injector size on 13b peripheral port

#1

injector size on 13b peripheral port

hello we are in the process of setting up a efi set up for my 13bpp engine originally we were going to use 2 550cc fc injectors as primarys and 2 id 1000cc as secondaries. now we want to fast track the build to get it running and the itb's i have only have one injector per throttle body so we were thinking of using 2 id 2200cc injectors to not only save money in setting up a extra fuel rail and buying 2 injectors inset of 4 but to save room and time and to mount it on a 30 to 45 deg angle towards the intake side strut tower it should look great, have any of you guys used just 2 big injectors any results or advice?

Last edited by nvmarx; 02-26-12 at 01:34 AM.

#4

+2

I did some quick math and two 1000cc is all you will ever need. Personally, I woud use higher base pressure, for better atomization and lower duty cycle in top end - overall better control of high rpm mixture.

I did some quick math and two 1000cc is all you will ever need. Personally, I woud use higher base pressure, for better atomization and lower duty cycle in top end - overall better control of high rpm mixture.

#5

Yup, ID1000's and bosch 044 for the win, I'm using the same with the 4-rotor I'm building.

@Liborek

Your right, injector dynamics recommends around 90psi fuel pressure for an n/a application if the fuel pump is capable, which most aren't, so get a decent one

@Liborek

Your right, injector dynamics recommends around 90psi fuel pressure for an n/a application if the fuel pump is capable, which most aren't, so get a decent one

The following users liked this post:

Westcoast FC (04-19-21)

#6

Only drawback is the fact, that its gravity fed pump and rather loud

Only drawback is the fact, that its gravity fed pump and rather loud

#7

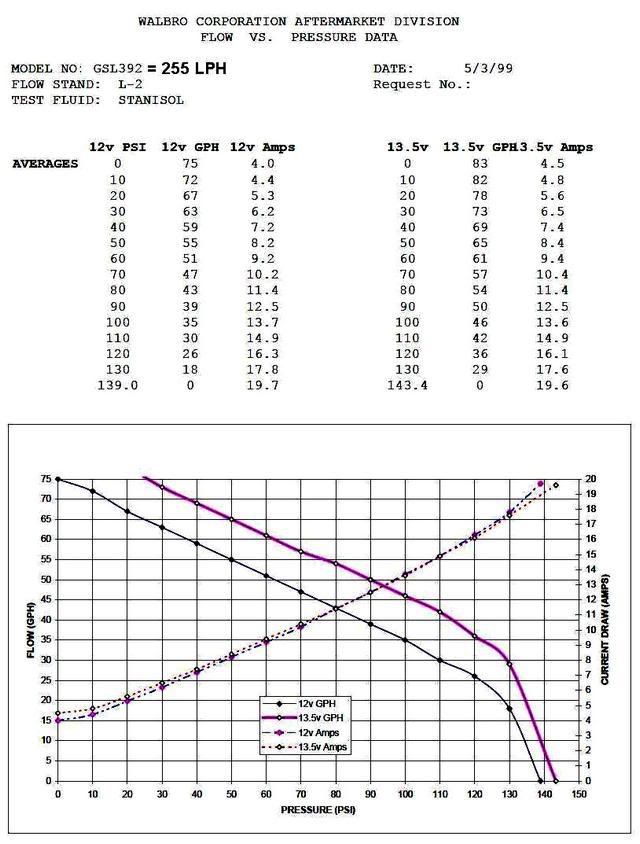

hey cheers for the info guys i have a carter pump to lift fuel out of tank to a surge tank and then to a walbro GSL392 500hp pump as the main pump do any of you know if it would be up to scratch or should i get a 044? the walbro is quite alot smaller than the 044..

it says the walbro working pressure is 35-100psi..

it says the walbro working pressure is 35-100psi..

Trending Topics

#8

What kind of base pressure are you planning? You should have no problem using up to 100 psi base pressure. Iīve researched use of very high pressures in port injected engines and apparently, it can produce up to 5% net increase in power - slightly higher alternator load is already substracted plus you donīt have to use ridiculous number of injectors

hey cheers for the info guys i have a carter pump to lift fuel out of tank to a surge tank and then to a walbro GSL392 500hp pump as the main pump do any of you know if it would be up to scratch or should i get a 044? the walbro is quite alot smaller than the 044..

it says the walbro working pressure is 35-100psi..

it says the walbro working pressure is 35-100psi..

So, you can probably use the walbro if you set the fuel pressure to something normal. Should work just fine. Replace it with a bosch if you really want to run a high fuel pressure for better atomisation or whatever.

#9

Assuming 12V, up to 90 psi, and with 13.5V, up to 110 psi. I must admit, that amperage is rather high, but flow is there.

#12

Interesting info on this thread. Would there be any benefits to running that much pressure on a side port engine? I've been running 45psi base on my 20b. What do the colors represent on your chart?

#13

Higher pressure generally means better fuel atomization - fuel spray mass having more momentum against airstream enhances atomization. But obviously, every fuel injector is different, some will benefit from high pressures, some donīt, for example when injection pattern deteriorates.

Overall, better atomization is always good thing, both for power production and fuel economy. And there are other benefits, pulsewidth with given injectors is shorter, giving you ability to inject fuel when you want to, and not when limited amount of time forces you.

F1 engines have rule imposed limit of 100 bar injection pressures - and by rules, they are port injected or with stand off injectors. 100 bar=1450 psi.

Simply said, better fuel is atomized, more of it contributes to combustion, effectively lowering fuel usage or fuel mass requirement for given power output, as less is wasted.

Food for thought http://www.apexspeedtech.com/phpbb/v...php?f=10&t=150

#14

hey on that note with my application will lower rev range/idol be afected with the two larger injectors? i was thinking it may be a bit more of a bitch than it all ready would be to drive in the lower rev range do you have any thoughts on this?

john are you just useing the 4 id1000cc injectors? one per rotor?

john are you just useing the 4 id1000cc injectors? one per rotor?

#15

Yes I'm going to use 1 injector per rotor, no staged injection. With the Id1000's it should run fine at lower loads and idle. I think this is better than using 2 older bad quality injectors with staged injection. Havent been able to test it yet though.

#17

Ive had x2 550's only running in a half bridge, Idle'd fine, drove well, Then i also had x2 new 880's, And it idle'd the same and drove the same, Ive got a mate with a RX3 turbo and it's running x4 ID2200's, 2 in primary, 2 in secondary, It idle's very well, Drive's very nice and goes like stink once on boost. So i think x2 ID1000's should be good for idle and slow stuff.

#19

This is why ID injectors are so nice, they have ever piece of data, not only static flow at 43.5 psi....

#21

You don't need a Bosch 044, you don't even need a Walbro fuel pump. A factory fuel pump from just about any standard turbo jap car will do the job. Standard FC3S, standard FD3S any standard 6 cylinder turbo toyota fuel pump will all do the job. In terms of fuel flow all you really need is a pair of 880cc/min injectors using a 40psi base pressure.

[edit]Taking price and reliability of new parts into it. I would get genuine 2xID1000s and a genuine walbro 342 direct from the states.

[edit]Taking price and reliability of new parts into it. I would get genuine 2xID1000s and a genuine walbro 342 direct from the states.

#22

This would seem to make injector placement and timing more critical. You wouldn't want to inject a high speed stream of fuel 90 degrees to the airflow during the intake stroke, that would be like slamming a valve shut.

(Ever walk through an air door?)

#23

Hmm, I never thought about the increased fuel velocity.

This would seem to make injector placement and timing more critical. You wouldn't want to inject a high speed stream of fuel 90 degrees to the airflow during the intake stroke, that would be like slamming a valve shut.

(Ever walk through an air door?)

This would seem to make injector placement and timing more critical. You wouldn't want to inject a high speed stream of fuel 90 degrees to the airflow during the intake stroke, that would be like slamming a valve shut.

(Ever walk through an air door?)

All the bends and turns in intake arenīt doing any good for this scenario. Best would be injecting from very top of the housing with rotor at BDC

#24

i have genuine parts for my car. this has got me thinking about my itb's now and the manifold design.. i will post pictures once aerosev has finished them to give you guys an idea of what im doing

#25

I just had a used on of the online calculators and seting the hp at 350, a 13bpp can potentially make 350 flywheel hp, and bsfc at .65 (i would imagine that a pp engine would be up around that figure) and injector duty at 90% you will need injectors to flow 1327cc per minute, on the injector dynamics site the they say the 1000cc injectors will flow just under 1300cc/minute, so you may be ok running 100% injector duty and 100psi of fuel pressure but it seems a bit a the danger side to me? Just to gain a slightly better atomisation? Wouldn't it be safer to just go bigger??