Ceramic coatings - lower & upper intake

#1

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

Greetings all -

I'm planning out some upgrade pathways and something I've been considering for quite some time is ceramic coating the intake manifolds.

Through my research into the various options for coating, I found one shop claiming that they do special coatings for intakes, instead of acting as a barrier for heat, it disperses heat out of the intake to the atmosphere. Well, I'm no expert in thermodynamics, but it sure seems to me that means its an absorptive, as opposed to a reflective, surface.

Wouldn't that just soak up all the heat from the headers and top of the engine? Seems to me you would want to have a reflective coating to bounce the heat of the engine and headers off the intake manifold.

Anyone here have actual experience ceramic coating intakes? Your thoughts / input greatly appreciated.

I'm planning out some upgrade pathways and something I've been considering for quite some time is ceramic coating the intake manifolds.

Through my research into the various options for coating, I found one shop claiming that they do special coatings for intakes, instead of acting as a barrier for heat, it disperses heat out of the intake to the atmosphere. Well, I'm no expert in thermodynamics, but it sure seems to me that means its an absorptive, as opposed to a reflective, surface.

Wouldn't that just soak up all the heat from the headers and top of the engine? Seems to me you would want to have a reflective coating to bounce the heat of the engine and headers off the intake manifold.

Anyone here have actual experience ceramic coating intakes? Your thoughts / input greatly appreciated.

#2

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

on the P port, the intake is really close to and right above the exhaust, so it gets hot. i used some header wrap and wrapped the intake, and it really did make a difference.

with it unwrapped there was a huge difference in the way the car ran hot vs cold, with the wrap its still there, but the effect is much smaller.

i'd think the easy cost effective way is really to buy/make a heat shield between the header and the intake

with it unwrapped there was a huge difference in the way the car ran hot vs cold, with the wrap its still there, but the effect is much smaller.

i'd think the easy cost effective way is really to buy/make a heat shield between the header and the intake

#3

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

I'm interested in the heat shielding as well, particularly with the 6 port setup. that rear actuator sits right on top of the header! Seems to me it would get toasted really quick. The headers definitely need some form of coating - be it wrapped or ceramic - though I like the ceramic for the aesthetic.

I will say though, I have seen a few very sharp looking wrap jobs.

I will say though, I have seen a few very sharp looking wrap jobs.

#4

Greetings all -

I'm planning out some upgrade pathways and something I've been considering for quite some time is ceramic coating the intake manifolds.

Through my research into the various options for coating, I found one shop claiming that they do special coatings for intakes, instead of acting as a barrier for heat, it disperses heat out of the intake to the atmosphere. Well, I'm no expert in thermodynamics, but it sure seems to me that means its an absorptive, as opposed to a reflective, surface.

Wouldn't that just soak up all the heat from the headers and top of the engine? Seems to me you would want to have a reflective coating to bounce the heat of the engine and headers off the intake manifold.

Anyone here have actual experience ceramic coating intakes? Your thoughts / input greatly appreciated.

I'm planning out some upgrade pathways and something I've been considering for quite some time is ceramic coating the intake manifolds.

Through my research into the various options for coating, I found one shop claiming that they do special coatings for intakes, instead of acting as a barrier for heat, it disperses heat out of the intake to the atmosphere. Well, I'm no expert in thermodynamics, but it sure seems to me that means its an absorptive, as opposed to a reflective, surface.

Wouldn't that just soak up all the heat from the headers and top of the engine? Seems to me you would want to have a reflective coating to bounce the heat of the engine and headers off the intake manifold.

Anyone here have actual experience ceramic coating intakes? Your thoughts / input greatly appreciated.

There are several types of Ceramic Coatings, Thermal Barriers and functional coatings. Traditional Ceramic Coatings and Thermal barriers are typically used on exhaust components, turbo components or pistons. Their primary purpose is to either keep hot or cold in or out of something much like a thermos. In the case of exhaust, you want to keep the heat within the exhaust pipe and exiting out the tailpipe as quickly as possible. In the case of an intake component, manifold or boost tube you generally want to keep heat out of it or reflect away any nearby radiated heat source.

The “special coating” they are referring to is a “heat dissipating coating. This coating has the ability to shed heat faster than the raw substrate could. Common uses for this type of coating would be radiators, oil related coolers, intercoolers, brake components, electronic equipment / enclosures, etc. In most cases it’s generally more effective to insulate an intake component from both engine generated heat and any exhaust related heat it may be in proximity to. This would entail coating both topside and bottom side surfaces. We have seen some limited uses (typical V8 applications) where owners have coated the bottom of the intake manifold with a thermal barrier and the top with a heat dissipating coating. I can see this being effective in a situation where the exhaust heat is being isolated from the intake area and the engine has access to incoming air.

To answer your last question, I don't know that heat dissipating coatings would posses any absorption properties going the other way, but they are certainly not going to offer any any heat rejection which is really your primary goal.

#5

On my car I have the interior runners teflon coated to prevent icing and the outside is ceramic chromed as a heat barrier. It's chronicled on my piece of **** build that I get depressed even thinking about.

#6

There are several types of Ceramic Coatings, Thermal Barriers and functional coatings. Traditional Ceramic Coatings and Thermal barriers are typically used on exhaust components, turbo components or pistons. Their primary purpose is to either keep hot or cold in or out of something much like a thermos. In the case of exhaust, you want to keep the heat within the exhaust pipe and exiting out the tailpipe as quickly as possible. In the case of an intake component, manifold or boost tube you generally want to keep heat out of it or reflect away any nearby radiated heat source.

The “special coating” they are referring to is a “heat dissipating coating. This coating has the ability to shed heat faster than the raw substrate could. Common uses for this type of coating would be radiators, oil related coolers, intercoolers, brake components, electronic equipment / enclosures, etc. In most cases it’s generally more effective to insulate an intake component from both engine generated heat and any exhaust related heat it may be in proximity to. This would entail coating both topside and bottom side surfaces. We have seen some limited uses (typical V8 applications) where owners have coated the bottom of the intake manifold with a thermal barrier and the top with a heat dissipating coating. I can see this being effective in a situation where the exhaust heat is being isolated from the intake area and the engine has access to incoming air.

To answer your last question, I don't know that heat dissipating coatings would posses any absorption properties going the other way, but they are certainly not going to offer any any heat rejection which is really your primary goal.

The “special coating” they are referring to is a “heat dissipating coating. This coating has the ability to shed heat faster than the raw substrate could. Common uses for this type of coating would be radiators, oil related coolers, intercoolers, brake components, electronic equipment / enclosures, etc. In most cases it’s generally more effective to insulate an intake component from both engine generated heat and any exhaust related heat it may be in proximity to. This would entail coating both topside and bottom side surfaces. We have seen some limited uses (typical V8 applications) where owners have coated the bottom of the intake manifold with a thermal barrier and the top with a heat dissipating coating. I can see this being effective in a situation where the exhaust heat is being isolated from the intake area and the engine has access to incoming air.

To answer your last question, I don't know that heat dissipating coatings would posses any absorption properties going the other way, but they are certainly not going to offer any any heat rejection which is really your primary goal.

A second question if I may, I bought my Racing Beat Headers with a ceramic coating. At that time I didn't know about the different types. Is there any way at this stage, to determine what type of coating was used? Is it primarily for looks or does it have some heat sheilding capabilities?

Eric

#7

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

There are several types of Ceramic Coatings, Thermal Barriers and functional coatings. Traditional Ceramic Coatings and Thermal barriers are typically used on exhaust components, turbo components or pistons. Their primary purpose is to either keep hot or cold in or out of something much like a thermos. In the case of exhaust, you want to keep the heat within the exhaust pipe and exiting out the tailpipe as quickly as possible. In the case of an intake component, manifold or boost tube you generally want to keep heat out of it or reflect away any nearby radiated heat source.

The “special coating” they are referring to is a “heat dissipating coating. This coating has the ability to shed heat faster than the raw substrate could. Common uses for this type of coating would be radiators, oil related coolers, intercoolers, brake components, electronic equipment / enclosures, etc. In most cases it’s generally more effective to insulate an intake component from both engine generated heat and any exhaust related heat it may be in proximity to. This would entail coating both topside and bottom side surfaces. We have seen some limited uses (typical V8 applications) where owners have coated the bottom of the intake manifold with a thermal barrier and the top with a heat dissipating coating. I can see this being effective in a situation where the exhaust heat is being isolated from the intake area and the engine has access to incoming air.

To answer your last question, I don't know that heat dissipating coatings would posses any absorption properties going the other way, but they are certainly not going to offer any any heat rejection which is really your primary goal.

The “special coating” they are referring to is a “heat dissipating coating. This coating has the ability to shed heat faster than the raw substrate could. Common uses for this type of coating would be radiators, oil related coolers, intercoolers, brake components, electronic equipment / enclosures, etc. In most cases it’s generally more effective to insulate an intake component from both engine generated heat and any exhaust related heat it may be in proximity to. This would entail coating both topside and bottom side surfaces. We have seen some limited uses (typical V8 applications) where owners have coated the bottom of the intake manifold with a thermal barrier and the top with a heat dissipating coating. I can see this being effective in a situation where the exhaust heat is being isolated from the intake area and the engine has access to incoming air.

To answer your last question, I don't know that heat dissipating coatings would posses any absorption properties going the other way, but they are certainly not going to offer any any heat rejection which is really your primary goal.

Excellent information. I'm curious about internal coatings on the intake - would there be a detriment to changing the surface of the inner tubing? For some reason I recall reading that a smoothed or polished internal surface can actually be detrimental to power. Would there even be any benefit for internal coating on the intake?

Thanks again for the download!

~Geoff

Trending Topics

#8

Subscribed. Same as u I heard its better to not have a smooth piping, but never had any evidence to back it up. I'm thinking mirror finish means no drag. Or even taking it as far as thinking about "rifling" and the effect that would have on power increase

#9

Do they make a coating that disperses heat out of the cooling system into the combustion chamber? That would be heat transferring backwards, too.

I can't think of a situation where the air in the intake manifold would be hotter than the manifold itself, or the surrounding air.

I did paint my intake manifold and carb hat with a white thermal barrier paint. Not sure if it does anything useful because I didn't do an A-B-A test, but at least it really picks up fingerprints and grime...

#10

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

I recall something about the surface texture creating micro turbulence to help keep the air/fuel mixed and prevent condensation. Could be total BS, I'm not convinced and my source was certainly parroting what they heard elsewhere.

#11

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

Do they make a coating that disperses heat out of the cooling system into the combustion chamber? That would be heat transferring backwards, too.

I can't think of a situation where the air in the intake manifold would be hotter than the manifold itself, or the surrounding air.

#12

It's true, and it works for the same reason that a rough surface can flow more than a smooth one - it allows the air to move faster, closer to the runner surface. Fast moving air keeps the fuel in suspension.

#13

I heard the micro turbulence thing talked about by a couple of guys who worked on v8 heads. What they explained was that a smooth, not shiny surface flows better. They would even induce larger turbulence on the inside radius or turns in a port runner to create a slingshot effect. The would do this by cutting steps or creating dimples right before the turn. I know these are different animals than ours but think of just how much power those monsters make based on small bolt ons I.e. heads or intake manifolds... Food for thought.

#14

I did my intake and exhaust with Cerakote high temp. 1800deg. Comes in air dry or oven cure. I still have some left over, as well as some of their chromex which is oven cure only. I never did get the chromex polished up enough to where I liked it, so I ended up doing both in the plain coating.

They do have the heat dissapating coating, air or oven cure.

Cerakote Coatings: Finishes

They do have the heat dissapating coating, air or oven cure.

Cerakote Coatings: Finishes

#15

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

I did my intake and exhaust with Cerakote high temp. 1800deg. Comes in air dry or oven cure. I still have some left over, as well as some of their chromex which is oven cure only. I never did get the chromex polished up enough to where I liked it, so I ended up doing both in the plain coating.

They do have the heat dissapating coating, air or oven cure.

Cerakote Coatings: Finishes

They do have the heat dissapating coating, air or oven cure.

Cerakote Coatings: Finishes

I don't need exact temps or anything, just general effectiveness. I've heard of some people paying for ceramic coatings and having no reduction in temps at all - just a glorified powder coat, where another shop puts on a thermal barrier making a huge diff.

#16

Well once I sort out an ignition issue, I'll let you know. I've been waiting on a couple parts. I did a real thick coating on both and it looks good but since I never did any temp readings I'll be just guessing by how it feels when I put my hand to the exhause when at running temps.

I still have quite a bit left over if anyone wants to try their hand and do a more scientific breakdown of before and after temps with the DIY kit.

I still have quite a bit left over if anyone wants to try their hand and do a more scientific breakdown of before and after temps with the DIY kit.

#18

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

There's also a bunch of inspiring and interesting information to be had at this website:

Why Ceramic Engines?

It would be cool to be a billionaire and fund a few experimental engine projects like this one

#19

Moderator

iTrader: (3)

Joined: Mar 2001

Posts: 31,203

Likes: 2,826

From: https://www2.mazda.com/en/100th/

can't you just buy a 3d printer?

i stumbled across some pics of a 2010+ Rx8 engine, and Mazda was putting some kind of non stick coating on the rotors in those, i think they were trying to minimize carbon buildup. of course, there's no info on it, and a non stick coating isn't really "normal" or part of the brochure!

i stumbled across some pics of a 2010+ Rx8 engine, and Mazda was putting some kind of non stick coating on the rotors in those, i think they were trying to minimize carbon buildup. of course, there's no info on it, and a non stick coating isn't really "normal" or part of the brochure!

#21

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

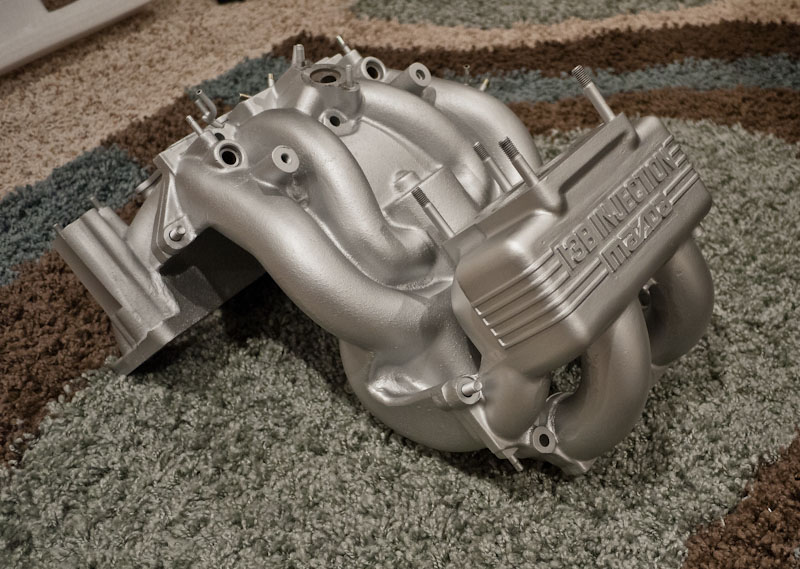

And here she is, moments before being boxed up and mailed out to Performance Coatings in Auburn, WA

Before grinding / smoothing:

After

The S5 N/A middle / VDI intake has got to be one of the sexiest intakes evar. After grinding and smoothing:

Took the LIM into All-Fab and had them weld up the exhaust port that heats up the intake:

Mailing this out today - should be 1 or 2 weeks and I'll post up the after-shots of the ceramic coating!

Geoff is STOKED

Before grinding / smoothing:

After

The S5 N/A middle / VDI intake has got to be one of the sexiest intakes evar. After grinding and smoothing:

Took the LIM into All-Fab and had them weld up the exhaust port that heats up the intake:

Mailing this out today - should be 1 or 2 weeks and I'll post up the after-shots of the ceramic coating!

Geoff is STOKED

#25

Thread Starter

'84 5-letter

iTrader: (5)

Joined: Jul 2002

Posts: 3,219

Likes: 7

From: Washington State

http://performancecoatings.com/

Geoff