Megasquirt MS3X Boost Control Not Working

#1

Thread Starter

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

MS3X Boost Control Not Working

I have a situation that isn't making much sense to me, so maybe getting a few more eyes on it will help.

The car is a pretty standard setup: S4 TII, stock CAS and coils, BNR Stage 3, FMIC, 460CC (yes, 460) primaries, 960CC secondaries.

MS3X is running latest firmware (1.2.1). BAC on MS3X, AEM UEGO wideband, Nitrous1 switching e-fan relay, Nitrous2 switching twin scroll solenoid, DIYAutoTune boost solenoid on Boost output.

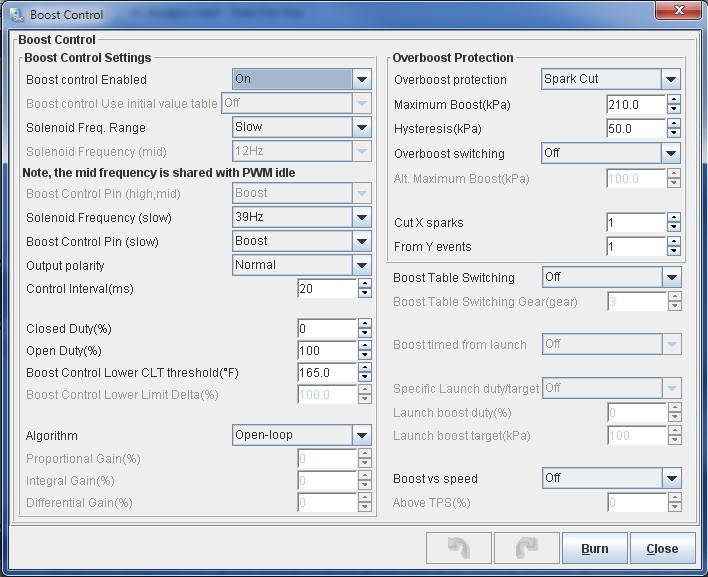

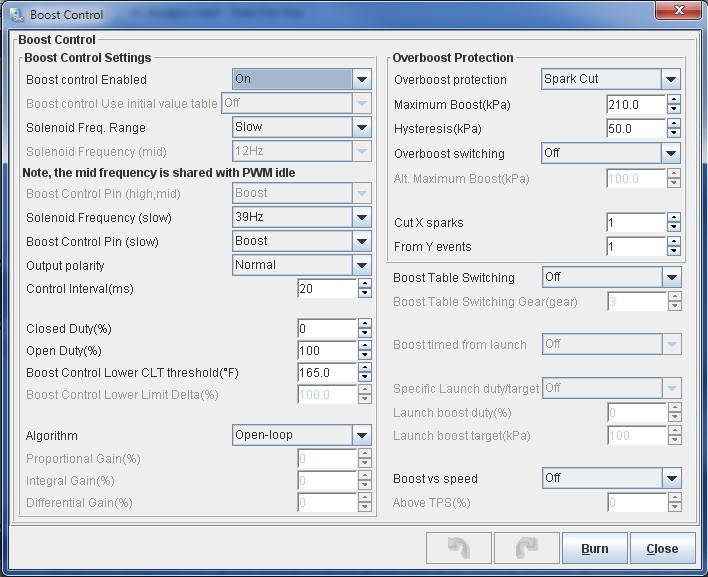

So here's the weird part: I can't get the boost controller to actually raise boost. Here is a screen shot of how I have it set up:

Changing the boost duty table does not effect boost in any way. 0% across the table has no effect, 100% across the table makes no difference. Boost stays right around 8 PSI. The software gauge in TunerStudio shows that the controller is outputting the duty cycle I have commanded.

The solenoid has been tested in I/O test mode. I can set the frequency to 39Hz, set PP3-Boost to "Pulsed", then vary the duty cycle and both hear and feel a response from the solenoid.

Going further, if I disconnect the vacuum hose from the compressor housing and connect to shop air, I can open the wastegate via air pressure. Then I can turn on I/O test, increase the duty cycle on the solenoid, and actually watch the wastegate close up as well as feel the vented air from the solenoid port.

So, I have proved that the solenoid is connected properly both electrically and pneumatically. Hence my confusion.

Any ideas?

The car is a pretty standard setup: S4 TII, stock CAS and coils, BNR Stage 3, FMIC, 460CC (yes, 460) primaries, 960CC secondaries.

MS3X is running latest firmware (1.2.1). BAC on MS3X, AEM UEGO wideband, Nitrous1 switching e-fan relay, Nitrous2 switching twin scroll solenoid, DIYAutoTune boost solenoid on Boost output.

So here's the weird part: I can't get the boost controller to actually raise boost. Here is a screen shot of how I have it set up:

Changing the boost duty table does not effect boost in any way. 0% across the table has no effect, 100% across the table makes no difference. Boost stays right around 8 PSI. The software gauge in TunerStudio shows that the controller is outputting the duty cycle I have commanded.

The solenoid has been tested in I/O test mode. I can set the frequency to 39Hz, set PP3-Boost to "Pulsed", then vary the duty cycle and both hear and feel a response from the solenoid.

Going further, if I disconnect the vacuum hose from the compressor housing and connect to shop air, I can open the wastegate via air pressure. Then I can turn on I/O test, increase the duty cycle on the solenoid, and actually watch the wastegate close up as well as feel the vented air from the solenoid port.

So, I have proved that the solenoid is connected properly both electrically and pneumatically. Hence my confusion.

Any ideas?

Last edited by Aaron Cake; 06-03-13 at 04:58 PM.

#2

That is confusing as everything sounds right to me.

Are you sure the firmware is up to date because this seemed to be an issue in 1.2.0

Megasquirt MSEXTRA / MS3EFI • Boost control CLT threshold not working. (View topic)

Are you sure the firmware is up to date because this seemed to be an issue in 1.2.0

Megasquirt MSEXTRA / MS3EFI • Boost control CLT threshold not working. (View topic)

#3

Thread Starter

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

I just confirmed in the MSQ that we are running 1.2.1:

Code:

versionInfo fileFormat="4.0" firmwareInfo="MS3 release 1.2.1 20130316 16:55GMT (c) JSM/KC ********" nPages="15" signature="MS3 Format 0262.07

#4

I messed with the software for a while last night and I can't think of anything that would be causing this, except maybe a boost leak. Probably would be a good idea to post this to the msextra forums to get some ideas.

#5

So from my understanding it will only run at W/G spring pressure? did the MS drive the solenoid when you had it hooked up to the shop air? If so sounds like you got picked a bad vacuum/boost reference point maybe.

#6

Yeah, if the MS is actually making the solenoid react then I'm not sure you're having an MS issue. It seems like the issue is external to the MS.

Which solenoid are you using? If you're using the DIY one, usually those should be run at a much lower frequency, like 19.5HZ (I think if I'm remembering correctly... it was around 19 in any case).

Ken

Which solenoid are you using? If you're using the DIY one, usually those should be run at a much lower frequency, like 19.5HZ (I think if I'm remembering correctly... it was around 19 in any case).

Ken

#7

Turbine inlet pressure / Exhaust manifold pressure can and will open the internal waste gate. I don't know about you but the newest FC3S turbos are now 22 years old. I have a hand full of them and they are all sloppy around the door cam. Also the waste gate can has insufficient spring tension to hold more than about 8psi at full revs anyway. At best case you will get it to peak between 13 and 15psi and then droop down to 8psi again at redline anyway.

My setup when executed like that always had lazy boost vs rpm response as well, I threw an external gate with a stiff spring onto the manifold (was using a custom steampipe one all along) and it completely changed how it worked.

V-trim / series 5 turbine is a great compressor turbine match with awesome response and flow for 12A's and 13B's but the actual execution of the install because of the internal wastegate always makes them a bucket of ****

My setup when executed like that always had lazy boost vs rpm response as well, I threw an external gate with a stiff spring onto the manifold (was using a custom steampipe one all along) and it completely changed how it worked.

V-trim / series 5 turbine is a great compressor turbine match with awesome response and flow for 12A's and 13B's but the actual execution of the install because of the internal wastegate always makes them a bucket of ****

Trending Topics

#8

Thread Starter

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

Thank you everyone for your help. At this point next time I'm looking at the car we will first look for a mechanical issue. Since everything is new, and the fact that testing with shop air showed the wastegate responding correctly, we moved onto troubleshooting at the EMS level.

Since the turbo is a brand new BNR hybrid stage 3, it comes with a brand new Garrett wastegate actuator. However I'm not sure what size spring is included by default. My guess is right around 8 PSI as that's what the turbo makes naturally. Since it is adjustable, it's possible that tension is set so soft that it's being forced open via exhaust gasses but still, I'd expect to see at least some change in boost level via the boost controller.

Regardless, the plan now is that next time I'm tuning the car, we will disconnect the wastegate air line from the compressor and run essentially "no wastegate". Obviously with a sane boost cut level in the MS. The expected result should be high uncontrollable boost. If we don't get that, then there is something up (BOV opening, big boost leak, etc.). I tend to think it's not a boost leak as the turbo (with functional twin scroll) makes boost damn near instantly at any RPM.

Oh, regarding the solenoid it is the newer style DIYAutoTune solenoid, which on the website they spec as running from 19HZ to 40HZ. Not sure what frequency they are happiest with so I just picked 39Hz. Seemed to work in bench testing.

Since the turbo is a brand new BNR hybrid stage 3, it comes with a brand new Garrett wastegate actuator. However I'm not sure what size spring is included by default. My guess is right around 8 PSI as that's what the turbo makes naturally. Since it is adjustable, it's possible that tension is set so soft that it's being forced open via exhaust gasses but still, I'd expect to see at least some change in boost level via the boost controller.

Regardless, the plan now is that next time I'm tuning the car, we will disconnect the wastegate air line from the compressor and run essentially "no wastegate". Obviously with a sane boost cut level in the MS. The expected result should be high uncontrollable boost. If we don't get that, then there is something up (BOV opening, big boost leak, etc.). I tend to think it's not a boost leak as the turbo (with functional twin scroll) makes boost damn near instantly at any RPM.

Oh, regarding the solenoid it is the newer style DIYAutoTune solenoid, which on the website they spec as running from 19HZ to 40HZ. Not sure what frequency they are happiest with so I just picked 39Hz. Seemed to work in bench testing.

#10

Thread Starter

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

I know, I know. I'm always harping on people to post a datalog or an MSQ when they have a problem.  I just didn't get one because the boost duty cycle gauge in TunerStudio was responding as it should, showing the exact duty cycle that I commanded in the table. Just for initial setup and to get a feel for how the solenoid effects boost I just set the same value across the entire table. Probably won't get messed with this weekend, but likely revisited next weekend.

I just didn't get one because the boost duty cycle gauge in TunerStudio was responding as it should, showing the exact duty cycle that I commanded in the table. Just for initial setup and to get a feel for how the solenoid effects boost I just set the same value across the entire table. Probably won't get messed with this weekend, but likely revisited next weekend.

I just didn't get one because the boost duty cycle gauge in TunerStudio was responding as it should, showing the exact duty cycle that I commanded in the table. Just for initial setup and to get a feel for how the solenoid effects boost I just set the same value across the entire table. Probably won't get messed with this weekend, but likely revisited next weekend.

I just didn't get one because the boost duty cycle gauge in TunerStudio was responding as it should, showing the exact duty cycle that I commanded in the table. Just for initial setup and to get a feel for how the solenoid effects boost I just set the same value across the entire table. Probably won't get messed with this weekend, but likely revisited next weekend.

#11

Thread Starter

Engine, Not Motor

iTrader: (1)

Joined: Feb 2001

Posts: 29,793

Likes: 119

From: London, Ontario, Canada

Guess I should update this topic with the resolution.

The issue turned out to be the idiocy of BNR supplying a 5.6 PSI spring in the "upgraded" wastegate actuator on the stage 3. It boggles the mind why a 5.6 PSI spring is included with a turbo efficient on the 13B around 15 PSI, with no documentation on the website stating that little fact. A call to BNR confirmed it and my friend (owner of the car) is now in the battle with BNR to have a reasonable wastegate actuator shipped.

This was troubleshooted using two methods:

1. Air line was removed from the wastegate actuator. With no boost signal to the wastegate, one would expect uncontrollable boost. The reality was 8 PSI as the wastegate flapper was forced open by exhaust

2. An external spring was added to the actuator arm. With more spring tension, we were able to use the boost solenoid to raise the boost to the desired 15 PSI.

Currently waiting on a new wastegate actuator to be shipped from BNR. An upgraded actuator was paid for when the turbo was purchased, otherwise we would have just bought one from ATP.

The issue turned out to be the idiocy of BNR supplying a 5.6 PSI spring in the "upgraded" wastegate actuator on the stage 3. It boggles the mind why a 5.6 PSI spring is included with a turbo efficient on the 13B around 15 PSI, with no documentation on the website stating that little fact. A call to BNR confirmed it and my friend (owner of the car) is now in the battle with BNR to have a reasonable wastegate actuator shipped.

This was troubleshooted using two methods:

1. Air line was removed from the wastegate actuator. With no boost signal to the wastegate, one would expect uncontrollable boost. The reality was 8 PSI as the wastegate flapper was forced open by exhaust

2. An external spring was added to the actuator arm. With more spring tension, we were able to use the boost solenoid to raise the boost to the desired 15 PSI.

Currently waiting on a new wastegate actuator to be shipped from BNR. An upgraded actuator was paid for when the turbo was purchased, otherwise we would have just bought one from ATP.