Why Apex Seals Fail

#51

Wow, that comment hit home really hard. Currently looking into the new AEM Series 2 EMS and upgrading everything that will be going with it (Coils, Mitsubishi Knock Sensor, EMS speed based controlled boost, 30-2 crank sensor setup, integrated AI control, etc.). After looking at the control features on the new and old AEM software makes me regret using a PFC for so long. The AEM with it's overboost, knock feedback and closed loop features would have saved my last three motors.

I was reading about that new AEM it seems pretty lagit.

I was reading about that new AEM it seems pretty lagit.

#53

#55

#57

Obviously a good ignition setup and build is a must, but I think the key ingredients is a good tune and lots of fuel. Alot of guys skimp on the fuel setup. You need to run huge fuel lines and a very good fuel pump(s). There's no big secret in tuning. Just like anything else out there, some people are better than others and you have to know what you're doing or you'll blow an engine. My .02

#59

Is there a such thing as a temperature sensing ring or piece of hardware that can be a part of a spark plug? Something like a CHT we could adapt to our motors to see the temps at the head of the spark plug?

Also, I like the idea of doing the lateral grinding grooves on the water jackets of the old rotor housings. Notice, however, that the Renesis rotor housings' water jackets at and around the spark plug bosses are cast differently!

B

Also, I like the idea of doing the lateral grinding grooves on the water jackets of the old rotor housings. Notice, however, that the Renesis rotor housings' water jackets at and around the spark plug bosses are cast differently!

B

#60

Its more important to have a bigger ignition then fuel system.

With the ignition system their is no point having huge amounts of fuel.

MOST important thing over ALL THING is keeping KNOCK to a minimum. At the end of the day this is what bends/breaks apex seals.

With the ignition system their is no point having huge amounts of fuel.

MOST important thing over ALL THING is keeping KNOCK to a minimum. At the end of the day this is what bends/breaks apex seals.

#61

I disagree. Too weak of an ignition system will make the motor run like ****, but will not damage a seal. But a fuel system that is too small will snap em like toothpicks. The MSD 6 series boxes are more than enough for most applications out there.

#62

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,201

Likes: 2,825

From: https://www2.mazda.com/en/100th/

seems like cruising, you WANT 80-85c temps, its only under load where in jim mederers words you need the temperature delta.

#64

Who has had apex seals warp? All of the teardown inspections that I have been in on were on Mazda seals and none of them were warped. They would lie flat on a surface plate!

Are we speaking of soft seals that warp?

Are we speaking of soft seals that warp?

#65

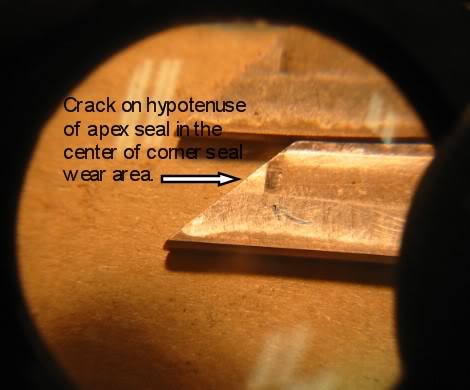

Look closely about 1-2 mm from the apex face there is a wear stress-riser where it should break if pressure was the culprit.

#67

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,201

Likes: 2,825

From: https://www2.mazda.com/en/100th/

Actually this is what this thread is all about. My contention is that it is not pressure at all. If it were the break would be higher on the tip.

Look closely about 1-2 mm from the apex face there is a wear stress-riser where it should break if pressure was the culprit.

Look closely about 1-2 mm from the apex face there is a wear stress-riser where it should break if pressure was the culprit.

#69

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,201

Likes: 2,825

From: https://www2.mazda.com/en/100th/

#70

#71

I'm sorry I do have that one, RE by KenichiYamamoto-1981

I reread it and it and couldn't find anything about pressure buildup on pages 44-45, only temp increases with knocking.

More specifically" In the rotary engine, on the contrary, no damage will be caused because there is no local temperature rise."

Did you have another where section on pressure that you were thinking of?

Barry

#73

My thought would be that preignition lifting of the apex seal would relate to very short engine/seal life.

The problem we are dealing with is lifting of the apex seals as shown in the photo below.

As you can see the carbon stains are similar, located in the same spot, and seem to have been building there for a long period.

The seal tip failed from "high cycle fatigue" (30,000 miles would be about 25 million cycles).

Barry

#74

I had done an mock up similar to your feeler-gauge/apex seal rocking setups barry. Got playing around one night.....

I realize it may be a work around not addressing the heat issue itself, but the though had crossed my mind. What if you were to taper or even radius the ends of the apex seals where they meet the side housings? Whether a one piece or two piece design, it would allow some compliance when the apex seal rocks across the spark plug area. The corner seals should still be doing most of the sealing against the iron, and the sealing surface in the center of the corner seal to the apex seal will still be intact.

I've gone through the gammot of "typical" mods to the housings. REMedey water pump (fc engine ) ribbed housings, current engine has one "common" ribbed housing, one with clipped dowl lands, and horizontal ribs. Tear down will show how effective each was, but so far, nothing has made a dent in the gigantic amount of heat present in that area. Or I suppose more accurately, that you can make headway in removing the heat from the housing, but until the heat is brought down to a level of manageability on par with the rest of the surface area of the engine, the problem will still exist.

) ribbed housings, current engine has one "common" ribbed housing, one with clipped dowl lands, and horizontal ribs. Tear down will show how effective each was, but so far, nothing has made a dent in the gigantic amount of heat present in that area. Or I suppose more accurately, that you can make headway in removing the heat from the housing, but until the heat is brought down to a level of manageability on par with the rest of the surface area of the engine, the problem will still exist.

The only mod I've yet to accomplish and still feel really good about the possibilitys of is adding entirely new "webs" around the boss area to allow the heat more places to sink to.

I realize it may be a work around not addressing the heat issue itself, but the though had crossed my mind. What if you were to taper or even radius the ends of the apex seals where they meet the side housings? Whether a one piece or two piece design, it would allow some compliance when the apex seal rocks across the spark plug area. The corner seals should still be doing most of the sealing against the iron, and the sealing surface in the center of the corner seal to the apex seal will still be intact.

I've gone through the gammot of "typical" mods to the housings. REMedey water pump (fc engine

) ribbed housings, current engine has one "common" ribbed housing, one with clipped dowl lands, and horizontal ribs. Tear down will show how effective each was, but so far, nothing has made a dent in the gigantic amount of heat present in that area. Or I suppose more accurately, that you can make headway in removing the heat from the housing, but until the heat is brought down to a level of manageability on par with the rest of the surface area of the engine, the problem will still exist.

) ribbed housings, current engine has one "common" ribbed housing, one with clipped dowl lands, and horizontal ribs. Tear down will show how effective each was, but so far, nothing has made a dent in the gigantic amount of heat present in that area. Or I suppose more accurately, that you can make headway in removing the heat from the housing, but until the heat is brought down to a level of manageability on par with the rest of the surface area of the engine, the problem will still exist.The only mod I've yet to accomplish and still feel really good about the possibilitys of is adding entirely new "webs" around the boss area to allow the heat more places to sink to.

#75

j9fd3s,

My thought would be that preignition lifting of the apex seal would relate to very short engine/seal life.

The problem we are dealing with is lifting of the apex seals as shown in the photo below.

As you can see the carbon stains are similar, located in the same spot, and seem to have been building there for a long period.

The seal tip failed from "high cycle fatigue" (30,000 miles would be about 25 million cycles).

Barry

My thought would be that preignition lifting of the apex seal would relate to very short engine/seal life.

The problem we are dealing with is lifting of the apex seals as shown in the photo below.

As you can see the carbon stains are similar, located in the same spot, and seem to have been building there for a long period.

The seal tip failed from "high cycle fatigue" (30,000 miles would be about 25 million cycles).

Barry

Whatcha think, Barry?

B

The world will be ours shortly.......

The world will be ours shortly.......