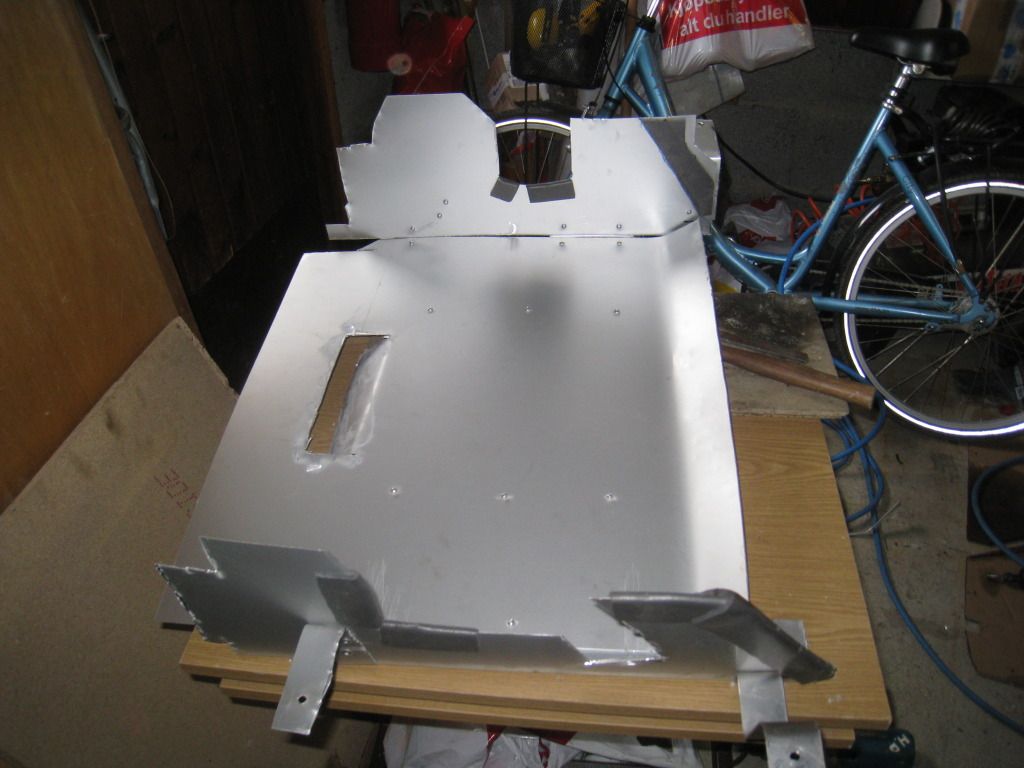

Crappy temporary first try at Radiator ducting.

#1

Crappy temporary first try at Radiator ducting.

So it's not long until the first track weekend, so i wanted to make some ducting for the radiator to help keep things cool, i think i will call this my prototype and make a new one later on, out of thicker aluminium and bend it from one piece, so it looks and seals better.

Anyway, made it out of thin aluminium, and it should work ok, i hope.

Anyway, made it out of thin aluminium, and it should work ok, i hope.

#3

Moderating the Trochoid

iTrader: (56)

Joined: Oct 2005

Posts: 1,899

Likes: 3

From: Willamette Valley, OR

I don't think its crappy at all. Its functional and to most of us, that's the name of the game.

You can't always expect it to look like a laser cut machined product that has been through trial and error many times on your first go around. In fact that is rather impressive for your first go!

You can't always expect it to look like a laser cut machined product that has been through trial and error many times on your first go around. In fact that is rather impressive for your first go!

#5

if you can get your hands on a bending brake it will make your second attempt way easier and look better. Not that this isnt a great 1st attempt, especially considering that it was pretty much free hand. but if you are wanting to do another out of 1 sheet like you said a brake will be more accurate, easier and faster.

http://www.harborfreight.com/18-inch...ake-39103.html

http://www.harborfreight.com/18-inch...ake-39103.html

#6

Thanks, yes i def need one of those. And i will use more than half a saturday to make the next one.

I need to learn how to fabricate stuff from aluminium, since i plan too build front and rear diffusers + some misc engine bay and interior parts.

I need to learn how to fabricate stuff from aluminium, since i plan too build front and rear diffusers + some misc engine bay and interior parts.

Trending Topics

#8

petterson, nice job, especially for your first attempt i see you have some rubber in some of the cut outs, but some angles look a bit scary, just make sure the duct doesnt rub on the harness and cut it!

what are you using to cut the aluminum? im fortunate enought to have a stomp shear, but a lot of the fabrication guys recommend air nibblers. im yet to pick one up yet but you may want to look into it to help cutting

http://www2.northerntool.com/Air-Nibblers.htm

what are you using to cut the aluminum? im fortunate enought to have a stomp shear, but a lot of the fabrication guys recommend air nibblers. im yet to pick one up yet but you may want to look into it to help cutting

http://www2.northerntool.com/Air-Nibblers.htm

#12

Another thing worth mentioning, it would be worth the time to get some of the larger panels bead rolled to add some rigidity. It really can make a significant improvement in how flimsy the parts feel.

#14

Fantastic work. A bit of sanding around the edges with a flap disk or drum and it will look great.

A few tips for your next project.

~5052 aluminium is more corrosion resistant and easier to bend, and as a bonus cheaper.

~Drill holes in the corners of you cut outs. This makes it easier to cut out the section and looks nicer.

~If you can find them, use aluminum rivets. They weigh less and wont rust.

~Red scotchbrite on a vibratory sander will create a nice finish with little effort.

A few tips for your next project.

~5052 aluminium is more corrosion resistant and easier to bend, and as a bonus cheaper.

~Drill holes in the corners of you cut outs. This makes it easier to cut out the section and looks nicer.

~If you can find them, use aluminum rivets. They weigh less and wont rust.

~Red scotchbrite on a vibratory sander will create a nice finish with little effort.

#15

i love when people come through with input like that! nice work Level Zero! people sharing experience/knowledge is what this place is about.

any progress on the 2nd attempt?

any progress on the 2nd attempt?

Thread

Thread Starter

Forum

Replies

Last Post