Steering knuckle mod "moar angle"

#101

Yeah, you're gonna have to make them yourself. I would look into it but there doesn't seem to be much interest for the fd. Also from an engineering standpoint the cut weld spindles scare me. It puts the welds in shear rather than tension/compression like mine do. It appears people have had good luck with them though, we will have to see how mine hold up.

#102

as long as it's cut/welded properly there shouldn't be a problem.. i've dirty dropped each front tire pretty hard at willow, slammed into tanner during tandem, and neither have broken.

i'm looking forward to trying yours out though, it's definitely an easier attempt at what seems to be the same thing.

i'm looking forward to trying yours out though, it's definitely an easier attempt at what seems to be the same thing.

#103

maybe this is a stupid question, but i'm trying to wrap my head around a few things here.

This would throw toe out and require a re-alignment wouldn't it?

I'm N/A, so i won't be doing any spindle modifying. I want to put spacers on my inner tie rods, so am I going to need a re-alignment afterwards? Something tells me this is a retarded question, but my brain is dead. Lol.

What i don't understand is how does this give you more angle? Wouldn't you just have to adjust the tie rods to compensate for the spacer, and then you're back to square one again? Someone please explain this?

Oh and btw I'm running 16x7 +16 wheels up front with a 205/45 tire

This would throw toe out and require a re-alignment wouldn't it?

I'm N/A, so i won't be doing any spindle modifying. I want to put spacers on my inner tie rods, so am I going to need a re-alignment afterwards? Something tells me this is a retarded question, but my brain is dead. Lol.

What i don't understand is how does this give you more angle? Wouldn't you just have to adjust the tie rods to compensate for the spacer, and then you're back to square one again? Someone please explain this?

Oh and btw I'm running 16x7 +16 wheels up front with a 205/45 tire

#104

The inner tie rods bottom out on the rack to stop movement. By adding the spacer you're moving the bump stop out and allowing more lateral rack movement. Yes you will need an alignment after and you may have to cut a couple threads off the inner tie rods.

#106

we can soon have S-chassis-like angle

Hrees the link from Zilvia.

or you can go to their official website

http://zilvia.net/f/advertiser-speci...-knuckles.html

Hrees the link from Zilvia.

or you can go to their official website

http://zilvia.net/f/advertiser-speci...-knuckles.html

#109

Yeah but I have 16x8 0 offset wheels now. The wheel is just barely touching the swaybar. I'll remove the swaybar and throw in the steering rack spacers I have and maybe add a slip on spacer for a couple extra degrees.

#112

remember every 25mm is about one inch. t2 rotor has 16x8 0 offset, wezzmo has 17x9 -7 the extra inch is another 25mm wider making it hit the lca and swaybar easier. Minus the -7 offset. I would just find some 1" spacers and add abit of camber..

The wider wheels you run the more Neg. offset youll need to clear the lca and swaybar, especialy if you have mad steering angle. Then you will also have to take the front fenders into consideration to make the fitment and angle functional.

I wish the front LCA was longer.... Its pretty short..

Numbers numbers lol

The wider wheels you run the more Neg. offset youll need to clear the lca and swaybar, especialy if you have mad steering angle. Then you will also have to take the front fenders into consideration to make the fitment and angle functional.

I wish the front LCA was longer.... Its pretty short..

Numbers numbers lol

#114

remember every 25mm is about one inch. t2 rotor has 16x8 0 offset, wezzmo has 17x9 -7 the extra inch is another 25mm wider making it hit the lca and swaybar easier. Minus the -7 offset. I would just find some 1" spacers and add abit of camber..

The wider wheels you run the more Neg. offset youll need to clear the lca and swaybar, especialy if you have mad steering angle. Then you will also have to take the front fenders into consideration to make the fitment and angle functional.

I wish the front LCA was longer.... Its pretty short..

Numbers numbers lol

The wider wheels you run the more Neg. offset youll need to clear the lca and swaybar, especialy if you have mad steering angle. Then you will also have to take the front fenders into consideration to make the fitment and angle functional.

I wish the front LCA was longer.... Its pretty short..

Numbers numbers lol

really need 40 profile tyres..

#115

well, to give a close idea, this is my 215/35 on a 9.5wide .The smaller sidewall gives it more stretch, plenty of clearance from rubbing!  can actualy have the rims come out of the body while the tires inside the fender. Running at 70psi, need alot of psi to hold air.Running stretch lets you have more NEg. offset=more angle. Im guna have this pair in the front when I find another wider pair of wheels for the back.

can actualy have the rims come out of the body while the tires inside the fender. Running at 70psi, need alot of psi to hold air.Running stretch lets you have more NEg. offset=more angle. Im guna have this pair in the front when I find another wider pair of wheels for the back.

Im might try out t2 rotors spindle mod when If I can haz money..Il also need to get the mazdatrix angle kit to work with the t2 rotors mod am I correct?.. damn angle aintt cheap.. For now im just stuck at tierod spacers...

can actualy have the rims come out of the body while the tires inside the fender. Running at 70psi, need alot of psi to hold air.Running stretch lets you have more NEg. offset=more angle. Im guna have this pair in the front when I find another wider pair of wheels for the back.

can actualy have the rims come out of the body while the tires inside the fender. Running at 70psi, need alot of psi to hold air.Running stretch lets you have more NEg. offset=more angle. Im guna have this pair in the front when I find another wider pair of wheels for the back.

Im might try out t2 rotors spindle mod when If I can haz money..Il also need to get the mazdatrix angle kit to work with the t2 rotors mod am I correct?.. damn angle aintt cheap.. For now im just stuck at tierod spacers...

Last edited by dkwasherexd; 11-05-08 at 02:23 AM.

#118

cut a piece of hose, wrap it around the wheel in between the lip and bead of the tire, cut to size, the spray a little tire lube, and fill.. easy and safe.

on my ame wheels i had at sema last year, i had a 215/35/18 on a 10, suprisingly they didn't even need the hose method.

on my ame wheels i had at sema last year, i had a 215/35/18 on a 10, suprisingly they didn't even need the hose method.

#120

the only wheels that ever gave me troubles were my rpf1s, i even went up to a 245 but it didnt help much. i filled in the gaps with tire lube goo, about 4 handfuls total and it sealed it enough to pop the bead. it makes a huge mess though when it pops  it shoots everywhere, its pretty funny really. but most of it you can put back in the can and reuse.

it shoots everywhere, its pretty funny really. but most of it you can put back in the can and reuse.

anyway good work at least thinking of doing this with the fds. now i should actually read this thread and see whats going on.

it shoots everywhere, its pretty funny really. but most of it you can put back in the can and reuse.

it shoots everywhere, its pretty funny really. but most of it you can put back in the can and reuse.anyway good work at least thinking of doing this with the fds. now i should actually read this thread and see whats going on.

#122

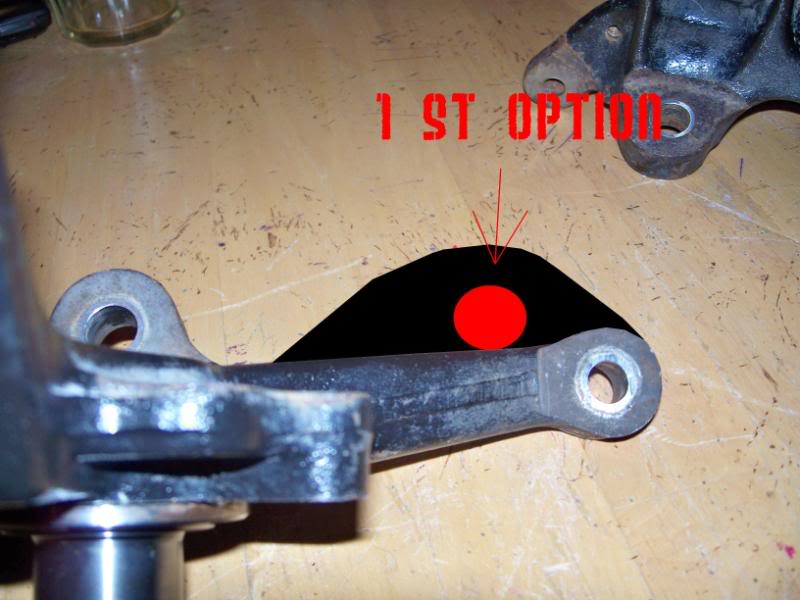

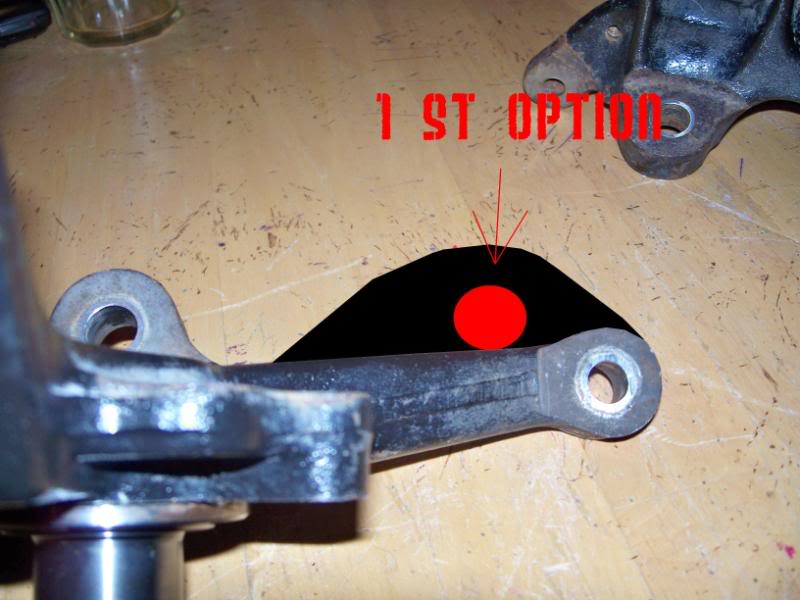

1st option: the same as the FC mod.

2nd option: Welding a drop piece of metal to the spindle and drilling to hole thru it. One for super angle and the other slap YO mama max angle. It would also correct bumpsteer on hella dropped FD's.

3rd option: Drilling the spindle and re enforcing it with 1/4 plates on each side. May not work because of the drop angle the OEM mounting point is at.

Let me know what you guys think. I have an extra set of knuckles I want to mod.

2nd option: Welding a drop piece of metal to the spindle and drilling to hole thru it. One for super angle and the other slap YO mama max angle. It would also correct bumpsteer on hella dropped FD's.

3rd option: Drilling the spindle and re enforcing it with 1/4 plates on each side. May not work because of the drop angle the OEM mounting point is at.

Let me know what you guys think. I have an extra set of knuckles I want to mod.

#123

2nd option, the arm is on too much of an angle to properly gusset, and drilling a hole through the arm would significantly weaken it. I would have the stock tie rod hold drilled out to remove the taper and get an appropriate sized bolt and DOM tube. Put the bolt through the tie rod hole and put the tubing over the bolt and weld it all up to the arm. Get a 1/4in plate and drill it for the OD of the tubing and weld that and figure out something for the other side upright brace.