Porting for torque

#1

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Porting for torque

I'm rebuilding the engine on my S5 T2 autocross car and I'm flip flopping on what to do about porting...

for autocross you want as much torque low down as possible to pull you out of corners (down shifting to first isn't really an option).

The more I read about porting the more I come to the conclusion that any porting I do will reduce my low rpm torque.... So I'm slowing coming to the conclusion that I should just clean up the casting marks on the stock ports and call it a day.

I've seen this thread:

https://www.rx7club.com/single-turbo...d-dyno-956766/

and BlueTII posted some good stuff in my build thread:

https://www.rx7club.com/build-thread.../#post11541080

any opinions/experience would be appreciated.

for autocross you want as much torque low down as possible to pull you out of corners (down shifting to first isn't really an option).

The more I read about porting the more I come to the conclusion that any porting I do will reduce my low rpm torque.... So I'm slowing coming to the conclusion that I should just clean up the casting marks on the stock ports and call it a day.

I've seen this thread:

https://www.rx7club.com/single-turbo...d-dyno-956766/

and BlueTII posted some good stuff in my build thread:

https://www.rx7club.com/build-thread.../#post11541080

any opinions/experience would be appreciated.

#2

Put a 3.90 diff in and call it a day. My first gear tops out around 47 mph which is plenty for autocrosses here. Plus that puts me at max power from the engine compared to whatever lower amount in second gear.

#3

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

STIs on street tires hit their 2nd gear rev limiter (~55 mph) every autocross.

I already have 4.3 gears which helps a bit. When I finally put some aero and some decent condition tires on the car its going to get a lot faster...

#5

I've bounced off hte rev limiter in second gear .

and in my miata i've hit rev limiter in 3rd .

yeah I agree with him

Also You may want to concider a quick spooling turbo for the torque .

and more importantly .. Improve on the driver so you always maintain yourself in the powerband . keep yourself in the high rpms at all time . and you will improve as a driver trust your car .

and in my miata i've hit rev limiter in 3rd .

yeah I agree with him

Also You may want to concider a quick spooling turbo for the torque .

and more importantly .. Improve on the driver so you always maintain yourself in the powerband . keep yourself in the high rpms at all time . and you will improve as a driver trust your car .

Last edited by Tem120; 08-08-13 at 01:29 PM.

#6

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

I've bounced off hte rev limiter in second gear .

and in my miata i've hit rev limiter in 3rd .

yeah I agree with him

Also You may want to concider a quick spooling turbo for the torque .

and more importantly .. Improve on the driver so you always maintain yourself in the powerband . keep yourself in the high rpms at all time . and you will improve as a driver trust your car .

and in my miata i've hit rev limiter in 3rd .

yeah I agree with him

Also You may want to concider a quick spooling turbo for the torque .

and more importantly .. Improve on the driver so you always maintain yourself in the powerband . keep yourself in the high rpms at all time . and you will improve as a driver trust your car .

Trending Topics

#9

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

and BlueTII posted some good stuff in my build thread:

https://www.rx7club.com/build-thread.../#post11541080

any opinions/experience would be appreciated.

https://www.rx7club.com/build-thread.../#post11541080

any opinions/experience would be appreciated.

Blue Tii has been playing with his setup for maybe a decade and he's tried all the options. for torque, you want to leave the intake closing timings stock. the exhaust opening needs to stay stock, opening earlier = less power stroke.

opening the intake earlier, does help torque, this is basically what Mazda did with the Rx8. closing the exhaust later doesn't seem to do much, except add overlap, which is undesirable.

#10

i'd have to agree with J9FD3S. my advice would be leave the intake closing stock, but get it open earlier. I would also leave the runners alone. for the exhaust, to be honest, I would maybe get it open a few degrees earlier, but leave the closing end virtually untouched.

I can't help but invoke the persona of Jeff20B in noting that the T2 secondaries come stock with the old "big port" specs (circa 1974-76). when used in context, this tidbit appears to be quite significant that Mazda would come back to it for their turbocharged cars.

__________________

aside: have I made you proud, Jeff?

I can't help but invoke the persona of Jeff20B in noting that the T2 secondaries come stock with the old "big port" specs (circa 1974-76). when used in context, this tidbit appears to be quite significant that Mazda would come back to it for their turbocharged cars.

__________________

aside: have I made you proud, Jeff?

#11

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Mazda kind of built the car to have maximum low RPM torque already, but

Blue Tii has been playing with his setup for maybe a decade and he's tried all the options. for torque, you want to leave the intake closing timings stock. the exhaust opening needs to stay stock, opening earlier = less power stroke.

opening the intake earlier, does help torque, this is basically what Mazda did with the Rx8. closing the exhaust later doesn't seem to do much, except add overlap, which is undesirable.

Blue Tii has been playing with his setup for maybe a decade and he's tried all the options. for torque, you want to leave the intake closing timings stock. the exhaust opening needs to stay stock, opening earlier = less power stroke.

opening the intake earlier, does help torque, this is basically what Mazda did with the Rx8. closing the exhaust later doesn't seem to do much, except add overlap, which is undesirable.

I thought they did it on the RX-8 because they got rid of the overlap due to the side exhaust ports.

#13

so opening the intake earlier adds torque (on a turbo engine) even though in increases overlap?

I have not seen any studies on turbo rotaries, but with few exceptions if you take an NA motor with more torque and add a turbo, you will have more torque.

The dyno power, VE, BSFC, etc graphs I have seen for port timing comparisons are from the development of the rotary engine where the various manufacturers were trying to set their port layout (note no emissions concerns in this late 60s era).

NSU, Suzuki, Sachs, Citroen, Mercedes, etc, etc chose peripheral port intakes and exhausts.

Mazda chose side port intake and peripheral exhaust ports for their smoothness/driveability despite the loss of power. A few years later it proved a boon as emissions regulations were enacted.

Well, the first Mazda production motor (early production Cosmo Sports) featured side ports and auxiliary peripheral intake ports, but there was little power gain over just side ports with what Mazda deemed a smooth, driveable, quiet exhaust- so they gave up on that.

Early opening intake

Peripheral intake ports with the same port closing (and of course much earlier opening) make more power everywhere on the dyno charts than the side ports in these studies.

I will try to remember to take pictures of the graphs for you.

I have not seen any studies on turbo rotaries, but with few exceptions if you take an NA motor with more torque and add a turbo, you will have more torque.

The dyno power, VE, BSFC, etc graphs I have seen for port timing comparisons are from the development of the rotary engine where the various manufacturers were trying to set their port layout (note no emissions concerns in this late 60s era).

NSU, Suzuki, Sachs, Citroen, Mercedes, etc, etc chose peripheral port intakes and exhausts.

Mazda chose side port intake and peripheral exhaust ports for their smoothness/driveability despite the loss of power. A few years later it proved a boon as emissions regulations were enacted.

Well, the first Mazda production motor (early production Cosmo Sports) featured side ports and auxiliary peripheral intake ports, but there was little power gain over just side ports with what Mazda deemed a smooth, driveable, quiet exhaust- so they gave up on that.

Early opening intake

Peripheral intake ports with the same port closing (and of course much earlier opening) make more power everywhere on the dyno charts than the side ports in these studies.

I will try to remember to take pictures of the graphs for you.

#14

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

So you just ported up to "scissor" the port a bit?

You guys think using the pineapple templates opening side boundary then just bringing the stock ports closing boundary over to that would work well?

You guys think using the pineapple templates opening side boundary then just bringing the stock ports closing boundary over to that would work well?

#15

Do everything you can - everything - to increase sealing. Run everything to the tight end of spec. I can tell when an engine is getting tired just from driving it, they get softer at low RPM as they age but the top end still feels good.

#16

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

[QUOTE=peejay;11542372

Do everything you can - everything - to increase sealing. Run everything to the tight end of spec. I can tell when an engine is getting tired just from driving it, they get softer at low RPM as they age but the top end still feels good.[/QUOTE]

true! the NSU SAE paper has a comparison of seal lengths between the rotary and the piston, and the rotaries is longer. the longer the seals, the more places to leak.

when you couple this with the 270 degree (longer) strokes, there is more time for it to leak too

Do everything you can - everything - to increase sealing. Run everything to the tight end of spec. I can tell when an engine is getting tired just from driving it, they get softer at low RPM as they age but the top end still feels good.[/QUOTE]

true! the NSU SAE paper has a comparison of seal lengths between the rotary and the piston, and the rotaries is longer. the longer the seals, the more places to leak.

when you couple this with the 270 degree (longer) strokes, there is more time for it to leak too

#17

So you just ported up to "scissor" the port a bit?

Kind of.

I ported up so I could make the "spigot" bigger. This is the crease where the oil control seal bowl meets the port closing line bowl. This is your area of highest velocity as it is the outside radius and through happy coincidence points the correct direction and is open late into intake/compression stroke.

This is why Rob's primary port template is reverse scissored. He kept the port face volume low and the volume of the runner leading to it low for high velocity while enlarging the spigot area and matching the secondary port closing line. This porting should work very well for low end torque, especially if used with the stock throttle body's double throttle keeping airflow out of the secondary runners during tip in throttle.

Looking just at my port template or line scribed on the side housing in the previous thread you might think I took away "scissor", but I should have included a finished picture.

In fact, I ported from the bowl a straight line to the edge of the line scribed by the port template, but THEN put a slight bevel at the top closing line of the port. More bevel at the outer edge working to no bevel at the inner edge.

I did that because I wanted a low volume small port with good flow, but I am not brave enough to risk my side seals to a reverse scissor primary port.

The first engine I built was after taking apart a Pineapple and talking to Rob. That Pineapple motor did have side seal wear at the tips from striking the un-scissored port top.

You guys think using the pineapple templates opening side boundary then just bringing the stock ports closing boundary over to that would work well?

That doesn't work for the reasons I tried to describe above. You want more spigot than the stock port but somehow you want proper scissor.

Judge Ito has the only templates I have seen with full scissor on both primary and secondary ports, but they are late closing with an enlarged primary port (ported down) for top end power.

My friend just used Racing Beat templates on his FD and we corrected the outer top corner of the ports for full scissor (just a smaller radius curve).

I see now why Rob is so long winded. Every time I type something I go off an a tangent related to porting and I have to backspace to keep it in a digestible lump.

Kind of.

I ported up so I could make the "spigot" bigger. This is the crease where the oil control seal bowl meets the port closing line bowl. This is your area of highest velocity as it is the outside radius and through happy coincidence points the correct direction and is open late into intake/compression stroke.

This is why Rob's primary port template is reverse scissored. He kept the port face volume low and the volume of the runner leading to it low for high velocity while enlarging the spigot area and matching the secondary port closing line. This porting should work very well for low end torque, especially if used with the stock throttle body's double throttle keeping airflow out of the secondary runners during tip in throttle.

Looking just at my port template or line scribed on the side housing in the previous thread you might think I took away "scissor", but I should have included a finished picture.

In fact, I ported from the bowl a straight line to the edge of the line scribed by the port template, but THEN put a slight bevel at the top closing line of the port. More bevel at the outer edge working to no bevel at the inner edge.

I did that because I wanted a low volume small port with good flow, but I am not brave enough to risk my side seals to a reverse scissor primary port.

The first engine I built was after taking apart a Pineapple and talking to Rob. That Pineapple motor did have side seal wear at the tips from striking the un-scissored port top.

You guys think using the pineapple templates opening side boundary then just bringing the stock ports closing boundary over to that would work well?

That doesn't work for the reasons I tried to describe above. You want more spigot than the stock port but somehow you want proper scissor.

Judge Ito has the only templates I have seen with full scissor on both primary and secondary ports, but they are late closing with an enlarged primary port (ported down) for top end power.

My friend just used Racing Beat templates on his FD and we corrected the outer top corner of the ports for full scissor (just a smaller radius curve).

I see now why Rob is so long winded. Every time I type something I go off an a tangent related to porting and I have to backspace to keep it in a digestible lump.

#18

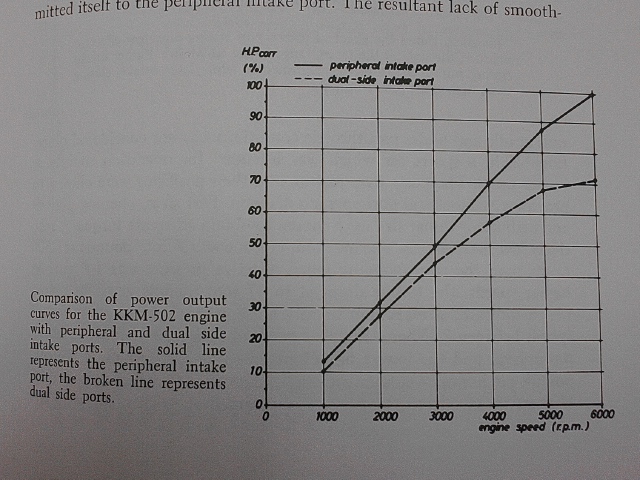

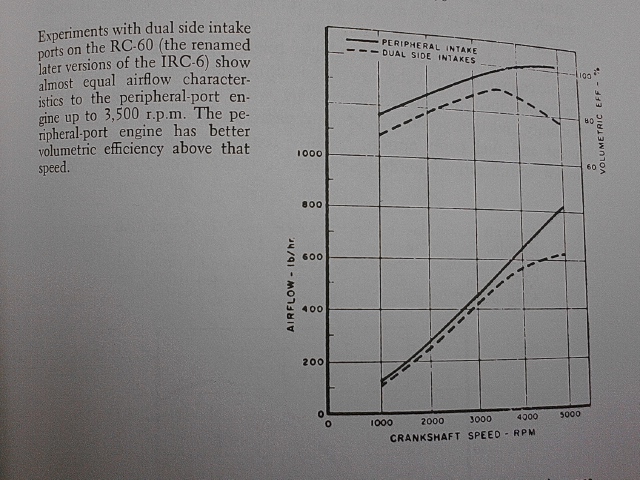

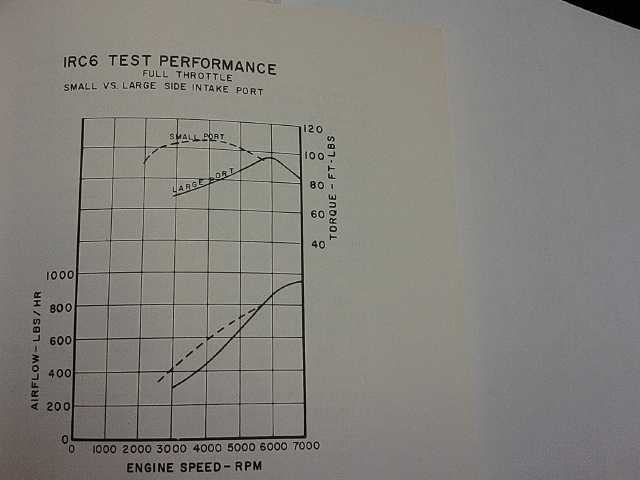

Here are the pictures I promised I would look for from the Norbye book on the development of the rotary.

They show that a higher overlap peripheral port motor does make more low end power than a side port engine.

Here is a chart of the NSU KKM-502, the same engine that powered the production NSU Spider car (though in detuned 64hp trim).

The picture shows one configuration with dual side ports and the higher power one with peripheral port as in the production version.

The second chart of the Curtiss-Wright RC-60 with both dual side intake ports and with a peripheral port shows volumetric efficiency and airflow.

Here is another chart showing large side ports and small side ports power comparison.

They show that a higher overlap peripheral port motor does make more low end power than a side port engine.

Here is a chart of the NSU KKM-502, the same engine that powered the production NSU Spider car (though in detuned 64hp trim).

The picture shows one configuration with dual side ports and the higher power one with peripheral port as in the production version.

The second chart of the Curtiss-Wright RC-60 with both dual side intake ports and with a peripheral port shows volumetric efficiency and airflow.

Here is another chart showing large side ports and small side ports power comparison.

#19

i'm sure that I don't get this. could you expand a bit?

I don't mind.

I see now why Rob is so long winded. Every time I type something I go off an a tangent related to porting and I have to backspace to keep it in a digestible lump.

#20

The first engine I ported. I didn't touch the port opening line, the oil seal line (dur), and all I did was alter the closing window so the opening line's point was about 10mm higher but the corner seal line's was as close to stock as I could get while smoothing the port-chamber interface . Basically an extreme "scissor" port. The bowl was beveled and rounded and smoothed so that there wasn't a sharp edge at the port window, but more of a smooth transition.

The theory was, the point of fastest chamber opening and therefore highest CFM load on the engine was somewhere around 120ABDC (I think, it was so long ago... and Paul Yaw's taken his information down from his website) and therefore I should aim the port's window so that the air had a kind of straight shot to the center of the chamber at that point. The smooth interface was because air will flow right off a sharp edge but follow a curve. (For an object lesson, check out the C5 Corvette's butt. Some say it's ugly but I think it's beautiful. The sides and top are creases but the bottom is a smooth curve, just right for making downforce via pulling air up from underneath but not generating much drag)

It was hampered by poor carburetion and exhaust, to be sure, but one of the things I liked to do with it was chug along at 1000rpm in 5th and whack the throttle open. It pulled very well at any RPM.

The theory was, the point of fastest chamber opening and therefore highest CFM load on the engine was somewhere around 120ABDC (I think, it was so long ago... and Paul Yaw's taken his information down from his website) and therefore I should aim the port's window so that the air had a kind of straight shot to the center of the chamber at that point. The smooth interface was because air will flow right off a sharp edge but follow a curve. (For an object lesson, check out the C5 Corvette's butt. Some say it's ugly but I think it's beautiful. The sides and top are creases but the bottom is a smooth curve, just right for making downforce via pulling air up from underneath but not generating much drag)

It was hampered by poor carburetion and exhaust, to be sure, but one of the things I liked to do with it was chug along at 1000rpm in 5th and whack the throttle open. It pulled very well at any RPM.

#21

I'm reading this from my phone but you are saying you believe leaving the opening edge alone and extending the closing edge as high as possible is the best route to take?r

The first engine I ported. I didn't touch the port opening line, the oil seal line (dur), and all I did was alter the closing window so the opening line's point was about 10mm higher but the corner seal line's was as close to stock as I could get while smoothing the port-chamber interface . Basically an extreme "scissor" port. The bowl was beveled and rounded and smoothed so that there wasn't a sharp edge at the port window, but more of a smooth transition.

The theory was, the point of fastest chamber opening and therefore highest CFM load on the engine was somewhere around 120ABDC (I think, it was so long ago... and Paul Yaw's taken his information down from his website) and therefore I should aim the port's window so that the air had a kind of straight shot to the center of the chamber at that point. The smooth interface was because air will flow right off a sharp edge but follow a curve. (For an object lesson, check out the C5 Corvette's butt. Some say it's ugly but I think it's beautiful. The sides and top are creases but the bottom is a smooth curve, just right for making downforce via pulling air up from underneath but not generating much drag)

It was hampered by poor carburetion and exhaust, to be sure, but one of the things I liked to do with it was chug along at 1000rpm in 5th and whack the throttle open. It pulled very well at any RPM.

The theory was, the point of fastest chamber opening and therefore highest CFM load on the engine was somewhere around 120ABDC (I think, it was so long ago... and Paul Yaw's taken his information down from his website) and therefore I should aim the port's window so that the air had a kind of straight shot to the center of the chamber at that point. The smooth interface was because air will flow right off a sharp edge but follow a curve. (For an object lesson, check out the C5 Corvette's butt. Some say it's ugly but I think it's beautiful. The sides and top are creases but the bottom is a smooth curve, just right for making downforce via pulling air up from underneath but not generating much drag)

It was hampered by poor carburetion and exhaust, to be sure, but one of the things I liked to do with it was chug along at 1000rpm in 5th and whack the throttle open. It pulled very well at any RPM.

#22

As peejay says the downsides of the overlap are low load performance- low load meaning the throttle plates are closed.

The dynamic during overlap in a rotary engine is often misunderstood.

In stock Mazda form where you have a late closing exhaust port and an intake port that opens 32 deg. After Top Dead Center (or 45 deg ATDC on 89-2002 motors) it is true that the expanding intake chamber volume sucks exhaust from the exhaust stroke chamber below through the gap in the rotor and rotor housing before the intake port opens. Once the intake port opens there is first a reversion charge of higher energy exhaust gas entering the intake tract and then the direction changes again and intake begins to flow into the engine.

Sounds horribly inefficient, but Mazda had to have the opening at 32 deg ATDC intake opening to keep both side seals on the plate for full reliability/emissions. The earlier limited production Cosmos came with "street ported" 24 deg ATDC opening intakes and the '89 and later came with the later 45 deg ATDC opening ports to carry over more exhaust for EGR function and prevent as many intake hydrocarbons from getting sucked out the exhaust.

Mazda made it work for them by using the pulse of the exhaust expanding into the intake tract on late port opening to supercharge the opposing intake port that was about to close.

However, in a rotary with an early opening intake the dynamic is different. With the intake port open at or before TDC the higher velocity exhaust gas exiting the exhaust port sets up a low pressure area between the narrow gap of the rotor and the rotor housing drawing the lower velocity intake charge into the exhaust stroke once the intake port opens.

It is the closed throttle plates on a high overlap rotary that interfere with allowing enough intake charge through to both feed the chamber below siphoning intake charge out the exhaust port and to fill the expanding chamber in the intake stroke during the time allowed by the rotor travel.

The closed throttle plate chokes out the volume of intake flow available to the point where the vacuum of the expanding intake chamber above has to draw exhaust in from the exhaust stroke below and you have a misfire from intake charge diluted too heavily with exhaust.

By the time a couple more chambers have misfired and dumped their mixture of intake air and now diluted exhaust from that power stroke (a couple of chambers ago) into the exhaust port area, the expanding intake stroke begins to suck up this (now diluted) exhaust/intake mix from the chamber below in "exhaust" stroke with enough fresh intake to get the mixture to fire. Brap brap

Take that same high overlap engine at the same idle rpm and "lug" it up a hill with the throttle plates wide open and it does not brap brap, but pulls smoothly up the hill.

The dynamic during overlap in a rotary engine is often misunderstood.

In stock Mazda form where you have a late closing exhaust port and an intake port that opens 32 deg. After Top Dead Center (or 45 deg ATDC on 89-2002 motors) it is true that the expanding intake chamber volume sucks exhaust from the exhaust stroke chamber below through the gap in the rotor and rotor housing before the intake port opens. Once the intake port opens there is first a reversion charge of higher energy exhaust gas entering the intake tract and then the direction changes again and intake begins to flow into the engine.

Sounds horribly inefficient, but Mazda had to have the opening at 32 deg ATDC intake opening to keep both side seals on the plate for full reliability/emissions. The earlier limited production Cosmos came with "street ported" 24 deg ATDC opening intakes and the '89 and later came with the later 45 deg ATDC opening ports to carry over more exhaust for EGR function and prevent as many intake hydrocarbons from getting sucked out the exhaust.

Mazda made it work for them by using the pulse of the exhaust expanding into the intake tract on late port opening to supercharge the opposing intake port that was about to close.

However, in a rotary with an early opening intake the dynamic is different. With the intake port open at or before TDC the higher velocity exhaust gas exiting the exhaust port sets up a low pressure area between the narrow gap of the rotor and the rotor housing drawing the lower velocity intake charge into the exhaust stroke once the intake port opens.

It is the closed throttle plates on a high overlap rotary that interfere with allowing enough intake charge through to both feed the chamber below siphoning intake charge out the exhaust port and to fill the expanding chamber in the intake stroke during the time allowed by the rotor travel.

The closed throttle plate chokes out the volume of intake flow available to the point where the vacuum of the expanding intake chamber above has to draw exhaust in from the exhaust stroke below and you have a misfire from intake charge diluted too heavily with exhaust.

By the time a couple more chambers have misfired and dumped their mixture of intake air and now diluted exhaust from that power stroke (a couple of chambers ago) into the exhaust port area, the expanding intake stroke begins to suck up this (now diluted) exhaust/intake mix from the chamber below in "exhaust" stroke with enough fresh intake to get the mixture to fire. Brap brap

Take that same high overlap engine at the same idle rpm and "lug" it up a hill with the throttle plates wide open and it does not brap brap, but pulls smoothly up the hill.

#23

So you might think for the best torque you could combine a high overlap peripheral port engine I have just shown makes more torque and a turbo or supercharger.

In fact the turbo compressor map or set volume of the positive displacement supercharger act in the same way as the closed throttle plate.

Both a turbo compressor and supercharger will only flow a set amount of air at a given rpm so you get into a dynamic where you open the throttle plates and the high overlap ports are still starving from air from the exhaust scavenging until the turbo spools or the supercharger rpm is high enough to satisfy the expanding intake volume and the loss from scavenging.

You can find a peripheral ported supercharged rotary on youtube and note that it has to idle at a much higher rpm while still braping rapidly and braps still on throttle application until a certain speed.

This should prove to one that it is not exhaust pressure pushing up into the intake (the boost from the blower would negate this effect).

At least with a turbo the intake charge lost out the exhaust helps to spool the turbo quickly- though you get some weird transient turbo response.

Semi peripheral ports and bridge ports do not suffer as badly from this effect.

The semi peripheral port has a port opening small and high enough that the rotor face posses restriction to the intake charge exiting the exhaust port, whereas the full peripheral port is exposed more early on to the rotor tub "combustion chamber" for intake to exhaust gas transfer through.

Likewise, the narrow bridge port favored on turbo cars has the rotor flank restricting the intake port as well as the rotor face to rotor housing interface blocking the transfer of intake to exhaust.

Most peoples knowledge on rotary overlap is kind of like their knowledge of exhaust pipe diameter. Most people have an understanding of the effects, but the wrong idea on what is causing the effects.

In both cases its not exhaust back pressure... its exhaust velocity.

In fact the turbo compressor map or set volume of the positive displacement supercharger act in the same way as the closed throttle plate.

Both a turbo compressor and supercharger will only flow a set amount of air at a given rpm so you get into a dynamic where you open the throttle plates and the high overlap ports are still starving from air from the exhaust scavenging until the turbo spools or the supercharger rpm is high enough to satisfy the expanding intake volume and the loss from scavenging.

You can find a peripheral ported supercharged rotary on youtube and note that it has to idle at a much higher rpm while still braping rapidly and braps still on throttle application until a certain speed.

This should prove to one that it is not exhaust pressure pushing up into the intake (the boost from the blower would negate this effect).

At least with a turbo the intake charge lost out the exhaust helps to spool the turbo quickly- though you get some weird transient turbo response.

Semi peripheral ports and bridge ports do not suffer as badly from this effect.

The semi peripheral port has a port opening small and high enough that the rotor face posses restriction to the intake charge exiting the exhaust port, whereas the full peripheral port is exposed more early on to the rotor tub "combustion chamber" for intake to exhaust gas transfer through.

Likewise, the narrow bridge port favored on turbo cars has the rotor flank restricting the intake port as well as the rotor face to rotor housing interface blocking the transfer of intake to exhaust.

Most peoples knowledge on rotary overlap is kind of like their knowledge of exhaust pipe diameter. Most people have an understanding of the effects, but the wrong idea on what is causing the effects.

In both cases its not exhaust back pressure... its exhaust velocity.

#24

No matter what you do to a two rotor your never going to get any significant low end torque. So to overcome the key is gearing. You need to gear both the rear end and the transmission for your type of racing and it's going to cost money to get it right. If your low budget than stick with the lowest ring and pinion gear you can get.

#25

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

The closed throttle plate chokes out the volume of intake flow available to the point where the vacuum of the expanding intake chamber above has to draw exhaust in from the exhaust stroke below and you have a misfire from intake charge diluted too heavily with exhaust.

By the time a couple more chambers have misfired and dumped their mixture of intake air and now diluted exhaust from that power stroke (a couple of chambers ago) into the exhaust port area, the expanding intake stroke begins to suck up this (now diluted) exhaust/intake mix from the chamber below in "exhaust" stroke with enough fresh intake to get the mixture to fire. Brap brap

Take that same high overlap engine at the same idle rpm and "lug" it up a hill with the throttle plates wide open and it does not brap brap, but pulls smoothly up the hill.

By the time a couple more chambers have misfired and dumped their mixture of intake air and now diluted exhaust from that power stroke (a couple of chambers ago) into the exhaust port area, the expanding intake stroke begins to suck up this (now diluted) exhaust/intake mix from the chamber below in "exhaust" stroke with enough fresh intake to get the mixture to fire. Brap brap

Take that same high overlap engine at the same idle rpm and "lug" it up a hill with the throttle plates wide open and it does not brap brap, but pulls smoothly up the hill.

so in an attempt to add more air, while keeping the throttle plates so that they were still using the idle hole, i started drilling holes in them. i started small, 0.010" and went way up to about 0.060" and it made no difference in idle speed

BUT up to the point where there isn't enough intake vacuum to make the carb actually function, driveability got better. to the point where it actually idled normally, and drove like a stock port car. the other tradeoff is you loose a little throttle response.

since having a P port that doesn't brap at idle kind of defeats the point of having one, i did solder the holes closed, i think i settled on 0.020", so it braps a little, you can drive down the street in 1st gear (least load), @2000rpm, and it just goes like any other rotary.

oh the other thing, torque, i've driven it back to back with another 1st gen, with all the toys, the sterling carb, RB exhaust, etc, and the P port makes more torque by 2000rpm....

*notice, the original idea, was a complete flop, i like every other weber/mukini/dellorto carb on a rotary is idling on the 1st transition hole. drilling giant holes in the throttle plates raised the idle like 50rpm, or something. so i'm stuck with a 900rpm idle. the engine will idle @700rpm no problem, its just the carb doesn't work.