Power FC Any new info on the high impedance injector front? Question about sizing?

#1

Any new info on the high impedance injector front? Question about sizing?

Where do we stand with these injectors and how do they compare with the Injector Dynamics?

Are there any other sources for high impedance injectors to consider?

http://www.fiveomotorsport.com/produ...?p=055IMP1000X

http://www.fiveomotorsport.com/produ...p=0426IMP2000X

part numbers:

0426IMP2000X

055IMP1000X

Can anyone comment on how people should* be sizing their injectors, by flow rate proportionally Primary VS Secondary, assuming there is a fairly solidified consensus answer to this? Did the 550/850 combination have any significance on the stock system?

If a person knows their desired power range and has reached a point where changes to a system are minimized, are there advantages to selecting components that meet the requirements (with a reasonable SF of course) of a engine and power level?

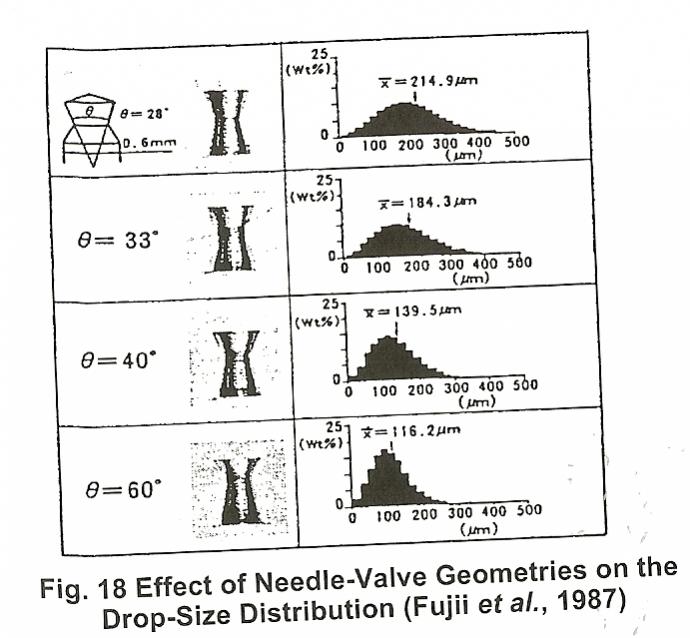

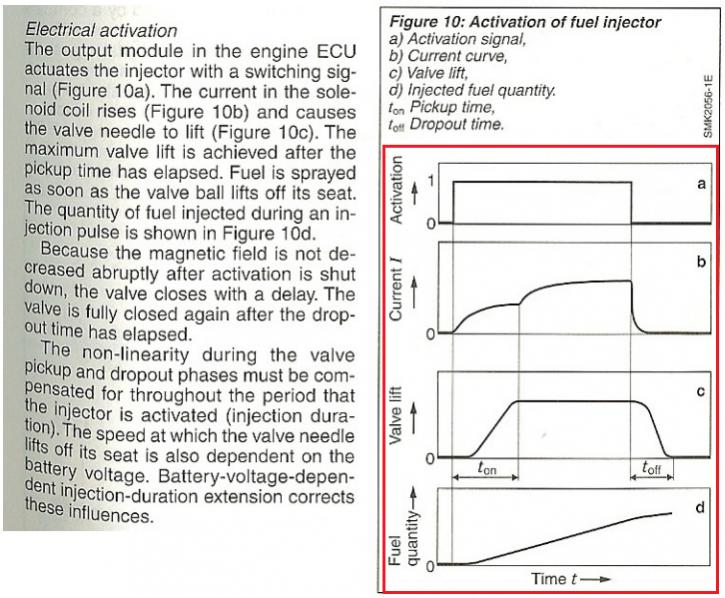

Are smaller injectors really the way to go to be able to attain good/optimal precession control in the idle range? Is there typically a duty cycle/range that should be maintained to supply the best spray patterns and control of the injector?

What is the ideology we are trying to accomplish rather than just bigger is better when it comes to injectors and hopeful taking into account a specific system and power level?

Hypothetically if you knew your HP goal was 400 hp and you knew the supporting equipment would not change and was without issue of capability to support the requirements needed to drive injectors, what would be the optimal injector sizing that one would choose knowing the primary goal was drivability and no further power needs were to be desired?

Is there any sense to size injectors to power needs rather than just throwing common flowrates at a system and then dealing with the issues?

TIA

Are there any other sources for high impedance injectors to consider?

http://www.fiveomotorsport.com/produ...?p=055IMP1000X

http://www.fiveomotorsport.com/produ...p=0426IMP2000X

part numbers:

0426IMP2000X

055IMP1000X

Can anyone comment on how people should* be sizing their injectors, by flow rate proportionally Primary VS Secondary, assuming there is a fairly solidified consensus answer to this? Did the 550/850 combination have any significance on the stock system?

If a person knows their desired power range and has reached a point where changes to a system are minimized, are there advantages to selecting components that meet the requirements (with a reasonable SF of course) of a engine and power level?

Are smaller injectors really the way to go to be able to attain good/optimal precession control in the idle range? Is there typically a duty cycle/range that should be maintained to supply the best spray patterns and control of the injector?

What is the ideology we are trying to accomplish rather than just bigger is better when it comes to injectors and hopeful taking into account a specific system and power level?

Hypothetically if you knew your HP goal was 400 hp and you knew the supporting equipment would not change and was without issue of capability to support the requirements needed to drive injectors, what would be the optimal injector sizing that one would choose knowing the primary goal was drivability and no further power needs were to be desired?

Is there any sense to size injectors to power needs rather than just throwing common flowrates at a system and then dealing with the issues?

TIA

#2

Where do we stand with these injectors and how do they compare with the Injector Dynamics?

Are there any other sources for high impedance injectors to consider?

http://www.fiveomotorsport.com/produ...?p=055IMP1000X

http://www.fiveomotorsport.com/produ...p=0426IMP2000X

part numbers:

0426IMP2000X

055IMP1000Xp

Are there any other sources for high impedance injectors to consider?

http://www.fiveomotorsport.com/produ...?p=055IMP1000X

http://www.fiveomotorsport.com/produ...p=0426IMP2000X

part numbers:

0426IMP2000X

055IMP1000Xp

Can anyone comment on how people should* be sizing their injectors, by flow rate proportionally Primary VS Secondary, assuming there is a fairly solidified consensus answer to this? Did the 550/850 combination have any significance on the stock system?

If a person knows their desired power range and has reached a point where changes to a system are minimized, are there advantages to selecting components that meet the requirements (with a reasonable SF of course) of a engine and power level?

Are smaller injectors really the way to go to be able to attain good/optimal precession control in the idle range? Is there typically a duty cycle/range that should be maintained to supply the best spray patterns and control of the injector?

What is the ideology we are trying to accomplish rather than just bigger is better when it comes to injectors and hopeful taking into account a specific system and power level?

Hypothetically if you knew your HP goal was 400 hp and you knew the supporting equipment would not change and was without issue of capability to support the requirements needed to drive injectors, what would be the optimal injector sizing that one would choose knowing the primary goal was drivability and no further power needs were to be desired?

Don't reinvent the wheel when there's no need to. The reason why I say that in this situation is that the biggest obstacles are figuring out injector latency/deadtime settings and staging settings that work. If you pick something that everybody else has tried before, you have a starting point to minimize that hassle.

Is there any sense to size injectors to power needs rather than just throwing common flowrates at a system and then dealing with the issues?

Most of the "real science" behind fuel injector sizing and control has to do with emissions and that is not much of an issue in this application... the strictest California tailpipe tests are nowhere near as tough as what is required for EPA certification of a vehicle.

Thread

Thread Starter

Forum

Replies

Last Post

Frisky Arab

2nd Generation Specific (1986-1992)

13

08-18-15 05:30 PM