Crankcase ventilation - exhaust?

#1

Crankcase ventilation - exhaust?

I never really liked the oily film on everything when using turbo inlet for crankcase ventilation. Not sold on a can, vented can or breather..

In search of a more elegant solution, I came across a few setups that vent into the exhaust rather than the intake. It sounds like depending on the design and dump location, you can get some fairly effective vacuum.

Aside from additional emissions, what would the drawbacks be? I'm hard pressed to think of any. Has anyone tried this on a rotary?

Seems like it could be tested without any major or irreversible modifications. So... before I go out and try it, tell me why I shouldn't!

Thanks,

Alex

In search of a more elegant solution, I came across a few setups that vent into the exhaust rather than the intake. It sounds like depending on the design and dump location, you can get some fairly effective vacuum.

Aside from additional emissions, what would the drawbacks be? I'm hard pressed to think of any. Has anyone tried this on a rotary?

Seems like it could be tested without any major or irreversible modifications. So... before I go out and try it, tell me why I shouldn't!

Thanks,

Alex

#2

Friend vented his Honda's catch can with exhaust scavenge.

Worked very well for crankcase evacuation, just more Blue smoke on throttle as the only negative.

_________

For my rotary I found a well baffled oil pan precludes needing to drain catch can overflow anywhere. It was only when I had oil sloshing up the oil fill neck on cornering the catch can would fill quickly.

On my FC I used the Mazda Competition oil pan which was a stock pan as a base with big flat sides brazed on for 7qt capacity and less slosh. To this I tack welded in a baffle plate on top as I hated having 2 sealing surfaces to leak when using the RB baffle sandwich plate.

On the FD I used the Bacon/Winchester Fabrication trap door oil pan.

Worked very well for crankcase evacuation, just more Blue smoke on throttle as the only negative.

_________

For my rotary I found a well baffled oil pan precludes needing to drain catch can overflow anywhere. It was only when I had oil sloshing up the oil fill neck on cornering the catch can would fill quickly.

On my FC I used the Mazda Competition oil pan which was a stock pan as a base with big flat sides brazed on for 7qt capacity and less slosh. To this I tack welded in a baffle plate on top as I hated having 2 sealing surfaces to leak when using the RB baffle sandwich plate.

On the FD I used the Bacon/Winchester Fabrication trap door oil pan.

#3

Arrogant Wankeler

The crank breather on my diesel utility is now through a catch can to a downstream facing spike post cat. Seems to work, will probably do something similar for the rx7 when the engine bay is redone.

The following users liked this post:

neit_jnf (09-27-22)

#7

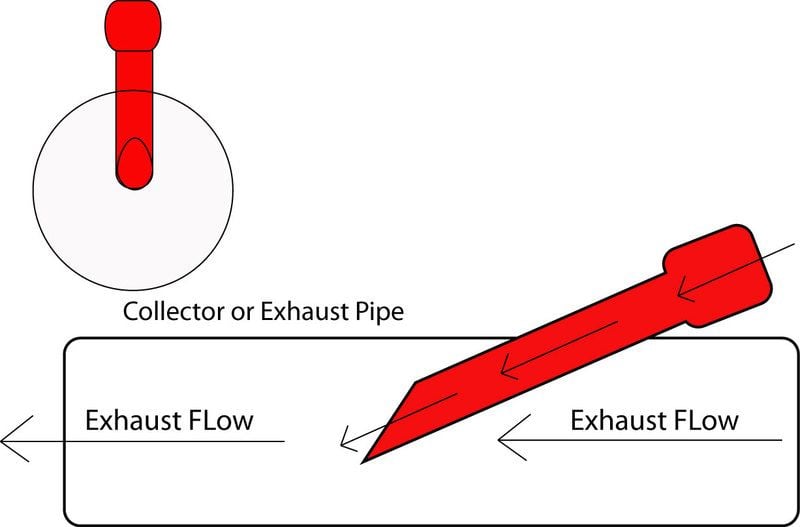

it doesn’t have to be angled; it can be vertical with a 45-60 deg angle cut on the backside

or you can reverse the angle cut to the front side into the flow to create a pressure source as well. Though that could be tricky with an 1800°F exhaust stream. RC airplane engines do that to pressurize the fuel tank for feeding fuel to the engine. Which used methanol, nitro, and castor oil back when I was 10 years old and learned all that, odd coincidence 🤔

.

or you can reverse the angle cut to the front side into the flow to create a pressure source as well. Though that could be tricky with an 1800°F exhaust stream. RC airplane engines do that to pressurize the fuel tank for feeding fuel to the engine. Which used methanol, nitro, and castor oil back when I was 10 years old and learned all that, odd coincidence 🤔

.

The following 2 users liked this post by TeamRX8:

KNONFS (09-28-22),

Relisys190 (10-20-22)

Trending Topics

#8

Sounds like this is worth trying! I just wonder if this is going to cause popping, flames, or have an undesirable effect on the exhaust sound.

I suspect I want an in line check valve? or should I just use a PCV valve? Seems like that would be helpful to make this all safe-ish.

I'll probably try to dump as far downstream as possible.

I suspect I want an in line check valve? or should I just use a PCV valve? Seems like that would be helpful to make this all safe-ish.

I'll probably try to dump as far downstream as possible.

#9

Usually exhaust scavenged positive crankcase pressure kits have a big metal checkvalve included.

Yes, an exhaust leak (and this will be one with the benefit of fuel vapors included) is the best way to get flames on decel with a rotary.

Plumbing will be easier the closer it is to the engine, what has you thinking further downstream is better?

Yes, an exhaust leak (and this will be one with the benefit of fuel vapors included) is the best way to get flames on decel with a rotary.

Plumbing will be easier the closer it is to the engine, what has you thinking further downstream is better?

#10

I had no idea you could buy a kit, haha. Cheap too! That makes things a bit easier.

I guess I figured further downstream would be better for longevity of the scavenge tube, less heat transfer, and obviously less chance of skewed O2 readings.

Conversely, dumping closer to the engine may do a better job of burning / vaporizing whatever passes through? Maybe I'll just go 10-12" past the O2 sensor.

I guess I figured further downstream would be better for longevity of the scavenge tube, less heat transfer, and obviously less chance of skewed O2 readings.

Conversely, dumping closer to the engine may do a better job of burning / vaporizing whatever passes through? Maybe I'll just go 10-12" past the O2 sensor.

#11

Arrogant Wankeler

Usually exhaust scavenged positive crankcase pressure kits have a big metal checkvalve included.

Yes, an exhaust leak (and this will be one with the benefit of fuel vapors included) is the best way to get flames on decel with a rotary.

Plumbing will be easier the closer it is to the engine, what has you thinking further downstream is better?

Yes, an exhaust leak (and this will be one with the benefit of fuel vapors included) is the best way to get flames on decel with a rotary.

Plumbing will be easier the closer it is to the engine, what has you thinking further downstream is better?

Placement to avoid contamination of wideband and catalyst would be my priority. Even very rich or lean cruise exhaust temps on a rotary will make crankcase gas meaningless relative to poor combustion.

Last edited by Slides; 10-03-22 at 03:24 AM.

#12

Big thanks to all who have replied. I feel like I have learned a ton here in the past few months, which is saying a lot considering I've been browsing a looong time.

Lots of great discussions and new topics lately, which is fantastic for a platform that is at minimum two decades old. Hats off to everyone who is still sharing their tricks and the continued improvement of these beautiful old machines. You are what make this community so special!

Alex

Lots of great discussions and new topics lately, which is fantastic for a platform that is at minimum two decades old. Hats off to everyone who is still sharing their tricks and the continued improvement of these beautiful old machines. You are what make this community so special!

Alex

#13

I have removed my crankcase catchcan and lit it on fire to flash the vapors off several times. If it smells like gas...

But, that is what remains in the catch can.

It is possible that as you say the gasses that were not oil soluble (nitrogen/oxides of) are abundent enough in the crankcase vapors to be a flame retardent.

If that is the case, the carbon introduced into the exhaust through the crankcase evacuation is more likely the source of enhanced decel "exhaust" ignition then.

But, that is what remains in the catch can.

It is possible that as you say the gasses that were not oil soluble (nitrogen/oxides of) are abundent enough in the crankcase vapors to be a flame retardent.

If that is the case, the carbon introduced into the exhaust through the crankcase evacuation is more likely the source of enhanced decel "exhaust" ignition then.

The following users liked this post:

j9fd3s (10-03-22)

Thread

Thread Starter

Forum

Replies

Last Post

KiyoKix

2nd Generation Specific (1986-1992)

21

10-22-02 03:00 AM