Haltech P1000 13B questions

#26

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Common mode for the win.

One of the guys suggested we try to run shop air (10psi) to the map sensor as we held the rpms at 4000. Well the secondary injectors came on as they were designed to. datalog showed they worked and motor started to bog really bad. Now to verify at the track Wednesday.

Things are looking up.

Thanks!

Things are looking up.

Thanks!

#28

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Chris,

check you email. Sent my map to you. Not complete yet but getting there.

Firmware is the one off the CD that was sent with the unit. 1.09

Looks like there is a update to 1.09.2

check you email. Sent my map to you. Not complete yet but getting there.

Firmware is the one off the CD that was sent with the unit. 1.09

Looks like there is a update to 1.09.2

#29

I looked at the map and didn't see anything obviously wrong with it. My problems were with a Sprint ECU and the latest firmware for those is 1.07, so I doubt that it's a firmware issue. I've sent an email to Matt and Eric about your issue. If you get a datalog of it showing the issue send it my way and I'll forward it.

#33

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

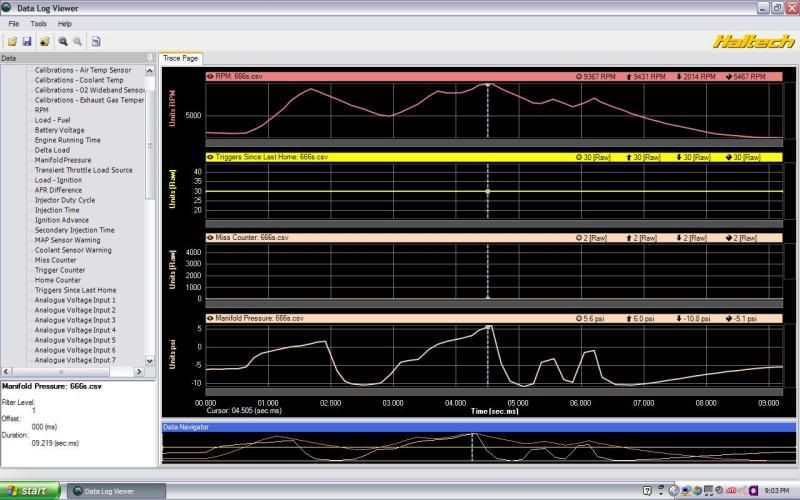

RPM drop at random RPMs and boost levels

Here is a screen shot of the problem. Only thing found was the trigger since last home go down rapidly when the problem happens.

Using the FF trigger wheel. The wheel is not centered 100% with the pickup.

Pickup wires are 4 inches from alternator and 8 inches from spark leads.

Shimmed trigger wheel to get it in the middle of the pickup. Better but not perfect.

Placed aluminum loom around pickup harness.

Can not test until Saturday but was hoping someone had ideas/suggestions.

Whats happening is, at random boost, throttle position and rpms points the rpm will fall fast like the ecu was turned off. But all the other sensors still show information and do not drop off. Just rpm.

Thanks again.

Using the FF trigger wheel. The wheel is not centered 100% with the pickup.

Pickup wires are 4 inches from alternator and 8 inches from spark leads.

Shimmed trigger wheel to get it in the middle of the pickup. Better but not perfect.

Placed aluminum loom around pickup harness.

Can not test until Saturday but was hoping someone had ideas/suggestions.

Whats happening is, at random boost, throttle position and rpms points the rpm will fall fast like the ecu was turned off. But all the other sensors still show information and do not drop off. Just rpm.

Thanks again.

#35

Just saw this.

Can you take a picture of the trigger setup and the misalignment? We've never heard of anyone having issues of the sensor not being centered on the wheel and want to make this right for you.

Can you take a picture of the trigger setup and the misalignment? We've never heard of anyone having issues of the sensor not being centered on the wheel and want to make this right for you.

#36

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

First two are of wheel offcenter and using both mounting bolts on the front cover.

Originally had the wheel mounted with out the pulley shim/washer and the pickup was mounted further outward from the motor. Then installed the shim/washer between the FFE wheel and pulley and that pushed the wheel outward and placed the pickup in the location the first two pictures show.

Next two pictures are of the pickup centered on the wheel. Is what I did was remove the lower mounting bolt and pushed the bottom of the mounting bracket outward and that placed the pickup dead center on the wheel. But the lower mounting bolt will not go in now.

Motor end play was checked by forcing the flywheel back and forth using a pry bar through the upper inspection cover on the motor/trans. No movement was noted at the wheel and pickup.

ALSO: It is a REW motor with a 1st gen cover and turboII pulley.

Will give the new pickup position a try Saturday.

Originally had the wheel mounted with out the pulley shim/washer and the pickup was mounted further outward from the motor. Then installed the shim/washer between the FFE wheel and pulley and that pushed the wheel outward and placed the pickup in the location the first two pictures show.

Next two pictures are of the pickup centered on the wheel. Is what I did was remove the lower mounting bolt and pushed the bottom of the mounting bracket outward and that placed the pickup dead center on the wheel. But the lower mounting bolt will not go in now.

Motor end play was checked by forcing the flywheel back and forth using a pry bar through the upper inspection cover on the motor/trans. No movement was noted at the wheel and pickup.

ALSO: It is a REW motor with a 1st gen cover and turboII pulley.

Will give the new pickup position a try Saturday.

#37

Hmm, can you get a pic of the wheel mounted without any shims? How thick are the shims you used? I've got an REW motor here and threw on the 1st gen cover to replicate what you have and everything is lining up..

#38

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

First two are of shim/spacer removed.

Last two are wheel centered but had to remove the top mounting bolt and move mount toward motor to get the pickup centered on the wheel.

The shim/spacer I talk about is in the last two pictures. It the stock piece that is used on the pulley.

Last two are wheel centered but had to remove the top mounting bolt and move mount toward motor to get the pickup centered on the wheel.

The shim/spacer I talk about is in the last two pictures. It the stock piece that is used on the pulley.

#39

Yeah no shim/spacer is required, it should be only the hub/pulley/trigger wheel assembly.

Also please ensure the polarity is wired correctly on your sensor.

(just as a reminder)

haltech 4 core trigger wire -->

yellow wire (signal +) ---> Pin 2

Green wire (signal -) ---> Pin 1

(pins are labeled 1 & 2 on back of connector)

Also please ensure the polarity is wired correctly on your sensor.

(just as a reminder)

haltech 4 core trigger wire -->

yellow wire (signal +) ---> Pin 2

Green wire (signal -) ---> Pin 1

(pins are labeled 1 & 2 on back of connector)

#41

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

FFE

I got mine centered. Only used the upper mounting bolt and swung the lower part of the mount toward the motor to center the pickup on the wheel. All good!

Tested it today and all is good with me. I would like to know why the pickup is not centered on the wheel with both bolts mounted, but with IFO Tulsa in two weeks, i gota do what makes the car run. Will investigate problem later.

Thanks

I have my settings on VR.

I got mine centered. Only used the upper mounting bolt and swung the lower part of the mount toward the motor to center the pickup on the wheel. All good!

Tested it today and all is good with me. I would like to know why the pickup is not centered on the wheel with both bolts mounted, but with IFO Tulsa in two weeks, i gota do what makes the car run. Will investigate problem later.

Thanks

I have my settings on VR.

#43

All of the suppported ECUs (and their settings) are in spreadsheet format that comes with the kits.

Sleeper7, if you did not receive these please let us know and i'll email them over.

The wheel should always be centered on the sensor, but as we talked about before there is something odd with your setup that doesn't add up. The mock of your block (REW/SA front cover/S4 hub) is sitting next to me and is dead centered.

You should not have to do/use any spacer/shim/hole redrilling etc. Please pm/email us so we can get this resolved. We are trying to help you to get whatever the issue is resolved, please let us.

#45

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Update on my trigger wheel issue.

Since everything was running good, transition, afr in boost and trigger working excellent even though I had it mounted with one mounting bolt to get the pickup centered on the wheel.

Rebuild my larger ported motor this weekend. Did not use any parts from my current motor except the oil pan. Used a REW motor, 1985 gsl-se front cover (100% sure) FC turboII hub. End play was perfect as was my old motor. Installed the FFE trigger setup on new motor and BAM. Pickup in dead center on wheel with both mounting bolts installed. Perfect.

It appears my older motor had a front cover from a really old 13B. Reason for the misalignment.

Just wanted to say I would highly recommend FFE trigger set up for the Haltech. Great product. It was obvious that my issue was not anything FFE did, it was my motor that did run 9.9et at 144mph on my old ECU.

Since everything was running good, transition, afr in boost and trigger working excellent even though I had it mounted with one mounting bolt to get the pickup centered on the wheel.

Rebuild my larger ported motor this weekend. Did not use any parts from my current motor except the oil pan. Used a REW motor, 1985 gsl-se front cover (100% sure) FC turboII hub. End play was perfect as was my old motor. Installed the FFE trigger setup on new motor and BAM. Pickup in dead center on wheel with both mounting bolts installed. Perfect.

It appears my older motor had a front cover from a really old 13B. Reason for the misalignment.

Just wanted to say I would highly recommend FFE trigger set up for the Haltech. Great product. It was obvious that my issue was not anything FFE did, it was my motor that did run 9.9et at 144mph on my old ECU.

#46

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

#47

Good to hear! Glad it was a simple front cover issue. Although you know it would look a lot better with a couple of black socket cap screws holding it on!

I'd like to see some vids of your car too btw!

I'd like to see some vids of your car too btw!

Update on my trigger wheel issue.

Since everything was running good, transition, afr in boost and trigger working excellent even though I had it mounted with one mounting bolt to get the pickup centered on the wheel.

Rebuild my larger ported motor this weekend. Did not use any parts from my current motor except the oil pan. Used a REW motor, 1985 gsl-se front cover (100% sure) FC turboII hub. End play was perfect as was my old motor. Installed the FFE trigger setup on new motor and BAM. Pickup in dead center on wheel with both mounting bolts installed. Perfect.

It appears my older motor had a front cover from a really old 13B. Reason for the misalignment.

Just wanted to say I would highly recommend FFE trigger set up for the Haltech. Great product. It was obvious that my issue was not anything FFE did, it was my motor that did run 9.9et at 144mph on my old ECU.

Since everything was running good, transition, afr in boost and trigger working excellent even though I had it mounted with one mounting bolt to get the pickup centered on the wheel.

Rebuild my larger ported motor this weekend. Did not use any parts from my current motor except the oil pan. Used a REW motor, 1985 gsl-se front cover (100% sure) FC turboII hub. End play was perfect as was my old motor. Installed the FFE trigger setup on new motor and BAM. Pickup in dead center on wheel with both mounting bolts installed. Perfect.

It appears my older motor had a front cover from a really old 13B. Reason for the misalignment.

Just wanted to say I would highly recommend FFE trigger set up for the Haltech. Great product. It was obvious that my issue was not anything FFE did, it was my motor that did run 9.9et at 144mph on my old ECU.

#48

Thread Starter

Rotary Enthusiast

Joined: Aug 2006

Posts: 1,216

Likes: 10

From: Melbourne FL/San Antonio TX/Okinawa Japan

Just putting this out there.

Currently running four stock leading ignitor and four stock trailing coils. No boxes. No missfire at all. Four 1800cc injector and two 1000cc injectors above 30psi with injector duty cycle at 100%. AFR 11.8/12.2. And around 100shot of NOS.

Car went 117mph in the eighth. Bad launch and missed second gear shift that drop the boost way down in second. NOS only in third gear.

Stock coils and ignitors are bad ***.

Currently running four stock leading ignitor and four stock trailing coils. No boxes. No missfire at all. Four 1800cc injector and two 1000cc injectors above 30psi with injector duty cycle at 100%. AFR 11.8/12.2. And around 100shot of NOS.

Car went 117mph in the eighth. Bad launch and missed second gear shift that drop the boost way down in second. NOS only in third gear.

Stock coils and ignitors are bad ***.