downpipe looks so darn nice that it's a shame that I have to install it on the car, it should be hanging on my living room wall. The fitment is over the top. This thing has great welds and no cheating of any radius.

The wait is over. The downpipe looks so darn nice that it's a shame that I have to install it on the car, it should be hanging on my living room wall. The fitment is over the top. This thing has great welds and no cheating of any radius.

Last edited by JEROME; 08-13-08 at 02:16 AM.