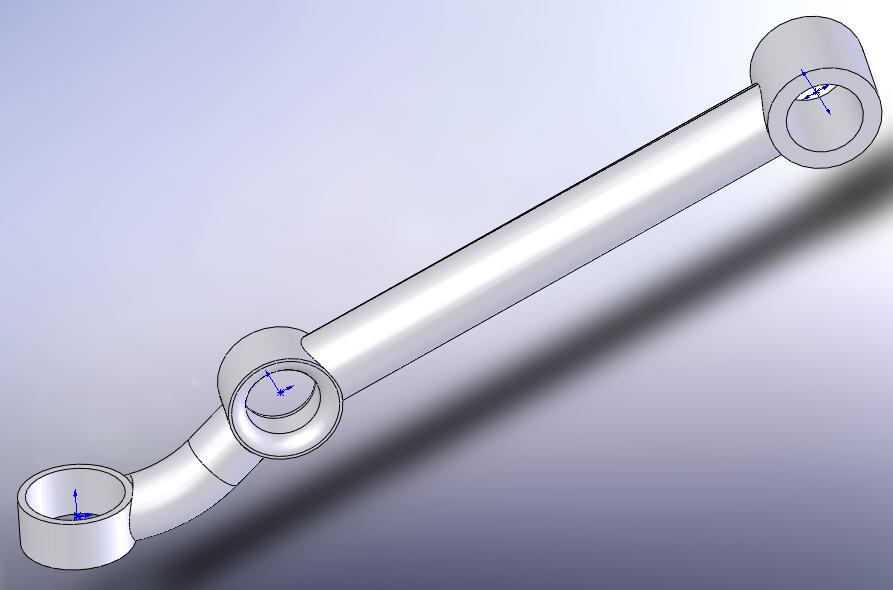

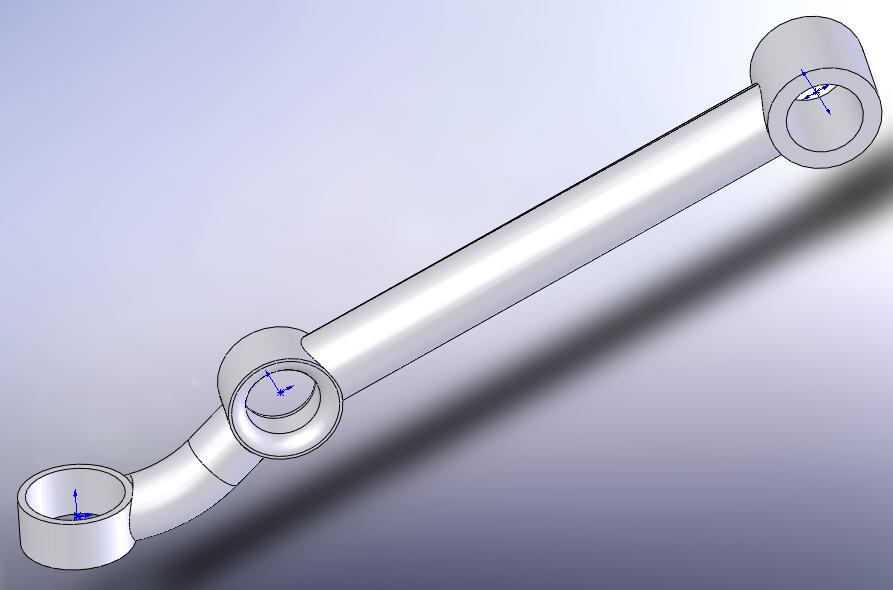

RX-2 / RX-3 Lower Control Arm teaser

#1

Thread Starter

Banned. I got OWNED!!!

iTrader: (3)

Joined: Nov 2001

Posts: 2,483

Likes: 1

From: London, Ontario

Well I think the design for the tubing of the arms finalized! Took a few tries to get it right where I want it, nothing like being at the shop till 2am! I just sent the Cad Files of the tubing to our CNC tube bending and notcher company for quotes and requesting one of each tube to be done for trial fitting.

I still need to finalize the other areas where the spherical bearing will be going (control arm to subframe bolt, tie rod, and possibly sway bar.)

Now from my understanding, the RX2 uses a thicker swaybar than the RX3. Can anyone verify for me what both sizes are so I know what bearing to work with?

Cheers!

I still need to finalize the other areas where the spherical bearing will be going (control arm to subframe bolt, tie rod, and possibly sway bar.)

Now from my understanding, the RX2 uses a thicker swaybar than the RX3. Can anyone verify for me what both sizes are so I know what bearing to work with?

Cheers!

#2

they very from 19-21 mm but that makes no difference in the eye diameter in the control arm

, just in the sway bar up to the point where it goes through the large washer and bush

as such the D shackle bushes up front have different ID

also ,, rx3 has similar front end to capella /616 but not rx2

the main difference is in the inside of the control arm to subframe bush

( beyond bumpstop flares on some later types )

the rx2 has a different inside diameter ,, and width to the 616 / rx3 type

the inside bush of the control arm in an rx2 mounts the main banana shaped crossmember facing rewards on a large OD trailing pin and is captive only at one end

( this banana crossmember suspension setup is also seen in STB /r100 )

and the capella 616/618 /rx3/808/929/rx4 etc all use a drilled crossmember with a through bolt that holds it captive at both ends inside the crossmember

rotary versions of these have the engine held by a seperate crossmember bolted under the sway bar holes

as a result there is detail change in the ID and width of the inner control arm bushing

, just in the sway bar up to the point where it goes through the large washer and bush

as such the D shackle bushes up front have different ID

also ,, rx3 has similar front end to capella /616 but not rx2

the main difference is in the inside of the control arm to subframe bush

( beyond bumpstop flares on some later types )

the rx2 has a different inside diameter ,, and width to the 616 / rx3 type

the inside bush of the control arm in an rx2 mounts the main banana shaped crossmember facing rewards on a large OD trailing pin and is captive only at one end

( this banana crossmember suspension setup is also seen in STB /r100 )

and the capella 616/618 /rx3/808/929/rx4 etc all use a drilled crossmember with a through bolt that holds it captive at both ends inside the crossmember

rotary versions of these have the engine held by a seperate crossmember bolted under the sway bar holes

as a result there is detail change in the ID and width of the inner control arm bushing

#3

Thread Starter

Banned. I got OWNED!!!

iTrader: (3)

Joined: Nov 2001

Posts: 2,483

Likes: 1

From: London, Ontario

I'm a little lost on what your trying to say here.

So you're saying the sway bar is the same thickness at the section where it bolts up in the control arm? Or are you just saying the OD of the bushing is the same but the ID varies?

The pictures that you show there, the one that has a "flat spot" on the top, what exactly is that off of? That is an RX-2 one correct?

Can somebody snap me some pictures of how it mounts on the RX2 subframe then?

So you're saying the sway bar is the same thickness at the section where it bolts up in the control arm? Or are you just saying the OD of the bushing is the same but the ID varies?

The pictures that you show there, the one that has a "flat spot" on the top, what exactly is that off of? That is an RX-2 one correct?

Can somebody snap me some pictures of how it mounts on the RX2 subframe then?

they very from 19-21 mm but that makes no difference in the eye diameter in the control arm

, just in the sway bar up to the point where it goes through the large washer and bush

as such the D shackle bushes up front have different ID

also ,, rx3 has similar front end to capella /616 but not rx2

the main difference is in the inside of the control arm to subframe bush

( beyond bumpstop flares on some later types )

the rx2 has a different inside diameter ,, and width to the 616 / rx3 type

the inside bush of the control arm in an rx2 mounts the main banana shaped crossmember facing rewards on a large OD trailing pin and is captive only at one end

( this banana crossmember suspension setup is also seen in STB /r100 )

and the capella 616/618 /rx3/808/929/rx4 etc all use a drilled crossmember with a through bolt that holds it captive at both ends inside the crossmember

rotary versions of these have the engine held by a seperate crossmember bolted under the sway bar holes

as a result there is detail change in the ID and width of the inner control arm bushing

, just in the sway bar up to the point where it goes through the large washer and bush

as such the D shackle bushes up front have different ID

also ,, rx3 has similar front end to capella /616 but not rx2

the main difference is in the inside of the control arm to subframe bush

( beyond bumpstop flares on some later types )

the rx2 has a different inside diameter ,, and width to the 616 / rx3 type

the inside bush of the control arm in an rx2 mounts the main banana shaped crossmember facing rewards on a large OD trailing pin and is captive only at one end

( this banana crossmember suspension setup is also seen in STB /r100 )

and the capella 616/618 /rx3/808/929/rx4 etc all use a drilled crossmember with a through bolt that holds it captive at both ends inside the crossmember

rotary versions of these have the engine held by a seperate crossmember bolted under the sway bar holes

as a result there is detail change in the ID and width of the inner control arm bushing

#5

I'm a little lost on what your trying to say here.

So you're saying the sway bar is the same thickness at the section where it bolts up in the control arm? Or are you just saying the OD of the bushing is the same but the ID varies?

The pictures that you show there, the one that has a "flat spot" on the top, what exactly is that off of? That is an RX-2 one correct?

Can somebody snap me some pictures of how it mounts on the RX2 sub-frame then?

So you're saying the sway bar is the same thickness at the section where it bolts up in the control arm? Or are you just saying the OD of the bushing is the same but the ID varies?

The pictures that you show there, the one that has a "flat spot" on the top, what exactly is that off of? That is an RX-2 one correct?

Can somebody snap me some pictures of how it mounts on the RX2 sub-frame then?

the bush that fits there is the same part amongst all the suppliers and the nut and washer that fits is the same parts also

big hints that the sway bars all turn down to the same diameter where they pass through the eye

the D shackle bushing at front of the sway bar is different between models and listings and they give you hints as to what sway bar goes where,, though this doesn't concern you and the fab of the control arms

note that some makers list the ID of the D bush,, others list the ID of the bar,, and this amounts to why some listings will say 21mm while others 22mm etc

bumpstops also should not concern you ,,

i have sans bumpstops in both capella and rx2 types

its on and off between years and models and the A arms themselves are all the same exception of that inner metal eye

the narrow eye unit pictured sans bumpstops is actually a south african rx2 unit

and generally STB and r100 and early rx2 examples will be similar

in that picture it is fitted with customised generic local ford ploy bushes so as to make it fit inside the capella/rx4 style crossmember

in the rx2 photo below,, the wrong capella A arms are fitted with another custom poly bush so as to fit the larger control pin

so- evidence you can mix and match them if you have a clue ( custom the poly bush ID and or OD )

if you wish to sell the product as interchange for either you should provide choice of metal or poly bush to suit either thick control pin ( and narrower head )

,, or thinner control bolt ( and wider head )

that way your product will suit anything from STB/r100 to 75 rx4 /929

genuine rx2 front ends

( note this is a 75 onwards s3/s4 front and as such has longer engine mount pads )

#6

I don't see a big market for tubular lower control arms. The stock one's don't wear out and the bushings and ball joints are replaceable. The only advantage I see a tubular one has over stock is a slight decrease in weight. Now if you made the lower control arm adjustable like a tie rod then I could see a big use for them as you can adjust camber very easily. Might want to consider that.

Having said that i think there are other more important issues regarding parts for rx2's and rx3's than lower control arms. Lower control arms would have to be the very last item on my list if I were to upgrade my rx2. I would recommend concentrating on camber/caster plates, affortable coil over struts for front and rear(rx2's have struts in rear), bushings and ball joint kits that you don't have to buy from Australia, steering components- tie rods, idler arms and pitman arms. Did I miss anything else guys? Oh yeah, I know it's a pipe dream but fiberglass body components would be very nice too. I think that would be a big hit here in the States because there are"0" people making or selling any and there a alot of racers like me that race ol school cars that would buy them in a heart beat.

Having said that i think there are other more important issues regarding parts for rx2's and rx3's than lower control arms. Lower control arms would have to be the very last item on my list if I were to upgrade my rx2. I would recommend concentrating on camber/caster plates, affortable coil over struts for front and rear(rx2's have struts in rear), bushings and ball joint kits that you don't have to buy from Australia, steering components- tie rods, idler arms and pitman arms. Did I miss anything else guys? Oh yeah, I know it's a pipe dream but fiberglass body components would be very nice too. I think that would be a big hit here in the States because there are"0" people making or selling any and there a alot of racers like me that race ol school cars that would buy them in a heart beat.

#7

Thread Starter

Banned. I got OWNED!!!

iTrader: (3)

Joined: Nov 2001

Posts: 2,483

Likes: 1

From: London, Ontario

The control arm would be part of the coil over/ shock issue. Further talking to Billy about it today on the phone, the lower control arms need to extend a bit more forward of where the stock arm sits if you the FB shock assembly is to be used to correct camber and kingpin angle.

Trending Topics

#8

I don't see a big market for tubular lower control arms. The stock one's don't wear out and the bushings and ball joints are replaceable. The only advantage I see a tubular one has over stock is a slight decrease in weight. Now if you made the lower control arm adjustable like a tie rod then I could see a big use for them as you can adjust camber very easily. Might want to consider that.

Having said that i think there are other more important issues regarding parts for rx2's and rx3's than lower control arms. Lower control arms would have to be the very last item on my list if I were to upgrade my rx2. I would recommend concentrating on camber/caster plates, affortable coil over struts for front and rear(rx2's have struts in rear), bushings and ball joint kits that you don't have to buy from Australia, steering components- tie rods, idler arms and pitman arms. Did I miss anything else guys? Oh yeah, I know it's a pipe dream but fiberglass body components would be very nice too. I think that would be a big hit here in the States because there are"0" people making or selling any and there a alot of racers like me that race ol school cars that would buy them in a heart beat.

Having said that i think there are other more important issues regarding parts for rx2's and rx3's than lower control arms. Lower control arms would have to be the very last item on my list if I were to upgrade my rx2. I would recommend concentrating on camber/caster plates, affortable coil over struts for front and rear(rx2's have struts in rear), bushings and ball joint kits that you don't have to buy from Australia, steering components- tie rods, idler arms and pitman arms. Did I miss anything else guys? Oh yeah, I know it's a pipe dream but fiberglass body components would be very nice too. I think that would be a big hit here in the States because there are"0" people making or selling any and there a alot of racers like me that race ol school cars that would buy them in a heart beat.

#9

The control arm would be part of the coil over/ shock issue. Further talking to Billy about it today on the phone, the lower control arms need to extend a bit more forward of where the stock arm sits if you the FB shock assembly is to be used to correct camber and kingpin angle.

#12

#13

As long as it accepts the rx7 ball joint will be good,on the other hand how would the heim joint bolt up to the steering arm and fb strut assembly?unless its an adjustable heim joint to where it bolts up to the crossmember then accepting a fb ball joint to where it bolts up to the steering arm and strut assembly.

#14

this is needed because I simply can not find brake rotors for my rx3.

we have tried going to 2nd gen brakes but ended up with not enough camber and ate through a set of tires with a quickness. ( do to not enough negative camber)

sooo either get with willwood and have them make some custom hats to bolt to a 4 piston caliper to teh stock stuff. or modify the LCA to get more camber and run bigger vented FC stuff.

(this is an rx3 old SCCA ITA road race car, being set up to do time trials and hill climbs.)

we have tried going to 2nd gen brakes but ended up with not enough camber and ate through a set of tires with a quickness. ( do to not enough negative camber)

sooo either get with willwood and have them make some custom hats to bolt to a 4 piston caliper to teh stock stuff. or modify the LCA to get more camber and run bigger vented FC stuff.

(this is an rx3 old SCCA ITA road race car, being set up to do time trials and hill climbs.)

#15

anyone know where I can get a polyurethane "lower control arm" and "sway bar to LCA" bushings? My sway bar is 1 1/16th with 5/8 eyelet. The ones I've seen in the US are mainly stock. I bought 3 sets of tie rods and ball joints from RockAuto

#17

Finally! This is great news! I remember talking to Billy about doing these RX2 tubular arms 4 years ago. I think this is a great product for RX2 owners. If you have it accept RX7 ball joints you could make a set of camber plates available for purchase as well.

Have you thought of offering modified spindles? You could modify 1st gen spindles to have the same kingpin inclination as the RX2. You would probably want to do a core charge though. This would keep you from having to extend the control arm to correct camber.

Here is a pic along the lines of what I was thinking to modify the spindles:

Have you thought of offering modified spindles? You could modify 1st gen spindles to have the same kingpin inclination as the RX2. You would probably want to do a core charge though. This would keep you from having to extend the control arm to correct camber.

Here is a pic along the lines of what I was thinking to modify the spindles:

#19

Wacky I got Superpro brand from Australia they are good quality but a very dark blue color. If you want people to cream in their pants looking at your under body get the Nolethane brand they are bright red. Superpro are always on eBay.com.au. Nolethane are harder to find seem to be more common in NZ

#20

Finally! This is great news! I remember talking to Billy about doing these RX2 tubular arms 4 years ago. I think this is a great product for RX2 owners. If you have it accept RX7 ball joints you could make a set of camber plates available for purchase as well.

Have you thought of offering modified spindles? You could modify 1st gen spindles to have the same kingpin inclination as the RX2. You would probably want to do a core charge though. This would keep you from having to extend the control arm to correct camber.

Here is a pic along the lines of what I was thinking to modify the spindles:

Have you thought of offering modified spindles? You could modify 1st gen spindles to have the same kingpin inclination as the RX2. You would probably want to do a core charge though. This would keep you from having to extend the control arm to correct camber.

Here is a pic along the lines of what I was thinking to modify the spindles:

#22

I'm not a big fan of the Full Function set up. It's just another generic overseas coilover probably using the same off the shelf dampers that are used on virtually every other set of cheap eBay coilovers. D2, Meagan Racing, Ksport, etc.

What makes it even crazier is that cost wise they are a total ripoff. A set of Function and Form coilovers for a Honda will set you back $600-$800 depending where you buy them, but for a RX2 you are looking at $1600-$1800. So having the spindle already included is worth an extra grand of your cash? Not for me.

Sorry for the rant. I just hate cheap quality coilovers!

#23

Thread Starter

Banned. I got OWNED!!!

iTrader: (3)

Joined: Nov 2001

Posts: 2,483

Likes: 1

From: London, Ontario

The idea is if we extend the lower control arm, it would be easier to do as such than having to modify every shock, thats doing 2 things where modifying only one is really needed. How far out did you have to extend yours to get the king pin angle correct.

I might have an RX-2 being dropped here at the shop for mocking up on so should make my life a bit easier.

The camber plates, coil over, and big brake will all be transferable from our first gen catalog.

Can anyone tell me if I could run a straight piece of tube from the sway bar area to the balljoint without interference from the steering arm (that is provided the arm is longer by say about 1/2" to 3/4")

The reason that I ask that is because that will bring the cost down of the whole project, manufacturing that angled piece would be a bit of a pain on a higher volume.

I might have an RX-2 being dropped here at the shop for mocking up on so should make my life a bit easier.

The camber plates, coil over, and big brake will all be transferable from our first gen catalog.

Can anyone tell me if I could run a straight piece of tube from the sway bar area to the balljoint without interference from the steering arm (that is provided the arm is longer by say about 1/2" to 3/4")

The reason that I ask that is because that will bring the cost down of the whole project, manufacturing that angled piece would be a bit of a pain on a higher volume.

#24

You can. here is a pic of my setup. I don't really like the bulkiness of it and plan on changing it up down the road. I was thinking about getting the tube crossmember setup and running tubing forward to the sway bar mounting point and then attaching the strut rod to the tubing. I also had to add a tube in between the mounts i made because the kept rotating slightly under hard braking.

#25

Thread Starter

Banned. I got OWNED!!!

iTrader: (3)

Joined: Nov 2001

Posts: 2,483

Likes: 1

From: London, Ontario

You can. here is a pic of my setup. I don't really like the bulkiness of it and plan on changing it up down the road. I was thinking about getting the tube crossmember setup and running tubing forward to the sway bar mounting point and then attaching the strut rod to the tubing. I also had to add a tube in between the mounts i made because the kept rotating slightly under hard braking.