Another 4 rotor build

#54

Hehe u need to get your car finished first. Right now it's not even a rolling shell :P

But im going there next august i belive. Going with some freinds, if i can afford it though. With how the stock market is going these days i might be out of a jobb next year. But i hope not :P

Im not even sure i dare drive the rex on the ring. It's going to be a beast on that track.

JT

But im going there next august i belive. Going with some freinds, if i can afford it though. With how the stock market is going these days i might be out of a jobb next year. But i hope not :P

Im not even sure i dare drive the rex on the ring. It's going to be a beast on that track.

JT

#55

Hehe u need to get your car finished first. Right now it's not even a rolling shell :P

But im going there next august i belive. Going with some freinds, if i can afford it though. With how the stock market is going these days i might be out of a jobb next year. But i hope not :P

Im not even sure i dare drive the rex on the ring. It's going to be a beast on that track.

JT

But im going there next august i belive. Going with some freinds, if i can afford it though. With how the stock market is going these days i might be out of a jobb next year. But i hope not :P

Im not even sure i dare drive the rex on the ring. It's going to be a beast on that track.

JT

Yes it`s going way to slow...

Sendt the prints of the fuelcell to Safe motorsport today, so hope this is sorted until I get back from work..

Would be fun to try the Ring anyway..

#57

Got some pics today from Green Brothers in New Zealand who is sourcing out all the parts for me, and doing some mods to the parts

This is just pure engine picture ****

The estimated time on shipping is about 5 weeks from now. Then it's ready to be asembled in england

JT

This is just pure engine picture ****

The estimated time on shipping is about 5 weeks from now. Then it's ready to be asembled in england

JT

Last edited by jantore; 10-24-08 at 07:45 AM.

#59

Interesting jacket mod, it appears they've just ported out an area in the jacket unlike the traditional grooves, as well as cut a bit on the inside of the tension bolt lands....Any more info on the whys of that vs. grooving?

Looks great BTW The machine work on the rotors, the side port filling all look absolutely top drawer.

The machine work on the rotors, the side port filling all look absolutely top drawer.

Looks great BTW

The machine work on the rotors, the side port filling all look absolutely top drawer.

The machine work on the rotors, the side port filling all look absolutely top drawer.

#60

Richard who owns and runs Green Brothers in NZ has his own way of doing the water jacket mods. And according to him this helps alot along with an electrical waterpump system. And as i will be running NA the heat around the spark plug hole won't get so bad.

But what i have seen so far of his work is top notch. The engine will get the P ports made in england after the engine builder/tuners specs on the way he likes them. So they will be made in the UK.

JT

But what i have seen so far of his work is top notch. The engine will get the P ports made in england after the engine builder/tuners specs on the way he likes them. So they will be made in the UK.

JT

#61

#63

I have one (probably stupid) question. It appears from the photos that the filled sideports are not flush with the surface of the iron, is there a reason for that? Just wondering.

#64

the filled sideports are not flush with the surface of the iron

The thin filler material at the meniscus can flex more easily than the whole of volume of the intake runner of filler and if the sideseals don't touch it they can't wear it down

#66

JT

#67

Interesting jacket mod, it appears they've just ported out an area in the jacket unlike the traditional grooves, as well as cut a bit on the inside of the tension bolt lands....Any more info on the whys of that vs. grooving?

Looks great BTW The machine work on the rotors, the side port filling all look absolutely top drawer.

The machine work on the rotors, the side port filling all look absolutely top drawer.

Looks great BTW

The machine work on the rotors, the side port filling all look absolutely top drawer.

The machine work on the rotors, the side port filling all look absolutely top drawer.-J

#70

Besides im moving the engine back as well about 6" so that will put the front plate just over the stearing rack. So the weight distrobution will be ok, and the car will weigh bellow 1200kg anyway, and that is more then eough. With the carbon doors the car will drop bellow 1150kg and that's light enough.

Lasse

No extra doweling will be don. But the stock dowels on one side will be replaced by a full engine length dowel. And the engine will not be turboed, so not expecting any twisting. And i will also have a pretty thick dry sump pan as well that will support the engine. And also 4 engine mounts, i will use "stock" FD style engine mounts in the rear and fabricate new ones for the front.

JT

#71

I wish I was driving!

Joined: Dec 2001

Posts: 5,241

Likes: 84

From: BC, Canada

That is done so that flakes of filler material don't mess up the engine as the sideseals drag across the surface and/or material cracks away from the port edge with differential expansion in heat cycles.

The thin filler material at the meniscus can flex more easily than the whole of volume of the intake runner of filler and if the sideseals don't touch it they can't wear it down

The thin filler material at the meniscus can flex more easily than the whole of volume of the intake runner of filler and if the sideseals don't touch it they can't wear it down

The rotors have a machined blowby gas groove that allows transfer of the built up blowby gas into the intake port, where it can be mixed with the intake charge and consumed by the engine. The recess still allows this process to take place.

#72

I see Jantore. Don,t know if i am right but wouldn't it be wise to have some extra dowels becausse of the lenghth of the engine? I mean the the dry sump pan does no good strengten the engine combustionable so to speak? Of course you have tension bolts from both sides and may be bigger ones. But think if you will like to tune with methanol in the futurere 800 hp N/A is a big deal for the stock dovel pins. "Just my hard earned Swedish kronor" Any way nice to hear the engine program is goin!

/Lasse

/Lasse

#73

I see Jantore. Don,t know if i am right but wouldn't it be wise to have some extra dowels becausse of the lenghth of the engine? I mean the the dry sump pan does no good strengten the engine combustionable so to speak? Of course you have tension bolts from both sides and may be bigger ones. But think if you will like to tune with methanol in the futurere 800 hp N/A is a big deal for the stock dovel pins. "Just my hard earned Swedish kronor" Any way nice to hear the engine program is goin!

/Lasse

/Lasse

And they do run this engine in NZ and Australia with just the full engine length tension bolts. But they are made of a diffrent material then the stock mazda ones. If i had gone turbo i would have had to gone the 12.7mm stud kit they make to get it rigid enough. And maybe add some steel on the side of the engine to keep it together.

Only about 3 more weeks now untill the 4 rotor kit is finished and it's ready to ship out to england

JT

#74

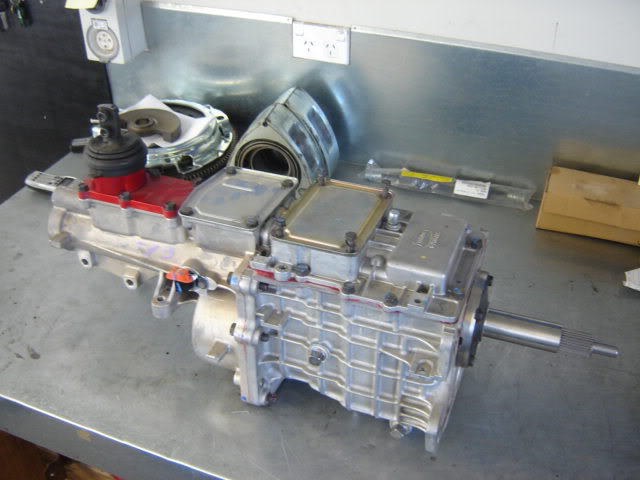

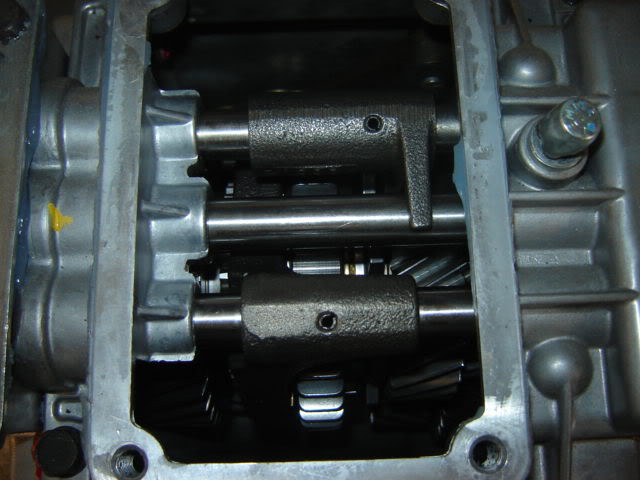

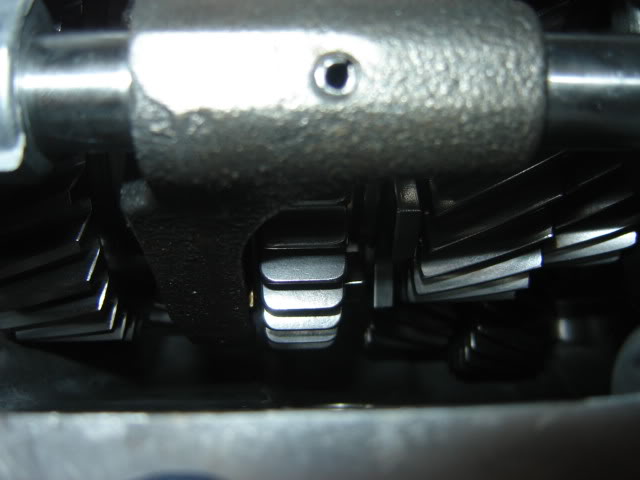

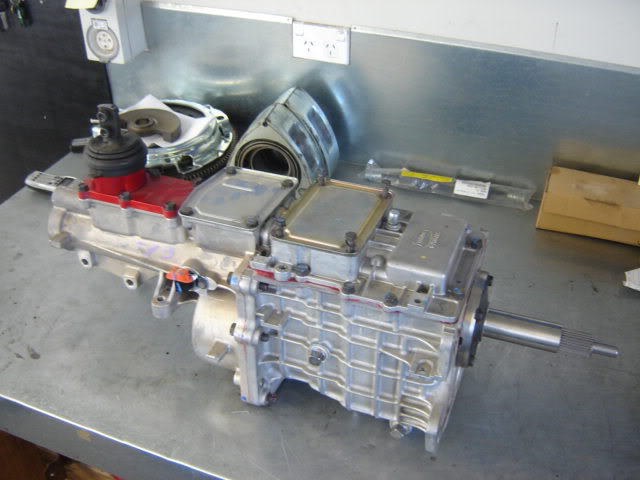

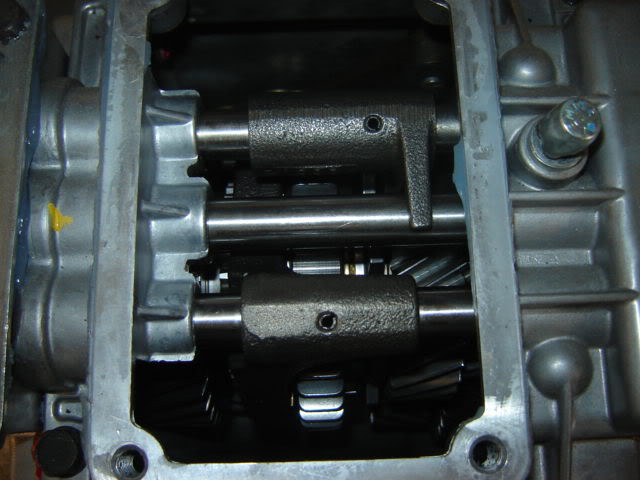

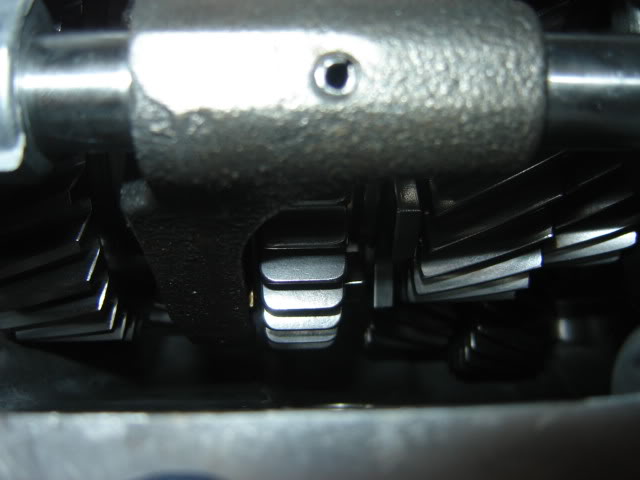

So i got some pictures of the transmission i will be using. It's a Libertys Gears modified Tremec TKO600. It's been modified to also have dog engagement on 1st and 5th as well, not just 2nd-4th. It's been surface enhanced and face plated to handle more rpms.

Now it's just about 1 more week untill the kit is finished by Jeff Bruce and it will be almost ready for shipment to england

JT

Now it's just about 1 more week untill the kit is finished by Jeff Bruce and it will be almost ready for shipment to england

JT