ZERO-Modification, high-mount track wing (no drilling!)

#1

Background: I'm rebuilding my RX-7 from the ground up, and I would like to do some time attack events when it's done. My car came without a rear wing, and I know how the rear end can feel light at high speeds without one. I wanted to add a wing for tracking the car, but I don't want to ruin my wingless trunk lid by drilling holes. Furthermore, I still want to drive the car around town once in awhile, so I don't want a giant wing attached all the time. Well, I came up with a solution, and with JhnRx7's CAD-help we're making it a reality.

I don't want to post any photos yet, but I will say this much: we've developed a mounting system for the APR GTC-300 carbon fiber wing that allows you to install the wing onto an FD3S without any permanent modification to the car - as in, no drilling / no cutting.

The mounting system for the wing that uses CNC'd 2-piece aluminum risers & steel mounting brackets with (4) points of attachment to the body using existing bolts/mounting holes. The mounts install in a matter of minutes using a screwdriver and socket wrench. Once the mounts are installed, they can stay attached to the car (completely hidden from sight) even when the risers are not attached. APR helped us to find the ideal location for the wing to sit - just below the RX-7's roof line, based on their airflow data and testing. As an added bonus, the wing does not interfere with the trunk lid, so you can still open & close it as needed, even with the risers & wing installed.

We are currently having the parts produced and we plan to track test the wing & mounting system. JhnRx7 has done extensive stress simulation using his engineering skills & CAD software. After about 30+ revisions to the design we finally came up with a version that is ready for physical prototyping.

I've also worked out a deal with APR to sell us carbon fiber wings (without risers) for a discounted price as part of the kit we're developing. For our development we are using the 67" GTC-300 carbon fiber airfoil and end panels. We'll also sell the risers & mounts WITHOUT the wing if people want that too (Some people might already have the wing and they just want the mounts, or some people might want to use a different wing with our mounts).

At this point I just want to share all this info with forum members, and would love to hear your feedback--

I don't want to post any photos yet, but I will say this much: we've developed a mounting system for the APR GTC-300 carbon fiber wing that allows you to install the wing onto an FD3S without any permanent modification to the car - as in, no drilling / no cutting.

The mounting system for the wing that uses CNC'd 2-piece aluminum risers & steel mounting brackets with (4) points of attachment to the body using existing bolts/mounting holes. The mounts install in a matter of minutes using a screwdriver and socket wrench. Once the mounts are installed, they can stay attached to the car (completely hidden from sight) even when the risers are not attached. APR helped us to find the ideal location for the wing to sit - just below the RX-7's roof line, based on their airflow data and testing. As an added bonus, the wing does not interfere with the trunk lid, so you can still open & close it as needed, even with the risers & wing installed.

We are currently having the parts produced and we plan to track test the wing & mounting system. JhnRx7 has done extensive stress simulation using his engineering skills & CAD software. After about 30+ revisions to the design we finally came up with a version that is ready for physical prototyping.

I've also worked out a deal with APR to sell us carbon fiber wings (without risers) for a discounted price as part of the kit we're developing. For our development we are using the 67" GTC-300 carbon fiber airfoil and end panels. We'll also sell the risers & mounts WITHOUT the wing if people want that too (Some people might already have the wing and they just want the mounts, or some people might want to use a different wing with our mounts).

At this point I just want to share all this info with forum members, and would love to hear your feedback--

Last edited by GoodfellaFD3S; 02-24-13 at 12:34 PM. Reason: As per OP's request

#3

I've thought about this a lot. Something that would add a lot of value would be a set of mount caps.

What I mean is small 1/8th aluminum piece that has the same bottom as the wing mounts (for mating to the hatch, but the top is just curved. These get painted body color, and on non- track days you just take the wing off and install the caps. Should be an easy piece to make, and is something no other wing providers are providing.

What I mean is small 1/8th aluminum piece that has the same bottom as the wing mounts (for mating to the hatch, but the top is just curved. These get painted body color, and on non- track days you just take the wing off and install the caps. Should be an easy piece to make, and is something no other wing providers are providing.

#4

Our wing doesn't mount to the trunk lid...at all. So there are no caps needed.

It mounts through the reverse light reflector holes in the rear bumper, and also under the car to the tiedown mount location. Pics coming soon...

It mounts through the reverse light reflector holes in the rear bumper, and also under the car to the tiedown mount location. Pics coming soon...

#5

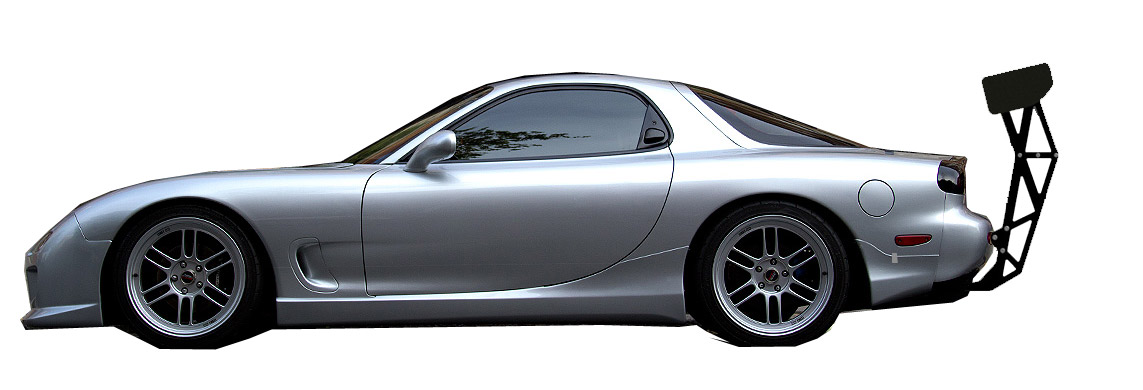

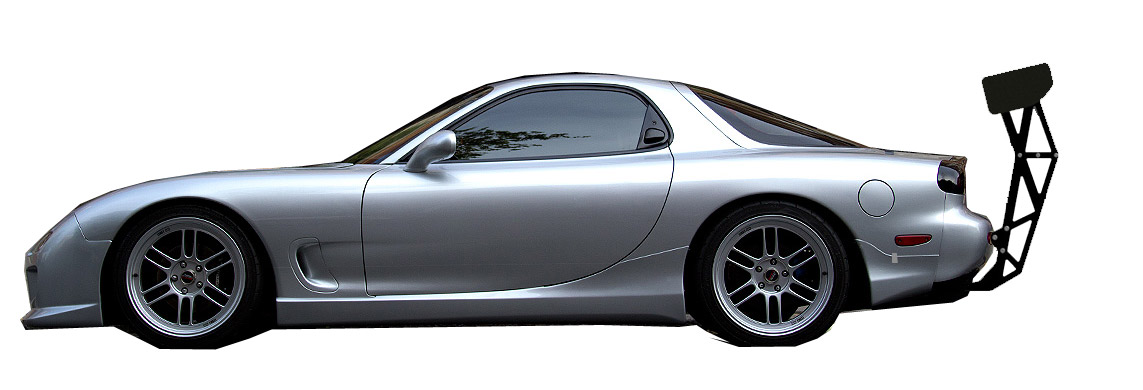

Just got some renders from JhnRx7...also passed our stress testing well beyond the maximum downforce generated by this airfoil according to APRs data on the GTC-300.

The airfoil (wing) in the rendering is obviously not the correct - it was just quickly created for mock-up illustration.

Here's a view from an above rear angle:

Close up of the driver's side risers & brackets:

Side view:

Another rear angle & above view:

Close up of the upper riser mounts:

Close up of the 3 bolts that attach the upper & lower riser pieces. Obviously we won't be using hardware that large. lol

Simulated stress testing with over 4x the maximum downforce that the wing can generate - PASS!

The airfoil (wing) in the rendering is obviously not the correct - it was just quickly created for mock-up illustration.

Here's a view from an above rear angle:

Close up of the driver's side risers & brackets:

Side view:

Another rear angle & above view:

Close up of the upper riser mounts:

Close up of the 3 bolts that attach the upper & lower riser pieces. Obviously we won't be using hardware that large. lol

Simulated stress testing with over 4x the maximum downforce that the wing can generate - PASS!

#6

Here are some 1:1 scale cardboard mockups I made (this is an earlier version of the design):

Upper mount - goes though reverse light / reflector opening in bumper:

^ The upper mount is actually 2 pieces. An "adapter" that stays installed, and a removable "L bracket" that is uninstalled when the wing is not being used (so you can re-install the reverse light / reflector).

Lower mount (without catback installed):

Lower mount (without catback installed):

Bolted up:

One last MSPaint-quality approximate side view mockup...lol

^ the wing actually sits below the roofline in the ideal spot, but it looks taller due to the side pieces.

This is a front angle (if you were standing kinda of in front of the car, to the side):

Upper mount adjust-holes:

Straight rear view (standing behind the car):

Another side profile:

Upper mount - goes though reverse light / reflector opening in bumper:

^ The upper mount is actually 2 pieces. An "adapter" that stays installed, and a removable "L bracket" that is uninstalled when the wing is not being used (so you can re-install the reverse light / reflector).

Lower mount (without catback installed):

Lower mount (without catback installed):

Bolted up:

One last MSPaint-quality approximate side view mockup...lol

^ the wing actually sits below the roofline in the ideal spot, but it looks taller due to the side pieces.

This is a front angle (if you were standing kinda of in front of the car, to the side):

Upper mount adjust-holes:

Straight rear view (standing behind the car):

Another side profile:

#7

Very cool and a great idea. Reminds me of the BenSopra and Rocket Bunny style risers. I've always liked when the wing attaches to something more substantial than just the decklid. Kudos to you, these will be a hit!

Trending Topics

#8

The best part about our wing is that is a true "bolt on" and requires absolutely no modification of the car. It installs / uninstalls in about 15 minutes using about 2 common tools.

#9

This is a great idea guys

Definitely gives full track day ability without the downside of driving with a huge wing on the street

And actually it's in theory more effective than mounting trunk lid because the trunk lid flexes and this will be solid to the body and mounted higher and further back for cleaner air

Definitely following this!! Great that you guys are developing new parts for our cars!!

Definitely gives full track day ability without the downside of driving with a huge wing on the street

And actually it's in theory more effective than mounting trunk lid because the trunk lid flexes and this will be solid to the body and mounted higher and further back for cleaner air

Definitely following this!! Great that you guys are developing new parts for our cars!!

#12

Very very very cool! Great idea you guys came up with! I really like the fact that you can actually take it in between track weekends if you really wanted to and the "zero modification" is the best part!!

#14

Those were definitely inspiration, however those are still different in that they require you to physically modify the car (drilling holes, cutting)...

The best part about our wing is that is a true "bolt on" and requires absolutely no modification of the car. It installs / uninstalls in about 15 minutes using about 2 common tools.

The best part about our wing is that is a true "bolt on" and requires absolutely no modification of the car. It installs / uninstalls in about 15 minutes using about 2 common tools.

I wanted to develop something like this myself, also inspired by the rocketbunny BRZ and the sexyknights FD3s.

Count me in for your interest list!

#17

I agree David but for some reason it wouldn't allow me to post there. I think the permissions for that forum are messed up.

Actually no it doesn't sit that far back. I think my crappy mockup isn't very accurate.

Actually no it doesn't sit that far back. I think my crappy mockup isn't very accurate.

#19

^ The mysteries of the forum. Been some strange tech stuff going on lately.

The bracket that goes into the light assembly, what do those bolts attach to? Is there some metal back there, maybe the bumper support or is it something else? I am wondering how sturdy it will be. I've had my lights out but have never look behind them and as I recall, the lights themselves just screw into the bumper plastic.

The bracket that goes into the light assembly, what do those bolts attach to? Is there some metal back there, maybe the bumper support or is it something else? I am wondering how sturdy it will be. I've had my lights out but have never look behind them and as I recall, the lights themselves just screw into the bumper plastic.

#21

The upper brackets (that go into the bumper holes) attach to large studs coming directly out of the chassis - those bolts hold the rear rebar to the body. They are offset and large diameter studs.

The rebar mounting plates are not a flat surface, so I designed a CNC'd adapter plate to attach the upper bracket to the body.

The rebar mounting plates are not a flat surface, so I designed a CNC'd adapter plate to attach the upper bracket to the body.