need hammer and dolly tips/tricks?

#1

need hammer and dolly tips/tricks?

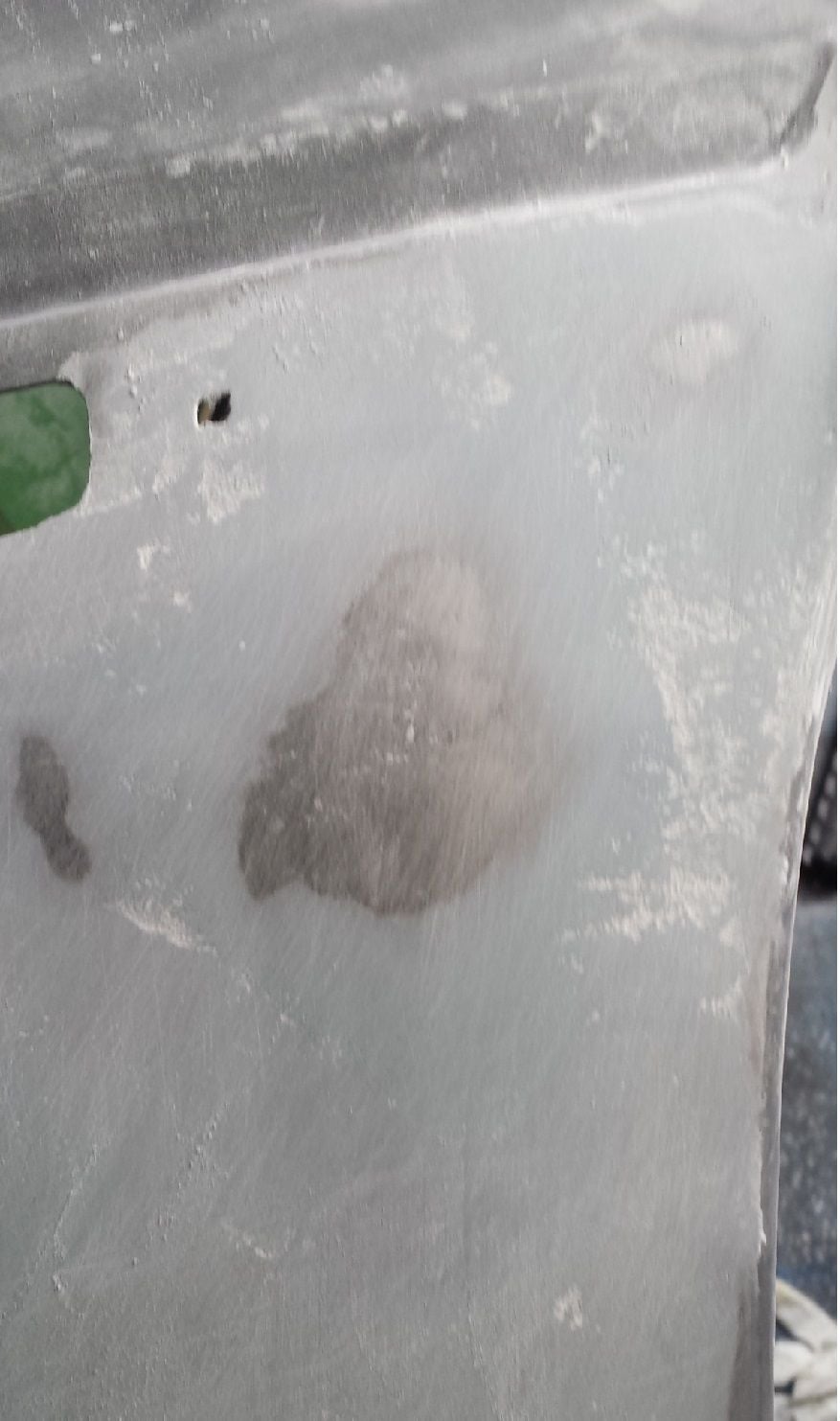

iv seen videos of people repairing dents with a hammer and dolly back to pretty much perfect and it only needs filler primer to cover the imperfections and not have to use body filler to finish.

the guy who repaired the fender before me just caked on the body filler pretty thick to repair it and didn't really try to straighten things out or knock the high spots down.

what are some tips to hammer and dolly the panel on my S1 rx7 dead straight with a dolly so I don't have to really use filler?? iv got it pretty close but it could be a lot better.

the guy who repaired the fender before me just caked on the body filler pretty thick to repair it and didn't really try to straighten things out or knock the high spots down.

what are some tips to hammer and dolly the panel on my S1 rx7 dead straight with a dolly so I don't have to really use filler?? iv got it pretty close but it could be a lot better.

Last edited by sandy_RE; 08-28-15 at 05:06 AM.

#2

Well there are a couple techniques for hammering and dollying, there is hammer on dolly as well as placing dolly on low spot and hammering on high spot. Alot of time you can not get a body perfectly straight because the sheet metal stretched. So you may have to get a shrinking hammer or a shrinking disk. You should go to Hot Rod, Street Rod, and Muscle Car Mega-site -- Hotrodders.com and re ask the same question as there are a lot more experienced people then me.

BTW there is nothing wrong using a little bit of body filler just make sure you apply it properly on clean metal, stick with u-pol flyweight gold or evercoat rage gold.

Thanks

Richard

BTW there is nothing wrong using a little bit of body filler just make sure you apply it properly on clean metal, stick with u-pol flyweight gold or evercoat rage gold.

Thanks

Richard

#3

My tip is to play around with sheet metal, learning techniques before you start pounding on your car.

You need a goal (a shape you are trying to achieve) so making armor is a good fun way to get some practice.

You will learn to coax metal into the shape you desire without stretching it by using many light blows.

If the initial impact was the kind that stretched the metal instead of just folding it over you will need to shrink the metal to get it back to stock shape as mentioned above.

I amazed myself when I folded my rear 3/4 panel under on my FC and was able to bring it back to stock with about 4 hours, a body hammer and 2x4 "dolly".

Didn't even need a repaint, just some cracks in the clear coat give away that anything happened.

You need a goal (a shape you are trying to achieve) so making armor is a good fun way to get some practice.

You will learn to coax metal into the shape you desire without stretching it by using many light blows.

If the initial impact was the kind that stretched the metal instead of just folding it over you will need to shrink the metal to get it back to stock shape as mentioned above.

I amazed myself when I folded my rear 3/4 panel under on my FC and was able to bring it back to stock with about 4 hours, a body hammer and 2x4 "dolly".

Didn't even need a repaint, just some cracks in the clear coat give away that anything happened.

#4

I think it is stretched a bit the high spot just wont get level and its next to the wheel arch body line so I didn't want to go crazy at it. who knows what they did when they repaired it before me.

yea light blows with the hammer is the way to go, hitting it hard only stretches the metal more right?

yea ricardo I only apply direct to to clean metal after iv wiped it down with the some wax and grease remover and let it flash.

it didn't look that bad in etch primer but the whole front bottom of the fender needed to be filled it was pretty wavey.

im a bit over it iv filled it and sanded it all off 3 times because i wasn't happy with the finish, i hammer and dollied it a bit more today and filled it with some water resistant filler. ill sand it down tomorrow and see how it comes up and ill try post some pics.

i might have to look at getting some of that evercoat stuff here in australia iv herd about it before, is it water resistant? and how durable is it?

yea light blows with the hammer is the way to go, hitting it hard only stretches the metal more right?

yea ricardo I only apply direct to to clean metal after iv wiped it down with the some wax and grease remover and let it flash.

it didn't look that bad in etch primer but the whole front bottom of the fender needed to be filled it was pretty wavey.

im a bit over it iv filled it and sanded it all off 3 times because i wasn't happy with the finish, i hammer and dollied it a bit more today and filled it with some water resistant filler. ill sand it down tomorrow and see how it comes up and ill try post some pics.

i might have to look at getting some of that evercoat stuff here in australia iv herd about it before, is it water resistant? and how durable is it?

#5

Ever coat is very durable but has a bit of flex, so that the panel repair will not crack because of heat or cold expansion. When you use body filler do not over sand, by what I mean is do not undercut the material. You must use a standing block, a don't sabd in one direction go closs to cross, back and forth, up and down. When you sand you may start hitting metal as it may be a high spot, use a body hammer and knock it down carfully you may want to watch some you tube videos.

Thanks

Richard

Thanks

Richard

#6

haven't had much chance to work on the panel the past few days. started sanding it down a bit and can already see some high spots coming up. might have to strip it down and hammer and dolly it a bit more.

I always you a bloc when sanding and sand in a "X". anyone got any tips for sanding wheel arches back to shape??

I always you a bloc when sanding and sand in a "X". anyone got any tips for sanding wheel arches back to shape??

#7

Wheel arches are bit tricky to sand, I would ask on hotrodder forum very informative people on there. There are a few people on there that monitor posts like you would not believe and they all work in a production autobody repair shop.

Thanks

Thanks

Trending Topics

#10

I like using a slapper and dolly. Slapping the edge around the dent until its shrunk then progressively moving inward. Never strike directly on the high spot. You slowly work the edges of the high spot.

#11

that's probably why the slapper didn't work as well as it should of I had the dolly taking shape of the panel behind and slapping the center of the highspot, I didn't want to hit the surrounding straight metal making the dint bigger and for next time do you use the slapper on or off dolly?

just finished knocking the high spots down its looking and feeling a lot straighter and iv reskimmed it hopefully I can finish it off today.

thanks for the info aswell boys.

just finished knocking the high spots down its looking and feeling a lot straighter and iv reskimmed it hopefully I can finish it off today.

thanks for the info aswell boys.

#12

You always use the tool off dolly if you want to gather/shrink the metal. On dolly hits only stretch metal. The metal if you have a dent is stretched. You always need to gather/shrink the material to bring it back to original.

#13

its looking better already now am just having trouble sanding the body line in the wheel arch ill try get some photos up when its all done.

Thread

Thread Starter

Forum

Replies

Last Post

Jeff20B

1st Generation Specific (1979-1985)

73

09-16-18 07:16 PM

Frisky Arab

2nd Generation Specific (1986-1992)

13

08-18-15 05:30 PM