Haltech Locked Timing - Anyone know what the split is?

#1

Locked Timing - Anyone know what the split is?

when setting base timing in an FD, you must read off the Trailing front rotor, and LOCK timing at 10 degrees.

anyone know what the split is?

I'm considering running a hard zero split ignition and I'm wondering if I need to recheck my base timing?

anyone know what the split is?

I'm considering running a hard zero split ignition and I'm wondering if I need to recheck my base timing?

#2

Have a read at the HITman's "zeroing the timing" report, its a good starting point. You have to take extra care when doing this, since if you are too advance and dont know it you will brake the motor.

If you use zero split you loose some low end torque, at any rate, the split in idle and part throttle is 13-17 degrees depending on who you talk to, and as RPMs and load increase the split gets shorter and shorter, until eventually there is no split.

So BE CAREFUL!

If you use zero split you loose some low end torque, at any rate, the split in idle and part throttle is 13-17 degrees depending on who you talk to, and as RPMs and load increase the split gets shorter and shorter, until eventually there is no split.

So BE CAREFUL!

Last edited by Claudio RX-7; 02-15-06 at 08:50 AM.

#3

Originally Posted by dubulup

when setting base timing in an FD, you must read off the Trailing front rotor, and LOCK timing at 10 degrees.

anyone know what the split is?

I'm considering running a hard zero split ignition and I'm wondering if I need to recheck my base timing?

anyone know what the split is?

I'm considering running a hard zero split ignition and I'm wondering if I need to recheck my base timing?

#4

Originally Posted by Claudio RX-7

at any rate, the split in idle and part throttle is 13-17 degrees depending on who you talk to, and as RPMs and load increase the split gets shorter and shorter, until eventually there is no split.

So BE CAREFUL!

So BE CAREFUL!

#5

Originally Posted by crispeed

Actualy the FD's timing mark is 20deg. ATDC for T1

L1=>5 ATDC

T1=>20ATDC

If not, please post what the factory timing marks are for both FC's and FD's.

Justin

#6

From Hitman's site

NOTE FOR SERIES 6 ENGINES - the timing check process for these engines is a little different. Some models of E6S and E6K are not adjustable for the timing lock, and some that are cannot be locked to -20 degrees to line up the single notch these motors have at 20ATDC.

The easy way is to lock the timing at -5 and check the timing with the light on T1. This should be firing at -20BTDC (20ATDC) and should line up with the notch directly.

The other way for E6S owners to do this check is to cheat a little. Start the engine and lock the timing at 10 degrees, this is the default timing lock number for all Haltech systems. Now with a timing light connected to Lead 1 spark plug lead, check where the mark on the disc lines up. By adjusting the Trigger Angle value make the notch line up with the pointer, remembering that increasing the value retards the ignition and increasing it advances the ignition timing. The engine will die down a bit at this retarded ignition which is normal for now. Once the notch lines up turn the Timing Lock to OFF. Look at your Trigger Angle value and now subtract 30 and enter the new number. For example if the timing lined up at 95 degrees, then a new value of 65 degrees should be entered.

NOTE FOR SERIES 6 ENGINES - the timing check process for these engines is a little different. Some models of E6S and E6K are not adjustable for the timing lock, and some that are cannot be locked to -20 degrees to line up the single notch these motors have at 20ATDC.

The easy way is to lock the timing at -5 and check the timing with the light on T1. This should be firing at -20BTDC (20ATDC) and should line up with the notch directly.

The other way for E6S owners to do this check is to cheat a little. Start the engine and lock the timing at 10 degrees, this is the default timing lock number for all Haltech systems. Now with a timing light connected to Lead 1 spark plug lead, check where the mark on the disc lines up. By adjusting the Trigger Angle value make the notch line up with the pointer, remembering that increasing the value retards the ignition and increasing it advances the ignition timing. The engine will die down a bit at this retarded ignition which is normal for now. Once the notch lines up turn the Timing Lock to OFF. Look at your Trigger Angle value and now subtract 30 and enter the new number. For example if the timing lined up at 95 degrees, then a new value of 65 degrees should be entered.

#7

Originally Posted by pistonsuk

Isn't this ^ true for both FC and FD's?

L1=>5 ATDC

T1=>20ATDC

If not, please post what the factory timing marks are for both FC's and FD's.

Justin

L1=>5 ATDC

T1=>20ATDC

If not, please post what the factory timing marks are for both FC's and FD's.

Justin

Trending Topics

#10

^good tip.

I plan to run the front rotor off one leading coil, trigger'd by the front trailing signal and the rear rotor off another leading coil, trigger'd by the rear trailing signal.

Set Split to zero for all ranges

and tune the ignition map as normal.

In theory the trailing signal would fire at whatever the leading was set too.

do you see any holes in this zero split set-up? any advice to ZERO timing this way...I have to think about this for a bit to get a good picture of what I'm trying to zero.

I plan to run the front rotor off one leading coil, trigger'd by the front trailing signal and the rear rotor off another leading coil, trigger'd by the rear trailing signal.

Set Split to zero for all ranges

and tune the ignition map as normal.

In theory the trailing signal would fire at whatever the leading was set too.

do you see any holes in this zero split set-up? any advice to ZERO timing this way...I have to think about this for a bit to get a good picture of what I'm trying to zero.

#11

Originally Posted by dubulup

^good tip.

I plan to run the front rotor off one leading coil, trigger'd by the front trailing signal and the rear rotor off another leading coil, trigger'd by the rear trailing signal.

Set Split to zero for all ranges

and tune the ignition map as normal.

In theory the trailing signal would fire at whatever the leading was set too.

do you see any holes in this zero split set-up? any advice to ZERO timing this way...I have to think about this for a bit to get a good picture of what I'm trying to zero.

I plan to run the front rotor off one leading coil, trigger'd by the front trailing signal and the rear rotor off another leading coil, trigger'd by the rear trailing signal.

Set Split to zero for all ranges

and tune the ignition map as normal.

In theory the trailing signal would fire at whatever the leading was set too.

do you see any holes in this zero split set-up? any advice to ZERO timing this way...I have to think about this for a bit to get a good picture of what I'm trying to zero.

Now bring the rpm up to about 5K to 6K rpm and note the timing values. I'll bet you'll be shock to see the difference it is from your idle settings. I'll guess 4 to 5deg retarded from idle settings.

#12

Originally Posted by crispeed

Set the trigger gains as low as possible to get stable ign/timing values.

Now bring the rpm up to about 5K to 6K rpm and note the timing values. I'll bet you'll be shock to see the difference it is from your idle settings. I'll guess 4 to 5deg retarded from idle settings.

Now bring the rpm up to about 5K to 6K rpm and note the timing values. I'll bet you'll be shock to see the difference it is from your idle settings. I'll guess 4 to 5deg retarded from idle settings.

the rest of what you wrote makes no sense to me

If I'm idling 3deg at idle, you bet I'm around 7-8deg 5k-6k? is this with a locked/zero split? could you give more detail about the point you are trying to get me to understand?

If I'm idling 3deg at idle, you bet I'm around 7-8deg 5k-6k? is this with a locked/zero split? could you give more detail about the point you are trying to get me to understand?From Haltech

Lock Timing

This field allows the Timing to be locked at a specified angle regardless of engine

speed. Select Yes or No to enable or disable Timing Lock.

Lock Timing Angle - °BTDC

This field defines that angle in °BTDC at which the timing is locked. 10° is common

but this value can be in the range 0-25°BTDC to suit the timing marks that are

available on the timing pulley.

Originally Posted by crispeed

Or you can set all Leading ranges to 0 deg and set all trailing ranges to a 20 deg split lock timing at for eg. 67 deg and check timing on T1 and adjust the trigger angle to suit.

I have a WB, and now the EGT is going in, I'm trying to get as much knowledge as possible for when I re-tune (w/ hard zero split). My tune now, is someone else's ignition map with my base timing and actual A:F's...its been reliable for 12k miles up to 18psi, but I feel this isn't ideal, knowing timing is so crucial for making good reliable power.

Last edited by dubulup; 02-15-06 at 10:49 AM.

#15

Good luck getting the engine to run that high locked at around TDC.

I've found that most 13B's don't like doing that cause of the too retarded timing!

EGT's skyrocket like crazy, so don't hold it for too long!

-Ted

I've found that most 13B's don't like doing that cause of the too retarded timing!

EGT's skyrocket like crazy, so don't hold it for too long!

-Ted

#16

Originally Posted by RETed

Good luck getting the engine to run that high locked at around TDC.

I've found that most 13B's don't like doing that cause of the too retarded timing!

EGT's skyrocket like crazy, so don't hold it for too long!

-Ted

I've found that most 13B's don't like doing that cause of the too retarded timing!

EGT's skyrocket like crazy, so don't hold it for too long!

-Ted

That's also why all my pullies or trigger wheels in the FD's case are marked at 15 deg!

Last edited by crispeed; 02-18-06 at 04:20 AM.

#17

Zero split by disconnecting the leading coil

Originally Posted by dubulup

I plan to run the front rotor off one leading coil, trigger'd by the front trailing signal and the rear rotor off another leading coil, trigger'd by the rear trailing signal.

Set Split to zero for all ranges

and tune the ignition map as normal.

In theory the trailing signal would fire at whatever the leading was set too.

do you see any holes in this zero split set-up? any advice to ZERO timing this way...I have to think about this for a bit to get a good picture of what I'm trying to zero.

I was thinking about doing this too. It sounds like a rock solid zero-split setup. Is these anything wrong with letting the leading coil signal go unconnected? It just pulls to ground so it's not a big deal right?

Justin

#18

Originally Posted by crispeed

Set the trigger gains as low as possible to get stable ign/timing values.

Now bring the rpm up to about 5K to 6K rpm and note the timing values. I'll bet you'll be shock to see the difference it is from your idle settings. I'll guess 4 to 5deg retarded from idle settings.

Now bring the rpm up to about 5K to 6K rpm and note the timing values. I'll bet you'll be shock to see the difference it is from your idle settings. I'll guess 4 to 5deg retarded from idle settings.

I believe this phenomenon does not happen under non-locked contitions, right? Doesnt the haltech take into account the increased rpm and start the dwell time earlier?

Justin

#19

Haltech tuning secrets:) Magnetic triggers

pistonsuk Does this have to do with the necassary dwell time needed vs. time available (due to increases rpm)?

I believe this phenomenon does not happen under non-locked contitions, right?

YES IT DOES!

Doesnt the haltech take into account the increased rpm and start the dwell time earlier?

IT'S NOT DONE PERFECTLY.

Justin

Due to the design of magnetic/reluctor triggers as rpm increases ignition timing will vary or retard. I'm not going to get into why that happens but do the research and you'll find out for yourself. Most modern ECU's have some type of system built in to remedy that problem. Both the E-8 and 11 ecu series got variable trigger angle vs rpm so basicaly you can eliminate that problem, The previous or earlier 6 series didn't. Timing would retard depending on application up to 10 deg at high rpm. That problem got even worse if gains were increased. Anything placed between the ECU and the coils would aid the problem even further.Everyone's favorite Knock retard and Ignition amplifier box would be prime examples. I've seen up to 10 deg of retard at high rpm. Now for the dangerous part about this whole ordeal would be by placing the metioned above units only on the leading side would result in even more leading ignition high rpm retard than on the trailing side and we all know what that leads to if you're trying to run zero or just a little ignition split again depending on the application, on a heavy load or boosted application. KABOOM!

This is the main reason why the earlier Haltech ecu's were known to fire the trail before the leading when the split got very close. This is not a problem with the latter series once igntion setup is done properly.

You must always verify ignition timing at varied rpm levels for both leading and trailing events.

I believe this phenomenon does not happen under non-locked contitions, right?

YES IT DOES!

Doesnt the haltech take into account the increased rpm and start the dwell time earlier?

IT'S NOT DONE PERFECTLY.

Justin

Due to the design of magnetic/reluctor triggers as rpm increases ignition timing will vary or retard. I'm not going to get into why that happens but do the research and you'll find out for yourself. Most modern ECU's have some type of system built in to remedy that problem. Both the E-8 and 11 ecu series got variable trigger angle vs rpm so basicaly you can eliminate that problem, The previous or earlier 6 series didn't. Timing would retard depending on application up to 10 deg at high rpm. That problem got even worse if gains were increased. Anything placed between the ECU and the coils would aid the problem even further.Everyone's favorite Knock retard and Ignition amplifier box would be prime examples. I've seen up to 10 deg of retard at high rpm. Now for the dangerous part about this whole ordeal would be by placing the metioned above units only on the leading side would result in even more leading ignition high rpm retard than on the trailing side and we all know what that leads to if you're trying to run zero or just a little ignition split again depending on the application, on a heavy load or boosted application. KABOOM!

This is the main reason why the earlier Haltech ecu's were known to fire the trail before the leading when the split got very close. This is not a problem with the latter series once igntion setup is done properly.

You must always verify ignition timing at varied rpm levels for both leading and trailing events.

Last edited by crispeed; 02-19-06 at 07:24 AM.

#20

Originally Posted by pistonsuk

I was thinking about doing this too. It sounds like a rock solid zero-split setup. Is these anything wrong with letting the leading coil signal go unconnected? It just pulls to ground so it's not a big deal right?

Justin

Justin

#21

First of all, thanks for your detailed response.

I do plan to reseach this some more myself.

I am running a Jacobs rotary pack. I assume this too will aggravate the problem?

Is the offset linear with rpm? Is it consistant?

Can it be corrected for by simply recording the amount of error at 7000k by reving the engine with locked timing and then using interpolation/extrapolation to apply this much more advance in your base maps according to there rpm designation?

Thanks,

Justin

I do plan to reseach this some more myself.

Originally Posted by crispeed

Anything placed between the ECU and the coils would aid the problem even further.

Is the offset linear with rpm? Is it consistant?

Can it be corrected for by simply recording the amount of error at 7000k by reving the engine with locked timing and then using interpolation/extrapolation to apply this much more advance in your base maps according to there rpm designation?

Thanks,

Justin

#22

FD Ignition Routing

Originally Posted by crispeed

Anything placed between the ECU and the coils would aid the problem even further.Everyone's favorite Knock retard and Ignition amplifier box would be prime examples.

You must always verify ignition timing at varied rpm levels for both leading and trailing events.

You must always verify ignition timing at varied rpm levels for both leading and trailing events.

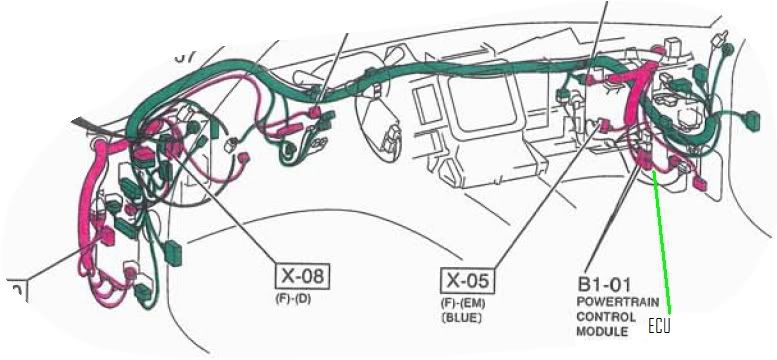

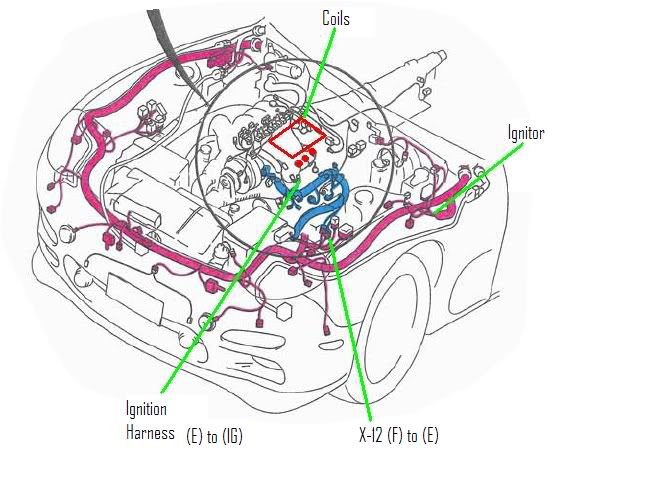

the ECU (FD) is on the passenger side kick panel...the Front harness wraps around the entire car, inputs the ignitor, the "shielded" output travels back down the driver's side and connects to the Emissions harness (X-12), travels toward the block where another connector breaks out the IGnition harness.

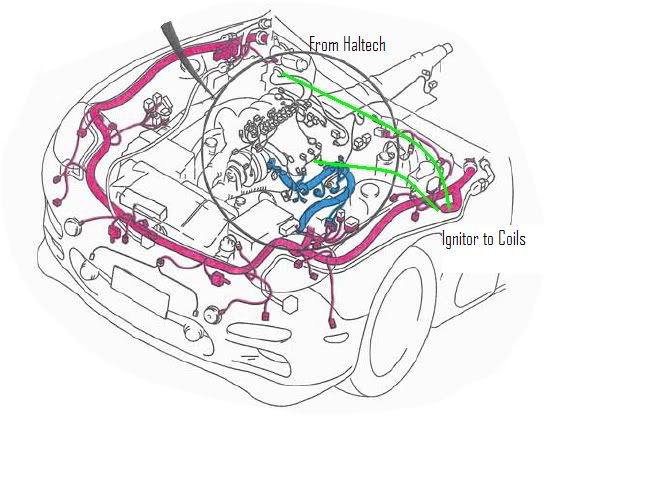

My inputs to the ignitor already run along the fire wall (from haltech install), I just need to build a short harness from the ignitor straight to the coils (two leadings I plan to run) this should eliminate many FEET of un-needed wire.

Also when I go in to do this I am removing my MSD 6A and will be running an un-AMP'd ignition. I will be starting my tuning at 10psi, and tuning until the ignition breaks-up. Stock ignition (with coil inputs along the firewall) broke up @ 13-14psi, 11.1-11.5 A:F. MSD 6A and WI, I have no issues running 18psi and feel the engine wants more

#23

Originally Posted by pistonsuk

First of all, thanks for your detailed response.

I do plan to reseach this some more myself.

I am running a Jacobs rotary pack. I assume this too will aggravate the problem?

Is the offset linear with rpm? Is it consistant?

Can it be corrected for by simply recording the amount of error at 7000k by reving the engine with locked timing and then using interpolation/extrapolation to apply this much more advance in your base maps according to there rpm designation?

Thanks,

Justin

I do plan to reseach this some more myself.

I am running a Jacobs rotary pack. I assume this too will aggravate the problem?

Is the offset linear with rpm? Is it consistant?

Can it be corrected for by simply recording the amount of error at 7000k by reving the engine with locked timing and then using interpolation/extrapolation to apply this much more advance in your base maps according to there rpm designation?

Thanks,

Justin

Justin

#25

Originally Posted by crispeed

. .....Timing would retard depending on application up to 10 deg at high rpm. That problem got even worse if gains were increased.....

Thanks for sharing this info BTW!