Here's how to figure out intake runner length

#51

FTD Wanna Be

Join Date: Jun 2002

Location: Virginia

Posts: 1,252

Likes: 0

Received 0 Likes

on

0 Posts

I recieved an email just the other day from a guy who built and flys a 13B powered aircraft. It's a really nice looking machine with about 200 hours on it now. Anyway, he took the time to send me a long email about the VDI system according to Mazda engineering papers from the 80s. Instead of a negative pressure pulse created from the opening of the port (which inverts and the end of the runner and returns back to the SAME rotor b.t.w.), the remaining exhaust gases that aren't expelled during the exhaust CYCLE (  ) create a high pressure pulse when the intake port opens. This is what VDI uses to create a positive pressure pulse before the second rotor intake port closes. Apparently, for a stock exhaust system I imagine, the Mazda engineers found this pulse to be much more significant than the accustic pulse.

) create a high pressure pulse when the intake port opens. This is what VDI uses to create a positive pressure pulse before the second rotor intake port closes. Apparently, for a stock exhaust system I imagine, the Mazda engineers found this pulse to be much more significant than the accustic pulse.

You may have already known this, but I found it very interesting. He also mentioned there are many different intake dynamics to 'tune' to. I guess that's why we've been 'arguing' for the past two weeks. We're talking about two somewhat different intake dynamic theories. Thats the problem with the internet. It takes forever to end a debate!

On that note, I'm still going to design my 1st gen 13B intake on my calculator. I'm assuming the exhaust will be open enough that the exhaust pressure pulse will be less significant.

I'm assuming the exhaust will be open enough that the exhaust pressure pulse will be less significant.

I'm still interested in how your intake runners perform, so let me know how it goes. With the rebuild kit I have and the used motor & ECU on the way, I may have my motor built by this winter, so I'll report back here. I probably won't have any dyno numbers until next year.

) create a high pressure pulse when the intake port opens. This is what VDI uses to create a positive pressure pulse before the second rotor intake port closes. Apparently, for a stock exhaust system I imagine, the Mazda engineers found this pulse to be much more significant than the accustic pulse.

) create a high pressure pulse when the intake port opens. This is what VDI uses to create a positive pressure pulse before the second rotor intake port closes. Apparently, for a stock exhaust system I imagine, the Mazda engineers found this pulse to be much more significant than the accustic pulse.You may have already known this, but I found it very interesting. He also mentioned there are many different intake dynamics to 'tune' to. I guess that's why we've been 'arguing' for the past two weeks. We're talking about two somewhat different intake dynamic theories. Thats the problem with the internet. It takes forever to end a debate!

On that note, I'm still going to design my 1st gen 13B intake on my calculator.

I'm assuming the exhaust will be open enough that the exhaust pressure pulse will be less significant.

I'm assuming the exhaust will be open enough that the exhaust pressure pulse will be less significant.I'm still interested in how your intake runners perform, so let me know how it goes. With the rebuild kit I have and the used motor & ECU on the way, I may have my motor built by this winter, so I'll report back here. I probably won't have any dyno numbers until next year.

#52

It would be neat to find a way to compare results and find a truly perfect system. Then again I guess that would take a dyno and lots of time/experimentation.

Thats pretty interesting about the whole exhaust pressure thing. All I ever read was that it was an acoustic thing since acoustic waves have high and low pressure troughs. There was never any elaboration as to where these originated though. Makes sense when you think about it. That is the one thing that the rotary has an advantage of using since the closing pulse isn't really there like you've said.

Yep there are way too many things going on that can get confused with one another. This has been an educational little debate though!

I hope you haven't taken anything in a personal way here. We're all friends.

Thats pretty interesting about the whole exhaust pressure thing. All I ever read was that it was an acoustic thing since acoustic waves have high and low pressure troughs. There was never any elaboration as to where these originated though. Makes sense when you think about it. That is the one thing that the rotary has an advantage of using since the closing pulse isn't really there like you've said.

Yep there are way too many things going on that can get confused with one another. This has been an educational little debate though!

I hope you haven't taken anything in a personal way here. We're all friends.

#53

Just found this. I have to agree with Zack that the fundamental formula appears to have an error in it. Towit: There are 2 ways of calculating tuned runner length. One uses exhaust closing as the start event and the other uses inlet opening. Over this side of the pond we always tend to use the latter as we are heavily into webers and other IR setups that can use this tuning. Stateside you are more into V8s and plenums, where you have to use 3 wave tuning off the exhaust closing to fit everything in.

Back on the rotary. If we start with an IR setup, then you are only considering 1 rotor. For a stock port, a new intake event starts every 360degrees with duration being around 330. So you have about 330 degrees to play with in the pulse tuning on the inlet.

As to where to tune. you tune for a peak VE at some point (as has been discussed) which will be the peak torque figure. For the 6-port mentioned, peak torque will be at around 5K for a 6k5 peak power. Likewise if you tune your runners for peak torque at 6K5 peak power will be over 8000RPM. Where this is not true is for aviation apps where you tune for effectively a single peak efficiency point, which is your cruise speed.

When you have a plenum setup like the 6-port on the primaries then you are looking at tuning for the return pulse to come in at 180 degree intervals so the primaries help each other out.

I'm fighting dry sump hoses at the moment, but if I get some time will locate the formula I use for intake lengths and try and work out why, despite their being a factor of 2 error in calculations you are coming up with the right sort of ball park figures (17" gives peak torque at 6000RPM). Suspect it is because, with 6-port primaries that gives you a peak at 3000RPM, which is what I think it was designed for, but I need to think about that

Bill

P.S. dry sumping a front mounted 13B is a PITA

Back on the rotary. If we start with an IR setup, then you are only considering 1 rotor. For a stock port, a new intake event starts every 360degrees with duration being around 330. So you have about 330 degrees to play with in the pulse tuning on the inlet.

As to where to tune. you tune for a peak VE at some point (as has been discussed) which will be the peak torque figure. For the 6-port mentioned, peak torque will be at around 5K for a 6k5 peak power. Likewise if you tune your runners for peak torque at 6K5 peak power will be over 8000RPM. Where this is not true is for aviation apps where you tune for effectively a single peak efficiency point, which is your cruise speed.

When you have a plenum setup like the 6-port on the primaries then you are looking at tuning for the return pulse to come in at 180 degree intervals so the primaries help each other out.

I'm fighting dry sump hoses at the moment, but if I get some time will locate the formula I use for intake lengths and try and work out why, despite their being a factor of 2 error in calculations you are coming up with the right sort of ball park figures (17" gives peak torque at 6000RPM). Suspect it is because, with 6-port primaries that gives you a peak at 3000RPM, which is what I think it was designed for, but I need to think about that

Bill

P.S. dry sumping a front mounted 13B is a PITA

#56

Like superstring theory it is often better to accept that its easier to have 2 simple equations that one complex one :-)

However I'll get back to you when I have some minutes

However I'll get back to you when I have some minutes

#58

BY gum I can get back on again.

Time is a little short, so this will have to be one part of several replies. ( was painting and replacing barge boards today, so no car time and she's calling me)

First off: scene setting. volumetric efficiency is everything. When tuning a car you are playing around with that, as VE makes torque (VE curve doesn't quite track torque curve, but close enough for non SAE work).

Now there is no free lunch. If you work to optimise VE at one point, you may lose it somewhere else. Fact of life is you have to compromise. IMHO the standard 6-port is compromised too much towards people used to driving V8s, but I come from a country with very few, and most of those were your cast offs (Rover V8, rolls royce etc).

Where you peak VE has a huge effect on the overall drivability. For example, if you take the curves published by racing beat for the carb vs FI work they did, both the EFI and the dellorto produced identical peak torque figures (162) but the carb, due mainly to longer runners, produced about 11 less HP at 8000. However at 5500 it produced nearly 15 more. And this was from moving the torque peak from 6300RPM to 6800RPM. And this is why peak HP figures on their own are less useful than farts.

As to how to affect VE. There are 3 things at play that I will discuss: helmholtz resonances, exhaust scavenging and inlet pulse tuning.

starting with helmholtz. This is true of any volume with a pipe coming off it and is why a wine bottle makes a noise when you blow across it. In a car it is fairly wideband in nature so is best left to airboxes, although I will do the sums for the resonant frequency in a rotary at some stage. With an airbox you should aim to use it to widen your torque curve, so tune a little lower than peak. Again sums to follow. (aside, you can add additional resonators off the airbox if you want/have space).

Secondly exhaust scavenging. At some point if you have a decent exhaust there will be scavenging pulse timed exactly as the inlet opens which will do 2 things: slurp in fresh fuel/air mix and set up a strong pulse up the inlet tract. This is a fairly narrow band effect, although it will have harmonics which will have to wait until another time.

Thirdly you have inlet tuning. IN the rotary this is predominantly the returning pulse caused by the inlet opening. Again it is relatively narrow band, but in the rotary this still gives you a good torque spread. It is this effect, helped by exhaust scavenging that gains you high power in NA rotaries, and is why slapping on an IDA gives great power. You loose low end, but you are grinning too much to care.

Like I said, all of these work together to give the overall torque curve, and the engine hasn't always read the text book. Over the next week or so I'll collect the equations up with some 13B examples and a list of web references to go to for total confusion.

Sorry I haven't got more time for the full analyses and real numbers but they will come.

Time is a little short, so this will have to be one part of several replies. ( was painting and replacing barge boards today, so no car time and she's calling me)

First off: scene setting. volumetric efficiency is everything. When tuning a car you are playing around with that, as VE makes torque (VE curve doesn't quite track torque curve, but close enough for non SAE work).

Now there is no free lunch. If you work to optimise VE at one point, you may lose it somewhere else. Fact of life is you have to compromise. IMHO the standard 6-port is compromised too much towards people used to driving V8s, but I come from a country with very few, and most of those were your cast offs (Rover V8, rolls royce etc).

Where you peak VE has a huge effect on the overall drivability. For example, if you take the curves published by racing beat for the carb vs FI work they did, both the EFI and the dellorto produced identical peak torque figures (162) but the carb, due mainly to longer runners, produced about 11 less HP at 8000. However at 5500 it produced nearly 15 more. And this was from moving the torque peak from 6300RPM to 6800RPM. And this is why peak HP figures on their own are less useful than farts.

As to how to affect VE. There are 3 things at play that I will discuss: helmholtz resonances, exhaust scavenging and inlet pulse tuning.

starting with helmholtz. This is true of any volume with a pipe coming off it and is why a wine bottle makes a noise when you blow across it. In a car it is fairly wideband in nature so is best left to airboxes, although I will do the sums for the resonant frequency in a rotary at some stage. With an airbox you should aim to use it to widen your torque curve, so tune a little lower than peak. Again sums to follow. (aside, you can add additional resonators off the airbox if you want/have space).

Secondly exhaust scavenging. At some point if you have a decent exhaust there will be scavenging pulse timed exactly as the inlet opens which will do 2 things: slurp in fresh fuel/air mix and set up a strong pulse up the inlet tract. This is a fairly narrow band effect, although it will have harmonics which will have to wait until another time.

Thirdly you have inlet tuning. IN the rotary this is predominantly the returning pulse caused by the inlet opening. Again it is relatively narrow band, but in the rotary this still gives you a good torque spread. It is this effect, helped by exhaust scavenging that gains you high power in NA rotaries, and is why slapping on an IDA gives great power. You loose low end, but you are grinning too much to care.

Like I said, all of these work together to give the overall torque curve, and the engine hasn't always read the text book. Over the next week or so I'll collect the equations up with some 13B examples and a list of web references to go to for total confusion.

Sorry I haven't got more time for the full analyses and real numbers but they will come.

#59

I agree with all of that completely.

A great example is the new Renesis. It is designed for a nice powerbadn up very high in the rpm range. Unfortunately the low end really suffers. I've driven one. My GSL-SE kills it up to 7000 rpm. The Renesis starts wanting to get moving at about 6000 rpm. I don't care what anyone says about how flat the torque curve is. It doesn't make it quick.

Helmholtz tuning does aid certain spots at the expense of others. So does certain runner tunings and plenum volumes. That's part of the fun of designing a truly good system.

A great example is the new Renesis. It is designed for a nice powerbadn up very high in the rpm range. Unfortunately the low end really suffers. I've driven one. My GSL-SE kills it up to 7000 rpm. The Renesis starts wanting to get moving at about 6000 rpm. I don't care what anyone says about how flat the torque curve is. It doesn't make it quick.

Helmholtz tuning does aid certain spots at the expense of others. So does certain runner tunings and plenum volumes. That's part of the fun of designing a truly good system.

#60

We come with the Hardcore

iTrader: (2)

Join Date: Nov 2001

Location: Springfield, MO

Posts: 2,456

Likes: 0

Received 0 Likes

on

0 Posts

I know this is gravedigging... however...

Is the Mazdatrix T-II template used on the secondairy AND primary intake ports? That's QUITE a bit of metal if so.

Didn't figure anyone would mind, this is a very good post!

Is the Mazdatrix T-II template used on the secondairy AND primary intake ports? That's QUITE a bit of metal if so.

Didn't figure anyone would mind, this is a very good post!

#61

50mpg - oooooh yeah!

Join Date: Mar 2003

Location: UK

Posts: 527

Likes: 0

Received 0 Likes

on

0 Posts

WEll, since it's been dug up, I've got a quick question as well......

Is the length measurement inclusive of the distance INSIDE the engine? What I mean is, when you say something like 17", do you measure 17" away from the body of the engine, or 17" from the centreline of the port itself?

Is the length measurement inclusive of the distance INSIDE the engine? What I mean is, when you say something like 17", do you measure 17" away from the body of the engine, or 17" from the centreline of the port itself?

#62

Sorry to intrude but this thread is great! Info like this is impossible to obtain in New Zealand. If people know anything of value they generally keep it to themselves. Go the internet!

When I get time I will build another experimantal n/a PP and plan to try different manifolds. Now that I've found this thread I will try a manifold built to each formula put foward and see what happens, just out of curiosity.

Can someone post an intake diameter formula??

Factory side port inlet manifolds draw from one collective point(throttle body). Has anybody tried this with a pp? i.e drawing from one throttle plate instead of two completely seperate.

When I get time I will build another experimantal n/a PP and plan to try different manifolds. Now that I've found this thread I will try a manifold built to each formula put foward and see what happens, just out of curiosity.

Can someone post an intake diameter formula??

Factory side port inlet manifolds draw from one collective point(throttle body). Has anybody tried this with a pp? i.e drawing from one throttle plate instead of two completely seperate.

#63

I have found some very interesting info with the formula in regards to the Renesis. I can't get the numbers to work. They work almost perfectly for the RX-7 engines. I am thinking that due to the fact that the primary and secondary ports on the Renesis are siamesed through part of their length and through VDI that there is some strange effect which throws the numbers off. I've stared at it a geat deal and it makes sense. The aux ports just mess me way up.

I have also learned how to calculate VDI. I was thinking much too hard before. Make a long set of runners for a lower rpm. Then calculate the distance for a short set of runners for a high rpm peak. It is at this distance where the VDI valve would go. Simple. The VDI makes the engine see only the length after the valve. What is before it is irrelevant to tuning when the valve is open.

I generally used that length to determine the manifold length itself and not including the runners. This is why it was close but not exact with the different runners. This is a shortcut average. The exact isn't much different but much harder to figure out.

I have also learned how to calculate VDI. I was thinking much too hard before. Make a long set of runners for a lower rpm. Then calculate the distance for a short set of runners for a high rpm peak. It is at this distance where the VDI valve would go. Simple. The VDI makes the engine see only the length after the valve. What is before it is irrelevant to tuning when the valve is open.

I generally used that length to determine the manifold length itself and not including the runners. This is why it was close but not exact with the different runners. This is a shortcut average. The exact isn't much different but much harder to figure out.

#64

PV = nRT

Join Date: Jan 2003

Location: New Zealand (was California)

Posts: 2,250

Likes: 0

Received 0 Likes

on

0 Posts

rotarygod,

I just came across this thread and wanted to thank you for taking the time to provide your thoughts and information. It's very valuable to all of us and I appreciate and respect people who contribute in this fashion.

I just came across this thread and wanted to thank you for taking the time to provide your thoughts and information. It's very valuable to all of us and I appreciate and respect people who contribute in this fashion.

#65

FTD Wanna Be

Join Date: Jun 2002

Location: Virginia

Posts: 1,252

Likes: 0

Received 0 Likes

on

0 Posts

Well, we're gonna find out soon if my method works. The senior design project is underway!

https://www.rx7club.com/showthread.p...hreadid=248556

https://www.rx7club.com/showthread.p...hreadid=248556

#67

FTD Wanna Be

Join Date: Jun 2002

Location: Virginia

Posts: 1,252

Likes: 0

Received 0 Likes

on

0 Posts

I think its a pretty good senior design project. We don't have to reinvent the wheel or anything, just test our methods.

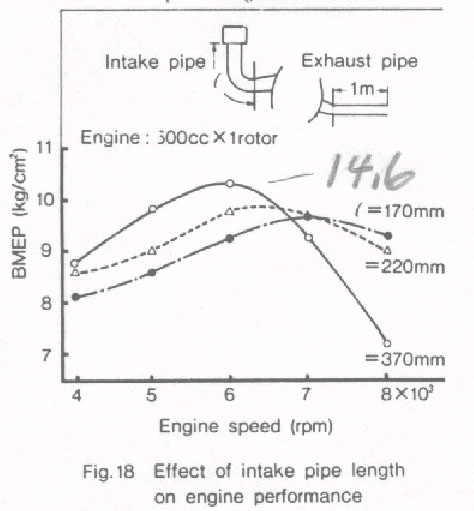

I'm a little confused with that graph. What is the y-axis representing? Mass/area?

I'm a little confused with that graph. What is the y-axis representing? Mass/area?

#68

Full Member

Join Date: Jun 2003

Location: Fredericton

Posts: 116

Likes: 0

Received 0 Likes

on

0 Posts

Hold on, your doing an ME senior design project on intake runner length and don't know what BMEP is?? Sorry for the flame. Might I suggest the book

Internal-Combustion Engine in Theory & Practice, Vol. 1

By Charles F. Taylor

Internal-Combustion Engine in Theory & Practice, Vol. 1

By Charles F. Taylor

#70

Thanks for that Ted. Wish I could afford an SAE membership (not a standard journal in most UK libraries). Well that certainly matches with what racing beat found empirically, at least for the shorter runners.

Bill

Bill

#71

It is a pretty well known fact that longer runners make peak power lower in the rpm range. Those exact numbers only apply if the port timing is the same as the engine that the chart is based off of. The lengths would be different for a streetport vs a peripheral port to tune at the same spot but the fact that a longer runner peaks earlier is still the same. That is all that the graph tells us and most people already know that. So unless his ports are the exact same ports that Mazda based that off of, he still won't know the proper length.

#72

Lives on the Forum

BMEP = brake mean effective pressure

It's a direct measure of the combustion pressure. By measuring this reading, you get an idea of how well the combustion process is. BMEP is directly related to poewr output.

-Ted

It's a direct measure of the combustion pressure. By measuring this reading, you get an idea of how well the combustion process is. BMEP is directly related to poewr output.

-Ted

#73

Lives on the Forum

Sure, you can argue that the results from that single 500cc rotor engine with the PP intake (and exhaust) is not a direct comparision with a production 13B, but the results will be similar, irregardless of PP or SP intake.

I'd like to so your experiements and results that claims otherwise, because the majority of the discussion has been theoretical with a whole lot of math that keeps everything in the theoretical universe.

There's a bunch of SAE papers here:

http://www.thecarricos.com/ACRE/

Someone converted some of them to PDF format, so it's easy to download and peruse.

This is where I got the reference graph from.

Enjoy!

-Ted

I'd like to so your experiements and results that claims otherwise, because the majority of the discussion has been theoretical with a whole lot of math that keeps everything in the theoretical universe.

There's a bunch of SAE papers here:

http://www.thecarricos.com/ACRE/

Someone converted some of them to PDF format, so it's easy to download and peruse.

This is where I got the reference graph from.

Enjoy!

-Ted

#75

Thats not an FC...

Join Date: Apr 2001

Location: spring hill, Fla

Posts: 844

Likes: 0

Received 0 Likes

on

0 Posts

hey, explain to me why i would choose a short lenth primary header over the full length (94").... or vice versa. ive got the materials to build it, i just need to figure out if i need the long or short version.