Jeff Jones FD3S Formula-D car buid

#1

Jeff Jones FD3S Formula-D car buid

Formula D 2010 season is just around the corner and I have been given the opportunity to once again rejoin my fellow rotary enthusiasts. Not long ago I decided to leave my always-favored FC3S for a 240 SX to use in competition for Formula D. This was not an ordinary SR-powered S13 but one with a 1JZ transplant. The 2009 season was an exhilarating and a new experience for me but it was time to “Go Big”…

This year has already shows better promise as Rotary Works has offered to build my team, Jeff Jones Racing, a monster drift machine to compete in for the 2010 season. We have chosen the FD3S chassis to build up and make custom to our needs. It wasn’t enough to leave the factory 13BREW engine in it to build on so we opted for the maximum cool factor… a Turbo charged 20B engine that we expect will make over 500+ WHP and deliver when put to challenge. Only days into our build, Rene Franco, engineer and fabricator of Rotary Works and founder of RMS (Rene’s Motorsports), began designing a tube-chassis style front end from scratch nonetheless.

The purpose of this thread is to share my personal experience in building a car capable of competing against factory-backed cars in the world of pro drifting that is Formula D. This is all possible with the help of my sponsors which include Rotary Works, CX Racing, EBC brakes, Clutch Net, Comp Turbo, K&N, to name a few. With all that being said I have decided to share some pictures of progress and will continue to do so until Rd.1 in Long Beach where I hope to meet some of my supporters and fans.

(It always begins with a car on a trailer making its way to a tuner garage)

(Pile O parts… Toyota transmission for high horsepower, 20B begging for a rebuild and front sub frame waiting to be hacked and customized)

Getting some ideas for the motor placement.

Pack it up and call it quits for the night.

The next day we got hard at work on removing the sound detaining.

With the help of a 20lb block of dry ice it took just one hour to get most of it off.

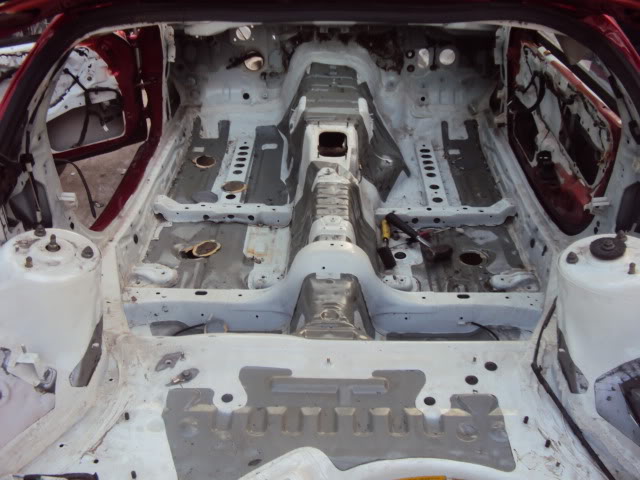

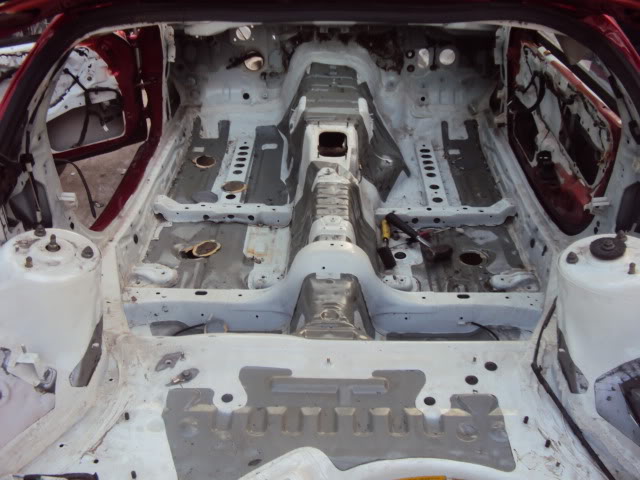

Now it was time to pull out the gas tank and sub frames.

This is after the tank and rear suspension was removed.

So there is a hole lot more to come. I'm still picking up parts from sponsors and collecting materials from Industrial metal supply.

This year has already shows better promise as Rotary Works has offered to build my team, Jeff Jones Racing, a monster drift machine to compete in for the 2010 season. We have chosen the FD3S chassis to build up and make custom to our needs. It wasn’t enough to leave the factory 13BREW engine in it to build on so we opted for the maximum cool factor… a Turbo charged 20B engine that we expect will make over 500+ WHP and deliver when put to challenge. Only days into our build, Rene Franco, engineer and fabricator of Rotary Works and founder of RMS (Rene’s Motorsports), began designing a tube-chassis style front end from scratch nonetheless.

The purpose of this thread is to share my personal experience in building a car capable of competing against factory-backed cars in the world of pro drifting that is Formula D. This is all possible with the help of my sponsors which include Rotary Works, CX Racing, EBC brakes, Clutch Net, Comp Turbo, K&N, to name a few. With all that being said I have decided to share some pictures of progress and will continue to do so until Rd.1 in Long Beach where I hope to meet some of my supporters and fans.

(It always begins with a car on a trailer making its way to a tuner garage)

(Pile O parts… Toyota transmission for high horsepower, 20B begging for a rebuild and front sub frame waiting to be hacked and customized)

Getting some ideas for the motor placement.

Pack it up and call it quits for the night.

The next day we got hard at work on removing the sound detaining.

With the help of a 20lb block of dry ice it took just one hour to get most of it off.

Now it was time to pull out the gas tank and sub frames.

This is after the tank and rear suspension was removed.

So there is a hole lot more to come. I'm still picking up parts from sponsors and collecting materials from Industrial metal supply.

Trending Topics

#10

Hello everyone.....I am Rene Franco,I am happy to see that Jeff Jones will be driving our Rotary-Works Rotary Powered Rx7 in 2010.Jeff Jones is a Talented driver,he can drive anything that slides fast and precise without the aid of cars costing a million bucks.

We at Rene's MotorSports/Rotary-Works took on the challenge of building a Formula Drift car in lest than 2 months,a car that was going to be scraped for metal and forgotten.Now in less than 2 weeks,we have put so much work engineering everything from Roll Cage to engine mounts,stich welding,seat mounting ,modified spindles V-mounta nd a complete custom tubular front end.

With our specialty in Rotary engine and custom fabrication we can engineer anything possible with the right tools and parts.We have many years of experience working with race cars in drag racing,Street/strip machines,Road Racing and Drifting.At our Shop we currently have 3 Running 3 Rotor cars from street to drift and adding one more to our shop with this 4th 3Rotor powered FD Rx7.

With Jeff Jones behind the wheel of this Newest 3 Rotor beast,we will sure have a good

year in promoting our Racing Products and Marketing our car Plus Jeff himself for the many Races to come.

Look for us at all the Formula drift Races,Jeff Jones and the Rest of the Crew will welcome the many fans with our cars.

Check out the before and after pictures

We at Rene's MotorSports/Rotary-Works took on the challenge of building a Formula Drift car in lest than 2 months,a car that was going to be scraped for metal and forgotten.Now in less than 2 weeks,we have put so much work engineering everything from Roll Cage to engine mounts,stich welding,seat mounting ,modified spindles V-mounta nd a complete custom tubular front end.

With our specialty in Rotary engine and custom fabrication we can engineer anything possible with the right tools and parts.We have many years of experience working with race cars in drag racing,Street/strip machines,Road Racing and Drifting.At our Shop we currently have 3 Running 3 Rotor cars from street to drift and adding one more to our shop with this 4th 3Rotor powered FD Rx7.

With Jeff Jones behind the wheel of this Newest 3 Rotor beast,we will sure have a good

year in promoting our Racing Products and Marketing our car Plus Jeff himself for the many Races to come.

Look for us at all the Formula drift Races,Jeff Jones and the Rest of the Crew will welcome the many fans with our cars.

Check out the before and after pictures

Last edited by Rotary-Works.com; 02-26-10 at 11:25 PM.

#13

So let the spot welding begin. This is Rene in his predator helmet getting down.

Now its time to play with some steering angle.

This is a jig I mad to keep the Ackerman the same after we cut and weld.

We got the new sub frame in from one of Rene’s old drag cars.

The old one was possibly bent so better start out fresh.

This is Ascension wire brushing the paint for more spot welds.

He has an Ls1 fc that Kelvin used in D1gp Anaheim.

His car in d1

Now back to the angle. Clean Chop Weld

We cut at 1 1/2 inch

….

Now its time to play with some steering angle.

This is a jig I mad to keep the Ackerman the same after we cut and weld.

We got the new sub frame in from one of Rene’s old drag cars.

The old one was possibly bent so better start out fresh.

This is Ascension wire brushing the paint for more spot welds.

He has an Ls1 fc that Kelvin used in D1gp Anaheim.

His car in d1

Now back to the angle. Clean Chop Weld

We cut at 1 1/2 inch

….

#15

Very nice. Question - you mention a Toyota tranny will be used. What are the details on this? I know someday I'll have to replace the stock tranny in my 20B buildup and thought the best option was a T56.

You have me curious!

You have me curious!

#16

We at our shop RMS/Rotary-Works are gonna prototype adapter plates for Supra tranny to Rotary bellhousing,and maybe a few others such as T-56 to mazda bell housing and possible Mustang T5 to mazda bell.We are also considering of being a distributor for full race transmissions Dog Box ,sequential shifter,differentials in the near future.Check us out at the vendor section......

Check out the super angle from the knuckles we moded up....

Check out the super angle from the knuckles we moded up....

Last edited by Rotary-Works.com; 02-27-10 at 12:34 PM.

#18

We at our shop RMS/Rotary-Works are gonna prototype adapter plates for Supra tranny to Rotary bellhousing,and maybe a few others such as T-56 to mazda bell housing and possible Mustang T5 to mazda bell.We are also considering of being a distributor for full race transmissions Dog Box ,sequential shifter,differentials in the near future.Check us out at the vendor section......

Check out the super angle from the knuckles we moded up....

Check out the super angle from the knuckles we moded up....

#19

Here is our other Car in Action the FC Turbo 3 Rotor powered Rx7......we took it out a few times last year and horsepower is not the issue,we have a Real Radical port on the Engine from past experiences of drag racing(Pretty much a first of its kind on a drift 3 Rotor Engine ,Semi Peripheral/monster streetport,9 INTAKE PORTS!!).Pretty much a drag Engine on a drift chassis......we had the power turned down running only 8-9 psi boost,still making 500 RWHP and keeping the drive train from breaking at the track.We manage to blow 1 clutch out and Diff mount that had been torn off the chassis last year.

These problems have been fixed we turned up the boost but we have been busy at the shop waiting to go to track soon again.Hopefully we will hava a better tranny on both cars to handle the horsepower soon ,but i the mean time we will use a stock Turbo or Supra tranny on both cars.We better stock up on these trannies LOL.

These problems have been fixed we turned up the boost but we have been busy at the shop waiting to go to track soon again.Hopefully we will hava a better tranny on both cars to handle the horsepower soon ,but i the mean time we will use a stock Turbo or Supra tranny on both cars.We better stock up on these trannies LOL.

Last edited by Rotary-Works.com; 02-27-10 at 02:23 PM.

#21

The wheel is a 18X91/2, off set is a 30 I think. With these rims we will need spacers or we might notch the lower control arm because it hits the back at full lock. Also the front being cut out helps.

#22

You can see this quick jig helps keep every thing lined up.

Rotary-Works is primarily a fabrication shop. With a lot of request to cut and weld spindles they will be making a few solid jigs soon. I will be testing them out on my personal cars.

This is one set up I will be testing. Others will be just shortening with out the step

Rene using the mig welder.

Fat bead, ready for install.

Other side.

Stupid angle. It’s hard to see but Rene also machines rack spacers.

Put some rims on for the pic.

Ok still a hole lot more to do.

Rotary-Works is primarily a fabrication shop. With a lot of request to cut and weld spindles they will be making a few solid jigs soon. I will be testing them out on my personal cars.

This is one set up I will be testing. Others will be just shortening with out the step

Rene using the mig welder.

Fat bead, ready for install.

Other side.

Stupid angle. It’s hard to see but Rene also machines rack spacers.

Put some rims on for the pic.

Ok still a hole lot more to do.