Port Matching my intake question

#1

Port Matching my intake question

Hey guys,

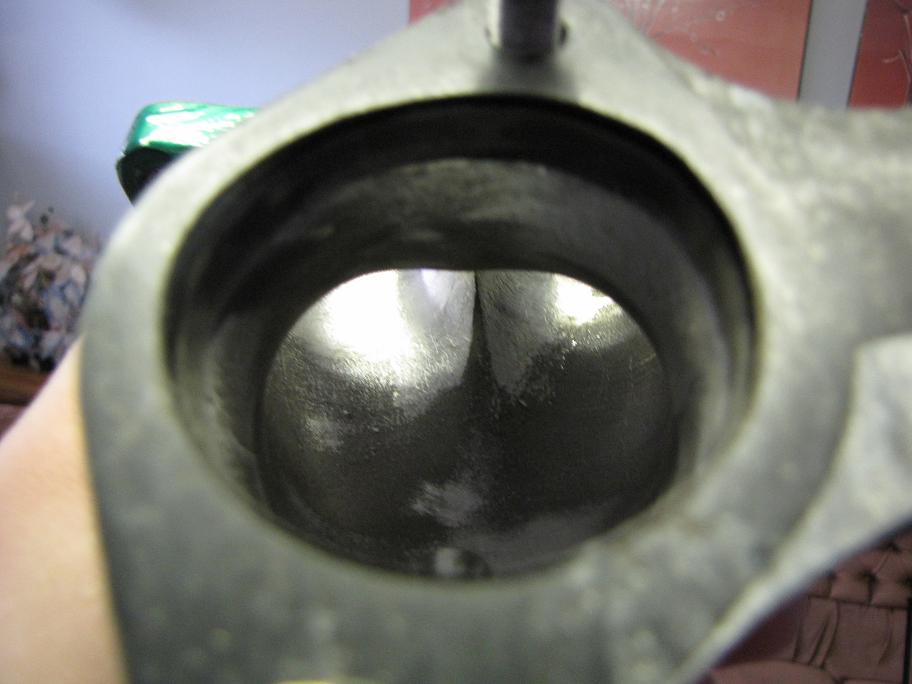

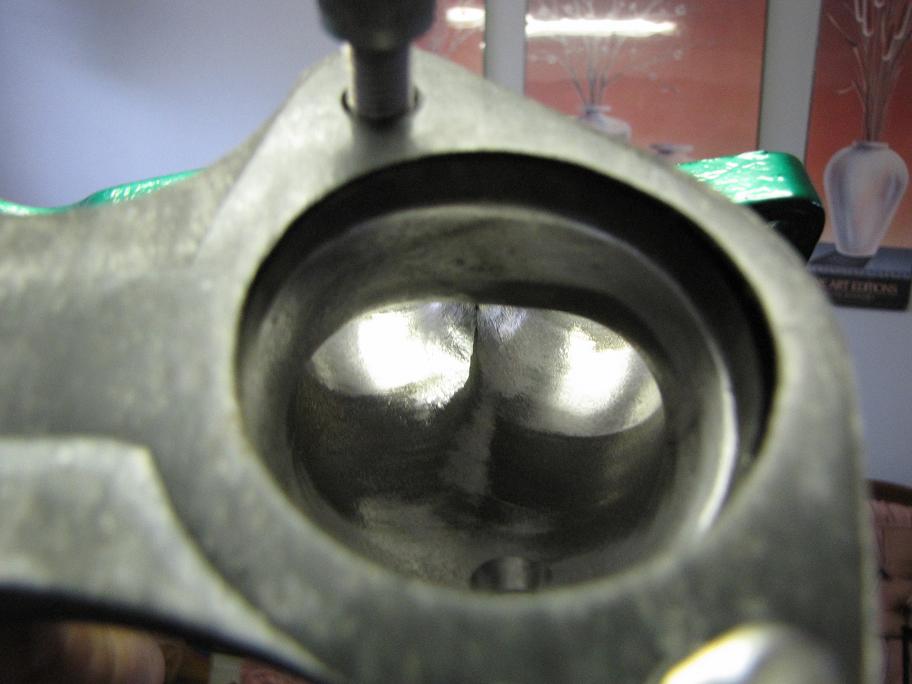

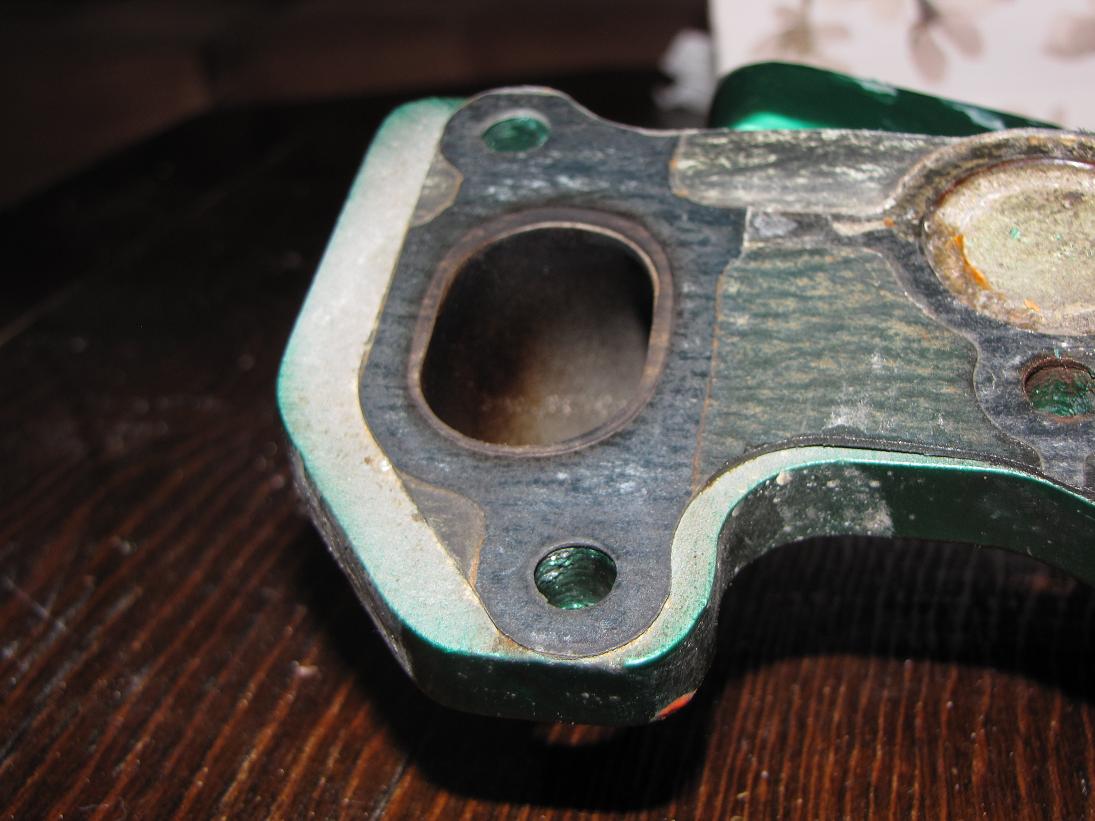

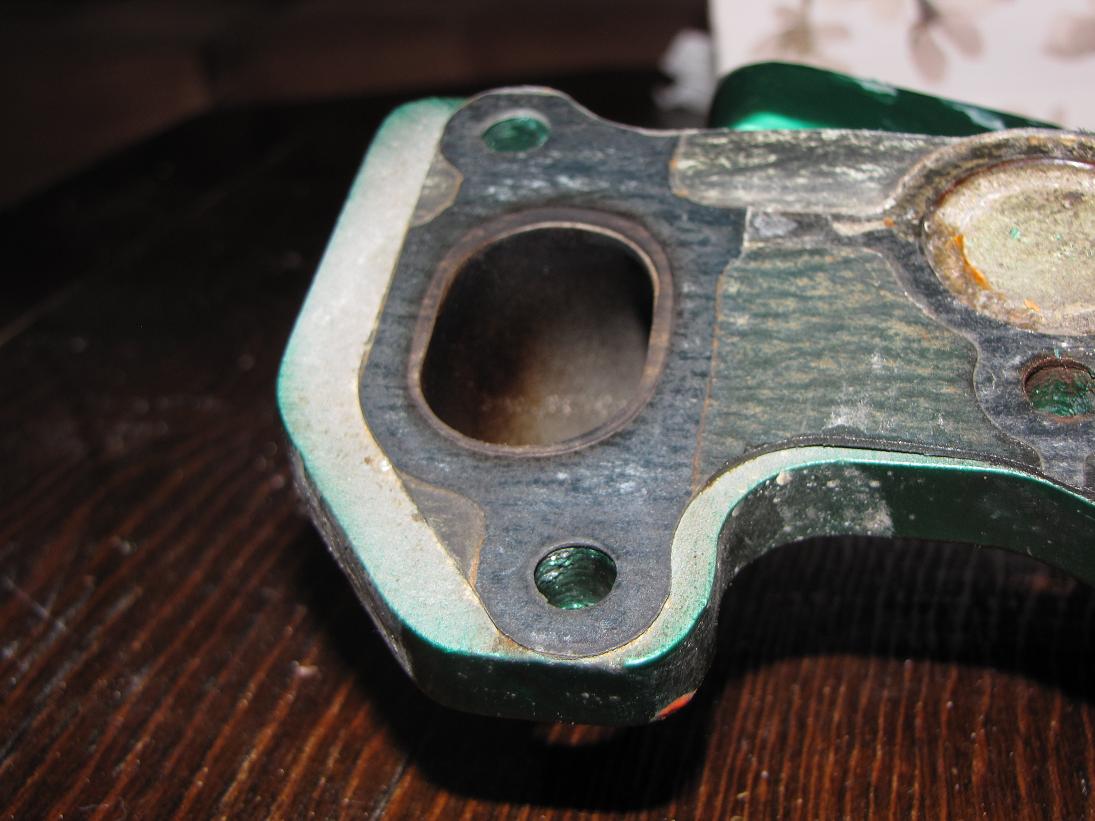

I would like to port match my intake a bit to smooth out flow. I have a 12a SP engine. You can tell the marking from the engine porting on the old gasket where the raised brown edge is.

A few thing that I don't know what to do is if you look at the primaries, the port on the left of the picture, has an edge that just hits the engine straight on should I try to weld a bead on there and then smooth it out?

Also how far up and down could I extend the primaries without hurting velocity much.

Sam

Sam

Sam

Sam

I would like to port match my intake a bit to smooth out flow. I have a 12a SP engine. You can tell the marking from the engine porting on the old gasket where the raised brown edge is.

A few thing that I don't know what to do is if you look at the primaries, the port on the left of the picture, has an edge that just hits the engine straight on should I try to weld a bead on there and then smooth it out?

Also how far up and down could I extend the primaries without hurting velocity much.

Sam

Sam

Sam

Sam

#2

Old [Sch|F]ool

Doing so will have the opposite effect.

None. The best you can do is make the short side radius flatter, so the port is D-shaped.

Also how far up and down could I extend the primaries without hurting velocity much.

#3

Also what tools do you guys normally use to port these out with? Its my first time ever trying to port anything. I did do some work yesterday on it though. I cleaned up the casting a bit and also on the upper intake where the runners split, I made the split into a sharp edge and milled my 2 holes for my extra fuel injectors.

I'll post up pics later on today.

#4

Old [Sch|F]ool

I linked this in your other thread and I'll link it here too for completeness:

https://www.rx7club.com/showthread.p...aw#post1044131

Opening up the primary manifold outlets is bad in two ways. It enhances reversion and kills airflow.

The only time a tall primary port is acceptable is on a flat Lake Cities style DCOE manifold. I think Atkins is reproducing these. This is because it's the only manifold that doesn't turn down right there.

If you knife-edged the port divide, roll them down to at least a 1/4" radius curve. It will actually flow better.

https://www.rx7club.com/showthread.p...aw#post1044131

Opening up the primary manifold outlets is bad in two ways. It enhances reversion and kills airflow.

The only time a tall primary port is acceptable is on a flat Lake Cities style DCOE manifold. I think Atkins is reproducing these. This is because it's the only manifold that doesn't turn down right there.

If you knife-edged the port divide, roll them down to at least a 1/4" radius curve. It will actually flow better.

#6

In regards to the knife edge split:

http://en.wikipedia.org/wiki/Vena_contracta

Vena contracta is the point in a fluid stream where the diameter of the stream is the least, such as in the case of a stream issuing out of a nozzle, (orifice). (Evangelista Torricelli, 1643).

The maximum contraction takes place at a section slightly on the downstream side of the orifice, where the jet is more or less horizontal.

The effect is also observed in flow from a tank into a pipe, or a sudden contraction in pipe diameter. Streamlines will converge just downstream of the diameter change, and a region of separated flow occurs from the sharp corner of the diameter change and extends past the vena contracta.

The reason for this phenomenon is that fluid streamlines cannot abruptly change direction. In the case of both the free jet and the sudden pipe diameter change, the streamlines are unable to closely follow the sharp angle in the pipe/tank wall. The converging streamlines follow a smooth path, which results in the narrowing of the jet (or primary pipe flow) observed.

http://en.wikipedia.org/wiki/Vena_contracta

Vena contracta is the point in a fluid stream where the diameter of the stream is the least, such as in the case of a stream issuing out of a nozzle, (orifice). (Evangelista Torricelli, 1643).

The maximum contraction takes place at a section slightly on the downstream side of the orifice, where the jet is more or less horizontal.

The effect is also observed in flow from a tank into a pipe, or a sudden contraction in pipe diameter. Streamlines will converge just downstream of the diameter change, and a region of separated flow occurs from the sharp corner of the diameter change and extends past the vena contracta.

The reason for this phenomenon is that fluid streamlines cannot abruptly change direction. In the case of both the free jet and the sudden pipe diameter change, the streamlines are unable to closely follow the sharp angle in the pipe/tank wall. The converging streamlines follow a smooth path, which results in the narrowing of the jet (or primary pipe flow) observed.

Trending Topics

#8

Here's an interesting question, with longer runners do you see less vaccum being pulled through the ecu? I used to idle at about 1000rpm and would see about 45kpa, with me cleaning up the ports, and adding that 1/2" spacer, i'm now seeing about 55kpa. Is this due to having more volume of air to pull through?

#9

Old [Sch|F]ool

It SHOULD make no difference.

I did notice a similar effect, though, when I switched from the TII intake to a modified S4 N/A intake. My engine used to idle at 55kpa (as a half bridge!!) and now it idles at about 65-70kpa.

I assume that you're using a Weber style throttle body and it is still independent-runner.

I did notice a similar effect, though, when I switched from the TII intake to a modified S4 N/A intake. My engine used to idle at 55kpa (as a half bridge!!) and now it idles at about 65-70kpa.

I assume that you're using a Weber style throttle body and it is still independent-runner.

#10

Yes still independent runners, I just didn't want this to mean that my engine was dying so its good to hear that.

I wasn't sure if it was that or I had a vacuum leak although I sprayed some brake cleaner around there with no engine sound change. I wonder what makes this happen. I kinda wonder if I would be able to see more vacuum further down stream right by the ports. My vacuum hooks up to ITB's so changing the length of of the wave that the runners seen, and i would imagine that the amplitude of the wave would decrease on a longer length with the same source creating the wave.

How much longer is the NA vs the T2 one?

I wasn't sure if it was that or I had a vacuum leak although I sprayed some brake cleaner around there with no engine sound change. I wonder what makes this happen. I kinda wonder if I would be able to see more vacuum further down stream right by the ports. My vacuum hooks up to ITB's so changing the length of of the wave that the runners seen, and i would imagine that the amplitude of the wave would decrease on a longer length with the same source creating the wave.

How much longer is the NA vs the T2 one?

#11

Old [Sch|F]ool

If the effect is there, I don't think it would be from the placement of the vacuum port, so much as it would be the increased volume of the manifold runner causing the intake pulses to be less sharp. That is to say, the vacuum that the engine can pull at low engine speeds with a shut throttle plate could be lower because there's more of a capacitor effect in the runner.

I am not sure how much longer the manifold is, it's at least a couple inches longer. (someone who plays with this sort of thing regularly might have the info) It's hard to tell visually because they are shaped differently. The engine definitely likes it more, though, since I had to add a lot more fuel in the 2000-5000rpm range, so from a practical standpoint, I got what I was shooting for: a table flat torque curve instead of the typical streetport okay midrange and then top-end hustle.

The top end hustle is still there, mind you. It pulls just as hard at the top end. The difference is that it pulls just as hard in the midrange, so as a side effect it feels slower because you don't get the "VTEC KICKED IN Y0" sensation at 5500rpm

I am not sure how much longer the manifold is, it's at least a couple inches longer. (someone who plays with this sort of thing regularly might have the info) It's hard to tell visually because they are shaped differently. The engine definitely likes it more, though, since I had to add a lot more fuel in the 2000-5000rpm range, so from a practical standpoint, I got what I was shooting for: a table flat torque curve instead of the typical streetport okay midrange and then top-end hustle.

The top end hustle is still there, mind you. It pulls just as hard at the top end. The difference is that it pulls just as hard in the midrange, so as a side effect it feels slower because you don't get the "VTEC KICKED IN Y0" sensation at 5500rpm

#12

I know what you mean, I've been doing nothing but adding fuel all day with this thing. apperently the 02 that i was trying to tune with is messed up so, once i looked at my EGTs i realized that i was running about 1300*F at Idle! A quick look outside and the headers are glowing red

#13

Well just a bit of an update on this, I had to revert back to the old firmware of the megasquirt and run with the old injectors in place (The ones on the throttle body), as oppose to trying to make the ones in the manifold my primaries, and the car show more vaccum being pulled now. Not too much more but 3-4kpa more. The car has a smoother idle now and seems to climb through the rpm range a little quicker than before, not sure on HP figures. I'll be going to the dyno soon enough though.

#14

A.K.A. LuisGT

dj55b what size injectors do you use? I have a similar setup to yours with exception I'm running a 13b and it is full bridge port. I normally have messed around with holley carbs and I'm new to EFI(Megasquirt) setups. This info will help me out! Thanks

#15

I used to run on only 2 x 720 cc injectors running fuel pressure at 60psi to not max out the injectors in higher rpm, but still reached a bit over 90% duty cycle. Optimal is to stay under 85% Duty Cycle.

Currently though with this new setup, I have 2 x 720cc and 2 x 750cc

Currently though with this new setup, I have 2 x 720cc and 2 x 750cc

#16

A.K.A. LuisGT

I started a thread on the Naturally Aspirated Performance Forum to seek help, because I was use to holley carbs and i'm trying to get up to speed on EFI systems. In my setup I am running two 48mm idf throttle bodies one 48mm throttle body per runner. It is capable of running 2 injectors per runner. And the engine is 13b 4port full bridgeport. Thanks for the help!

#17

A.K.A. LuisGT

Wether or not you decide to port match your intake the following tools are what i use to port and/or port match. When I port the iron steel plates or aluminum intakes/housings I mark the port (target area) and use carbide burrs to start material removal. You have burrs best suited for aluminum and others for harder metals, they come in different lengths, sizes and shapes. I use the 1/4" shank burrs with pneumatic tools and the 1/8" shank burrs with my dremel and/or flexible shaft pen. I use these to remove material close to target area. I then use cartridge rolls to bring to final target area on the port. Cartridge rolls are nothing but sandpaper rolled in to form different shapes, grits and sizes. These then thread onto a mandrel which can also be of 1/4" and/or 1/8" shank size (There is actually many other sizes but those are the ones i mostly use). Those have been the most effective for me, but i'm quite sure their might be other methods or approaches used by others.

#18

There are online calculators available for this stuff, but with my old setup I was at about 160 whp. If you run 4x720cc or so I'm sure you will be more than good for atleast 250 HP, stock turbo cars come with 4x550 I believe and you can easily get over that power range.

#20

It's all in the timing.

Join Date: Jun 2009

Location: Australia

Posts: 42

Likes: 0

Received 0 Likes

on

0 Posts

A good rough guide is every 100cc of injector flow will be able to make about 15hp atw...

Obviously there are a lot of variables that this doesn't take into account, but if you stay on the north side of this, you can't go too far wrong.

So for 300hp atw you want to have 2000cc combined injector flow, or more.

This is of course only in the ballpark for gasoline - Not Meth or anything else!

Because every engine is different, you then need to keep an eye on the duty cycle as you tune...

Obviously there are a lot of variables that this doesn't take into account, but if you stay on the north side of this, you can't go too far wrong.

So for 300hp atw you want to have 2000cc combined injector flow, or more.

This is of course only in the ballpark for gasoline - Not Meth or anything else!

Because every engine is different, you then need to keep an eye on the duty cycle as you tune...

Thread

Thread Starter

Forum

Replies

Last Post