Next Generation Renesis (Rotary Engine 16X), photos from Tokyo Auto Show

#101

There have been several reports of rotaries burning all kinds of fuels including diesel and jet fuels with no modifications to the engines themselves other than "jetting". This may be simplifying things a little bit but as you said it should be and apparently is possible. I'd love to see someone share how they did it. It can't be that hard to do. From what I've seen all attempts/success stories, have used some form of electrical ignition and not compression ignition.

What you describe is a prechamber ignition als knows as indirect injection. Many diesel engines have used this technique and it's what PATS was using on the rotary apu. Mazda has even used this same idea on early direct injected rotary test engines. As with anything it has it's advantages and disadvantages.

What you describe is a prechamber ignition als knows as indirect injection. Many diesel engines have used this technique and it's what PATS was using on the rotary apu. Mazda has even used this same idea on early direct injected rotary test engines. As with anything it has it's advantages and disadvantages.

#102

Yes, its a prechamber (the guys that engineered it called it a plasma chamber). But, unlike the MAZDA developed engine and most diesel engines, no fuel is squirted into this pre chamber. The engine I worked with used the stock carb which was piston timed rather then reed valved or crank timed which was drawn into the crank case like most two strokes. It was an interesting project. Off topic, I also got to get my hands dirty on other neat projects like carbon carbon pistons for gas and diesel engines, along with some pretty innovative engine designs like and opposed dual crank diesel engine (shared a common cylinder, the two pistons faced one another and diesel was injected in the middle). Talk about super high compression artio. I don't recall the CR, but it was WAY up there. This engine had GREAT efficiency (low rev, super high torque).

~Mike.........

~Mike.........

#104

compression ignition is not what were after, its the implications that it could have. which is a true diesel configuration.

when the wankel rotary came along it offered amazing power to weight ratios compared to piston engines of the same size but it came with a major disadvantage. that was at the cost of fuel efficiency. if a rotary engine were to come about that had both great power to weight ratio and fuel efficiency it would capture a much greater share of the internal combusion engine market. going true diesel vs semi diesel with spark ignition means higher compression ratio, no throttle body, and less wear to the apex seal since it doesnt need to operate at high rpms.

when the wankel rotary came along it offered amazing power to weight ratios compared to piston engines of the same size but it came with a major disadvantage. that was at the cost of fuel efficiency. if a rotary engine were to come about that had both great power to weight ratio and fuel efficiency it would capture a much greater share of the internal combusion engine market. going true diesel vs semi diesel with spark ignition means higher compression ratio, no throttle body, and less wear to the apex seal since it doesnt need to operate at high rpms.

#106

for what its worth my friend from japan (living in osaka) just told me he was reading the japanese motoring rumor mill and a lot of "well known motorist fortune tellers" are reporting that mazda has achieved 320 peak ps w/ the 16x and 30+ % increase in peak tq... i don't know how true this is but its the most recent update he could tell me and this is from the same magazine that said the next Z was going to be 370z ... what is it worth? who knows but its hopeful

#108

The rotary is a long way off from being mainstream. They are getting better but, they still have flooding and heavy carbon building characteristics. Both of which make the engine not too consumer friendly and unreliable. Plus fuel economy is falling way behind the piston. You also have to consider all the different variations of piston engined cars in the world. In the rotary world, we have had basically one engine that's been recycled for the past 25yrs. I'm glad Mazda is finally giving us different displacment versions of these engines because it will prove how divers a rotary can be.

#109

are they really going to get all the fueling done with just 1 injector per rotor? Or will they add secondaries on the intake like were used to seeing? If thats the case Im not sure you could call it true " direct injection".

also, great pics, thanks for sharing.

also, great pics, thanks for sharing.

#110

Toyota uses both direct in-cylinder injection and port injection in their Lexus 300hp V6 with injection programming to suit different engine loads requiring different injection performance.

Mazda will use the primary locations which they call semi-direct since they inject inside the intake ports additional to the top mounted direct injectors. Or they could use just two larger direct inejctors, for n/a applications up to 280bhp or so maybe two is enough.

Mazda will use the primary locations which they call semi-direct since they inject inside the intake ports additional to the top mounted direct injectors. Or they could use just two larger direct inejctors, for n/a applications up to 280bhp or so maybe two is enough.

#111

gorgeous pictures

im young and new at these still but seems to me like it'd rather just be made of something ligher on the inside but strongest on the outsides like the bmw z4 roadsters

seems like the extra rotor would do more efficentiently and reliable too.

im young and new at these still but seems to me like it'd rather just be made of something ligher on the inside but strongest on the outsides like the bmw z4 roadsters

seems like the extra rotor would do more efficentiently and reliable too.

#112

I feel relieved they are keeping our dear rotary alive. It's a good thing they are using DI for fuel economy and emissions.

I don't think we'll get anything better (or equal) than the FD in a while whether it's engine performance (twin turbo) or chassis (4 seats) but it's good too see that skunkwork of Mazda engineers keeping their heart at it.

http://www.greencarcongress.com/2007...developin.html

Joel

I don't think we'll get anything better (or equal) than the FD in a while whether it's engine performance (twin turbo) or chassis (4 seats) but it's good too see that skunkwork of Mazda engineers keeping their heart at it.

http://www.greencarcongress.com/2007...developin.html

Joel

#113

http://www.autoblog.com/2009/02/12/r...-rx-8-to-be-c/

the latest from the rumor mill indicates that the 16X will have a crank horsepower rating of at least 270 and will be placed in a 2 seater car that is lighter than the FD was. Fuel economy is supposed to be improved.

To the optimists among us, the next rotary sports car could be the fastest (based on rumored power-to-weight ratio), lowest emissions, and most fuel efficient we have seen from a production car.

the latest from the rumor mill indicates that the 16X will have a crank horsepower rating of at least 270 and will be placed in a 2 seater car that is lighter than the FD was. Fuel economy is supposed to be improved.

To the optimists among us, the next rotary sports car could be the fastest (based on rumored power-to-weight ratio), lowest emissions, and most fuel efficient we have seen from a production car.

#114

wow thats a beautiful motor, if only they stayed shiny lol. Does anyone know when its suppose to be released, or est. HP/TQ numbers, this motor is going to be a monster boosted.

#115

#116

the only issue i see with the renesis x16 yet is the same issue big rig diesel engine faced

how to cool the piston ?did you see what cummins had to do imagine the piston has some hole that channel oil in the piston thick part .i think they used that same method some other car company used not far back.lost foam casting .they showed a cutway view of the diesel piston its a nice piece but i wouldnt like to be the one that did the mold.as for the 2 rotor the main issue mazda face is exactly the same they will probably have to find a way to channel oil very close to the apex ring without weakening the rotor.lost foam casting is probably the only way with a complex piece like that .hell i bet cummins scratched their brain a lot to create that .250 diameter

oring channel all around the crow piston piece.but its the only way to improve rotary because the main issue rotary always had issue with is they are very easy to rise in temperature compared to other engine.because other engine invented oil squirter for piston a while back .dont think rotary have had those yet.one thing is sure

this is the best balanced engine period(rotary)be it 13b,20b,26b,renesis,renesis x~16

but since mazda only put it in their sport car and none other ,the other engine are advancing faster.i sure wish miata renesis x`16 was created and boot all other idea of new car for now on the sport or supersport front.miata is a good car it just need a beseark engine.as for polution mazda could use the same teck diesel engine have been using for what 2 years in america,simple yet effective!

as for reliability issue bad oil for rotary plus a lot of user cold running a rotary hastened theose user demise.

how to cool the piston ?did you see what cummins had to do imagine the piston has some hole that channel oil in the piston thick part .i think they used that same method some other car company used not far back.lost foam casting .they showed a cutway view of the diesel piston its a nice piece but i wouldnt like to be the one that did the mold.as for the 2 rotor the main issue mazda face is exactly the same they will probably have to find a way to channel oil very close to the apex ring without weakening the rotor.lost foam casting is probably the only way with a complex piece like that .hell i bet cummins scratched their brain a lot to create that .250 diameter

oring channel all around the crow piston piece.but its the only way to improve rotary because the main issue rotary always had issue with is they are very easy to rise in temperature compared to other engine.because other engine invented oil squirter for piston a while back .dont think rotary have had those yet.one thing is sure

this is the best balanced engine period(rotary)be it 13b,20b,26b,renesis,renesis x~16

but since mazda only put it in their sport car and none other ,the other engine are advancing faster.i sure wish miata renesis x`16 was created and boot all other idea of new car for now on the sport or supersport front.miata is a good car it just need a beseark engine.as for polution mazda could use the same teck diesel engine have been using for what 2 years in america,simple yet effective!

as for reliability issue bad oil for rotary plus a lot of user cold running a rotary hastened theose user demise.

Last edited by drbaltazar; 08-09-10 at 08:27 PM.

#118

hahaha!my bad then!sorry!how come so many user blow their rx7?is it that too many hit the rev limiter(run lean)or is it cold running rotary?cause i hear some say rotary are bulletproof and other say its the worst engine that was ever conceived.

ty for feedback !i thot the rotary didnt have the oil channel in the rotor.

ty for feedback !i thot the rotary didnt have the oil channel in the rotor.

#120

4th string e-armchair QB

iTrader: (11)

Joined: May 2005

Posts: 2,745

Likes: 0

From: North Bay, Ontario

epic first posts... People blow their engines for many different reasons, just like piston engines. Some are oil failures (bearing), some are seal failures, some get so carboned up that they get stuck seals and lose compression, and some people push the physical limits of the block and crack plates. Not every engine that blows is due to the same failure.

All in all, it has a lot to do with voodoo.

All in all, it has a lot to do with voodoo.

#123

I realize it hasn't been mentioned by Mazda at all, but if they get into a power contest with the domestic V6/V8 crowd, instead of going turbo they could make a 24X. How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

#124

I realize it hasn't been mentioned by Mazda at all, but if they get into a power contest with the domestic V6/V8 crowd, instead of going turbo they could make a 24X. How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.

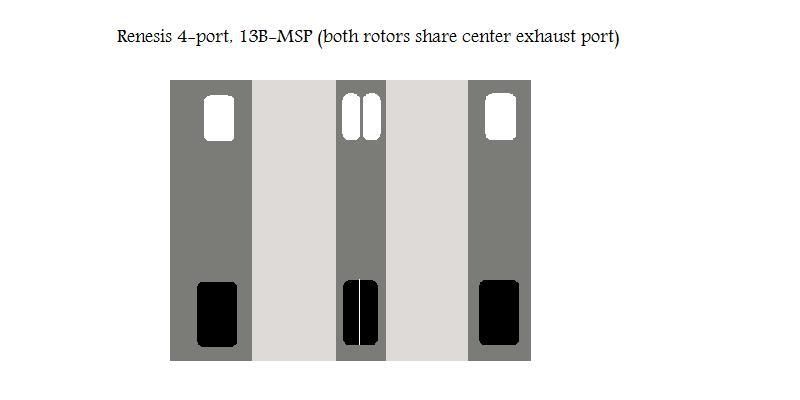

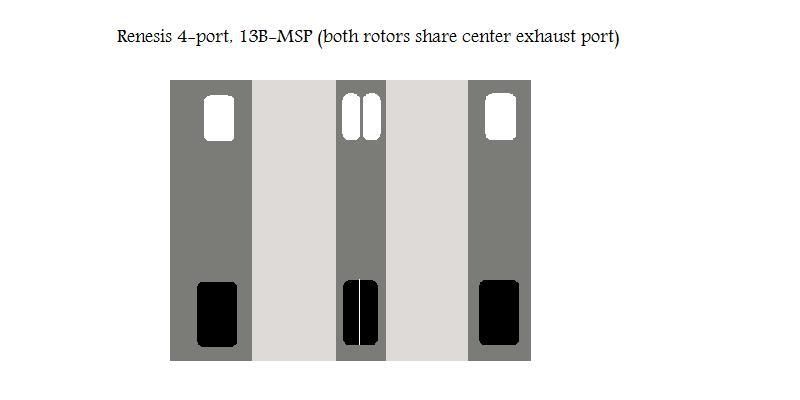

How much R&D does it take to slap on a third rotor? And since the rotors are slightly narrower, there's less of a problem with overall length.The Mutli-Side-Port design of the 13B-MSP (Renesis) with it's shared center exhaust port, doesn't lend itself to a triple rotor design, it baically requires rotor to be in pairs.

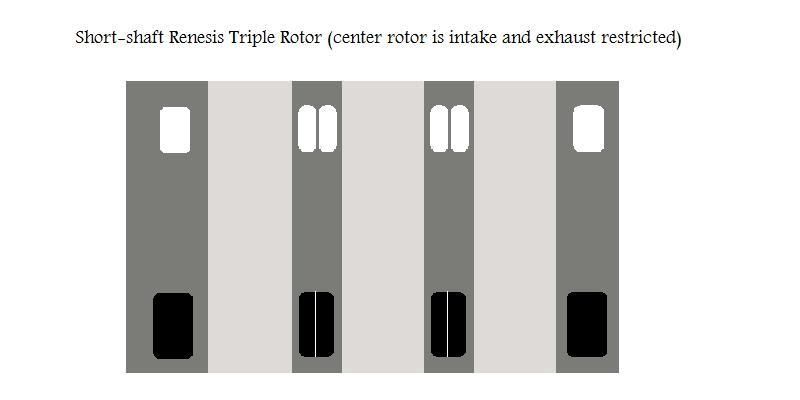

I know there are plenty of people here that know more about rotary engines than me, but here is a explaination of why a triple rotor renesis engine is a bad idea.

(complete with slapped together paint images to help).

This is the intake and exhaust port layout of a 13B-MSP (renesis) engine, I used a 4 port just to make life simplier, a 6 port only makes things worse in a triple rotor setup.

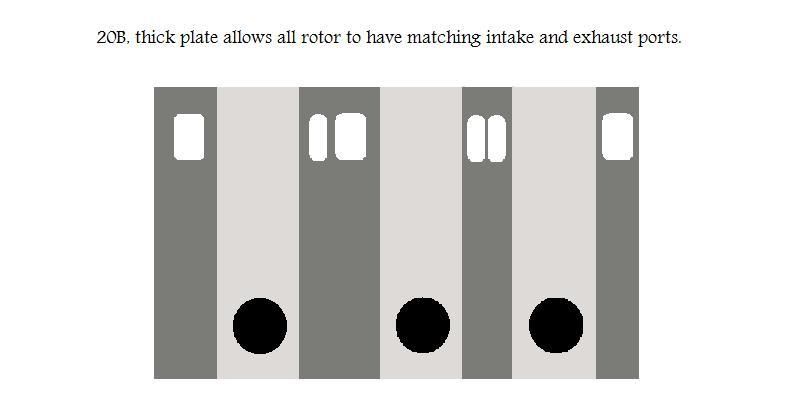

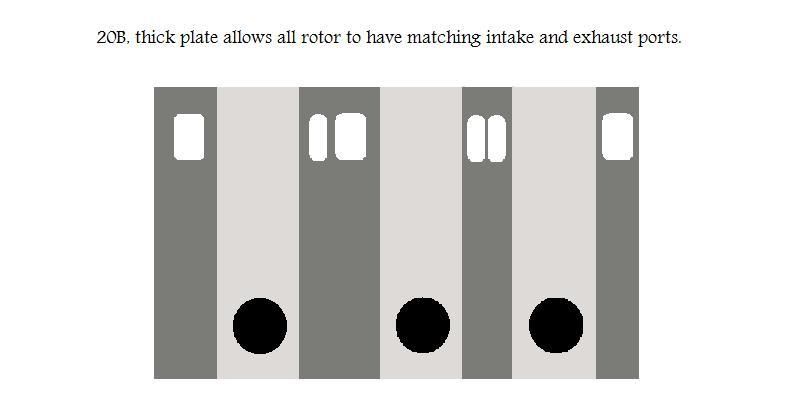

Below is the intake and exhaust port setup of a factory 20B triple rotor.

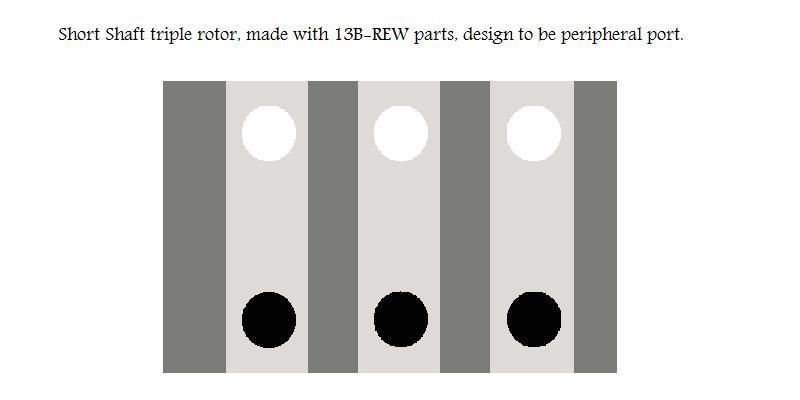

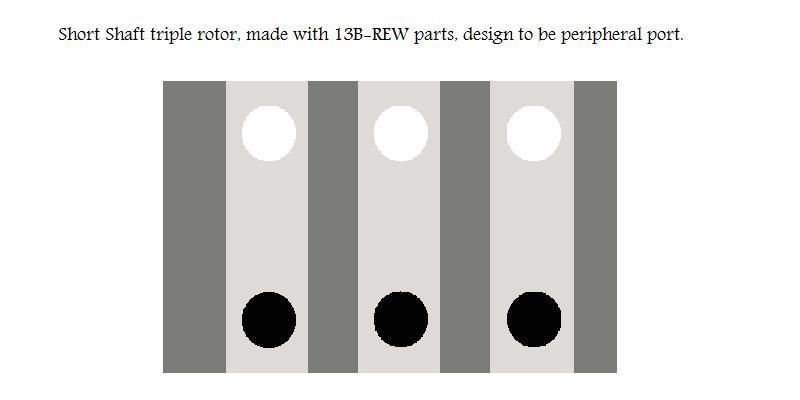

Now on to the fun stuff, with is the port layout of a short shaft triple rotor. note: this is a peripheral port engine, as retaining the side intake ports would leave the center rotor with less intake port area than the front and rear rotors.

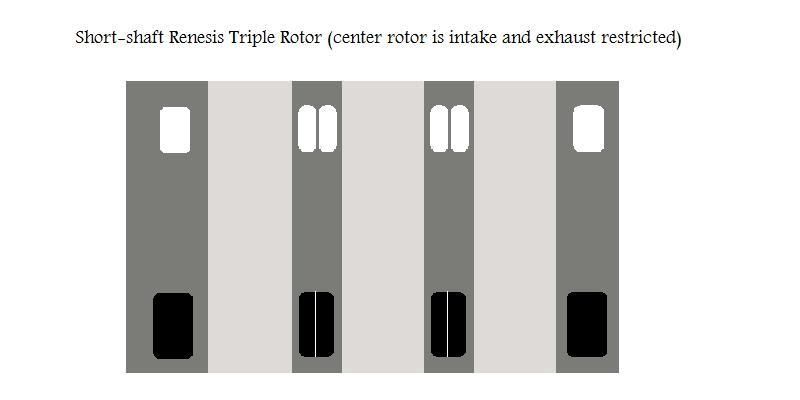

Now for the ugly, this is a short shaft, renesis triple rotor, problem is the center rotor only has to smaller primary intake ports and two smaller secondary exhaust ports, so very restricted in both areas.

This design has been done, and I'm impressed that they made it work, but it still an example of how not to build a rotor engine in my book.

From looking at the image it appears they balanced the intake ports, by only used the primary and secondary but not the auxiliary ports in the front & rear housings of a 6 port renesis, and then they likely heavily ported the both primary ports leading to the center rotor to make up for that rotors lack of a larger secondary port. The Y shaped intakes and ITB are also probably there to make sure that all three rotors have a balanced air intake, a plenom setup would almost certainly result in a major inbalance in the air intake across the three rotors with this design.

For the exhaust I guess they ported the secondary exhaust ports either side of the center rotor to try and balance the exhaust ports across the whole engine, but I expect the center rotor is still exhaust restricted when compared to the other two rotors, also the shared secondary exhaust port of a renesis are design for rotors 180deg out of sinc, not the 120deg of seperation of a triple rotor e-shaft, so I expect there may be issues with the exhaust pulses passing bewteen rotors.

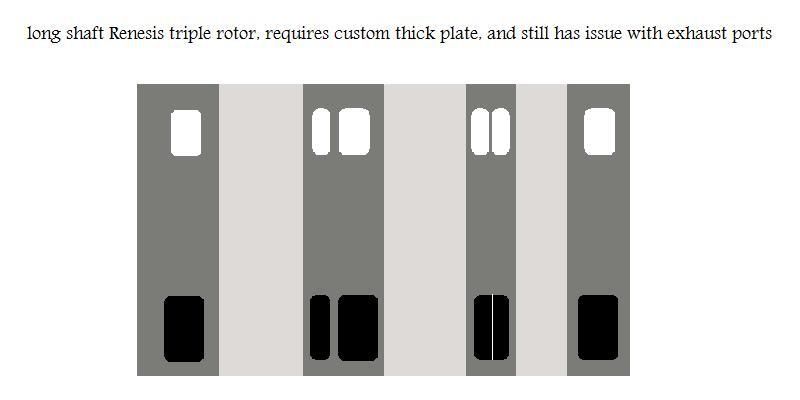

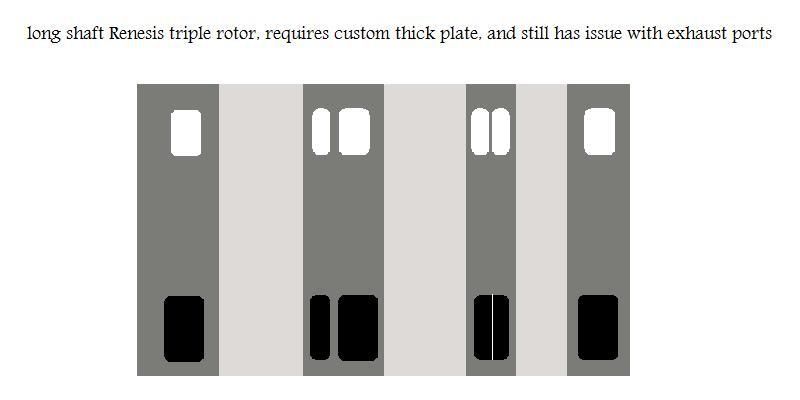

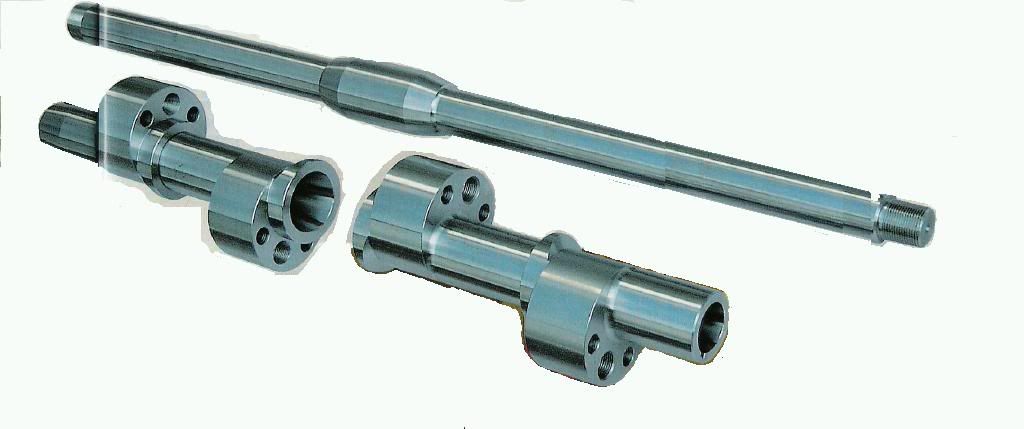

Final there is the expensive option, this is a triple rotor renesis engine layout using a 20b e-shaft, and a custom made thick center plate.

Problem here is one cost, you need to have a custom thinck center plate made that has both side intake and exhaust ports, this would have to be designed from scratch and then either made using a very complex cast or as two cnc billet items that sandwedge together to make a single plate, this is the only way to retain the internal water passages. the second issue is while this solve the intake port issue the same way the stock 20b engine does, it doesn't solve the problem of the miss-matched number of secondary exhaust ports and the 120deg exhaust pulse issue.

A quad rotor regesis engine could work and is more pratical if your going to spend the kind of money needed to produce the option above, but the problem is with the need for a custom center plate around 4" thick to house two secondary intake ports and two primary exhaust ports such an engine would need, it would end up being almost 3" longer than the current batch of peripheral port quad rotors.

I sure others will have a different take on what I've said, but basically a triple rotor MSP rotary is a bad idea, possible to build but in no way is a pratical option.

I know there are plenty of people here that know more about rotary engines than me, but here is a explaination of why a triple rotor renesis engine is a bad idea.

(complete with slapped together paint images to help).

This is the intake and exhaust port layout of a 13B-MSP (renesis) engine, I used a 4 port just to make life simplier, a 6 port only makes things worse in a triple rotor setup.

Below is the intake and exhaust port setup of a factory 20B triple rotor.

Now on to the fun stuff, with is the port layout of a short shaft triple rotor. note: this is a peripheral port engine, as retaining the side intake ports would leave the center rotor with less intake port area than the front and rear rotors.

Now for the ugly, this is a short shaft, renesis triple rotor, problem is the center rotor only has to smaller primary intake ports and two smaller secondary exhaust ports, so very restricted in both areas.

This design has been done, and I'm impressed that they made it work, but it still an example of how not to build a rotor engine in my book.

From looking at the image it appears they balanced the intake ports, by only used the primary and secondary but not the auxiliary ports in the front & rear housings of a 6 port renesis, and then they likely heavily ported the both primary ports leading to the center rotor to make up for that rotors lack of a larger secondary port. The Y shaped intakes and ITB are also probably there to make sure that all three rotors have a balanced air intake, a plenom setup would almost certainly result in a major inbalance in the air intake across the three rotors with this design.

For the exhaust I guess they ported the secondary exhaust ports either side of the center rotor to try and balance the exhaust ports across the whole engine, but I expect the center rotor is still exhaust restricted when compared to the other two rotors, also the shared secondary exhaust port of a renesis are design for rotors 180deg out of sinc, not the 120deg of seperation of a triple rotor e-shaft, so I expect there may be issues with the exhaust pulses passing bewteen rotors.

Final there is the expensive option, this is a triple rotor renesis engine layout using a 20b e-shaft, and a custom made thick center plate.

Problem here is one cost, you need to have a custom thinck center plate made that has both side intake and exhaust ports, this would have to be designed from scratch and then either made using a very complex cast or as two cnc billet items that sandwedge together to make a single plate, this is the only way to retain the internal water passages. the second issue is while this solve the intake port issue the same way the stock 20b engine does, it doesn't solve the problem of the miss-matched number of secondary exhaust ports and the 120deg exhaust pulse issue.

A quad rotor regesis engine could work and is more pratical if your going to spend the kind of money needed to produce the option above, but the problem is with the need for a custom center plate around 4" thick to house two secondary intake ports and two primary exhaust ports such an engine would need, it would end up being almost 3" longer than the current batch of peripheral port quad rotors.

I sure others will have a different take on what I've said, but basically a triple rotor MSP rotary is a bad idea, possible to build but in no way is a pratical option.

The 16X with it's thinner 70mm rotors also opens the door to a truely streetable quad rotor engine, a 32X would need a custom 4" center plate and center bearing 3 peice e-shaft, but would only be about a 1" longer than a peripheral port quad rotor, but without the noise, weight and idling issues.

A naturally aspirated 32X engine would offer up a light (Probably not much more than a 13-REW including turbos & stock manifold), powerful (a good guess would be 500-600 BHP), high torgue (four rotors and the larger rotor radius will do that for you), relatively fuel efficient for an engine of it size and power (a 600HP 3.2litre rotary is never going to go easy on the gas bill), option for those that want more power without the weight, complexity, and reliablity issues of a traditional big HP rotary engine.

I look forward to seeing the day this is possible.

A naturally aspirated 32X engine would offer up a light (Probably not much more than a 13-REW including turbos & stock manifold), powerful (a good guess would be 500-600 BHP), high torgue (four rotors and the larger rotor radius will do that for you), relatively fuel efficient for an engine of it size and power (a 600HP 3.2litre rotary is never going to go easy on the gas bill), option for those that want more power without the weight, complexity, and reliablity issues of a traditional big HP rotary engine.

I look forward to seeing the day this is possible.