Haltech P1000 13B questions

#52

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Power falling off?

Whats happening is the power is falling off as the night goes on. First few lite load passes are good. Then later in the night the power will fall off in 4th gear. Next run the power will fall off in third gear. So we are thinking it is heat related.

You can see in the datalog that throttle is 100% and rpm and boost is higher at the start of the gear then the end of the gear. AFR show good. Maybe .4 richer when the power is falling off

Stock coils. 4.5ms and changed to 3.5 and no change. Coils feel cool, not hot at all.

Checked air and water correction maps, Zeroed out.

Trigger show good according to the datalogs.

Turbo spinnes freely right after the runs.

Brakes are not getting hot. car rolls easy.

Datalog show all is good.

Water temp is below 170f. Air temp is below 130f. Plugs and wire show good. Tried different ones. No more E85. Strait Q16. Was running out of fuel on E85. (9200cc of fuel, and 55psi base fuel pressure)

wondering if the apex seals are loosing clearance as the motor gets hot??? Clearance was good when installed but maybe need more then spec.

Car does run fine on the way back to the pits. And start good with in 5 to 30 minutes after the run.

You can see in the datalog that throttle is 100% and rpm and boost is higher at the start of the gear then the end of the gear. AFR show good. Maybe .4 richer when the power is falling off

Stock coils. 4.5ms and changed to 3.5 and no change. Coils feel cool, not hot at all.

Checked air and water correction maps, Zeroed out.

Trigger show good according to the datalogs.

Turbo spinnes freely right after the runs.

Brakes are not getting hot. car rolls easy.

Datalog show all is good.

Water temp is below 170f. Air temp is below 130f. Plugs and wire show good. Tried different ones. No more E85. Strait Q16. Was running out of fuel on E85. (9200cc of fuel, and 55psi base fuel pressure)

wondering if the apex seals are loosing clearance as the motor gets hot??? Clearance was good when installed but maybe need more then spec.

Car does run fine on the way back to the pits. And start good with in 5 to 30 minutes after the run.

#55

Chris, does this apply to high resistance (11-15 ohm) injectors also? Any change required to the injector resistance settings on the PS1000.

#57

Do you have ignitors on your leading or are you using the CDI ingitors?

#58

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Got another 1st gen on the road and getting things worked out.

Have changed my ignition system to four leading ignitor and four trailing coils (turboII stuff).

Last night at 25 psi it ran 134mph in the 1/4 mile. Bad launch were the rpms dropped to 3500 and only produced 15 psi. Thinking it has a 10.6et at this boost level with a decent launch.

#59

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Stock ignitors and coils seem to be working great. 27/28 psi went 10.6 at 139 last night. Still had a bad launch. rpms dropped to 4000 in first. But had the front wheels off the ground.

#61

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Things are looking up. Was having some issues with the two step and high rpm above 9200. Resolved those issues and tested the car last night.

Here's a freeze frame.

Red trace is boost and yellow is afr. The dip a the top of first was me.

Still need lots of tuning but it is coming along.

Stock turboII leading igniters and four trailing coils with 19mm reach plugs. 6 x 1600cc injectors, base FP is 50psi

Here's a freeze frame.

Red trace is boost and yellow is afr. The dip a the top of first was me.

Still need lots of tuning but it is coming along.

Stock turboII leading igniters and four trailing coils with 19mm reach plugs. 6 x 1600cc injectors, base FP is 50psi

#62

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

update this thread

9.66 at 151 mph last month.

Also this month have been playing with the Haltech boost control option. Use to use a air tank and regulator to put press on the wastegate to regulate boost. This month have changed to a three port valve.

routing of hose,

from turbo outlet tee'd, one goes to valve, one goes to bottom of waste gate.

from valve to top of wastegate.

using open loop.

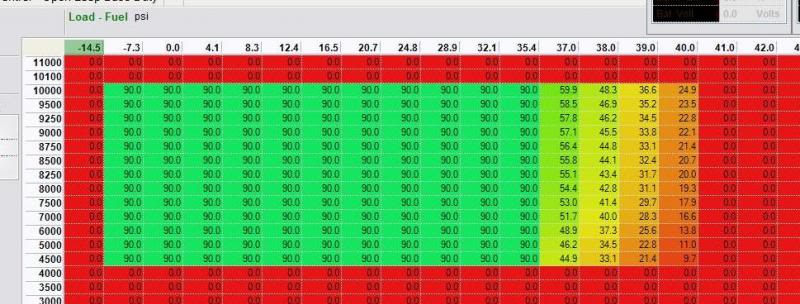

build a boost control map similar to fuel or timing map. in the photo, target boost will be 19psi

from zero psi to just before target boost insert 90% duty cycle.

at desired boost insert 25% duty to start with.

Something simular to the attached photo. Next time out going to add more duty cycle in the higher rpms at target boost. Looks like with the map in the photo the boost was tapering off as the rpms increased. This is not the boost I run, just an idea of how the map looks.

Your target duty cycle at max boost will depend on your set up.

9.66 at 151 mph last month.

Also this month have been playing with the Haltech boost control option. Use to use a air tank and regulator to put press on the wastegate to regulate boost. This month have changed to a three port valve.

routing of hose,

from turbo outlet tee'd, one goes to valve, one goes to bottom of waste gate.

from valve to top of wastegate.

using open loop.

build a boost control map similar to fuel or timing map. in the photo, target boost will be 19psi

from zero psi to just before target boost insert 90% duty cycle.

at desired boost insert 25% duty to start with.

Something simular to the attached photo. Next time out going to add more duty cycle in the higher rpms at target boost. Looks like with the map in the photo the boost was tapering off as the rpms increased. This is not the boost I run, just an idea of how the map looks.

Your target duty cycle at max boost will depend on your set up.

#63

That's the way its done. Instead of using the 3-port and a T, pick up a 4-port solenoid. A 4-port will allow a broader range of boost since you're controlling the top and bottom ports.

At your power level, you'll probably benefit a good deal from boost by gear or boost by speed.

At your power level, you'll probably benefit a good deal from boost by gear or boost by speed.

#64

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Think your right about the boost by speed or gear.

reason for changing boost control was since a bigger wastegate was installed, figured I would try something else to control boost.

12lbs spring, 60mm gate.

took roughly 5 test passes, two nights out to get the boost really close to my target boost. Really easy to set up.

Going to try closed loop next. keep the valve hose routing the same. Then try the four port valve after that. Then get a speed sensor on the car and try boost by speed.

It looks like boost by speed with the four port valve is going to be what I need. Currently hitting max boost in first gear and if the track is not prepped, nothing but wheel spin off the line.

current open loop set up is netting me full boost in each gear for 1500+ rpms. with in 500 rpms after shifting into the next gear max boost is reached. Getting the same boost response as the air tank setup but the ease of adjustments is allot better.

forgot to add, the hose from the 'T' to the bottom of the gate has a inline manual boost controller set up to not allow less then ##psi to reach the gate. Just trying something different in hopes to keep as much pressure off the bottom of the gate until necessary. manual boost is adjusted just a bit higher then spring pressure.

With the 12 lbs spring, currently getting more then three times the spring pressure for boost.

Once a good pass is made, a boost trace log will be posted so show the boost response. hopefully soon....

reason for changing boost control was since a bigger wastegate was installed, figured I would try something else to control boost.

12lbs spring, 60mm gate.

took roughly 5 test passes, two nights out to get the boost really close to my target boost. Really easy to set up.

Going to try closed loop next. keep the valve hose routing the same. Then try the four port valve after that. Then get a speed sensor on the car and try boost by speed.

It looks like boost by speed with the four port valve is going to be what I need. Currently hitting max boost in first gear and if the track is not prepped, nothing but wheel spin off the line.

current open loop set up is netting me full boost in each gear for 1500+ rpms. with in 500 rpms after shifting into the next gear max boost is reached. Getting the same boost response as the air tank setup but the ease of adjustments is allot better.

forgot to add, the hose from the 'T' to the bottom of the gate has a inline manual boost controller set up to not allow less then ##psi to reach the gate. Just trying something different in hopes to keep as much pressure off the bottom of the gate until necessary. manual boost is adjusted just a bit higher then spring pressure.

With the 12 lbs spring, currently getting more then three times the spring pressure for boost.

Once a good pass is made, a boost trace log will be posted so show the boost response. hopefully soon....

#66

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Spark plugs....

Use to run ngk # 2396. 5$ ones with great results. Ran 117mph in the 1/8. Ran 9.9 at 145 with the Tech GT, dumb coils. Fastest with the Haltech and stock coil was in the low mid 10s in the high 130s. Above 140mph was getting funny AFR reading. Had to add a bunch of fuel to get the afr down. then started to loose power. Think with the way the stock coil energizes the plugs, long duration, the plugs grounding strap was over heating. The 2396 is a nickel plug. The afr issue was only at the track. never on the dyno. Thinking since the dyno time was short burst vs long 1/4 mile passes, the plug did not over heat on the dyno.

Changed plugs to ngk#3857. Platinum plug. same gap of .025. AFR were easy to control and the power was back and was able to increase the boost level.

Use to run ngk # 2396. 5$ ones with great results. Ran 117mph in the 1/8. Ran 9.9 at 145 with the Tech GT, dumb coils. Fastest with the Haltech and stock coil was in the low mid 10s in the high 130s. Above 140mph was getting funny AFR reading. Had to add a bunch of fuel to get the afr down. then started to loose power. Think with the way the stock coil energizes the plugs, long duration, the plugs grounding strap was over heating. The 2396 is a nickel plug. The afr issue was only at the track. never on the dyno. Thinking since the dyno time was short burst vs long 1/4 mile passes, the plug did not over heat on the dyno.

Changed plugs to ngk#3857. Platinum plug. same gap of .025. AFR were easy to control and the power was back and was able to increase the boost level.

#67

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

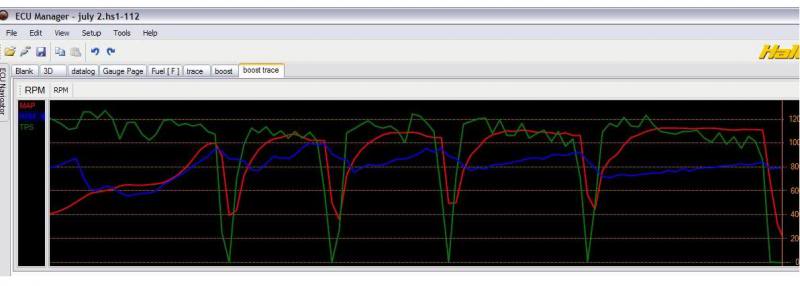

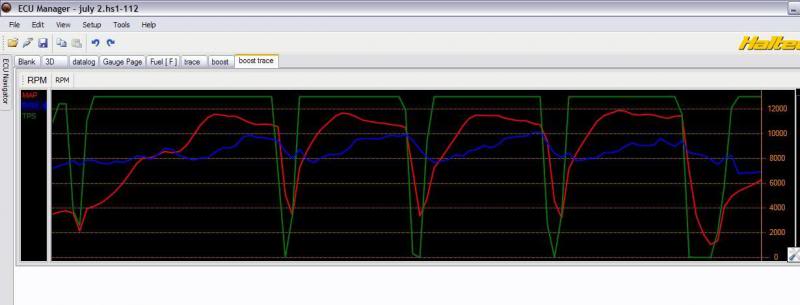

red is boost, green is tps, and blue is rpm

boost trace showing boost falling off at the higher rpms. using the haltech to control boost. Next time out will add more duty cycle in the high rpms range to stabilize the boost

First gear, going to lower my two step launch rpm from 8000 to 7000 when testing at the local track at night. 8000 and 20psi during the day works fairly good. still need more testing to dial it in. still testing the clutch flow control size jet.

#69

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

NO. see how the boost is falling off at the higher rpms. going to try and raise the duty cycle in the higher rpms so the boost does not fall off.

Will post a screen shot later of the projected boost map.

Will post a screen shot later of the projected boost map.

#70

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

something like this. lower the DC, lower boost. High DC equals higher boost.

not to concerned with boost spike, just want boost to not fall as the rpms goes up.

I would be ok if it spiked a few psi then leveled off vs spike then fall 4 or 5 psi.

For me spike mean reaching max boost quicker.

#71

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

tried close loop boost control. Seems to work good but did run more boost then targeted.

Think the 50mm gate is going back on and dumping the 60mm gate. The 50mm gate valve opens twice as much as the 60mm gate and feel the design of the 50mm gate is better controlling boost.

I don't use a boost cut. The map in the higher boost range is really rich. cost me some et and mph on the above run.

#72

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

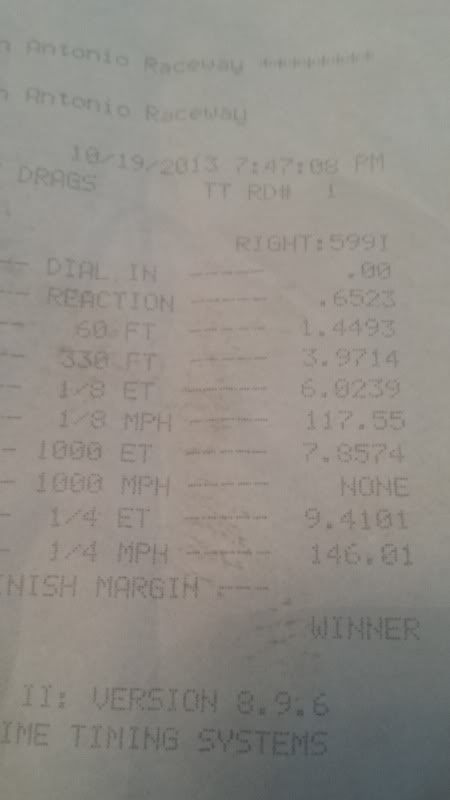

closed loop boost control works good. Made a few setting adjustments and the boost was just off by one psi in 1st and 2nd gear. 3rd was ok but could not control the boost in 4th gear. Need to change the waste gate. Peddling the throttle in 4th gear kept the boost down. ran a 9.53, 9.40 and last run of the day was a 9.25et.

best 1/8 mile time was 6.01 at 123mph.

best 1/8 mile time was 6.01 at 123mph.

#73

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

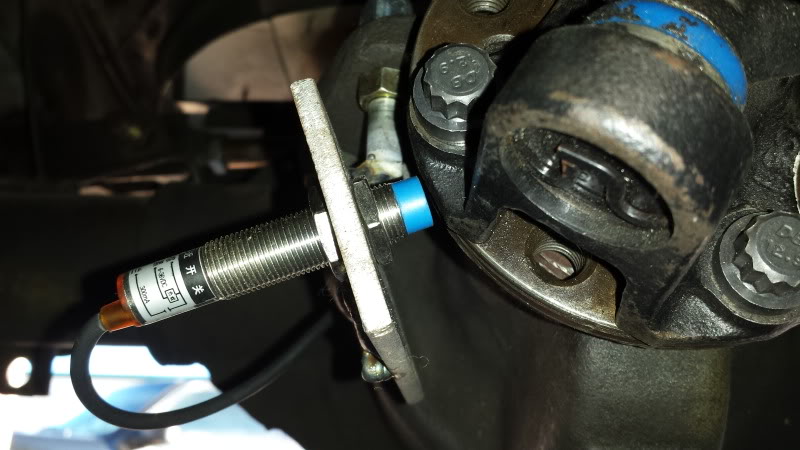

Installed a 5$ hall sensor for a speed sensor. Now to get it working so we can do boost by gear.

Also modified the 60mm gate so it would flow more exhaust. Hope things work..

#74

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Things are look good. Speed sensor is working as it should. Modified waste gate is working better then expected. At 50% duty to control boost.

Ran several 6.0# 1/8 mile passes so far and a few 9.5 1/4 mile passes with less boost. Now that were able to control boost in each gear we have more traction in first gear.

Also the boost by rpm is working great.

Ran several 6.0# 1/8 mile passes so far and a few 9.5 1/4 mile passes with less boost. Now that were able to control boost in each gear we have more traction in first gear.

Also the boost by rpm is working great.

#75

Good to hear Chuck!

I emailed C.Ludwig about a mac 3 port solenoid, and his response above got me thinking about a 4 por solenoid...

Still thinking wether to ditch the blitz sbc in favor of having the haltech control boost. Anyways, thanks for keeping this thread alive with regular feedback!

I emailed C.Ludwig about a mac 3 port solenoid, and his response above got me thinking about a 4 por solenoid...

Still thinking wether to ditch the blitz sbc in favor of having the haltech control boost. Anyways, thanks for keeping this thread alive with regular feedback!