Megasquirt Starts dies starts dies again

#1

Starts dies starts dies again

Starts dieís starts dies again v3 M1 stock 86 na w/stock harness detooth cas (harness adapted over) no idle control (wired to the air by-pass relay but unhooked at the sensor) n/b oem o2 sensor (I have a lm1 logger 4 later) the car was running fine and still will if I pull the cas and hook the oem ecm back up

Ok I got it to start and run for a few seconds till the megatuneís gauges in the main screen go all to hell and act like the ms lost power Rpm go to 0 but the motor is still spinning ,rpm;s jump all over the place pop pop and it dieís,, at one point megatune would not get any signals from the sensors (tps) until I turned power to the ms on and off then it will restart and do the same thing allover again tried messing around with the ve table took 10% out didnít do any thing took 5% out didnít do any thing add the same 10% and 5% didnít do any thing recut another cas grounded the teeth all the way down to make sure it wasnít picking up some thing there didnít change any thing!! A battery charger was hooked up the hole time I was starting and dieing !It looks to work fine on the stim but on the cars is another story,, I data logged both and here is my msq file witch is basically a copy of one I down loaded here to get it up and going!! Any ideaís

Ok I got it to start and run for a few seconds till the megatuneís gauges in the main screen go all to hell and act like the ms lost power Rpm go to 0 but the motor is still spinning ,rpm;s jump all over the place pop pop and it dieís,, at one point megatune would not get any signals from the sensors (tps) until I turned power to the ms on and off then it will restart and do the same thing allover again tried messing around with the ve table took 10% out didnít do any thing took 5% out didnít do any thing add the same 10% and 5% didnít do any thing recut another cas grounded the teeth all the way down to make sure it wasnít picking up some thing there didnít change any thing!! A battery charger was hooked up the hole time I was starting and dieing !It looks to work fine on the stim but on the cars is another story,, I data logged both and here is my msq file witch is basically a copy of one I down loaded here to get it up and going!! Any ideaís

#2

Usually if it starts and dies, it means you don't have enough fuel to the engine. If the guages were doing weird things, I'd first suggest detaching the battery charger, as that can cause noise issues.

I'll look at your log and msq when I've got time (hopefully tonight when I get home) to see if it's just a simple settings issue.

Ken

I'll look at your log and msq when I've got time (hopefully tonight when I get home) to see if it's just a simple settings issue.

Ken

#3

ok ty ken

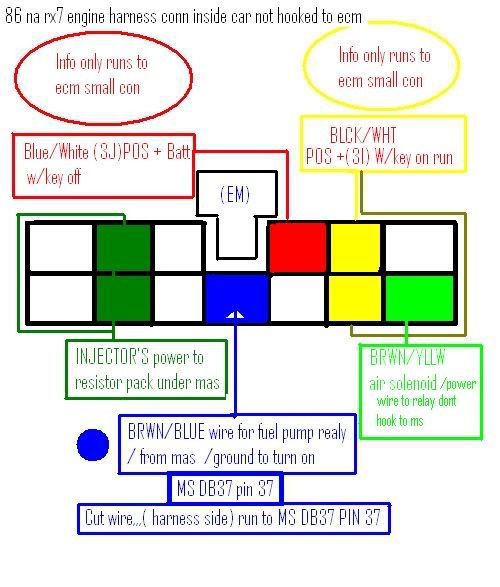

I think it has enough fuel, as i had to flodd clear it a few times and the nice backfire's in the exhaust i heard lol,, it starts right up faster than w/the stock ecm hooked up just will not stay running long then the dam gauges go all nuttie like the ms losses power than it dies (faster it spins the worse it gets) towards the end of the log rpm reached 17667(never realy did that log just said it did) and hum weard batt volts jumped to 18.1 maybe i try to take the charger and the alt off tomarrow.iIam running msextra latest v version and this is how i wired it to the stock harness (see below)! iam using the stock mas maf what ever sensor to turn on fuel right now however i did try it both ways w/ms turning on pump and w/maf turning on pump!

Megasquirt v3 M1(chip)

DB37 PINĒS 86 S4 OEM Harness Plugís

Pin 19 - Ground -------------------Common ground (all sensorís ground here)--2C

Pin 26 - TPS Ref voltage 5V ---------------------------------------------------------------2A

Pin 21 - Water temp ------------------------------------------------------------------------2I

Pin 20 - Intake air temp --------------------------------------------------------------------2L

Pin 23 - O2 sensor (shielded oem wire)-------------------------------------------------2D

Pin 30 ĖAir bypass relay -------------------------------------------------------------------1C

Pin 33 - Rear primary injector -------------------------------------------------------------3C

pin 35 - Rear secondary injector-----------------------------------------------------------3F

Pin 32 - Front primary injector ------------------------------------------------------------3E

Pin 34 - Front secondary injector ---------------------------------------------------------3H

Pin 28 - Main Relay -------------------------------------------------------------------------3I

Pin 22 - Throttle Sensor --------------------------------------------------------------------2G

Pin 8 - Ground (2R & 3A hook together in oem harness)-----------------------------2r

Pin 9 - Ground ------------------------------------------------------------------------------3A

Pin 10 - Ground -----------------------------------------------------------------------------3G

Pin 11 - Ground -----------------------------------------------------------------------------3G

* Detoothed CAS

*Pin 7 - Crank Angle Sensor (-Ne) (24 wheel White wire inside CAS) ----------1Q

*Pin 24 - Crank Angle Sensor (+Ne) (24 wheel red wire inside CAS) ------------1T

***** If it's set up as TSEL -> VROUTINV as shown in FAQ, then the above is fine. If you built it to MS assembly documentation defaults, (TSEL -> VROUT), then you'll have to reverse the VR sensor connections pin7 to 1T and pin24 to 1Q *******

> Unmoded CAS (w/2ND VR Circuit)

>Pin 7 - Crank Angle Sensor(-Ne) (24 wheel White wire inside CAS) ------------1Q

>Pin 24 - Crank Angle Sensor(+Ne) (24 wheel red wire inside CAS) --------------1T

>Vr2 In - Crank Angle Sensor (+G) (2 wheel green wire inside CAS) -------------1N

>Vr2 Ground - C.A.S (-G) (2 wheel white/black wire inside CAS) ------------------1P

Coilís

Pin 31 LED(-) 14 (G/Y Coil W/Igniter Leading IGT-L ignition timing signal) -------1V

Pin 29 LED(-) 15 (BR/Y Coil W/Igniter Trailing IGT-T select signal) -----------------1U

Pin 27 LED(-) 16 (L/Y Coil W/Igniter Trailing IGT-T ignition timing signal) ---------1X

*A/C Jump (hook together) OEM ecm plug 1E & 1F

Pin 37 - Fuel pump relay Brown/blue wire from mas goes to other connector (EM) in main engine harness cut wire or tap (harness side) and run to DB37 PIN 37. Or just leave the mas in place (hooked up) it will turn the fuel pump on!

I think it has enough fuel, as i had to flodd clear it a few times and the nice backfire's in the exhaust i heard lol,, it starts right up faster than w/the stock ecm hooked up just will not stay running long then the dam gauges go all nuttie like the ms losses power than it dies (faster it spins the worse it gets) towards the end of the log rpm reached 17667(never realy did that log just said it did) and hum weard batt volts jumped to 18.1 maybe i try to take the charger and the alt off tomarrow.iIam running msextra latest v version and this is how i wired it to the stock harness (see below)! iam using the stock mas maf what ever sensor to turn on fuel right now however i did try it both ways w/ms turning on pump and w/maf turning on pump!

Megasquirt v3 M1(chip)

DB37 PINĒS 86 S4 OEM Harness Plugís

Pin 19 - Ground -------------------Common ground (all sensorís ground here)--2C

Pin 26 - TPS Ref voltage 5V ---------------------------------------------------------------2A

Pin 21 - Water temp ------------------------------------------------------------------------2I

Pin 20 - Intake air temp --------------------------------------------------------------------2L

Pin 23 - O2 sensor (shielded oem wire)-------------------------------------------------2D

Pin 30 ĖAir bypass relay -------------------------------------------------------------------1C

Pin 33 - Rear primary injector -------------------------------------------------------------3C

pin 35 - Rear secondary injector-----------------------------------------------------------3F

Pin 32 - Front primary injector ------------------------------------------------------------3E

Pin 34 - Front secondary injector ---------------------------------------------------------3H

Pin 28 - Main Relay -------------------------------------------------------------------------3I

Pin 22 - Throttle Sensor --------------------------------------------------------------------2G

Pin 8 - Ground (2R & 3A hook together in oem harness)-----------------------------2r

Pin 9 - Ground ------------------------------------------------------------------------------3A

Pin 10 - Ground -----------------------------------------------------------------------------3G

Pin 11 - Ground -----------------------------------------------------------------------------3G

* Detoothed CAS

*Pin 7 - Crank Angle Sensor (-Ne) (24 wheel White wire inside CAS) ----------1Q

*Pin 24 - Crank Angle Sensor (+Ne) (24 wheel red wire inside CAS) ------------1T

***** If it's set up as TSEL -> VROUTINV as shown in FAQ, then the above is fine. If you built it to MS assembly documentation defaults, (TSEL -> VROUT), then you'll have to reverse the VR sensor connections pin7 to 1T and pin24 to 1Q *******

> Unmoded CAS (w/2ND VR Circuit)

>Pin 7 - Crank Angle Sensor(-Ne) (24 wheel White wire inside CAS) ------------1Q

>Pin 24 - Crank Angle Sensor(+Ne) (24 wheel red wire inside CAS) --------------1T

>Vr2 In - Crank Angle Sensor (+G) (2 wheel green wire inside CAS) -------------1N

>Vr2 Ground - C.A.S (-G) (2 wheel white/black wire inside CAS) ------------------1P

Coilís

Pin 31 LED(-) 14 (G/Y Coil W/Igniter Leading IGT-L ignition timing signal) -------1V

Pin 29 LED(-) 15 (BR/Y Coil W/Igniter Trailing IGT-T select signal) -----------------1U

Pin 27 LED(-) 16 (L/Y Coil W/Igniter Trailing IGT-T ignition timing signal) ---------1X

*A/C Jump (hook together) OEM ecm plug 1E & 1F

Pin 37 - Fuel pump relay Brown/blue wire from mas goes to other connector (EM) in main engine harness cut wire or tap (harness side) and run to DB37 PIN 37. Or just leave the mas in place (hooked up) it will turn the fuel pump on!

#4

here's an idea, and I am being serious. if you did not clean the board off with alcohol(Isopropanol) then this could be causing the problem. seriously dude, you may not know how badly that rosin left over from soldering can conduct between terminals on the board. Just a thought.

dpf22

dpf22

#7

I saw some of the same reset behavior as in your "incar.xls", try flashing 029T, and try to log again. I have been working on some extensive testing w/ 029V and hr_09 vs 029T and hr_08. I have heard some have 029V running, however my logs and your logs of 029V look very similar, yet I have no problems with any code version prior to 029U/V.

Trending Topics

#8

Originally Posted by dpf22

here's an idea, and I am being serious. if you did not clean the board off with alcohol(Isopropanol) then this could be causing the problem. seriously dude, you may not know how badly that rosin left over from soldering can conduct between terminals on the board. Just a thought.

dpf22

dpf22

#9

Originally Posted by T2GTUS

I saw some of the same reset behavior as in your "incar.xls", try flashing 029T, and try to log again. I have been working on some extensive testing w/ 029V and hr_09 vs 029T and hr_08. I have heard some have 029V running, however my logs and your logs of 029V look very similar, yet I have no problems with any code version prior to 029U/V.

Thanks 4 the reply's every one

#10

I dont see any resets on your new log which is good. (yes they are the long lines in megalogviewer, but they are clearly spelled out if you look at it in excel). If you are using the same msq as before, I would definitely look at your cranking pulsewidths, they seem really high to me, and you are also using first crank enrichment of 30%, so take that into consideration as well. Your warmup% seems very high to me also. Your tps ae numbers are all 0 except at 15v/s. Also the numbers at the low end of your fuel map seem extremely high to me as well (I think its just flooding out at the 1100 rpm and up bins)

There are some msq's in this thread, no guarantee but they may help you with some numbers to try Laptop Crashed.

There are some msq's in this thread, no guarantee but they may help you with some numbers to try Laptop Crashed.

#11

Good to see the resets are gone.

Some questions...

1.) What injector size?

2.) Are you running staged injection, and did you verify your primary/secondary injectors are connected to the correct MS outputs?

3.) Have you checked pressure during these run attempts? If so, what's the results

4.) Is the fuel pump controlled via MS or externally wired? Any chance you've got it wired to run the pump during crank, but not run?

5.) Did you do a plug check after stalling, or notice any over-rich symptoms (shudder/misfire prior to stall, stinky exhaust...)?

6.) Have you had any flooding issues during these start attempts?

I ask these questions as your injector pulse widths are higher than expected, and it appears to be stalling due to over-fueling. However, if that was the case, I'd expect you'd be pulling and drying plugs frequently but I don't see any mention of flooding problems.

Some questions...

1.) What injector size?

2.) Are you running staged injection, and did you verify your primary/secondary injectors are connected to the correct MS outputs?

3.) Have you checked pressure during these run attempts? If so, what's the results

4.) Is the fuel pump controlled via MS or externally wired? Any chance you've got it wired to run the pump during crank, but not run?

5.) Did you do a plug check after stalling, or notice any over-rich symptoms (shudder/misfire prior to stall, stinky exhaust...)?

6.) Have you had any flooding issues during these start attempts?

I ask these questions as your injector pulse widths are higher than expected, and it appears to be stalling due to over-fueling. However, if that was the case, I'd expect you'd be pulling and drying plugs frequently but I don't see any mention of flooding problems.

#12

Originally Posted by T2GTUS

I dont see any resets on your new log which is good. (yes they are the long lines in megalogviewer, but they are clearly spelled out if you look at it in excel). If you are using the same msq as before, I would definitely look at your cranking pulsewidths, they seem really high to me, and you are also using first crank enrichment of 30%, so take that into consideration as well. Your warmup% seems very high to me also. Your tps ae numbers are all 0 except at 15v/s. Also the numbers at the low end of your fuel map seem extremely high to me as well (I think its just flooding out at the 1100 rpm and up bins)

There are some msq's in this thread, no guarantee but they may help you with some numbers to try Laptop Crashed.

There are some msq's in this thread, no guarantee but they may help you with some numbers to try Laptop Crashed.

2marrow i get to play with getting the lm1 hook up any one know were to get a good tach signal for it and what method they used to hook it up?I know for my gsxr it was a real pain!!

any ways thanks for all the help!!

Last edited by twister7; 02-03-07 at 07:26 PM.

#13

Originally Posted by renns

Good to see the resets are gone.

Some questions...

1.) What injector size?

2.) Are you running staged injection, and did you verify your primary/secondary injectors are connected to the correct MS outputs?

3.) Have you checked pressure during these run attempts? If so, what's the results

4.) Is the fuel pump controlled via MS or externally wired? Any chance you've got it wired to run the pump during crank, but not run?

5.) Did you do a plug check after stalling, or notice any over-rich symptoms (shudder/misfire prior to stall, stinky exhaust...)?

6.) Have you had any flooding issues during these start attempts?

I ask these questions as your injector pulse widths are higher than expected, and it appears to be stalling due to over-fueling. However, if that was the case, I'd expect you'd be pulling and drying plugs frequently but I don't see any mention of flooding problems.

Some questions...

1.) What injector size?

2.) Are you running staged injection, and did you verify your primary/secondary injectors are connected to the correct MS outputs?

3.) Have you checked pressure during these run attempts? If so, what's the results

4.) Is the fuel pump controlled via MS or externally wired? Any chance you've got it wired to run the pump during crank, but not run?

5.) Did you do a plug check after stalling, or notice any over-rich symptoms (shudder/misfire prior to stall, stinky exhaust...)?

6.) Have you had any flooding issues during these start attempts?

I ask these questions as your injector pulse widths are higher than expected, and it appears to be stalling due to over-fueling. However, if that was the case, I'd expect you'd be pulling and drying plugs frequently but I don't see any mention of flooding problems.

1) stock oem 86 peak and hold 430 cc,, stock resistor pack under mas still there postive power side witch i was woundering about

2)yes and yes took apart a wiring harness to make sure each injector is wired as it was stock 1 wire from ms to one injector (conections are not bridged) 1 for primary frnt ,,1 for primay rear,, 1 secondary frnt,, 1 seconadary rear,, power comes from resistor pack through stock harness!!

3) bingo no

4) well stock maf was hooked up then and or now it is controlled ms wired it to stock harness see pic

5)with 029v yes ha to flood clear missed bang in the exhaust exctra 029t nope ran smooth just dies soon after starting (never pulled any plugs at all)

6)i had to fllod clear several time with the 029v code verry little or none at all with the 029t code

let me know if u know any thing about the lm-1 rpm hook up?

#14

OK, now you got the fuel situation sorted out. Helps to have the pump running eh? :-) LM-1 hookup AFAIK is the same as the LC-1. Program the analog output to suit (see MS docs), and you are good to go. I have no idea what LM-1 needs a tach signal for...

#15

Originally Posted by renns

OK, now you got the fuel situation sorted out. Helps to have the pump running eh? :-) LM-1 hookup AFAIK is the same as the LC-1. Program the analog output to suit (see MS docs), and you are good to go. I have no idea what LM-1 needs a tach signal for...

#16

I'd just use MS for datalogging, as it'll log AFR along with the other 2 dozen or so run-time variables. That'll save using two different logging tools.

The LM-1 has analog outputs as well, so you could use it directly with MS, or swap it for an LC-1.

The LM-1 has analog outputs as well, so you could use it directly with MS, or swap it for an LC-1.

Thread

Thread Starter

Forum

Replies

Last Post

rgordon1979

3rd Generation Specific (1993-2002)

40

03-15-22 12:04 PM