3 Spark plugs per rotor

#1

3 Spark plugs per rotor

Hi Everyone,

I've been doing some research as im looking to build a N/A 13b pp with as much power as possible. My question is, has anybody tried/seen a rotor with 3 spark plugs per housing besides the R26B? Im interested to see how they have done it and if there were any gains in power etc?

I've read up about it on the 26B and it seems like it was a major factor for their motor and the power they produced, and also the fuel conspution used.

Cheers

I've been doing some research as im looking to build a N/A 13b pp with as much power as possible. My question is, has anybody tried/seen a rotor with 3 spark plugs per housing besides the R26B? Im interested to see how they have done it and if there were any gains in power etc?

I've read up about it on the 26B and it seems like it was a major factor for their motor and the power they produced, and also the fuel conspution used.

Cheers

#3

It's my understanding that an extra sparkplug won't do anything significant. In fact, the main reason trailing sparkplugs are used on our cars is to clean up emissions and to give a very, very modest improvement in fuel economy. I don't think another plug on top of that would pose any real benefit, but I'd like to hear what the experts have to say.

#5

Trending Topics

#8

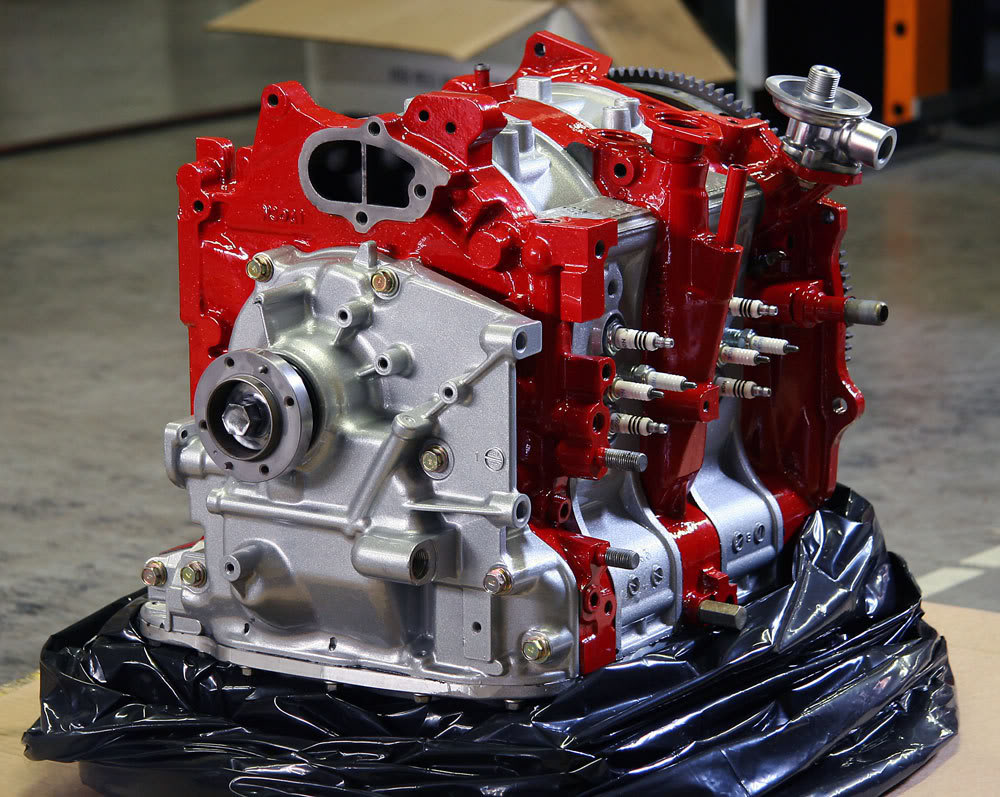

I believe Rotary God was specifically referring to the picture that was posted....

As for the "far trailing" plug that was used on the 787, I believe it was to ignite a last little bit of the fuel mixture that was actually in a "squish" area due to the compression that they were running, and the shape of the rotor compared to the housing. According to the technical paper it made a 2% increase in torque between 4.5k and 8k rpm. and about a 3% better BFC than the usual 2 plug design...

I have not seen it done, but if i were to try.... I would make a hole very much like the trailing plug hole so as to minimize compression loss across the apex seal... The hard part in my eyes would probably be figuring out when to fire it exactly, and how to trigger the extra spark when you do know the ideal timing....

just my .02

- Chris

As for the "far trailing" plug that was used on the 787, I believe it was to ignite a last little bit of the fuel mixture that was actually in a "squish" area due to the compression that they were running, and the shape of the rotor compared to the housing. According to the technical paper it made a 2% increase in torque between 4.5k and 8k rpm. and about a 3% better BFC than the usual 2 plug design...

I have not seen it done, but if i were to try.... I would make a hole very much like the trailing plug hole so as to minimize compression loss across the apex seal... The hard part in my eyes would probably be figuring out when to fire it exactly, and how to trigger the extra spark when you do know the ideal timing....

just my .02

- Chris

#9

I have a RE Magazine. The main feature is a cross port 3 sparkplug 13b. I cant read japanese so I dont know the important things being said. I know the engine is PP n/a and make alot of power. If I can scan pics I will post them.

#10

It's my understanding that an extra sparkplug won't do anything significant. In fact, the main reason trailing sparkplugs are used on our cars is to clean up emissions and to give a very, very modest improvement in fuel economy. I don't think another plug on top of that would pose any real benefit, but I'd like to hear what the experts have to say.

The idea of a "Far Trailing Plug" works well, obviously it's been proven.

On a Turbo engine, the higher combustion pressures require timing to be pulled out as the cylinder pressure (boost) increases. At any decent boos, the Timing requirements are very conservative, specially the Trailing timing. So much so that at 17 to 20 psi+ the engine gets happy when the Trailing is set at about TDC.

As the boost further increases, the Trailing must be retarded even further up to sometimes 6 degrees ATDC. This would place the Far Trailing plug OUTSIDE the physical constraints of the working chamber. On NA PP. Race engines, the plugs fire at about 20 degrees BTDC. and the Far "T" plug fires even before that in an effort to move the bulk of the mixture into the Leading side the chamber were it pushes on the Rotor. Flame Propagation, and Gas Transfer Velocity are issues that is always present, simply it must be managed other wise they will bite You.

Here is how you control it...

http://www.pertronix.com/prod/ig/strike/default.aspx

#12

#13

I like the second strike idea... If I had a better position to do some testing I would definitely be down to try that system and see what kind of gains one could get from it...

I am interested in quantified results...

I am interested in quantified results...

#14

Right from WIKI

"The trailing side of the rotary engine's combustion chamber develops a squeeze stream which pushes back the flamefront. With the conventional two-spark-plug or one-spark-plug system and homogenous mixture, this squeeze stream prevents the flame from propagating to the combustion chamber's trailing side in the mid and high engine speed ranges. This is why there can be more carbon monoxide and unburnt hydrocarbons in a Wankel's exhaust stream. A side port exhaust, as is used in the Mazda Renesis, avoids this because the unburned mixture cannot escape. The Mazda 26B avoided this issue through a 3-spark plug ignition system. (As a result, at the Le Mans 24 hour endurance race in 1991, the 26B had significantly lower fuel consumption than the competing reciprocating piston engines. All competitors had only the same amount of fuel available, because of the Le Mans 24h limited fuel quantity rule.[20])"

Not sure how reliable this is but hope it helps

"The trailing side of the rotary engine's combustion chamber develops a squeeze stream which pushes back the flamefront. With the conventional two-spark-plug or one-spark-plug system and homogenous mixture, this squeeze stream prevents the flame from propagating to the combustion chamber's trailing side in the mid and high engine speed ranges. This is why there can be more carbon monoxide and unburnt hydrocarbons in a Wankel's exhaust stream. A side port exhaust, as is used in the Mazda Renesis, avoids this because the unburned mixture cannot escape. The Mazda 26B avoided this issue through a 3-spark plug ignition system. (As a result, at the Le Mans 24 hour endurance race in 1991, the 26B had significantly lower fuel consumption than the competing reciprocating piston engines. All competitors had only the same amount of fuel available, because of the Le Mans 24h limited fuel quantity rule.[20])"

Not sure how reliable this is but hope it helps

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 05:40 PM