Megasquirt Looking for alot of help... stock S4 /w ITBs / RB Duals

#1

Looking for alot of help... stock S4 /w ITBs / RB Duals

I am looking for someone to help me setup megasquirt /w msns-e. I have an 88 S4 6 port motor. A one piece wrap around one piece manifold hooked up to a DCOE 52mm style TWMinduction single throttle body. I am also in the process right now of converting the OMP to use 2-stroke oil.

Can anyone be of help?

From what I understand so far that Ive been reading this setup should be alot easier.

Each barrel on the ITB setup has a place for a MAP sensor, 1 injector, and 1 TPS. Since I do not have the staged secondaries hooked up anymore it seems it would be much easier to setup.

If anyone can be of help thanks in advance.

Can anyone be of help?

From what I understand so far that Ive been reading this setup should be alot easier.

Each barrel on the ITB setup has a place for a MAP sensor, 1 injector, and 1 TPS. Since I do not have the staged secondaries hooked up anymore it seems it would be much easier to setup.

If anyone can be of help thanks in advance.

#2

it sounds like a really straight forward set-up. Realistically, you can have it run without a tps, or you could just have an on/off style tps using the standard plunger tps so you can have an idle function. You can set enrichments up like I do and use map based enrichment. I would put a couple of fairly large injectors in there if you only have 2. Something along the lines of 720cc or possibly 850cc/min. Just my suggestion. (since its n/a no big fuel issues there)

Have you figured out your ignition set-up yet?

dpf22

Have you figured out your ignition set-up yet?

dpf22

#3

I have 2 untouched CAS's and a distributor from a 12A. I kind of understand what I am doing in megasquirt but I am skeptical about doing it on my own without someones help who has a running motor.

I am using the 2 lower 460cc in the housings and 1 460cc in each barrel.

I am using the 2 lower 460cc in the housings and 1 460cc in each barrel.

#4

well, there are more than a few people on here with running motors including myself. you will want to modify the cas by cutting 2 opposing teeth out of the bottom wheel. it doesn't matter which teeth, just make sure that theya re 180degrees apart.

and the stock 460cc/min injectors should be plenty of fuel even for itb's

dpf22

and the stock 460cc/min injectors should be plenty of fuel even for itb's

dpf22

#5

That seems simple enough.. but what do you set the CAS to? You need a point of reference for timing? Any teeth? then how do you reinstall and calibrate it afterwards? I dont know how to explain it very well but you dont want it to randomly fire whenever. What is to doing that half of the CAS mod?

#6

The 24 tooth wheel runs at 1/2 crank speed. Carefully grind away 2 teeth - 180 degrees from each other, directly across the wheel from each other. Counting around the wheel you will a missing tooth, 11 intact teeth, another missing tooth then the second missing tooth. that brings you all the way around. As far as setting the trigger angle take a look at muy's sticky/FAQ at the top of this forum. when setting the trigger angle (stabbing the CAS) remember that the CAS shaft turns in the opposite direction, CCW, from the CW turning crank. This whole concept takes a little bit of thought to get your head straight on it, don't get discouraged. Also, you will want to run the idle and low load sections of your fueling on the irons located injectors and add the ITB injectors' fueling at higher loads. If you use the TB located injectors you have a large amount of wetted runner wall that makes tuning AE, etc. a bit more touchy and temperature sensitive. I use the ITB based injectors only as I have no irons based injector bosses - 12A - and have about 3 years experience with MS/rotary/etc. use and can testify to the fact that ITB based injection can be tough to tune in regards to AE, tipin, low load transition, etc.

-Mike

-Mike

Trending Topics

#8

I made an error in my last message, here's the correction:

Carefully grind away 2 teeth - 180 degrees from each other, directly across the wheel from each other. Counting around the wheel you will a missing tooth, 11 intact teeth, a missing tooth, then another 11 teeth.

I'll post a clear writeup on trigger angle, TDC setting, etc. as soon as I can find where I stored it!

-Mike

Carefully grind away 2 teeth - 180 degrees from each other, directly across the wheel from each other. Counting around the wheel you will a missing tooth, 11 intact teeth, a missing tooth, then another 11 teeth.

I'll post a clear writeup on trigger angle, TDC setting, etc. as soon as I can find where I stored it!

-Mike

#12

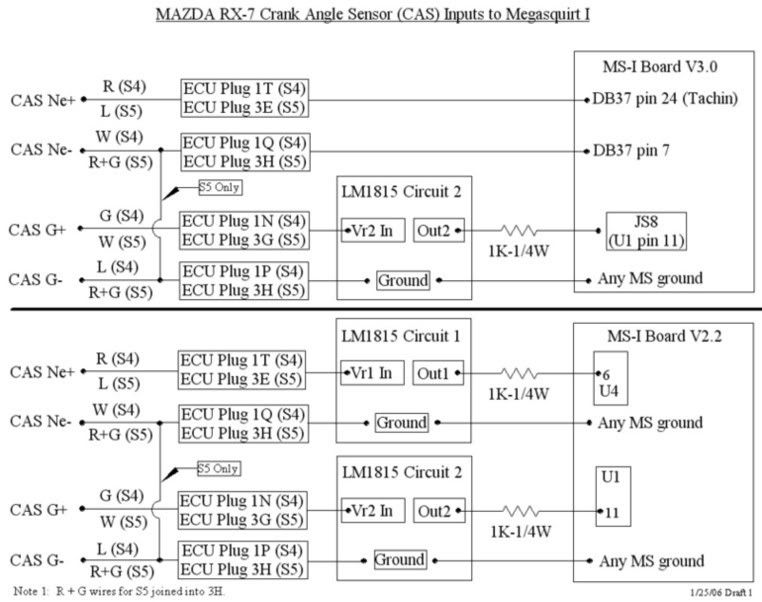

Here ya go.... It does not matter which teeth are machined off the 24 tooth section as long as they are opposed to each other. The 2 tooth upper wheel is not used at all and can be completely ignored in the 12-1 scheme. An oddity I've found is that the red wire needs to be connected to ground and the corresponding white wire needs to be connected to DB37 pin 24 - tach in. Second image has much better resolution!

-Mike

-Mike

Last edited by pmrobert; 01-28-07 at 10:18 PM.

#14

Mike,

Nice pics. Better than a 1000 words...

Regarding the selection of tooth pairs, it's true that any two teeth will function from a sensor standpoint. However, if you pick a poorly located pair, you may end up with poor adjustment range at the base of the CAS. With some care (or luck), you end up with the proper timing adjustment right in the middle of the slot.

Nice pics. Better than a 1000 words...

Regarding the selection of tooth pairs, it's true that any two teeth will function from a sensor standpoint. However, if you pick a poorly located pair, you may end up with poor adjustment range at the base of the CAS. With some care (or luck), you end up with the proper timing adjustment right in the middle of the slot.

#15

Roger, good point and I'm glad you brought that up. The drive teeth on the CAS shaft are for sure of coarse pitch (14, I think) so a change in 1 tooth moves the angular relationship quite a bit (360/7=51.xxx degrees I guess). I got lucky with the pair i chose to grind. Usually I finetune the trigger angle with the use of a timing light and fixed timing so things are spot on as far as the table's numbers are implemented. A couple of ways to skin the proverbial cat are available.

-mike

-mike

#17

I suppose you could but I'm not sure what the advantage would be. I'm thinking risk/benefit. Those teeth are really soft steel and it doesn't take much to accidentally ding or bend the ones on the wheel you want to keep. Also, that wheel may not come off with just force. Depending on how it was manufactured it might need some thermal assistance to come off, potentially changing the temper and/or magnetic characteristics of the shaft/wheel respectively. Those are a couple of risks I can think of in 10 seconds time. Benefits? It doesn't hurt to leave the unused hardware in there so no gain there re functionality. A very minor reduction in weight. Aesthetics - it would certainly "look" better under the top plate. Personally I would get things functional first and then experiment on a spare CAS. Priorities, ya know? I have a couple of junk ones and may, if I can find my small gear puller, give this a shot. If that top wheel comes right off this may be a nobrainer and worth the small risk. I'm playing devil's advocate here, and in no way intend on appearing to pee in your corn flakes :-) ; I just want your install to go well.

-Mike

-Mike

#18

I also have a spare, I'm going to attempt it today and post the results, seems a couple other people have removed the 2 tooth wheel, so the top reluctor would serve no purpose. Its not even wired up.

#19

I pulled the wheels off one of my CAS's when switching to an internal 72-2 wheel pickup system. The stock 2-tooth wheel came off quite easily. Carefull work with appropriate tools should make short work of it.

#21

Works just fine, but no programmable split. I have the two VR sensors adjusted to give about 5 degrees trailing split throughout. I've run about 6 months with that setup, the last few with the S5 turbo setup. No complaints at all. When I run out of stuff to do, I'll look at switching to std CAS and FC coil packs just to standardize the hardware, but there's a bunch of other stuff higher in the priority list for now.

#23

Sorry - I inadvertently threadjacked and confused you. The wheel that Roger was referring to (a custom made 72-2 CAS wheel which provides the same functionality of a crank mounted 36-1 wheel) was for Ford EDIS use which has nothing to do with the 12-1 concept. The 12-1 modded Mazda CAS will give you full control over split, etc. To summarize: 12-1 works just fine. Roger indicates that he was able to easily pull the stock wheels off the CAS shaft so you should be good to go if you want to pull that unused upper 2 tooth wheel and the associated reluctor.

-Mike

-Mike

#24

Originally Posted by pmrobert

Here ya go.... It does not matter which teeth are machined off the 24 tooth section as long as they are opposed to each other. The 2 tooth upper wheel is not used at all and can be completely ignored in the 12-1 scheme. An oddity I've found is that the red wire needs to be connected to ground and the corresponding white wire needs to be connected to DB37 pin 24 - tach in. Second image has much better resolution!

-Mike

-Mike

#25

Depends on how you built your V3.0 board. If it's set up as TSEL -> VROUTINV as shown in FAQ, then the above is fine. If you built it to MS assembly documentation defaults, (TSEL -> VROUT), then you'll have to reverse the VR sensor connections as Mike mentioned above.