Bike for dirt drags with 13B NA

#551

50 mm PLX gauge

Was thinking (( yea I know every time I think it costs me more money but were almost done boss )) instead of mounting the plx multi gauge in the dash pot , maybe mount it in the hard case also .. there is certainly no chance of having a look at that when in motion and little to no reason to look at it when warming up . More of a tuning device than some thing to gaze upon like an OP gauge or temp gauge , when this part is over then the device to sent all info to my laptop will be installed in the hard bag also (( it's only around 100 bucks )) .

then there wouldn't even be a reason to open the door to look at the gauge Or am I thinkin outa the wrong end again . I could mount it to the bottom of the hard bag door and it would fold right up in view when open ,, cant figure the gauge being worth a **** to see with the sunlight shining on the face either .. going once ,, going twice .. any thoughts

I could mount it to the bottom of the hard bag door and it would fold right up in view when open ,, cant figure the gauge being worth a **** to see with the sunlight shining on the face either .. going once ,, going twice .. any thoughts

then there wouldn't even be a reason to open the door to look at the gauge Or am I thinkin outa the wrong end again .

Last edited by gerald m; 03-29-15 at 11:31 PM. Reason: cant spell

#552

seems Ok to me

though would prefer that they are still visible when the case is closed

as not everywhere will you have ample reception, or even the lap top to hand

feedback for the AFR will be vital when setting up the throttle switch position, something you can do on a dyno or during a burnout , just glancing at the AFR trends

though would prefer that they are still visible when the case is closed

as not everywhere will you have ample reception, or even the lap top to hand

feedback for the AFR will be vital when setting up the throttle switch position, something you can do on a dyno or during a burnout , just glancing at the AFR trends

#553

Now I remember why I was all into relays ,, the cooling fan turns into a dynamo when the ign. switch is turned off and can actually create enough power to excite the alternator and in return feed the ignition system and allow the engine to run on .. . so it needs a relay to isolate the fan when the switch is turned off .. that cooling fan although it seems to do the job draws more power than the rest of the machine all put together .

was also thinking later on to run a double groove alt pulley , not for the alt so much but to get a bit more belt surface on the water pump pulley without making everything over tight .

was also thinking later on to run a double groove alt pulley , not for the alt so much but to get a bit more belt surface on the water pump pulley without making everything over tight .

#554

PLX sensor positions

So the egt probee will go down somewhere close to engine . I know the AFR sensor should be they say on a 15 deg. angle with the flow of exhaust . They say nothing about the EGT probe weather it mounts at 90 deg. with exhaust pipe or weather it works best on a bit of an angle with the exhaust pipe .

The EGT probe is 1/8 NPT .. The 3/16 thick exhaust pipe is plenty thick to just drill into and do a 1/8 tap . but what me thinking is that the entire probe will be inside of exhaust pipe or should I tap it to 1/4 and use a ss fitting like the brass one in pics and have only half of the probe exposed to the exhaust flow ?? Possibly it makes no difference much .

The AFR they say should be 36 inches from engine after turbo and before ( catalytic converter ) of course we dont have one . In the third pic is where I thought maybe a good spot ,, The probe would be in maximum exhaust flow weather the waste gate is open or closed . i could find a spot before the turbo if it makes no difference . sorry for the dumb *** questions but it is important I get this right the first time .

You know bumpstart it will be 5 years of learning about the little engines in Sept with all hands on experience mostly good success but I am the first to realize that I have barely scratched the surface .. I can see why it takes many years of experience before a guy really knows whats up when it comes to the Mazda R series vehicle reading is one thing doing is another . A big to all you guys .

to all you guys .

The EGT probe is 1/8 NPT .. The 3/16 thick exhaust pipe is plenty thick to just drill into and do a 1/8 tap . but what me thinking is that the entire probe will be inside of exhaust pipe or should I tap it to 1/4 and use a ss fitting like the brass one in pics and have only half of the probe exposed to the exhaust flow ?? Possibly it makes no difference much .

The AFR they say should be 36 inches from engine after turbo and before ( catalytic converter ) of course we dont have one . In the third pic is where I thought maybe a good spot ,, The probe would be in maximum exhaust flow weather the waste gate is open or closed . i could find a spot before the turbo if it makes no difference . sorry for the dumb *** questions but it is important I get this right the first time .

You know bumpstart it will be 5 years of learning about the little engines in Sept with all hands on experience mostly good success but I am the first to realize that I have barely scratched the surface .. I can see why it takes many years of experience before a guy really knows whats up when it comes to the Mazda R series vehicle reading is one thing doing is another . A big

#556

Seems to me you thought you had ignition problems , what are you doing for that .? Keep us updated with the install and setup . good to hear from you , thanks for stopping in .

#557

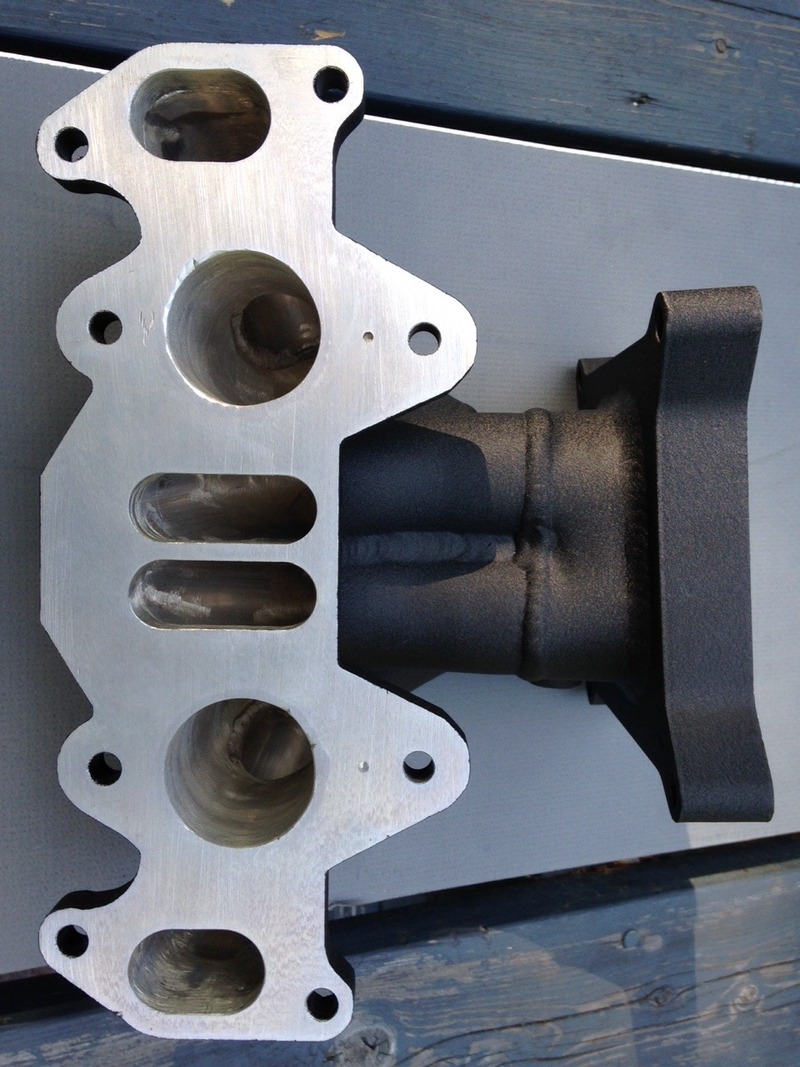

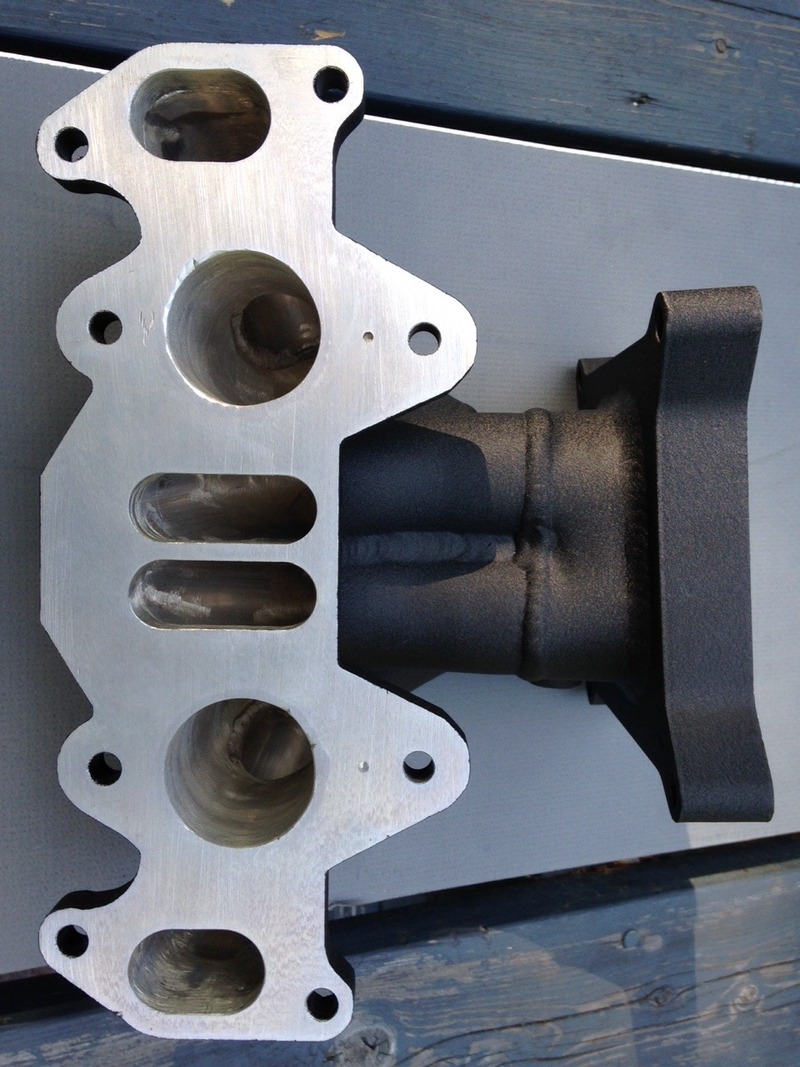

The intake finally cam in today. Now I get to fabricate an intake gasket and start putting it together. Hoping to have it ready to run this weekend.

12a Stealth Bullet Slideshow by traffordracing | Photobucket

12a Stealth Bullet Slideshow by traffordracing | Photobucket

#558

Hi Darryl ,Everything takes time to build , seems to me you were using a holley on the last engine . I like the holley but could never get my 500 from flooding ( Just the harmonics of the little engine I guess ) but I have never looked back since I changed to propane , what a nice clean burning fuel and is very forgiving for my lesser ignition system . good luck with the new power plant . looking forward to some good video footage .. for people that might be interested in darryls sand car look at Stafford racing .com

#559

For ignition we are using the stock crank angle sensor (drop in dist unit) to send a signal to the MSD 6-AL box, then firing 4 MSD coils, wired in series. All four plugs fire at once, for a hopped up version of a lost spark ignition.

We have been struggling with the old chrome plating on p-port housings not letting the apex seals seal up properly to allow it to make enough compression to start. The only way we have been able to get it to start is by dumping copious amounts of oil down the carburetor.

I pulled that motor out of the car yesterday. Dropping in a new street ported 12a on Wednesday (the new back up motor). That will allow us to finish out the race season while Luis at Wankel Works figures out what to use for apex seals.

Here's the sheet metal intake for the p-port/bridge-port motor. Built by the very talented fabricator at Kaizen Tuning in Boston. There are a bunch of other pictures at the photo bucket page too. I'll upload a video to the photo bucket folder, of the "stealth-bullet" running in a few minutes. It is very loud and nasty...

We have been struggling with the old chrome plating on p-port housings not letting the apex seals seal up properly to allow it to make enough compression to start. The only way we have been able to get it to start is by dumping copious amounts of oil down the carburetor.

I pulled that motor out of the car yesterday. Dropping in a new street ported 12a on Wednesday (the new back up motor). That will allow us to finish out the race season while Luis at Wankel Works figures out what to use for apex seals.

Here's the sheet metal intake for the p-port/bridge-port motor. Built by the very talented fabricator at Kaizen Tuning in Boston. There are a bunch of other pictures at the photo bucket page too. I'll upload a video to the photo bucket folder, of the "stealth-bullet" running in a few minutes. It is very loud and nasty...

#561

Been a busy summer maybe can get some more done now I'm finished doing polyurethane insulation for the Year.

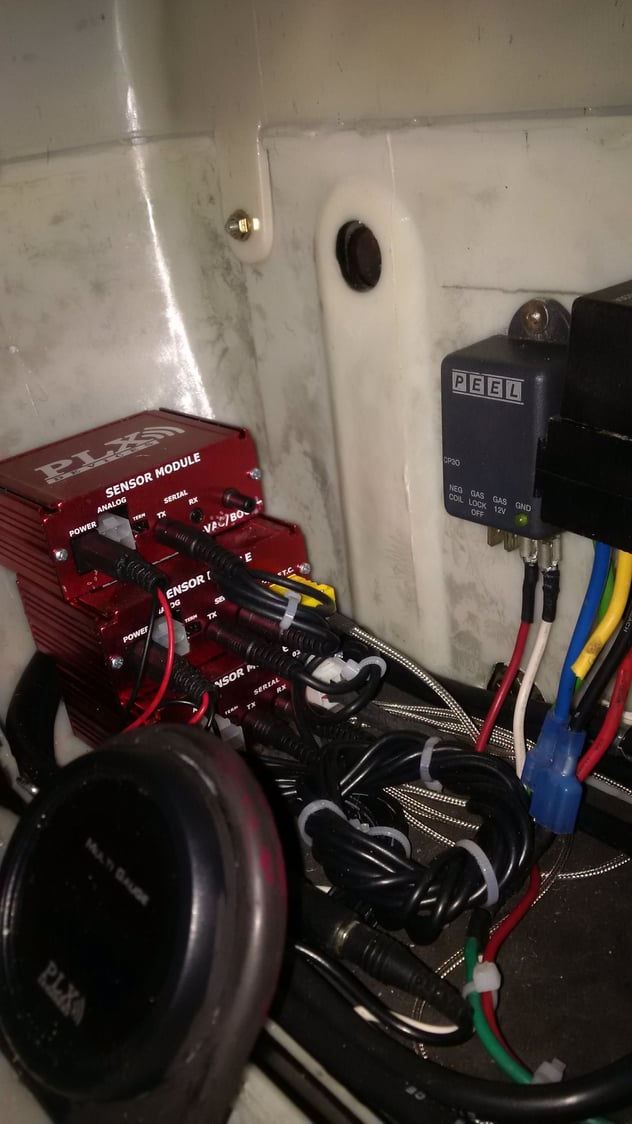

multi gauge mounted inside hard bag door, connectors.

plx devices wired in peel cp30 installed

Slow year Daryl

#562

6:

Last edited by gerald m; 10-17-17 at 05:41 PM.

Thread

Thread Starter

Forum

Replies

Last Post