Pics of BLUE TII's engine build- new type of primary port

#1

Pics of BLUE TII's engine build- new type of primary port

So I built my 1st engine from 3 used engines and minimal new parts and despite some "learning process" experiences it runs well.

Specs as follows-

8.5:1 comp rotors

Ser 5 rear housing

Ser 5 rotor housings

Ser 4 inter and front housings

Atkins? 2 piece 2mm seals

Porting-

-Large 2ndary ports (basically the largest you can fit in the S4 front housing) with large runners and early opening.

-Small early opening primaries, but with larger runners. Pointed up and accross 2ndary ports to put a siphon on the 2ndaries. Later closing primaries than 2ndaries to take advantage of their velocity.

-Exhaust ports open a bit earlier, close a bit later. Attention to flow not big timing.

Oil mods-

-Oil pump pick up velocity stacked

-ported, polished oil pump cavities

-relocated oil cooler outlet

-loop line

-e-shaft thermal bypass eliminator

-Race e-shaft rotor oil jets

-Race oil pressure regulator

-relieved e-shaft oil galleys

-windowed, clearanced stat gear bearings

-ported/polished stat gear oil galleys

-largest FD rotor bearings

-RB pan baffle

Misc mods-

-rotor housing coolant jacket mod

-McMaster-carr inner coolant seals

Specs as follows-

8.5:1 comp rotors

Ser 5 rear housing

Ser 5 rotor housings

Ser 4 inter and front housings

Atkins? 2 piece 2mm seals

Porting-

-Large 2ndary ports (basically the largest you can fit in the S4 front housing) with large runners and early opening.

-Small early opening primaries, but with larger runners. Pointed up and accross 2ndary ports to put a siphon on the 2ndaries. Later closing primaries than 2ndaries to take advantage of their velocity.

-Exhaust ports open a bit earlier, close a bit later. Attention to flow not big timing.

Oil mods-

-Oil pump pick up velocity stacked

-ported, polished oil pump cavities

-relocated oil cooler outlet

-loop line

-e-shaft thermal bypass eliminator

-Race e-shaft rotor oil jets

-Race oil pressure regulator

-relieved e-shaft oil galleys

-windowed, clearanced stat gear bearings

-ported/polished stat gear oil galleys

-largest FD rotor bearings

-RB pan baffle

Misc mods-

-rotor housing coolant jacket mod

-McMaster-carr inner coolant seals

#2

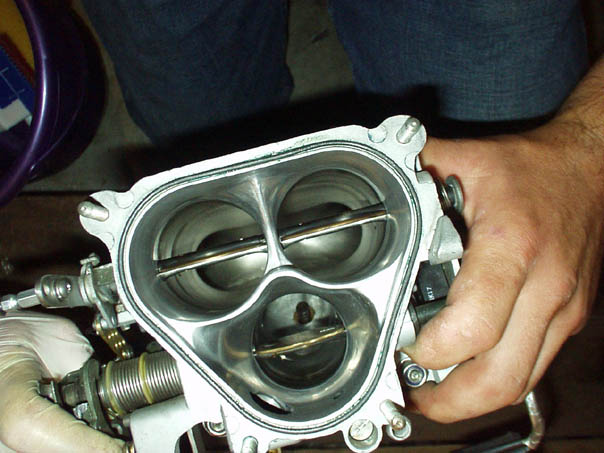

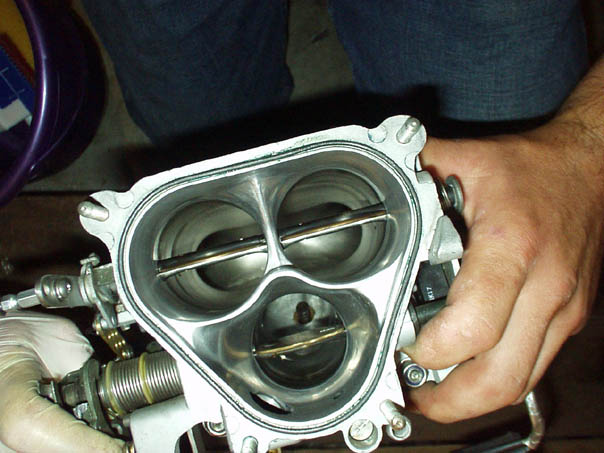

The story on the intake porting is this-

I had to add a bevel and scissor to the previous Pineapple ports to keep them from damaging the sideseals. When I did this to the Primaries it made the port volume way to high.

I started develping early opening primary ports that would be easy on the sideseals and have a small volume at the port face. I mocked up the sidehousings/lower manifold/ fake rotor and partial rotor housing.

I found the higher velocity primaries can blow accross the larger 2ndaries and put a vacuum on them. I tried to maximize that effect through more degrees of rotor movement. The effect was stronger if there was no bevel at the top of the primary port since the flow would diffuse off to the housing surface when beveled.

I had to add a bevel and scissor to the previous Pineapple ports to keep them from damaging the sideseals. When I did this to the Primaries it made the port volume way to high.

I started develping early opening primary ports that would be easy on the sideseals and have a small volume at the port face. I mocked up the sidehousings/lower manifold/ fake rotor and partial rotor housing.

I found the higher velocity primaries can blow accross the larger 2ndaries and put a vacuum on them. I tried to maximize that effect through more degrees of rotor movement. The effect was stronger if there was no bevel at the top of the primary port since the flow would diffuse off to the housing surface when beveled.

#3

I ported the Primaries runner out all the way around where the manifold meets the housing. Ported the bottom of the runner in the middle of the port and a bit off the outside radius to point the flow where I wanted it.

2ndary ports are pretty normal for an early opening while easy on the sideseals port except I made the runners larger on (all 4 ports) to match my ported manifolds. I couldn't round out the 2ndaries port top to runner transition any more without JB weld because of the lower waterjacket on the S4 front housing .

.

2ndary ports are pretty normal for an early opening while easy on the sideseals port except I made the runners larger on (all 4 ports) to match my ported manifolds. I couldn't round out the 2ndaries port top to runner transition any more without JB weld because of the lower waterjacket on the S4 front housing

.

.

#5

On the exhaust ports I was inspired by Paul Yaw's flowbench pictoral. Without the flowbench I just tried to copy what worked for him.

The top of the port also has a bevel to be easier of the apex seals if they sag into the port with high EGTs (imagine that) and it helps flow, but I wasn't wild about the idea of adding overlap by porting up. Works well though, low end power is geat with boost comming on so early.

4th gear data log showed boost at 1,300rpm with full boost (just 10psi for now) at 3,000rpm with my smaller 3" exhaust. Next week I will hopefully have my larger 3 1/2" exhaust on again- it spooled the turbo to full boost 500rpm sooner on my last engine and the very low rpm spool was even more affected.

It was so hard to keep it out of boost for break in since it is spool happy. Finally ended up settling for less than 8psi boost, 4,000rpm redline and less than 20% throttle for first 500 miles. It hits that 8psi ~15% throttle gently pulling onto the freeway ~2,500rpm.

The top of the port also has a bevel to be easier of the apex seals if they sag into the port with high EGTs (imagine that) and it helps flow, but I wasn't wild about the idea of adding overlap by porting up. Works well though, low end power is geat with boost comming on so early.

4th gear data log showed boost at 1,300rpm with full boost (just 10psi for now) at 3,000rpm with my smaller 3" exhaust. Next week I will hopefully have my larger 3 1/2" exhaust on again- it spooled the turbo to full boost 500rpm sooner on my last engine and the very low rpm spool was even more affected.

It was so hard to keep it out of boost for break in since it is spool happy. Finally ended up settling for less than 8psi boost, 4,000rpm redline and less than 20% throttle for first 500 miles. It hits that 8psi ~15% throttle gently pulling onto the freeway ~2,500rpm.

#7

The biggest mistakes I made were in tapping the rear housing heater outlet and the front housing oil cooler outlet. The pipe taps I used were worn and cracked the metal from too much spreading force. Next time I think I will do a straight thread with a crush washer seal to avoid this. Had to have housings TIG welded- luckily no warpage measured.

E-shaft rear stat gear journal has another hole drilled in it to aid flow to rotor bearing (front has two stock). The loop line decreases pressure drop to the front stat gear bearing so more flow also gets to the front rotor bearing.

The reliefs in the e-shaft are a duct cut on the leading edge and a bowl on the backside of the hole on the stat gear journal to push more oil into the e-shaft to feed the rotor bearing. The reliefs point the other way on the rotor bearing journal to increase outlet flow.

E-shaft rear stat gear journal has another hole drilled in it to aid flow to rotor bearing (front has two stock). The loop line decreases pressure drop to the front stat gear bearing so more flow also gets to the front rotor bearing.

The reliefs in the e-shaft are a duct cut on the leading edge and a bowl on the backside of the hole on the stat gear journal to push more oil into the e-shaft to feed the rotor bearing. The reliefs point the other way on the rotor bearing journal to increase outlet flow.

Trending Topics

#9

I polished the e-shaft in a lathe with 1800 grit and flapped/clearanced the bearings with 600 grit.

I know there is a lot of controversy around using the race rotor oil jets in a street car. I used them to limit oil pressure at idle/low rpm so i don't overwhelm the turbo oil drain and smoke (15-20psi at 800rpm idle now instead of 30-60psi), to cool the rotors better when I am boosting at very low rpm (which happens a lot) and to make sure the high clearance FD rotor bearings have more oil pressure at high rpms.

Oil pressure seems to be topping out at 90psi (hot on gassy 10-40) now reading off a quality mechanical guage. A lot lower than the Pineapple, but I think it is OK.??

I know there is a lot of controversy around using the race rotor oil jets in a street car. I used them to limit oil pressure at idle/low rpm so i don't overwhelm the turbo oil drain and smoke (15-20psi at 800rpm idle now instead of 30-60psi), to cool the rotors better when I am boosting at very low rpm (which happens a lot) and to make sure the high clearance FD rotor bearings have more oil pressure at high rpms.

Oil pressure seems to be topping out at 90psi (hot on gassy 10-40) now reading off a quality mechanical guage. A lot lower than the Pineapple, but I think it is OK.??

#10

How the hell do you get your parts so clean....and where do you get your parts at. The irons look like they have ZERO wear and the rotor housings look practically new.

I used a dirty solvent tank (thanks ScrapFC!), the coin op. car wash afterward and the dishwasher on some parts.

The S5 rear housing was from my Pinapple that had 3,000 miles on it since a lap job. I re-ported it to save my sideseals an make the runners bigger. It actually has wear in the combustion chamber side that hadn't been lapped out, but the coolant seal groove was getting shallow so I didn't have it lapped.

The other plates were lapped at RB.

The rotor housings are actually junk from a terrible rebuild job I bought from J-rat. The spark plug holes have cracks and there are several gouges on one of the rotor housings that catch your fingernail. Yet, they are post compression phase.

Apex seals are also from this J-rat engine.

Rotating assembly is from my 15,000+ mile original engine that coughed out an apex seal (minor gouge in middle of one groove). Out of the 3 engines most of the usable parts came from this engine.

I had to buy a new oil pump, 3 new outer coolant seals, 3 sideseals, 4 McMaster-carr inner coolant seals, rotor oil jets and that is about it.

I call this my "poop" motor because it is junk parts. Good practice though and to see if the porting works.

I used a dirty solvent tank (thanks ScrapFC!), the coin op. car wash afterward and the dishwasher on some parts.

The S5 rear housing was from my Pinapple that had 3,000 miles on it since a lap job. I re-ported it to save my sideseals an make the runners bigger. It actually has wear in the combustion chamber side that hadn't been lapped out, but the coolant seal groove was getting shallow so I didn't have it lapped.

The other plates were lapped at RB.

The rotor housings are actually junk from a terrible rebuild job I bought from J-rat. The spark plug holes have cracks and there are several gouges on one of the rotor housings that catch your fingernail. Yet, they are post compression phase.

Apex seals are also from this J-rat engine.

Rotating assembly is from my 15,000+ mile original engine that coughed out an apex seal (minor gouge in middle of one groove). Out of the 3 engines most of the usable parts came from this engine.

I had to buy a new oil pump, 3 new outer coolant seals, 3 sideseals, 4 McMaster-carr inner coolant seals, rotor oil jets and that is about it.

I call this my "poop" motor because it is junk parts. Good practice though and to see if the porting works.

#11

I made the sideseals as tight as possible and still have the move freely. You can get a feeler guage in there if you push and prod the sideseal and cornerseal, but it is basically "zero clearance".

This way the sideseals will wear grooves into the cornerseals when they expand from heat for a better gas seal.

It fired right up the 1st time despite the trash rotor housing. I haven't compression tested yet, but it feels good.

This way the sideseals will wear grooves into the cornerseals when they expand from heat for a better gas seal.

It fired right up the 1st time despite the trash rotor housing. I haven't compression tested yet, but it feels good.

#12

I found an easy way to do the spark plug coolant jacket mod.

Put the appropriate dremel bit in a drill press. Put a nut above and below the depth limiter to lock it to a set depth and move your housing around on the drill press table to cut.

Then move the depth adjuster down to the next cut height.

You can cut pretty deep as the 86 on rotor housings have MUCH thicker casting to make the coolant passages smaller for less coolant volume in the engine for faster warm up/ cold start emmisions.

Put the appropriate dremel bit in a drill press. Put a nut above and below the depth limiter to lock it to a set depth and move your housing around on the drill press table to cut.

Then move the depth adjuster down to the next cut height.

You can cut pretty deep as the 86 on rotor housings have MUCH thicker casting to make the coolant passages smaller for less coolant volume in the engine for faster warm up/ cold start emmisions.

#13

To prevent the boost creep I had experienced I also modified the turbo manifold and housing more as per Bryan at BNRs advice.

Turbo is a BNR Stage 4 w/ clipped "P" trim exhaust wheel and a 60mm external wastegate.

I reduced the velocity stack at the end of the stock exhaust manifold so it is only an 11% reduction in volume.

This should help slow the exhaust so it doesn't just want to continue on to the tubo even when the wastegate is open.

I squared out the top (short radius) for more flow. Since the stock manifold meets the turbo housing with a "cheated radius" I added a bowl to the bottom of the manifold runners to start the outside radius and cut the top up to a radius. I portmatched the manfold to housing and pinned it as well as adding complimentary radius to the housing runners.

I thought the decrease in velocity would hurt low end spool, but it is better than ever.

Turbo is a BNR Stage 4 w/ clipped "P" trim exhaust wheel and a 60mm external wastegate.

I reduced the velocity stack at the end of the stock exhaust manifold so it is only an 11% reduction in volume.

This should help slow the exhaust so it doesn't just want to continue on to the tubo even when the wastegate is open.

I squared out the top (short radius) for more flow. Since the stock manifold meets the turbo housing with a "cheated radius" I added a bowl to the bottom of the manifold runners to start the outside radius and cut the top up to a radius. I portmatched the manfold to housing and pinned it as well as adding complimentary radius to the housing runners.

I thought the decrease in velocity would hurt low end spool, but it is better than ever.

#14

I put the dual EGT probes in there so I can tell if I am getting a flow imbalance in the engine and adjust the injector trim accordingly.

I also had the turbo housing backwelded on the front runners WG so I could port the entry more (round the corner).

I have a divider that keeps the turbo divided all the way to the wastegate valve (like stock S5). This is a bit of a trick as the top has to float in the bend so it can expand with hear or else it cracks VERY rapidly. It is welded to the ring pictured and that ring can move with expansion.

Dividing like this helped they low end spool, but I didn't notice a difference in full boost rpm when I added it (on my old engine).

I also had the turbo housing backwelded on the front runners WG so I could port the entry more (round the corner).

I have a divider that keeps the turbo divided all the way to the wastegate valve (like stock S5). This is a bit of a trick as the top has to float in the bend so it can expand with hear or else it cracks VERY rapidly. It is welded to the ring pictured and that ring can move with expansion.

Dividing like this helped they low end spool, but I didn't notice a difference in full boost rpm when I added it (on my old engine).

#15

Rotating assembly is from my 15,000+ mile original engine that coughed out an apex seal (minor gouge in middle of one groove). Out of the 3 engines most of the usable parts came from this engine.

Ooops, I meant 150,000+ mile engine. Pineapple rebuild had 12,000 miles on it, the rebuild J-rat sold me looked like it failed shortly after start up from many oil system errors.

Ooops, I meant 150,000+ mile engine. Pineapple rebuild had 12,000 miles on it, the rebuild J-rat sold me looked like it failed shortly after start up from many oil system errors.

#16

development

neat project! great way to test untested mods...the "poop motor"!!

90psi seems low, but only time will tell...low idle oil pressure to save the turbo from smoke!?! just seems like you are sacrificing high rpm pressure? why not use a restrictor?

I'm not following you on the primary ports? They blow thru the secondary's and create vacuum?? why isn't there boost oposing the primary push?

what exactly does the spark plug coolant passage mod do?

little concerning that your oil is gassy with zero clearance side seals???

theory behind no screen velocity stack pick up?? picks up oil faster? all the oil galley port work for faster flow? better cooling or could the oil move too fast to transfer heat as well?

90psi seems low, but only time will tell...low idle oil pressure to save the turbo from smoke!?! just seems like you are sacrificing high rpm pressure? why not use a restrictor?

I'm not following you on the primary ports? They blow thru the secondary's and create vacuum?? why isn't there boost oposing the primary push?

what exactly does the spark plug coolant passage mod do?

little concerning that your oil is gassy with zero clearance side seals???

theory behind no screen velocity stack pick up?? picks up oil faster? all the oil galley port work for faster flow? better cooling or could the oil move too fast to transfer heat as well?

Last edited by dubulup; 12-09-05 at 12:27 PM.

#17

90psi seems low, but only time will tell...low idle oil pressure to save the turbo from smoke!?! just seems like you are sacrificing high rpm pressure? why not use a restrictor?

Turbo has a restrictor as small as I dare. The only way I could stop the smoking at idle before was to put the oil pan under vaccuum to help the turbo drain. Now sump is just vented. I hadn't anticipated lower high rpm pressure as this is not normal with rotor oil jet mod. I am still figuring that one out...

I'm not following you on the primary ports? They blow thru the secondary's and create vacuum?? why isn't there boost oposing the primary push?

The higher velocity primaries blow accross the 2ndary ports at and angle so inducing a low pressure area at the 2ndary ports- "siphon effect". This helps initiate 2ndary port flow despite its large port volume.

what exactly does the spark plug coolant passage mod do?

Helps cool the spark plugs so they are effectively a colder heat range plug. Trailing plug can easily be a cause of pre-ignition in the rotary,

little concerning that your oil is gassy with zero clearance side seals???

I am still on a conservative map so it is richer than 8:1 AF in boost- that fouls the oil fast. I am running the OMP modded for max flow and premixing 100:1 to avoid wash down.

theory behind no screen velocity stack pick up?? picks up oil faster? all the oil galley port work for faster flow? better cooling or could the oil move too fast to transfer heat as well?

Better flow and higher pressure for the oil mods. The oil cannot move too fast through the hotspots.

Turbo has a restrictor as small as I dare. The only way I could stop the smoking at idle before was to put the oil pan under vaccuum to help the turbo drain. Now sump is just vented. I hadn't anticipated lower high rpm pressure as this is not normal with rotor oil jet mod. I am still figuring that one out...

I'm not following you on the primary ports? They blow thru the secondary's and create vacuum?? why isn't there boost oposing the primary push?

The higher velocity primaries blow accross the 2ndary ports at and angle so inducing a low pressure area at the 2ndary ports- "siphon effect". This helps initiate 2ndary port flow despite its large port volume.

what exactly does the spark plug coolant passage mod do?

Helps cool the spark plugs so they are effectively a colder heat range plug. Trailing plug can easily be a cause of pre-ignition in the rotary,

little concerning that your oil is gassy with zero clearance side seals???

I am still on a conservative map so it is richer than 8:1 AF in boost- that fouls the oil fast. I am running the OMP modded for max flow and premixing 100:1 to avoid wash down.

theory behind no screen velocity stack pick up?? picks up oil faster? all the oil galley port work for faster flow? better cooling or could the oil move too fast to transfer heat as well?

Better flow and higher pressure for the oil mods. The oil cannot move too fast through the hotspots.

#18

development

I hadn't anticipated lower high rpm pressure as this is not normal with rotor oil jet mod. I am still figuring that one out...

theory behind no screen velocity stack pick up??

Better flow and higher pressure for the oil mods. The oil cannot move too fast through the hotspots.

^you don't think these are related?? all the porting generating lower pressure to begin with??? Say you have your velocity stack and ported "intake" for the pump...with all the oil passages stock...I would think this would create higher pressure<---Picking more up and forcing it thru the same space. Now if you port the "exhaust" side of the system (intake stock), that will slow things down, hence lower pressure, no? Sounds like a trial and error balancing act, and maybe your "exhaust" side is too ported causing the lower pressure?

I'm not convinced oil cannot move too fast...there is a limit for everything, if it isn't picking up enough heat in the hot spots...it certainly isn't dumping it in the cooler.

The higher velocity primaries blow across the 2ndary ports at and angle so inducing a low pressure area at the 2ndary ports- "siphon effect". This helps initiate 2ndary port flow despite its large port volume.

okay, so itís a good thing...I couldn't picture what you were describing. How are you measuring/testing this? Or is this theory?

Helps cool the spark plugs so they are effectively a colder heat range plug. Trailing plug can easily be a cause of pre-ignition in the rotary,

yes, I understand this, but what does the mod due to aid this?? do the "steps" just allow more coolant to flow in that area? Looks like it could hurt flow in the area...I have no idea, but steps can't be good for flow. I've never seen this mod and find it interesting...seems some coolant will get "stuck" on the steps...keeping the housing hotter than if it were smooth and coolant passed freely.

I am still on a conservative map so it is richer than 8:1 AF in boost- that fouls the oil fast. I am running the OMP modded for max flow and premixing 100:1 to avoid wash down.

GEEZE...if you have the means to measure A:F that accurate, why not lean it out a tad? to something less ridiculous like 10:1; which is plenty safe.

after re-reading this, I might sound like an ***...I'm not trying too, I really like what you are trying here so I'm asking questions. I don't find many threads here as intriguing as yours.

theory behind no screen velocity stack pick up??

Better flow and higher pressure for the oil mods. The oil cannot move too fast through the hotspots.

^you don't think these are related?? all the porting generating lower pressure to begin with??? Say you have your velocity stack and ported "intake" for the pump...with all the oil passages stock...I would think this would create higher pressure<---Picking more up and forcing it thru the same space. Now if you port the "exhaust" side of the system (intake stock), that will slow things down, hence lower pressure, no? Sounds like a trial and error balancing act, and maybe your "exhaust" side is too ported causing the lower pressure?

I'm not convinced oil cannot move too fast...there is a limit for everything, if it isn't picking up enough heat in the hot spots...it certainly isn't dumping it in the cooler.

The higher velocity primaries blow across the 2ndary ports at and angle so inducing a low pressure area at the 2ndary ports- "siphon effect". This helps initiate 2ndary port flow despite its large port volume.

okay, so itís a good thing...I couldn't picture what you were describing. How are you measuring/testing this? Or is this theory?

Helps cool the spark plugs so they are effectively a colder heat range plug. Trailing plug can easily be a cause of pre-ignition in the rotary,

yes, I understand this, but what does the mod due to aid this?? do the "steps" just allow more coolant to flow in that area? Looks like it could hurt flow in the area...I have no idea, but steps can't be good for flow. I've never seen this mod and find it interesting...seems some coolant will get "stuck" on the steps...keeping the housing hotter than if it were smooth and coolant passed freely.

I am still on a conservative map so it is richer than 8:1 AF in boost- that fouls the oil fast. I am running the OMP modded for max flow and premixing 100:1 to avoid wash down.

GEEZE...if you have the means to measure A:F that accurate, why not lean it out a tad? to something less ridiculous like 10:1; which is plenty safe.

after re-reading this, I might sound like an ***...I'm not trying too, I really like what you are trying here so I'm asking questions. I don't find many threads here as intriguing as yours.

#19

^you don't think these are related?? all the porting generating lower pressure to begin with??? Say you have your velocity stack and ported "intake" for the pump...with all the oil passages stock...I would think this would create higher pressure<---Picking more up and forcing it thru the same space. Now if you port the "exhaust" side of the system (intake stock), that will slow things down, hence lower pressure, no? Sounds like a trial and error balancing act, and maybe your "exhaust" side is too ported causing the lower pressure?

The Pineapple rebuild I had previously had all the oil mods except the rotor oil jets and the oil pick up tube and it had obnoxiously high oil pressure. Otherwise I would agree with you. If the race rotor oil jets flow less than stock at high rpms because of their smaller size it doesn't make sense it is them.

I think it may be because I did not shim the front oil pressure regulator. There were no washers in the Pineapple, so I didn't think it was needed. This was further reinforced by the fact I have read that relocating the oil cooler outlet bypasses that regulator. But now I am wondering...

I'm not convinced oil cannot move too fast...there is a limit for everything, if it isn't picking up enough heat in the hot spots...it certainly isn't dumping it in the cooler.

OK

okay, so it’s a good thing...I couldn't picture what you were describing. How are you measuring/testing this? Or is this theory?

I oakie bench tested it with the ports, a mock up rotor and partial rotor housing and intake manifold. Using low pressure compressed air in the primaries runners to suck confetti out of the 2ndary ports. I tried to maximize the effect through the highest degree of rotor phasing. The Pineapple ports I started with did this at limited rotor positions mine did it through most of the intake cycle.

yes, I understand this, but what does the mod due to aid this?? do the "steps" just allow more coolant to flow in that area? Looks like it could hurt flow in the area...I have no idea, but steps can't be good for flow. I've never seen this mod and find it interesting...seems some coolant will get "stuck" on the steps...keeping the housing hotter than if it were smooth and coolant passed freely.

It is a heatsink- more surface area. It is a pretty standard race mod trying to reduce temps at a hot spot.

GEEZE...if you have the means to measure A:F that accurate, why not lean it out a tad? to something less ridiculous like 10:1; which is plenty safe.

I was desperately trying to stay out of boost the 1st 500 miles (impossible) so I did not tune the boost maps. Now I am leaning out the low boost I am up to in the break-in.

after re-reading this, I might sound like an ***...I'm not trying too, I really like what you are trying here so I'm asking questions. I don't find many threads here as intriguing as yours.

Nah, you sound interested; I like that.

All hail the "poop motor". You have to say it like Beavis, its just required

The Pineapple rebuild I had previously had all the oil mods except the rotor oil jets and the oil pick up tube and it had obnoxiously high oil pressure. Otherwise I would agree with you. If the race rotor oil jets flow less than stock at high rpms because of their smaller size it doesn't make sense it is them.

I think it may be because I did not shim the front oil pressure regulator. There were no washers in the Pineapple, so I didn't think it was needed. This was further reinforced by the fact I have read that relocating the oil cooler outlet bypasses that regulator. But now I am wondering...

I'm not convinced oil cannot move too fast...there is a limit for everything, if it isn't picking up enough heat in the hot spots...it certainly isn't dumping it in the cooler.

OK

okay, so it’s a good thing...I couldn't picture what you were describing. How are you measuring/testing this? Or is this theory?

I oakie bench tested it with the ports, a mock up rotor and partial rotor housing and intake manifold. Using low pressure compressed air in the primaries runners to suck confetti out of the 2ndary ports. I tried to maximize the effect through the highest degree of rotor phasing. The Pineapple ports I started with did this at limited rotor positions mine did it through most of the intake cycle.

yes, I understand this, but what does the mod due to aid this?? do the "steps" just allow more coolant to flow in that area? Looks like it could hurt flow in the area...I have no idea, but steps can't be good for flow. I've never seen this mod and find it interesting...seems some coolant will get "stuck" on the steps...keeping the housing hotter than if it were smooth and coolant passed freely.

It is a heatsink- more surface area. It is a pretty standard race mod trying to reduce temps at a hot spot.

GEEZE...if you have the means to measure A:F that accurate, why not lean it out a tad? to something less ridiculous like 10:1; which is plenty safe.

I was desperately trying to stay out of boost the 1st 500 miles (impossible) so I did not tune the boost maps. Now I am leaning out the low boost I am up to in the break-in.

after re-reading this, I might sound like an ***...I'm not trying too, I really like what you are trying here so I'm asking questions. I don't find many threads here as intriguing as yours.

Nah, you sound interested; I like that.

All hail the "poop motor". You have to say it like Beavis, its just required

#20

count me in as another very interested third party ...  i salute your work thus far. admittedly some of your mods are a bit over my head ... may just be unfamiliar with the terminology you use.

i salute your work thus far. admittedly some of your mods are a bit over my head ... may just be unfamiliar with the terminology you use.

for example:

could you explain this in lay-person's terms for me? i can see some of what you did in the pictures, but some of it is lost on me.

also, i remain a little cloudy on the logic behind the primary intakes.

thanks

i salute your work thus far. admittedly some of your mods are a bit over my head ... may just be unfamiliar with the terminology you use.

i salute your work thus far. admittedly some of your mods are a bit over my head ... may just be unfamiliar with the terminology you use. for example:

Originally Posted by BLUE TII

E-shaft rear stat gear journal has another hole drilled in it to aid flow to rotor bearing (front has two stock). The loop line decreases pressure drop to the front stat gear bearing so more flow also gets to the front rotor bearing.

The reliefs in the e-shaft are a duct cut on the leading edge and a bowl on the backside of the hole on the stat gear journal to push more oil into the e-shaft to feed the rotor bearing. The reliefs point the other way on the rotor bearing journal to increase outlet flow.

The reliefs in the e-shaft are a duct cut on the leading edge and a bowl on the backside of the hole on the stat gear journal to push more oil into the e-shaft to feed the rotor bearing. The reliefs point the other way on the rotor bearing journal to increase outlet flow.

also, i remain a little cloudy on the logic behind the primary intakes.

thanks

#21

could you explain this in lay-person's terms for me? i can see some of what you did in the pictures, but some of it is lost on me.

The easiest way to see the benifit of the oil mods is to look at the oil flow schematic in the factory service manual and see what each mod does and how they work together. I believe there is a FSM online somewhere if you don't have this useful tool at home.

also, i remain a little cloudy on the logic behind the primary intakes

The best way to grasp this may be to check out how a siphon feed paint gun works (www.howstuffworks.com may have it). Then try to see how you could use that to suck air out of the 2ndary ports.

My primaries suck and the 2ndaries blow; I am happy with how poop motor is running

The easiest way to see the benifit of the oil mods is to look at the oil flow schematic in the factory service manual and see what each mod does and how they work together. I believe there is a FSM online somewhere if you don't have this useful tool at home.

also, i remain a little cloudy on the logic behind the primary intakes

The best way to grasp this may be to check out how a siphon feed paint gun works (www.howstuffworks.com may have it). Then try to see how you could use that to suck air out of the 2ndary ports.

My primaries suck and the 2ndaries blow; I am happy with how poop motor is running

#22

development

I don't know if TII UIM have double throttle butterflies...FD's have these so you can't build too much boost while the motor is cold (control via wax rod/solenoid).

while most highly modded guys remove for increase flow...

I have heard of one guy on this forum rewiring these to open/close off a boost switch ~3psi. Theory behind this is to increase primary port speed also...then once the turbo is spooled up a bit open the butterflys and allow air to flow into thru the secondary ports.

Sounds like your port work could benefit from this...if TII UIM's aren't equip with this, maybe it'd be worth it to move to a FD UIM???

while most highly modded guys remove for increase flow...

I have heard of one guy on this forum rewiring these to open/close off a boost switch ~3psi. Theory behind this is to increase primary port speed also...then once the turbo is spooled up a bit open the butterflys and allow air to flow into thru the secondary ports.

Sounds like your port work could benefit from this...if TII UIM's aren't equip with this, maybe it'd be worth it to move to a FD UIM???

#23

I don't understand how the primary port can 'blow across' the sec port when they are 80mm apart and opposite each other?

I fixed a s6 recently that had lower oil pressure at high rpm. The sump was dented creating a restriction at the pickup. Maybe your pickup doesn't have enough clearance?

All in all it looks good, you've definatly put a lot of thought into it. Be interesting to see what numbers it makes.

I fixed a s6 recently that had lower oil pressure at high rpm. The sump was dented creating a restriction at the pickup. Maybe your pickup doesn't have enough clearance?

All in all it looks good, you've definatly put a lot of thought into it. Be interesting to see what numbers it makes.

#24

I removed the double throttle in my 3rd gen UIM, ported and polished the runners, halfshafted the primary plate, contoured the 2ndaries, ported the TB and have the primary plates open the same time as the 2ndaries. There is ~3-5 deg movemnent in the primaries before the 2ndaries start to open.

Old pic of the set-up ~3 years ago. I have a real size filter now and ignition system. I will get some new pics up.

Turbo all together

Old pic of the set-up ~3 years ago. I have a real size filter now and ignition system. I will get some new pics up.

Turbo all together

#25

I have heard of one guy on this forum rewiring these to open/close off a boost switch ~3psi. Theory behind this is to increase primary port speed also...then once the turbo is spooled up a bit open the butterflys and allow air to flow into thru the secondary ports.

Sounds like your port work could benefit from this...

Actually, my porting works great having the 2ndaries open at the same time as the primaries because the higher velocity primaries put a low pressure area on the 2ndaries to help initiate their flow. Less intake pressure drop= turbo spools more easily.

I don't understand how the primary port can 'blow across' the sec port when they are 80mm apart and opposite each other?

Yes, you are correct. The primary ports blow accross the top of the 2ndary ports making a low pressure area in the intake chamber in the 2ndary ports discharge area.

It is really neat to see it actually working on the bench.

Grab an overported primary with some modeling clay to manipulate its shape and your regular 2ndary port. Put your lower intake manifold on it and assemble a rotor/e-shaft in there. Put a piece of cardboard between the plates to serve as a partial rotor housing while still allowing for discharge out of mock up engine.

Use low pressure compressed air down the primary of the LIM being careful to shroud the 2ndary openings so they don't get compressed air.

If you put light confetti in the 2ndary port you will be able to "suck" the confetti out with the primary ports once you have played with rotor angle and pri port shape.

Then you can develop a port shape to maximize the affect over the most rotor phasing.

I fixed a s6 recently that had lower oil pressure at high rpm. The sump was dented creating a restriction at the pickup. Maybe your pickup doesn't have enough clearance?

I did an oil change w/ fresh oil and the oil pressure jumped up to 110psi - much closer to where the last engine operated at. With the bigger largest size FD rotor bearings and clearanced stat gear bearings I could see how it would be a bit lower.

The pick up and pan are stock, pick up just has screen removed, flared at the end and a rings silver soldered on to allow material to port the velocity stack.

I'm not concerned about the oil pressure any more as I feel it is safe; I just have to get tuning so I am not dumping so much fuel in. I am sure everything breaking in will help it seal as well.

Sounds like your port work could benefit from this...

Actually, my porting works great having the 2ndaries open at the same time as the primaries because the higher velocity primaries put a low pressure area on the 2ndaries to help initiate their flow. Less intake pressure drop= turbo spools more easily.

I don't understand how the primary port can 'blow across' the sec port when they are 80mm apart and opposite each other?

Yes, you are correct. The primary ports blow accross the top of the 2ndary ports making a low pressure area in the intake chamber in the 2ndary ports discharge area.

It is really neat to see it actually working on the bench.

Grab an overported primary with some modeling clay to manipulate its shape and your regular 2ndary port. Put your lower intake manifold on it and assemble a rotor/e-shaft in there. Put a piece of cardboard between the plates to serve as a partial rotor housing while still allowing for discharge out of mock up engine.

Use low pressure compressed air down the primary of the LIM being careful to shroud the 2ndary openings so they don't get compressed air.

If you put light confetti in the 2ndary port you will be able to "suck" the confetti out with the primary ports once you have played with rotor angle and pri port shape.

Then you can develop a port shape to maximize the affect over the most rotor phasing.

I fixed a s6 recently that had lower oil pressure at high rpm. The sump was dented creating a restriction at the pickup. Maybe your pickup doesn't have enough clearance?

I did an oil change w/ fresh oil and the oil pressure jumped up to 110psi - much closer to where the last engine operated at. With the bigger largest size FD rotor bearings and clearanced stat gear bearings I could see how it would be a bit lower.

The pick up and pan are stock, pick up just has screen removed, flared at the end and a rings silver soldered on to allow material to port the velocity stack.

I'm not concerned about the oil pressure any more as I feel it is safe; I just have to get tuning so I am not dumping so much fuel in. I am sure everything breaking in will help it seal as well.