Billet Engines

#1

Newbie

Thread Starter

Join Date: Dec 2013

Location: UK

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Billet Engines

Hi All,

I have been away from the rotary market for awhile and looking to build another Rx. This time, with the progression of the 4 rotors and 5 rotors that are all billet, I was wondering which billet set up seems to be the best? Is it going to be BilletInc? Or BIlletPro? Or PacPerformance? Or even are there any other companies I should be looking at?

I am only looking for a 13b, ideally with an integrated drysump system.

I have been away from the rotary market for awhile and looking to build another Rx. This time, with the progression of the 4 rotors and 5 rotors that are all billet, I was wondering which billet set up seems to be the best? Is it going to be BilletInc? Or BIlletPro? Or PacPerformance? Or even are there any other companies I should be looking at?

I am only looking for a 13b, ideally with an integrated drysump system.

Popular Reply

06-07-24, 06:29 AM

I have tested

Billet Inc (Horrible product, support, wait times and essentially threw 15k+ in the bin with them)

Billet Pro (Pretty, inserts wear very quickly)

Billet Boss (First 2 generations had lots of issues, made significant improvements in 3rd gen plate, have a set in my street car) Inserts don't wear much at all, great oil pressure)

Billet by Pac (Have built and used half a dozen engines with Pac plates, coating does not wear at ALL, pretty much need the rotor to smash itself into the surface to do anything to it, very sensitive to bearing clearance and if you get it wrong, will have low oil pressure, downsides? Not so pretty, Has to be ported, coated and repaired by pac) otherwise it's a great product, Support isn't that great but in reality you don't need it, it just works. Also have them in a world time attack car, actually runs cooler in terms of coolant temps than cast engine did, oil temp is a little hotter which to be honest worked in our favour since it oil was generally too cold with the cast engine.

I should also point out another draw back to all plates with inserts, if you get them hot, the o-rings behind the inserts fail and you will have oil and water mix. Had it happen to me on billet pro.

I really like the Gen 3 Billet boss and the pac plates, they are my pick. I went billet boss in my own FD since they are a copy of OEM auto plates and have all the provisions for power steering bracket etc which pac do not have.

Of course this is all just my opinion/experience. Hopefully I didn't offend anyone lol.

Billet Inc (Horrible product, support, wait times and essentially threw 15k+ in the bin with them)

Billet Pro (Pretty, inserts wear very quickly)

Billet Boss (First 2 generations had lots of issues, made significant improvements in 3rd gen plate, have a set in my street car) Inserts don't wear much at all, great oil pressure)

Billet by Pac (Have built and used half a dozen engines with Pac plates, coating does not wear at ALL, pretty much need the rotor to smash itself into the surface to do anything to it, very sensitive to bearing clearance and if you get it wrong, will have low oil pressure, downsides? Not so pretty, Has to be ported, coated and repaired by pac) otherwise it's a great product, Support isn't that great but in reality you don't need it, it just works. Also have them in a world time attack car, actually runs cooler in terms of coolant temps than cast engine did, oil temp is a little hotter which to be honest worked in our favour since it oil was generally too cold with the cast engine.

I should also point out another draw back to all plates with inserts, if you get them hot, the o-rings behind the inserts fail and you will have oil and water mix. Had it happen to me on billet pro.

I really like the Gen 3 Billet boss and the pac plates, they are my pick. I went billet boss in my own FD since they are a copy of OEM auto plates and have all the provisions for power steering bracket etc which pac do not have.

Of course this is all just my opinion/experience. Hopefully I didn't offend anyone lol.

#2

Junior Member

Can’t say anything about BilletInc or PacPerformance as I haven’t heard of them but BilletPro has got some real trick pieces. I’ve seen full 3 and 4 rotor engine builds on YouTube using BilletPro plates but none with the other companies. Doesn’t mean they’re any worse though. Call them up and ask questions for your application, they’d surely help you out. As for your dry sump question I believe you can buy aftermarket billet dry sump front covers but it’ll cost you. (usually $6000+ from what i’ve seen) Mazdaspeed used to make dry sump covers as well but they’re NLA.

#3

Rotary Freak

Might be a month late - and won't slander anyone - just be aware, a toolmaker mate had a side hustle correcting centre plate hole position on one of the billet engine makers products. Haven't caught up with him recently, so don't know the current state of play......you'd hope they'd have fixed it in the intervening few years since I last saw one mounted on the mill though!

Billet Boss is another one on this side of the Tasman who might be worth checking out, from an all too rich for my blood perspective and totally out of that market, they seem to sell a few locally I've observed. If PPRE are still into it over in NZ, acquaintances have bought 3 and 4 rotor engine packages from there when that was the only game in town ~10 years ago, I assume they do a 13b and maybe the exchange rate might be more favourable.

The front cover dry sump is much neater of course, should be more than a few external pump alternatives at a much lesser price

Billet Boss is another one on this side of the Tasman who might be worth checking out, from an all too rich for my blood perspective and totally out of that market, they seem to sell a few locally I've observed. If PPRE are still into it over in NZ, acquaintances have bought 3 and 4 rotor engine packages from there when that was the only game in town ~10 years ago, I assume they do a 13b and maybe the exchange rate might be more favourable.

The front cover dry sump is much neater of course, should be more than a few external pump alternatives at a much lesser price

#4

Sponsor

RX7Club Vendor

Honesty haven't seen any long term successful billet rotaries. Great for drag, but they don't seem to last in a street or track situation. Thermal expansion of the alloy plates is a lot larger than the OEM plates. Slapping a keg together will require different torque values, different side clearencing etc. I think someone is testing 4032 alloy plates to help combat this

The following users liked this post:

gracer7-rx7 (06-03-24)

#5

ProMaz has a few videos for street built billet rotary engines and they’re big on the BilletPro brand, but I otherwise have no experience to offer and am just an interested observer on the topic.

https://www.promaz.com.au/collections/billetpro-plates

https://www.billetpro.com.au

I’d be surprised if you can get a billet front cover dry sump for $6k USD. A year ago you could get one for that price in the USA, but it was intended for an OE front iron and in addition to the price having increased to $8,500 there are rumors of the company closing and/or possibly filing for bankruptcy. I’m not aware of either of these being factual though.

I’m looking for the dry sump pickup tube mounting/installation mods that need to be made to the underside of the OE housings if anyone has that info and can PM me.

.

https://www.promaz.com.au/collections/billetpro-plates

https://www.billetpro.com.au

I’d be surprised if you can get a billet front cover dry sump for $6k USD. A year ago you could get one for that price in the USA, but it was intended for an OE front iron and in addition to the price having increased to $8,500 there are rumors of the company closing and/or possibly filing for bankruptcy. I’m not aware of either of these being factual though.

I’m looking for the dry sump pickup tube mounting/installation mods that need to be made to the underside of the OE housings if anyone has that info and can PM me.

.

Last edited by TeamRX8; 05-20-24 at 11:08 PM.

#6

Junior Member

Honesty haven't seen any long term successful billet rotaries. Great for drag, but they don't seem to last in a street or track situation. Thermal expansion of the alloy plates is a lot larger than the OEM plates. Slapping a keg together will require different torque values, different side clearencing etc. I think someone is testing 4032 alloy plates to help combat this

Unsure about the other plates but BilletPro plates have a cast iron insert that's also removeable with a tool, so I'm not sure if thermal expansion is an issue with those but I might be wrong. The plates themselves are made from "Certified ISO 9001:2015 AA7075 Billet Aerospace grade zinc aluminum." Haven't seen any long term billet rotaries either but I wanna try building a billet street motor in the future

WEIGHT REDUCTIONNNNNN.

WEIGHT REDUCTIONNNNNN.Link to the billet plate I'm talking about: https://www.billetrotary.com.au/prod...rmediate-plate

Last edited by s1ckksn0w; 05-21-24 at 01:26 AM.

#7

Junior Member

ProMaz has a few videos for street built billet rotary engines and they’re big on the BilletPro brand, but I otherwise have no experience to offer and am just an interested observer on the topic.

https://www.promaz.com.au/collections/billetpro-plates

https://www.billetpro.com.au

I’d be surprised if you can get a billet front cover dry sump for $6k USD. A year ago you could get one for that price in the USA, but it was intended for an OE front iron and in addition to the price having increased to $8,500 there are rumors of the company closing and/or possibly filing for bankruptcy. I’m not aware of either of these being factual though.

I’m looking for the dry sump pickup tube mounting/installation mods that need to be made to the underside of the OE housings if anyone has that info and can PM me.

.

https://www.promaz.com.au/collections/billetpro-plates

https://www.billetpro.com.au

I’d be surprised if you can get a billet front cover dry sump for $6k USD. A year ago you could get one for that price in the USA, but it was intended for an OE front iron and in addition to the price having increased to $8,500 there are rumors of the company closing and/or possibly filing for bankruptcy. I’m not aware of either of these being factual though.

I’m looking for the dry sump pickup tube mounting/installation mods that need to be made to the underside of the OE housings if anyone has that info and can PM me.

.

The link for it if you wanna check it out: https://chipsmotorsports.com/product...-dry-sump-kit/

Last edited by s1ckksn0w; 05-21-24 at 01:22 AM.

Trending Topics

#8

Sponsor

RX7Club Vendor

It appears Chips has skipped town with everyone’s money, there’s a long thread about it. Please read that thread before sending money his way. Nobody can find him or their parts and engines that were sent in for rebuilds.

The entire “iron” is now alloy, the whole keg heats up and grows in length. If you want a billet engine have them assemble it with all their tricks, you will likely have issues using typical clearances etc.

The stock irons are plenty strong. I’d be amazed if you actually needed the strength. I know it sounds cool, but it might just be a huge headache an a lot of money for no real benefit

The entire “iron” is now alloy, the whole keg heats up and grows in length. If you want a billet engine have them assemble it with all their tricks, you will likely have issues using typical clearances etc.

The stock irons are plenty strong. I’d be amazed if you actually needed the strength. I know it sounds cool, but it might just be a huge headache an a lot of money for no real benefit

#9

Junior Member

It appears Chips has skipped town with everyone’s money, there’s a long thread about it. Please read that thread before sending money his way. Nobody can find him or their parts and engines that were sent in for rebuilds.

The entire “iron” is now alloy, the whole keg heats up and grows in length. If you want a billet engine have them assemble it with all their tricks, you will likely have issues using typical clearances etc.

The stock irons are plenty strong. I’d be amazed if you actually needed the strength. I know it sounds cool, but it might just be a huge headache an a lot of money for no real benefit

The entire “iron” is now alloy, the whole keg heats up and grows in length. If you want a billet engine have them assemble it with all their tricks, you will likely have issues using typical clearances etc.

The stock irons are plenty strong. I’d be amazed if you actually needed the strength. I know it sounds cool, but it might just be a huge headache an a lot of money for no real benefit

Sucks to see shitty rotary shops/shitty shop owners, but atleast there’s some good ones still out there. I see what you mean now, makes sense how it would change as it’s a different material = different properties n all. Thanks for clarifying. Going back to what you said earlier, is that 4032 material any better?

#11

Rotary Enthusiast

What's up with all the bad FD tuners...sheez. seems every other day we hear of em. I get that it's a dying breed, but no need to be snakes.

The following users liked this post:

gracer7-rx7 (05-29-24)

#13

Sponsor

RX7Club Vendor

The other more traditional alloys for engine use like 2618 are slightly stronger and a little bit more resilient to flexing. People going for billet plates might just prefer a stronger material overall, and the thermal expansion wear is just the cost of greater strength.

I have no idea what the price difference would be. 4032 could be a terrible material choice for a reason I'm not aware of, and that's why I haven't seen it offered.

OEM steel plates and housings that have been modified for larger dowels are incredibly strong and will hold up to almost anything you can throw their way on street fuel. Billet is really for methanol and occasionally the bling factor. OEM 20b plates are getting increasingly difficult to find in decent condition, billet 20b plates are sitting on shelves ready to go..

#14

Junior Member

4032 is a hypereutectic alloy, it has a very high silicone content that gives it much lower thermal expansion compared to other more traditional alloys. Mahle uses it in their PowerPak line of pistons for street driven modified cars because it allows you to run a much tighter piston to bore clearance vs a more traditional alloy like 2618, but still have a very sturdy piston. There's a guy (can't remember who) who's using 4032 for aftermarket rotors he's developing. I had an online chat a few months ago with a couple of people, we might be seeing 4032 plates tested soon, this could be worth holding out for. Mahle coats their PowerPak pistons with a low friction teflon piston sleeve coating, and a ceramic top coat, so coating the plates in a high-wear surface likely won't be a problem (but I don't know enough about metallurgy to say for certain).

The other more traditional alloys for engine use like 2618 are slightly stronger and a little bit more resilient to flexing. People going for billet plates might just prefer a stronger material overall, and the thermal expansion wear is just the cost of greater strength.

I have no idea what the price difference would be. 4032 could be a terrible material choice for a reason I'm not aware of, and that's why I haven't seen it offered.

The other more traditional alloys for engine use like 2618 are slightly stronger and a little bit more resilient to flexing. People going for billet plates might just prefer a stronger material overall, and the thermal expansion wear is just the cost of greater strength.

I have no idea what the price difference would be. 4032 could be a terrible material choice for a reason I'm not aware of, and that's why I haven't seen it offered.

The following users liked this post:

FD Wheel Covers In Carbon (05-21-24)

#16

Sponsor

RX7Club Vendor

Your ability to make snide remarks is unmatched.

Had the iron vs billet conversation with Ma at Rotary Revolution. His dad built rotary engines at Mazda and worked in their race program. He now builds the fastest road raced FDs in Thailand. He doesn’t want to use billet because he isnt sure what clearances to use vs oem irons

Had the iron vs billet conversation with Ma at Rotary Revolution. His dad built rotary engines at Mazda and worked in their race program. He now builds the fastest road raced FDs in Thailand. He doesn’t want to use billet because he isnt sure what clearances to use vs oem irons

#17

Junior Member

Your ability to make snide remarks is unmatched.

Had the iron vs billet conversation with Ma at Rotary Revolution. His dad built rotary engines at Mazda and worked in their race program. He now builds the fastest road raced FDs in Thailand. He doesn’t want to use billet because he isnt sure what clearances to use vs oem irons

Had the iron vs billet conversation with Ma at Rotary Revolution. His dad built rotary engines at Mazda and worked in their race program. He now builds the fastest road raced FDs in Thailand. He doesn’t want to use billet because he isnt sure what clearances to use vs oem irons

Since billet motors expand more I'd wonder if you would go tighter or looser on the clearances. In my head tighter clearances makes sense as when the plates expand it'll be proper but figuring out THE clearance is the problem. It's cool that you had a discussion with someone like that, definitely knowledgeable on the subject. Now if these companies could share their clearance secrets/recommendations maybe more people like Ma would buy them -_-

The following users liked this post:

FD Wheel Covers In Carbon (06-02-24)

#19

so going backwards maybe could be forwards?

some piston crate engines are available in iron with higher power capability than aluminum

Mazda is going all aluminum not for greater power but for lighter weight and lower power at higher efficiency for ev generators.

Maybe an all iron rotary will provide better heat transfer and expansion characteristics and higher strength for crazy power potential?

some piston crate engines are available in iron with higher power capability than aluminum

Mazda is going all aluminum not for greater power but for lighter weight and lower power at higher efficiency for ev generators.

Maybe an all iron rotary will provide better heat transfer and expansion characteristics and higher strength for crazy power potential?

#20

That said, I have actual experience with both well known styles/manufacturers - granted in 3+ rotor NA applications - and can say they both have their pro's and cons. There's far more to it but I'll do pretty broad strokes:

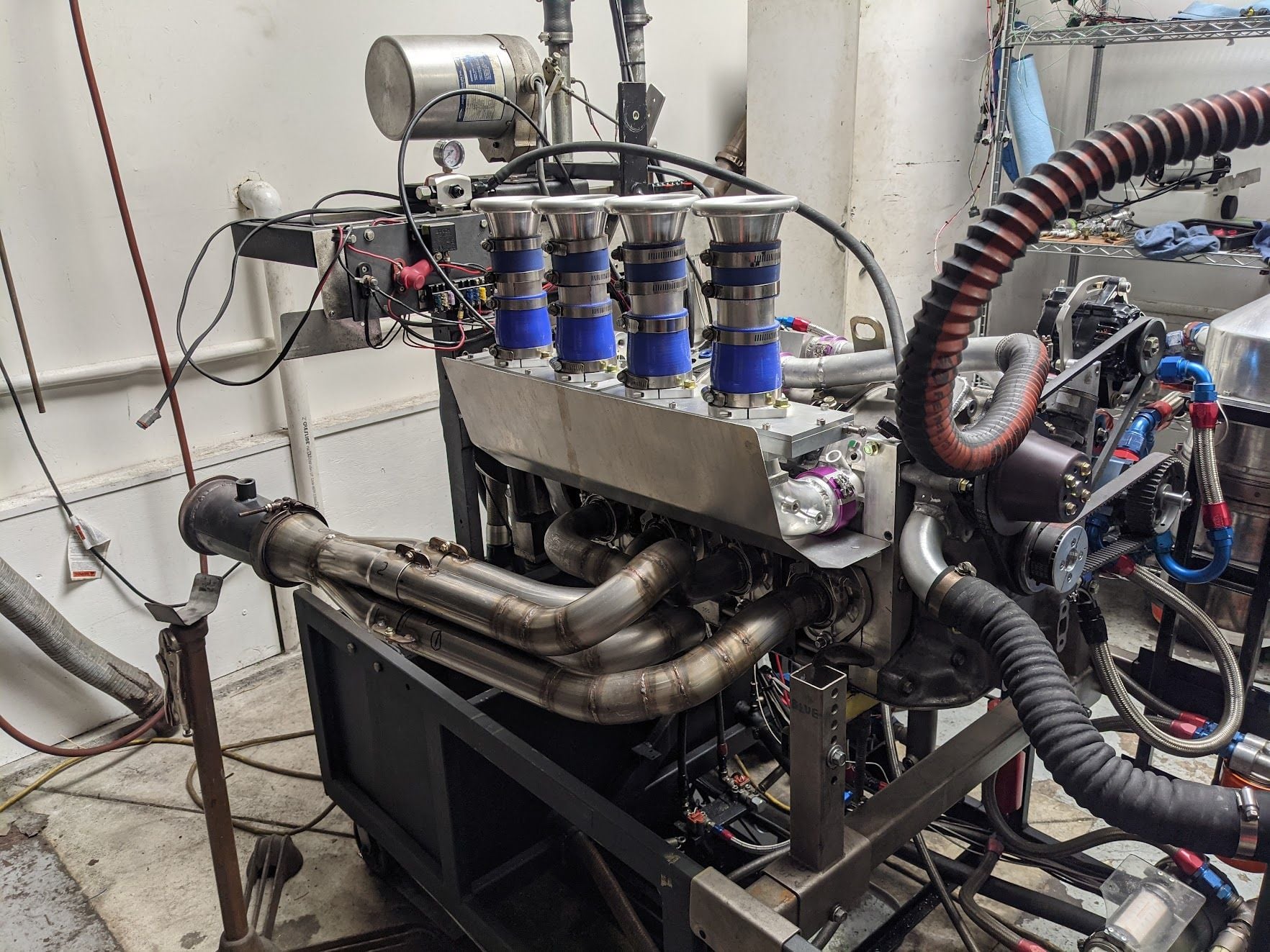

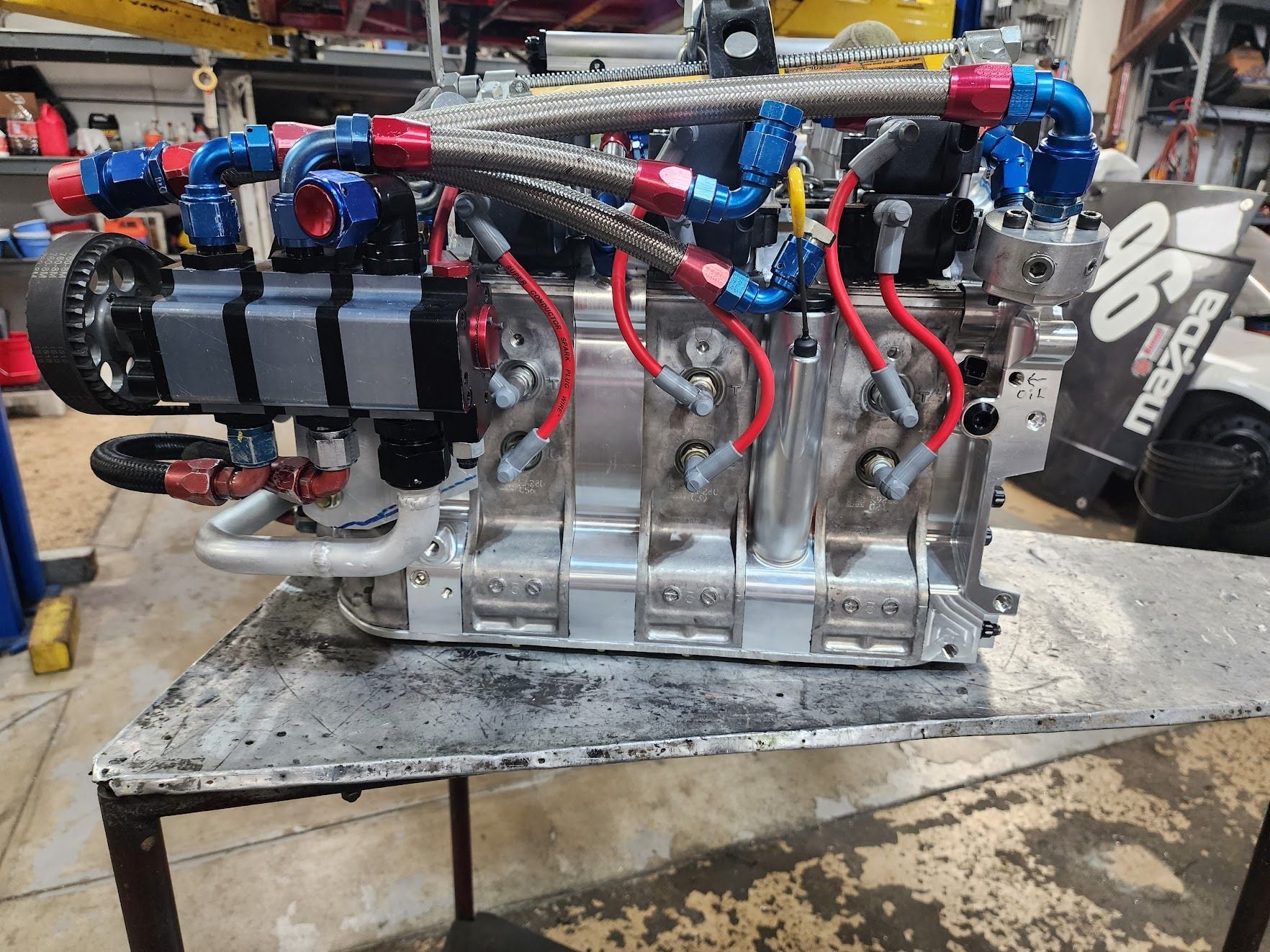

PAC - They just work for what they are, there is no fiddling and assembling passed the stationary gear which is relatively straight forward. My experience with them was repairing and rebuilding a 4 rotor that was originally assembled by someone else and had a failure on my dyno - what it was exactly is still somewhat murky but suffice it to say PAC was able to resurface the cermet which is in my estimation their largest downfall - if you're outside of Aus it's annoying to get them repaired. I also do not particularly like the water passage design however this engine was machined to act somewhat like Mazda's 787B in its coolant routing so I can't say if it would ever be a problem as as a street car. I did not treat clearances any differently on assembly:

Notice the straight shots as the axial water passages and regular 'trough' as the 'turnarounds' on the front and rear.

Post engine dyno failure, I've rebuilt and repaired it since

Ready to validate again on the dyno

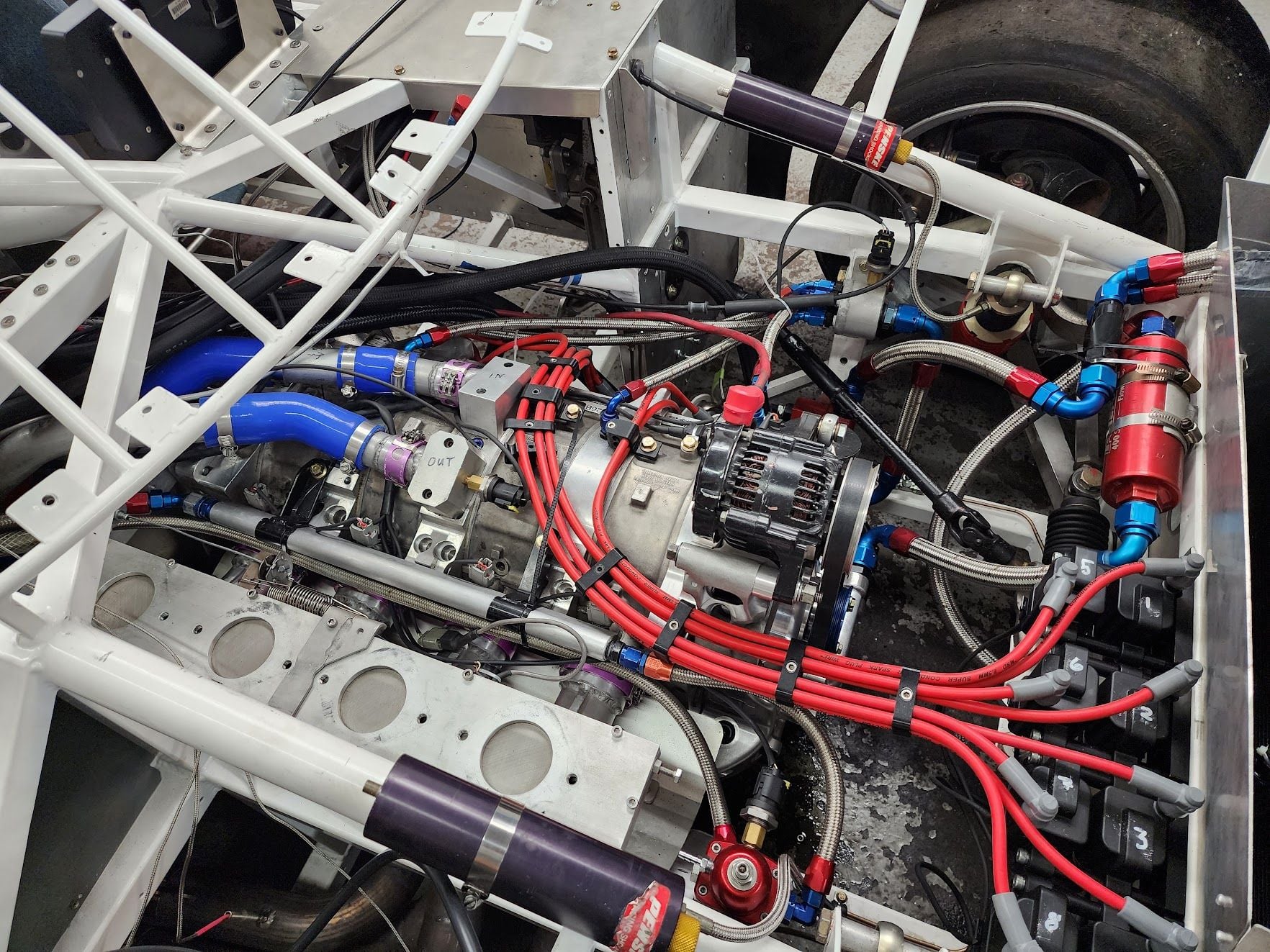

Installed, and has run on the track in this config

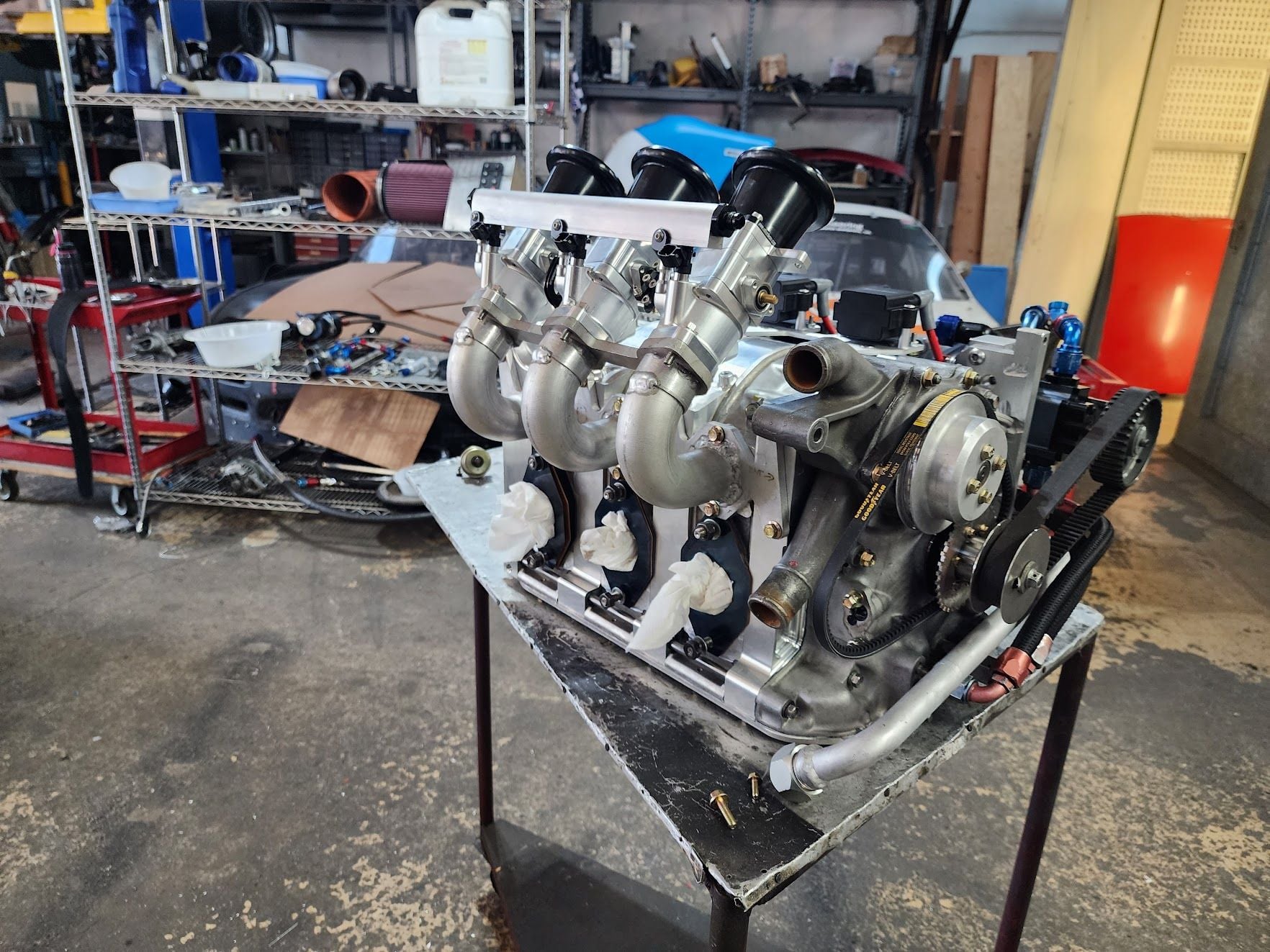

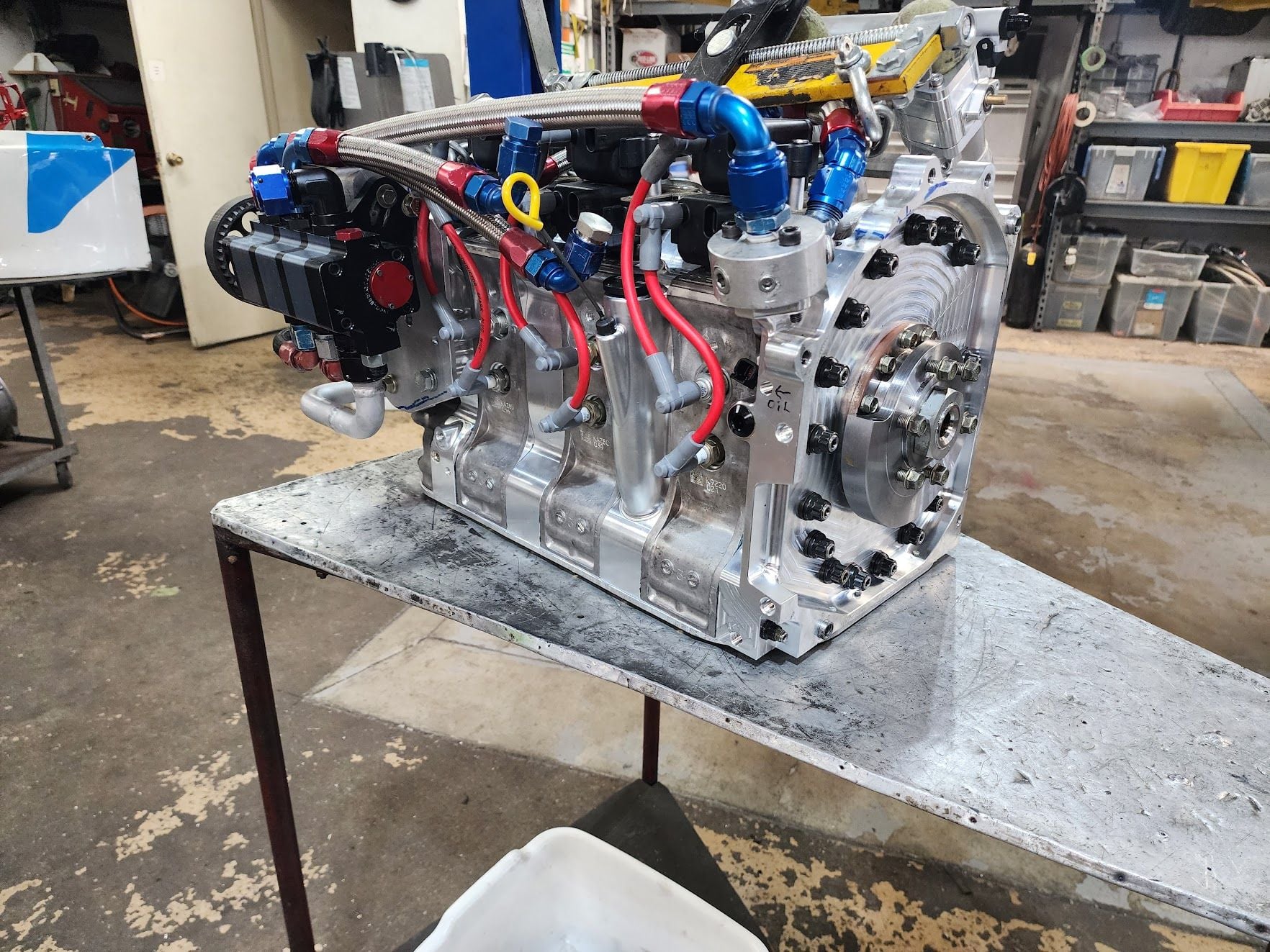

Billet Boss/Billet Rotary Store: This was from the ground up in house. These are shipped unassembled and when I received them (far too long ago for this projects current state) there was little to no documentation or YouTube tutorials as far as I know on how, I was given one off instructions over the phone and it left not the best taste in my mouth. I also don't like how the steel inserts weren't totally flat until they were installed - I was assured that this is standard though it still left a bad taste. I really like the water passages (sorry don't have photos) on these and would 100% say that these would be a better/cooler (with regards to temp) street or turbo setup but I would also say they're certainly NOT for the home gamer if they wanted to build their own engine (it's totally doable, but it's definitely more involved than stacking stock plates), whereas the PAC parts it'd be no sweat.. Again, I treated clearances as I would on a stock engine - however I haven't run this on the dyno or in a chassis yet.

Front

Back

Side to side

Still designing the air box that the gantry rail will bolt on to so as to not deal with fluids and wiring bulkheads.

The following 6 users liked this post by dguy:

diabolical1 (06-10-24),

FD Wheel Covers In Carbon (06-08-24),

j9fd3s (06-07-24),

Pete_89T2 (06-09-24),

s1ckksn0w (06-08-24),

and 1 others liked this post.

The following users liked this post:

dguy (06-06-24)

#23

Definitely, and that's where I'm of the opinion that the Billet Boss plates are superior in every way. The radiator and oil coolers that I've rigged on the PAC plates - as well as the 787B style cooling route that was rigged may keep it cool in its current configuration but I personally wouldn't opt for that style of plate on a street car.

#24

I have tested

Billet Inc (Horrible product, support, wait times and essentially threw 15k+ in the bin with them)

Billet Pro (Pretty, inserts wear very quickly)

Billet Boss (First 2 generations had lots of issues, made significant improvements in 3rd gen plate, have a set in my street car) Inserts don't wear much at all, great oil pressure)

Billet by Pac (Have built and used half a dozen engines with Pac plates, coating does not wear at ALL, pretty much need the rotor to smash itself into the surface to do anything to it, very sensitive to bearing clearance and if you get it wrong, will have low oil pressure, downsides? Not so pretty, Has to be ported, coated and repaired by pac) otherwise it's a great product, Support isn't that great but in reality you don't need it, it just works. Also have them in a world time attack car, actually runs cooler in terms of coolant temps than cast engine did, oil temp is a little hotter which to be honest worked in our favour since it oil was generally too cold with the cast engine.

I should also point out another draw back to all plates with inserts, if you get them hot, the o-rings behind the inserts fail and you will have oil and water mix. Had it happen to me on billet pro.

I really like the Gen 3 Billet boss and the pac plates, they are my pick. I went billet boss in my own FD since they are a copy of OEM auto plates and have all the provisions for power steering bracket etc which pac do not have.

Of course this is all just my opinion/experience. Hopefully I didn't offend anyone lol.

Billet Inc (Horrible product, support, wait times and essentially threw 15k+ in the bin with them)

Billet Pro (Pretty, inserts wear very quickly)

Billet Boss (First 2 generations had lots of issues, made significant improvements in 3rd gen plate, have a set in my street car) Inserts don't wear much at all, great oil pressure)

Billet by Pac (Have built and used half a dozen engines with Pac plates, coating does not wear at ALL, pretty much need the rotor to smash itself into the surface to do anything to it, very sensitive to bearing clearance and if you get it wrong, will have low oil pressure, downsides? Not so pretty, Has to be ported, coated and repaired by pac) otherwise it's a great product, Support isn't that great but in reality you don't need it, it just works. Also have them in a world time attack car, actually runs cooler in terms of coolant temps than cast engine did, oil temp is a little hotter which to be honest worked in our favour since it oil was generally too cold with the cast engine.

I should also point out another draw back to all plates with inserts, if you get them hot, the o-rings behind the inserts fail and you will have oil and water mix. Had it happen to me on billet pro.

I really like the Gen 3 Billet boss and the pac plates, they are my pick. I went billet boss in my own FD since they are a copy of OEM auto plates and have all the provisions for power steering bracket etc which pac do not have.

Of course this is all just my opinion/experience. Hopefully I didn't offend anyone lol.

The following 10 users liked this post by rx72c:

dguy (06-07-24),

diabolical1 (06-10-24),

elturbonitroso (06-12-24),

FD Wheel Covers In Carbon (06-08-24),

gracer7-rx7 (06-17-24),

and 5 others liked this post.