Rtek Anyone tuning on the stock load-based timing?

#1

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Now that I've solved the mysterious stuttering issue w/a fuel pump rewire, its time to start getting to business. I'm running the stock turbo until I can get a hybrid built so I figure its not worth converting to map-based timing yet. I'll still have to redo it when I go hybrid, plus the stock turbo runs well enough on the stock maps up to 10psi and I only plan to run 12max.

So my question is: has anyone messed w/the stock system, have any advice? How exactly does it work? I have removed fuel (5%) from below the secondary trans point to compensate for slightly larger primaries (580cc). I wonder about the upper rpm range though, if I remove fuel at say 5k does that mean it injects the same amt of fuel in vac as it would@ 10psi?

It seems like I just need to remove some fuel after the secondaries come online as it runs rich to the point if being sluggish. I'll know more once I get the wideband in I'm a day or two.

So my question is: has anyone messed w/the stock system, have any advice? How exactly does it work? I have removed fuel (5%) from below the secondary trans point to compensate for slightly larger primaries (580cc). I wonder about the upper rpm range though, if I remove fuel at say 5k does that mean it injects the same amt of fuel in vac as it would@ 10psi?

It seems like I just need to remove some fuel after the secondaries come online as it runs rich to the point if being sluggish. I'll know more once I get the wideband in I'm a day or two.

#2

um. like bro, you need to adjust below the 0 Psi threashold on 3d map mode, or table mode.

sounds like you are using the bar graph and it's confusing the ***** outta you.

Also you are getting two things confused.

Fuel trim tunning( getting your AFRs, lambda, what have you, rich enough to not toast your motor/engine.

Ignition timing tuning.(this one is load based factory and can be swapped to boost based( don't do it you're not ready!!)

When your title says tuning, and timing, you(or whoever) are talking ignition...

but what YOU are talking about.. is just AFR's.

sounds like you are using the bar graph and it's confusing the ***** outta you.

Also you are getting two things confused.

Fuel trim tunning( getting your AFRs, lambda, what have you, rich enough to not toast your motor/engine.

Ignition timing tuning.(this one is load based factory and can be swapped to boost based( don't do it you're not ready!!)

When your title says tuning, and timing, you(or whoever) are talking ignition...

but what YOU are talking about.. is just AFR's.

#3

Fueling is based on MAP(manifold air pressure)/RPM, Load based timing is based on TPS(throttle position sensor)/RPM, Boost Based Timing uses MAP/RPM.

I found that I had better low end power after I set up the MAP based timing, which wasn't that hard using the maps that Arghx posted, just takes like 1-2 hrs poking at the palm with the car in the run position, but engine not running. (I unplugged a bunch of fuses/stuff to ease the current draw on the batt.)

I run data logs with a Wideband o2 sensor and a bunch of engine perameters (psi, boost index, tps, temps, sec staging, etc.) and trim/add fuel accordingly. I wouldn't try to tune w/o a wideband 02 sensor.

The maps for Fuel have X and Y axis. psi/map which is your boost/vacuum and rpm which are the specific rpms. Say, if your at 10psi and 5000 rpm, adjusting the correction in that cell will adjust the fueling at that specific point... and will not affect the 0psi/5000rpm fueling.

I would suggest reading the instructions thoroughly, if you haven't done so already...

S4 rtek 2.1 (s5 similar), http://www.pocketlogger.com/instruct...cketlogger.pdf

Good luck!

I found that I had better low end power after I set up the MAP based timing, which wasn't that hard using the maps that Arghx posted, just takes like 1-2 hrs poking at the palm with the car in the run position, but engine not running. (I unplugged a bunch of fuses/stuff to ease the current draw on the batt.)

I run data logs with a Wideband o2 sensor and a bunch of engine perameters (psi, boost index, tps, temps, sec staging, etc.) and trim/add fuel accordingly. I wouldn't try to tune w/o a wideband 02 sensor.

The maps for Fuel have X and Y axis. psi/map which is your boost/vacuum and rpm which are the specific rpms. Say, if your at 10psi and 5000 rpm, adjusting the correction in that cell will adjust the fueling at that specific point... and will not affect the 0psi/5000rpm fueling.

I would suggest reading the instructions thoroughly, if you haven't done so already...

S4 rtek 2.1 (s5 similar), http://www.pocketlogger.com/instruct...cketlogger.pdf

Good luck!

#4

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Also you are getting two things confused.

Fuel trim tunning( getting your AFRs, lambda, what have you, rich enough to not toast your motor/engine.

Ignition timing tuning.(this one is load based factory and can be swapped to boost based( don't do it you're not ready!!)

When your title says tuning, and timing, you(or whoever) are talking ignition...

but what YOU are talking about.. is just AFR's.

Fuel trim tunning( getting your AFRs, lambda, what have you, rich enough to not toast your motor/engine.

Ignition timing tuning.(this one is load based factory and can be swapped to boost based( don't do it you're not ready!!)

When your title says tuning, and timing, you(or whoever) are talking ignition...

but what YOU are talking about.. is just AFR's.

I never intended to touch the timing as its still a stock turbo and doing so would have more potential for detriment than benefit. However, as you pointed out, using the bar graph view got me confused as to how one would adjust for various load levels at the same rpm.

#5

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Fueling is based on MAP(manifold air pressure)/RPM, Load based timing is based on TPS(throttle position sensor)/RPM, Boost Based Timing uses MAP/RPM.

I found that I had better low end power after I set up the MAP based timing, which wasn't that hard using the maps that Arghx posted, just takes like 1-2 hrs poking at the palm with the car in the run position, but engine not running. (I unplugged a bunch of fuses/stuff to ease the current draw on the batt.)

I found that I had better low end power after I set up the MAP based timing, which wasn't that hard using the maps that Arghx posted, just takes like 1-2 hrs poking at the palm with the car in the run position, but engine not running. (I unplugged a bunch of fuses/stuff to ease the current draw on the batt.)

When u say you noticed an improvement in low end switching to map based timing, did you try tuning w/ load based timing at all? Our is the improvement over the untuned stock maps? Also, how is fuel economy w/your setup?

[quote]I run data logs with a Wideband o2 sensor and a bunch of engine perameters (psi, boost index, tps, temps, sec staging, etc.) and trim/add fuel accordingly. I wouldn't try to tune w/o a wideband 02 sensor.[/ quote]

I hear ya, I'm just trying to compensate for the difference in what my injectors flow (580/710) and what the ecu expects (550/720)....as well as the increased flow from the fuel pump re wire. But the WB is coming soon, I'll probably hook it up in the stock location until I can get my bung welded on.

The maps for Fuel have X and Y axis. psi/map which is your boost/vacuum and rpm which are the specific rpms. Say, if your at 10psi and 5000 rpm, adjusting the correction in that cell will adjust the fueling at that specific point... and will not affect the 0psi/5000rpm fueling.

I would suggest reading the instructions thoroughly, if you haven't done so already...

S4 rtek 2.1 (s5 similar), http://www.pocketlogger.com/instruct...cketlogger.pdf

Good luck!

I would suggest reading the instructions thoroughly, if you haven't done so already...

S4 rtek 2.1 (s5 similar), http://www.pocketlogger.com/instruct...cketlogger.pdf

Good luck!

I'll keep you posted....

#6

False. While a fuel pump in general will put out more flow and PSI from 10v vs 13.5v. The fuel pressure reguator keeps the pressure to the injectors at the same level whether the pump is putting out high flow(13.5v) or medium flow(10v).

As i understand it, the reason mazda made the fuel pump run at 10v during cruise was because it put less load on the system as a whole, the regulator has to return less fuel to keep the pressure in check when you don't need the extra flow, and it lowers the voltage consumtion of the pump itself, thereby requiring less amps from the alternator. but don't quote me on that. maybe aghrx has some papers about the reason behind all of this.

As i understand it, the reason mazda made the fuel pump run at 10v during cruise was because it put less load on the system as a whole, the regulator has to return less fuel to keep the pressure in check when you don't need the extra flow, and it lowers the voltage consumtion of the pump itself, thereby requiring less amps from the alternator. but don't quote me on that. maybe aghrx has some papers about the reason behind all of this.

#7

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

False. While a fuel pump in general will put out more flow and PSI from 10v vs 13.5v. The fuel pressure reguator keeps the pressure to the injectors at the same level whether the pump is putting out high flow(13.5v) or medium flow(10v).

As i understand it, the reason mazda made the fuel pump run at 10v during cruise was because it put less load on the system as a whole, the regulator has to return less fuel to keep the pressure in check when you don't need the extra flow, and it lowers the voltage consumtion of the pump itself, thereby requiring less amps from the alternator. but don't quote me on that. maybe aghrx has some papers about the reason behind all of this.

As i understand it, the reason mazda made the fuel pump run at 10v during cruise was because it put less load on the system as a whole, the regulator has to return less fuel to keep the pressure in check when you don't need the extra flow, and it lowers the voltage consumtion of the pump itself, thereby requiring less amps from the alternator. but don't quote me on that. maybe aghrx has some papers about the reason behind all of this.

After re wiring the the pump that problem has stopped, however now I seem to have a rich spot when the secondaries come on which causes the motor to bog. I will post some logs once I get the wb in.

Trending Topics

#9

No, I didn't try load based timing at all, because I really didn't want my timing to be based on the TPS, and because all the info I read dealt with PSI vs timing.

After inputting the map it seemed to have more power down low, not as sluggish as stock. Fuel economy. Eh. Not very good. 13mpg around town with a heavy foot and 680/1000cc injectors 8.5:1 compression.

Go boost based, if you have the time to put in the maps...

After inputting the map it seemed to have more power down low, not as sluggish as stock. Fuel economy. Eh. Not very good. 13mpg around town with a heavy foot and 680/1000cc injectors 8.5:1 compression.

Go boost based, if you have the time to put in the maps...

#10

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

The last 2 months have given me a lot of hands hands on experience. When the pump wad getting 7v ther NB would be rich as I started to go into boost, then peg lean then go blank, it would buck, stutter, and vibrate....highly unpleasant. The plugs were all light brown w/very little black.

Now it boosts solid, the NB stays pegged rich until the secondaries come on then it goes blank. There is no vibration, acceleration just starts falling off and boost ceases to build.

Why is it so hard to believe that an un tuned car running higher than stock fuel issue w/upgrade injectors might be running rich?

After inputting the map it seemed to have more power down low, not as sluggish as stock. Fuel economy. Eh. Not very good. 13mpg around town with a heavy foot and 680/1000cc injectors 8.5:1 compression.

Go boost based, if you have the time to put in the maps...

Go boost based, if you have the time to put in the maps...

I don't doubt that map is better, I just want to see what can be done w/the stock system on a stock turbo, because it doesn't seem like the little bit I would gain in power would be worth the drop off in fuel economy....for now

#11

Same car, same turbo, same engine. New map vs stock map. Map based timing shouldn't affect your MPG too much, I think it might even go up. For me, the timing is more for safety. too much boost on stock load based timing w/o adding fuel or retarding timing = detonation.

Run some logs. What is your timing(L & T)at max boost at around 4500-5500rpm?

Here you can see my log of load based timing, it just keeps climbing even as boost kept climbing.

https://www.rx7club.com/showpost.php...6&postcount=10

Here you can see log of map based timing, stays pretty flat, consistant with boost.

https://www.rx7club.com/showpost.php...&postcount=148

About your fuel maps, your probably right.

Here's mine around the transition at 8 & 10 psi

https://www.rx7club.com/showpost.php...&postcount=158

Good luck!

Run some logs. What is your timing(L & T)at max boost at around 4500-5500rpm?

Here you can see my log of load based timing, it just keeps climbing even as boost kept climbing.

https://www.rx7club.com/showpost.php...6&postcount=10

Here you can see log of map based timing, stays pretty flat, consistant with boost.

https://www.rx7club.com/showpost.php...&postcount=148

About your fuel maps, your probably right.

Here's mine around the transition at 8 & 10 psi

https://www.rx7club.com/showpost.php...&postcount=158

Good luck!

#12

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Same car, same turbo, same engine. New map vs stock map. Map based timing shouldn't affect your MPG too much, I think it might even go up. For me, the timing is more for safety. too much boost on stock load based timing w/o adding fuel or retarding timing = detonation.

Run some logs. What is your timing(L & T)at max boost at around 4500-5500rpm?

Here you can see my log of load based timing, it just keeps climbing even as boost kept climbing.

https://www.rx7club.com/showpost.php...6&postcount=10

Here you can see log of map based timing, stays pretty flat, consistant with boost.

https://www.rx7club.com/showpost.php...&postcount=148

About your fuel maps, your probably right.

Here's mine around the transition at 8 & 10 psi

https://www.rx7club.com/showpost.php...&postcount=158

Good luck!

https://www.rx7club.com/showpost.php...6&postcount=10

Here you can see log of map based timing, stays pretty flat, consistant with boost.

https://www.rx7club.com/showpost.php...&postcount=148

About your fuel maps, your probably right.

Here's mine around the transition at 8 & 10 psi

https://www.rx7club.com/showpost.php...&postcount=158

Good luck!

#13

A correction: the load-based maps are determined primarily by rpm and airflow, not rpm and TPS.

RPM and TPS calibration is called Alpha-Numeric, and that's only used on race cars. The R26B four rotor on the 787B Lemans car used RPM and TPS only.

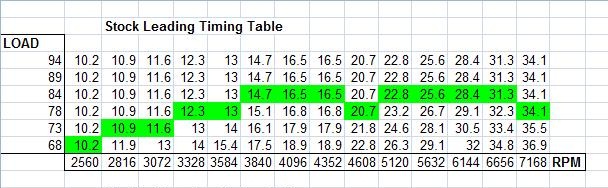

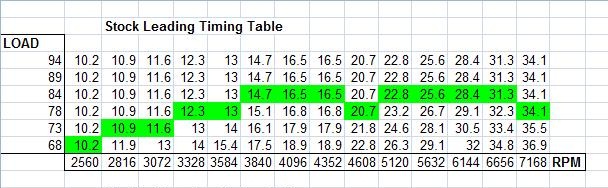

On a system that uses an airflow meter (or MAF sensor), the load is some function of engine airflow divided by rpm. Timing advance increases with rpm but decreases with load. Basically, the more air being crammed into the intake stroke, the later you fire the plugs. The faster the engine is spinning, the earlier you fire the plugs. Somebody posted this chart of the factory timing maps:

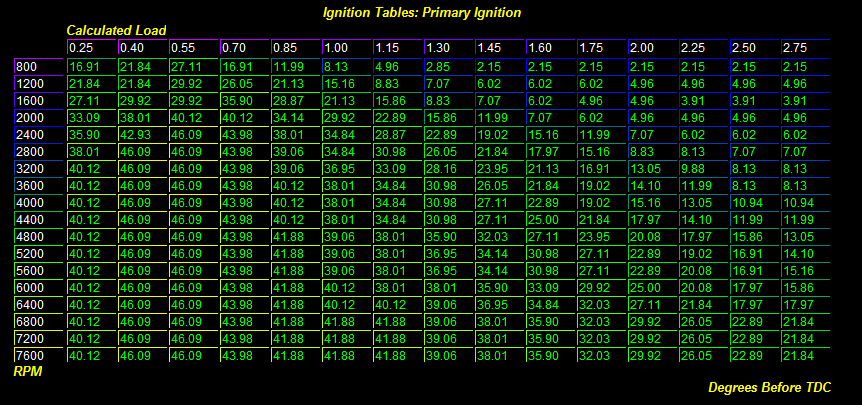

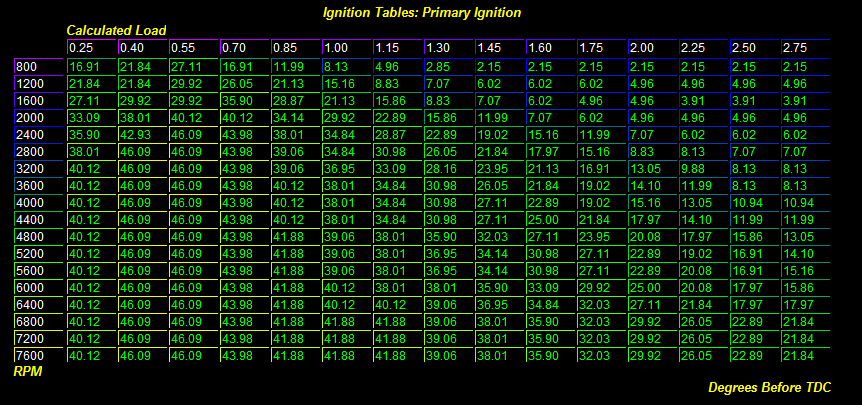

From what I'm seeing here, the stock maps need less timing at higher load ranges. See how the top three rows have the same numbers? Now, check out the stock ignition map (before knock learning is applied) for a 2005 STi:

Y axis is rpm. X axis is load in grams of airflow per engine revolution. The basic load calculation is easy to figure out on a Subaru. It's MAF sensor airflow, in grams/sec * 60 divided by engine rpm. So grams/sec becomes grams/rev . Now compare the trend across each axis in the Subaru map versus the Mazda map. As load increases, the STi runs less and less timing. On the T2 map above the engine stops retarding timing at a certain point.

RPM and TPS calibration is called Alpha-Numeric, and that's only used on race cars. The R26B four rotor on the 787B Lemans car used RPM and TPS only.

On a system that uses an airflow meter (or MAF sensor), the load is some function of engine airflow divided by rpm. Timing advance increases with rpm but decreases with load. Basically, the more air being crammed into the intake stroke, the later you fire the plugs. The faster the engine is spinning, the earlier you fire the plugs. Somebody posted this chart of the factory timing maps:

From what I'm seeing here, the stock maps need less timing at higher load ranges. See how the top three rows have the same numbers? Now, check out the stock ignition map (before knock learning is applied) for a 2005 STi:

Y axis is rpm. X axis is load in grams of airflow per engine revolution. The basic load calculation is easy to figure out on a Subaru. It's MAF sensor airflow, in grams/sec * 60 divided by engine rpm. So grams/sec becomes grams/rev . Now compare the trend across each axis in the Subaru map versus the Mazda map. As load increases, the STi runs less and less timing. On the T2 map above the engine stops retarding timing at a certain point.

#14

There are two main reasons why Rx-7 tuners usually use MAP-based timing:

1) long standing conventions. The FD doesn't have an airflow meter and none of the other engine management systems use one. So all the information out there is based around conventional wisdom used on other systems

2) limitations of the FC airflow meters. When you max out these AFM's you're pretty much out of luck. On hot wire (Evo X, STi, Rx-8), hot film (GM LSx engines), or Karmann type (DSM/3000GT/Evo up to IX) there are work arounds to expland the measurement capability of the sensor. You can use a completely different sensor, a different pipe design, and/or recalibrate the existing sensor. You can't do that on these FC AFM's.

I can tell you from personal experience though that airflow-based tuning is in many ways actually easier to tune than boost-based. A main reason for this is because higher flowing turbos will draw in more air and you will be able to see that by the airflow reading and the load calculation. On a boost-based system, you could have two different turbos running at 15psi but one is flowing much more air. IMO it takes more experience and more guesswork to optimally tune boost-based timing. Having said that, I acknowledge that I am comparing apples-to-oranges. Tuning load-based timing on an STi is not the same as doing so on a T2 because there is no way to recalibrate the airflow meter on the T2.

Here are some charts you guys might find interesting. These are from a log of me tuning a 2005 STi with a Blouch 18G-XT turbo. Cobb refuses to develop a real log viewer so I am stuck using Excel charts. X axis is time in seconds on all charts.

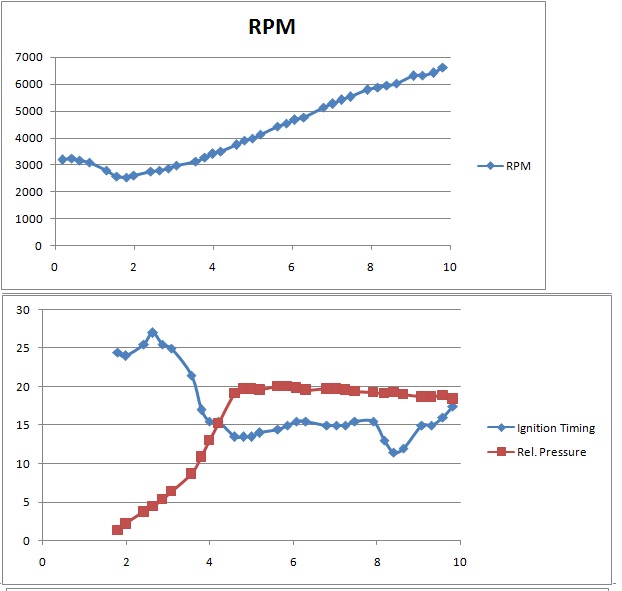

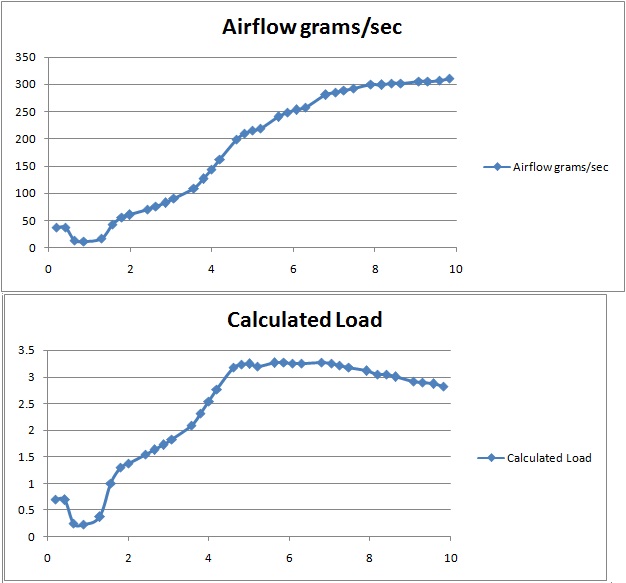

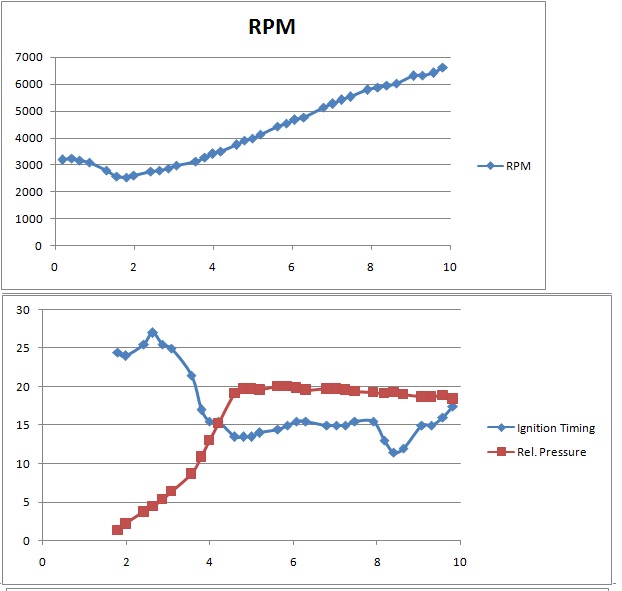

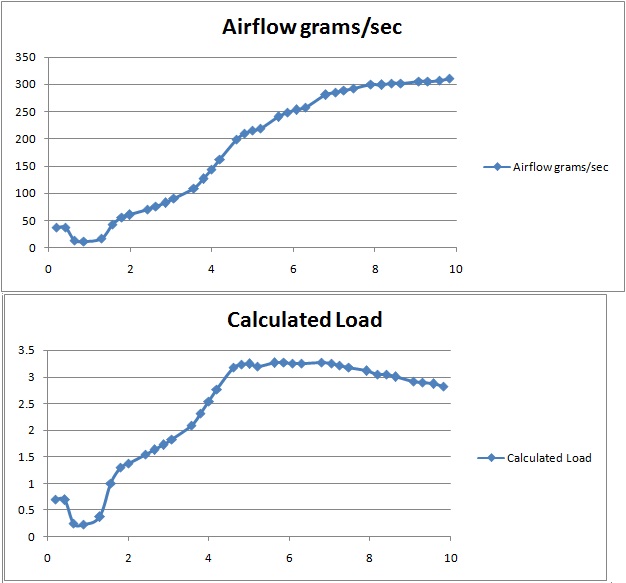

So here we have RPM, boost (STi has a MAP sensor used for the OEM electronic boost control), and logged ignition timing. You can see that as the rpm increases, the timing increases--until the boost kicks in and peaks at 20psi. The timing "bottoms out" just as the engine hits full boost. Then it slowly ramps up a little bit, flattens, then dips some as the knock sensor picks up some noise. Finally it continues to increase until redline. I made significant changes to this STi timing map compared to what I would run on a stock turbo. On a stock turbo timing would increase at a much steeper rate after reaching peak load if this were a stock turbo. Now on this same pull here is a log showing MAF airflow in grams/sec and calculated load in grams/rev:

Now look at these graphs carefully. Notice that

1) boost tapers off slightly. Boost has a natural tendency to taper off if the wastegate is flowing enough.

2) airflow continues to rise all the way to red line

3) load falls. How could engine load, in grams of airflow per revolution, go down when airflow is going up? It's very simple calculus. Remember that on just about every airflow-based system, load is proportional to airflow / rpm .

-- IF the rpms are increasing faster than the airflow is increasing, calculated load will decrease

-- IF the airflow is increasing faster than the rpms are increasing, calculated load will increase

Just to review: from the factory the T2 calculates timing based on rpm and airflow just like every almost other engine management system using an AFM/MAF sensor. The more air crammed into the intake stroke, the higher the load will be and the less timing you will want to run. MAP based timing isn't automatically better than load-based timing. On an FC though there are so many constraints with the AFM that I would only consider using load-based timing on a stock turbo, and only if you know what you're doing.

End of snooze-inducing lecture.

1) long standing conventions. The FD doesn't have an airflow meter and none of the other engine management systems use one. So all the information out there is based around conventional wisdom used on other systems

2) limitations of the FC airflow meters. When you max out these AFM's you're pretty much out of luck. On hot wire (Evo X, STi, Rx-8), hot film (GM LSx engines), or Karmann type (DSM/3000GT/Evo up to IX) there are work arounds to expland the measurement capability of the sensor. You can use a completely different sensor, a different pipe design, and/or recalibrate the existing sensor. You can't do that on these FC AFM's.

I can tell you from personal experience though that airflow-based tuning is in many ways actually easier to tune than boost-based. A main reason for this is because higher flowing turbos will draw in more air and you will be able to see that by the airflow reading and the load calculation. On a boost-based system, you could have two different turbos running at 15psi but one is flowing much more air. IMO it takes more experience and more guesswork to optimally tune boost-based timing. Having said that, I acknowledge that I am comparing apples-to-oranges. Tuning load-based timing on an STi is not the same as doing so on a T2 because there is no way to recalibrate the airflow meter on the T2.

Here are some charts you guys might find interesting. These are from a log of me tuning a 2005 STi with a Blouch 18G-XT turbo. Cobb refuses to develop a real log viewer so I am stuck using Excel charts. X axis is time in seconds on all charts.

So here we have RPM, boost (STi has a MAP sensor used for the OEM electronic boost control), and logged ignition timing. You can see that as the rpm increases, the timing increases--until the boost kicks in and peaks at 20psi. The timing "bottoms out" just as the engine hits full boost. Then it slowly ramps up a little bit, flattens, then dips some as the knock sensor picks up some noise. Finally it continues to increase until redline. I made significant changes to this STi timing map compared to what I would run on a stock turbo. On a stock turbo timing would increase at a much steeper rate after reaching peak load if this were a stock turbo. Now on this same pull here is a log showing MAF airflow in grams/sec and calculated load in grams/rev:

Now look at these graphs carefully. Notice that

1) boost tapers off slightly. Boost has a natural tendency to taper off if the wastegate is flowing enough.

2) airflow continues to rise all the way to red line

3) load falls. How could engine load, in grams of airflow per revolution, go down when airflow is going up? It's very simple calculus. Remember that on just about every airflow-based system, load is proportional to airflow / rpm .

-- IF the rpms are increasing faster than the airflow is increasing, calculated load will decrease

-- IF the airflow is increasing faster than the rpms are increasing, calculated load will increase

Just to review: from the factory the T2 calculates timing based on rpm and airflow just like every almost other engine management system using an AFM/MAF sensor. The more air crammed into the intake stroke, the higher the load will be and the less timing you will want to run. MAP based timing isn't automatically better than load-based timing. On an FC though there are so many constraints with the AFM that I would only consider using load-based timing on a stock turbo, and only if you know what you're doing.

End of snooze-inducing lecture.

#15

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Wow! Thanks, That's a lot to take in...

So it seems my situation meet one of those requirements (stock turbo...lol). At stock boost levels the stock timing doesn't seem to be much of a problem (although I have seen you call it "aggressive" previously). Once that level is exceeded however I'm guessing things get a bit more sketchy.

From my understanding, the main drawbacks off boost-based timing are:

The inability to account for different sized turbos moving different volumes of air@ the same psi (a non-issue unless you are swapping often)

And

The inability to compensate for variations in load/airflow in the upper rpm range when load might actually be decreasing but boost could remain constant, I'm guessing boost creep could aggravate this further?

The first part doesn't really concern me, but the second could become an issue (although doubtful on the stock turbo). I'll have to take some logs to find out what ther timing is up to.

It seems the bigger issue is this shitty afm, what good is load based timing if the"load" figures aren't accurate and what good is either if you don't have enough fuel? Fortunately that is not a problem w/which I must contend atm. It would bee nice though if we had a solution by the time I get my hybrid.

So it seems my situation meet one of those requirements (stock turbo...lol). At stock boost levels the stock timing doesn't seem to be much of a problem (although I have seen you call it "aggressive" previously). Once that level is exceeded however I'm guessing things get a bit more sketchy.

From my understanding, the main drawbacks off boost-based timing are:

The inability to account for different sized turbos moving different volumes of air@ the same psi (a non-issue unless you are swapping often)

And

The inability to compensate for variations in load/airflow in the upper rpm range when load might actually be decreasing but boost could remain constant, I'm guessing boost creep could aggravate this further?

The first part doesn't really concern me, but the second could become an issue (although doubtful on the stock turbo). I'll have to take some logs to find out what ther timing is up to.

It seems the bigger issue is this shitty afm, what good is load based timing if the"load" figures aren't accurate and what good is either if you don't have enough fuel? Fortunately that is not a problem w/which I must contend atm. It would bee nice though if we had a solution by the time I get my hybrid.

#16

From my understanding, the main drawbacks off boost-based timing are:

The inability to account for different sized turbos moving different volumes of air@ the same psi (a non-issue unless you are swapping often)

The inability to account for different sized turbos moving different volumes of air@ the same psi (a non-issue unless you are swapping often)

The inability to compensate for variations in load/airflow in the upper rpm range when load might actually be decreasing but boost could remain constant, I'm guessing boost creep could aggravate this further?

It seems the bigger issue is this shitty afm, what good is load based timing if the"load" figures aren't accurate and what good is either if you don't have enough fuel?

#18

I'd like to see what load cells that's falling into and some overall logs. With the 87 octane you would definitely want to pull some timing from the stock maps in the higher load range, especially from about 3500-5500.

it appears that the charts from my other post about tuning an STi have disappeared.

it appears that the charts from my other post about tuning an STi have disappeared.

#21

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

That's my next task. I've been driving around making observations for a day, cruising is prefect 14-15 afr, idle is a bit low 12.8 -13.x Unfortunately it is still leaning out under boost....sometimes. I have added 5% fuel above 0psi @ all rpm.

I can roll into boost in 4th and it will go nicely up to 5-8psi w/ 12.X afr, however if I get on it hard in 2nd gear it will boost to about 3psi w/ afr of 14.X then they shoot up to ther 20's.

I can roll into boost in 4th and it will go nicely up to 5-8psi w/ 12.X afr, however if I get on it hard in 2nd gear it will boost to about 3psi w/ afr of 14.X then they shoot up to ther 20's.

#22

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Ok, so apparently something is wrong w/ the wideband interface w/the rtek. I have gone in and set up the var resistor input as follows :

0v = 7.35

5v = 22.39

The gauge reads fine, but the palm logs values of 3.61 when the afr is 13.X

In other news, I bumped the fuel pressure up to 35psi @idle, it had fine nothing, if anything it seems like its running leaner. I've got a walbro I might throw in cuz at this point I've run out of ideas.

0v = 7.35

5v = 22.39

The gauge reads fine, but the palm logs values of 3.61 when the afr is 13.X

In other news, I bumped the fuel pressure up to 35psi @idle, it had fine nothing, if anything it seems like its running leaner. I've got a walbro I might throw in cuz at this point I've run out of ideas.

#24

Thread Starter

Rotary Revolutionary

iTrader: (16)

Joined: May 2006

Posts: 3,881

Likes: 2

From: Jacksonville, Tampa & Tallahassee

Is that the way its supposed to work? Or did u just apply some deductive reasoning to the specific example I provided?

I'll try it, but it seems kind of silly that we have a linear 0-5v output, a 0-5v input, a scale for voltage reference and we would still need to offset the parameter to get an accurate reading. Maybe there's something I'm missing....

I'll try it, but it seems kind of silly that we have a linear 0-5v output, a 0-5v input, a scale for voltage reference and we would still need to offset the parameter to get an accurate reading. Maybe there's something I'm missing....

#25

In the wideband setup, the entries that you put in values for the 0 and 5 V readings mearly calculates the multiplier and offset. Those are the parameters that matter. What multiplier and offset are you using? And what is the output of the WB?