thewird's 20B Track Beast Project Finally Started :D

#104

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

I'm going to start porting it next week. I'm doing a custom monster streetport on it  . Finally decided on the port timing I want.

. Finally decided on the port timing I want.

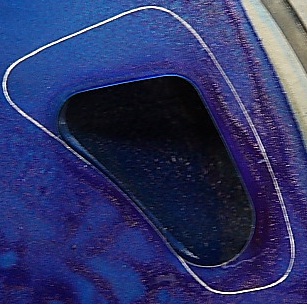

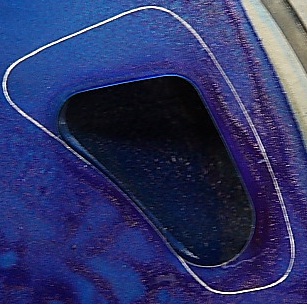

Little teaser of the primary port... I might end up rounding the bottom part, haven't decided.

thewird

. Finally decided on the port timing I want.

. Finally decided on the port timing I want.Little teaser of the primary port... I might end up rounding the bottom part, haven't decided.

thewird

#107

#110

4th string e-armchair QB

iTrader: (11)

Joined: May 2005

Posts: 2,745

Likes: 0

From: North Bay, Ontario

This isn't meant as a criticism, but why are you porting down? It doesn't net you any port timing/duration, and only increases the bowl volume which will only slow the charge down even more than it already is, right before entering the chamber.

It's not like it's the limiting factor, since it's larger than the runner stock. I believe you'd net more torque without it.

It's not like it's the limiting factor, since it's larger than the runner stock. I believe you'd net more torque without it.

#111

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

Because we're not talking about static ports, the intake port shape changes throughout the intake cycle. By having it pulled down further allows for more intake volume when the port opens and by the time its fully open, that bottom part starts (or is already) closing. Trying to optimize flow in the short period the port is fully open wouldn't be ideal in my opinion. I think given a set amount of port timing, having it pulled down wouldn't have any negative effects, only positives. If I get bored enough I'll make a video of the intake cycle with the port. Of course this is theory and I'm sure everyone has their own opinions. If I ever get a dyno, I will probably test different port designs on a test car to turn theory into fact.

But some side notes... the cosmo intake runners are pulled down a lot more and are fed by a much larger intake tube then any other motor. Also, I've decided my goal with this motor is for top-end which is why I decided to do radical porting. Too much torque would just make me spin tires coming out of corners which is wasting time. Also, don't use that picture as reference as that is an REW iron, the cosmo stock port is even smaller.

thewird

But some side notes... the cosmo intake runners are pulled down a lot more and are fed by a much larger intake tube then any other motor. Also, I've decided my goal with this motor is for top-end which is why I decided to do radical porting. Too much torque would just make me spin tires coming out of corners which is wasting time. Also, don't use that picture as reference as that is an REW iron, the cosmo stock port is even smaller.

thewird

#112

4th string e-armchair QB

iTrader: (11)

Joined: May 2005

Posts: 2,745

Likes: 0

From: North Bay, Ontario

Ok, but how long is the port ~3/4 or greater open for vs the short amount of time that it is just opening though? I think it's the opposite, trying to optimize the short period of port opening wouldn't be ideal.

The best testing for port design is on N/A's, because everything is applicable to turbo engines, but without the aid of FI to change torque figures. The highest-powered streetport 13B that I've seen on here was Defined's, using 13B-RE irons. His design did not port anything down, I would have to say that that agrees with my thought on it. Remember the Venturi effect, when cross-sectional area increases, flow speed decreases. It's your engine, I'm just trying to be helpful, tell me if I'm out of line.

Man, for all out you should totally go semi-pp. I've always dreamed of doing a semi-pp turbo 20B, but the block I picked up from Joe Ferguson is already bridged in the thick iron, and I'm torn now. I swear there would be no better sound in a turbo engine...

#113

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

I don't mind it but I think a discussion over port designs wouldn't lead to anything productive without actually testing with an identical setup on the same dyno to compare torque curves. I've always found Defined's dyno's to be on the high-end. The 500 rwhp GT35R @ 16 PSi on pump gas comes to mind. Not to say its wrong, some dyno's read high and some read low. So without comparing apples to apples, your never really getting the true story.

I see that area as useful space so I will use it but maybe I will curve it instead. Will really come down to when I actually do it and see how the runner leads up to it. I'll post pics for those that are interested.

I thought about Semi-pp but I don't think its right for me. Besides I can always do it later when I get a tranny. You know most of the semi-pp drag cars have bridge + semi-pp right. I would still do it if you want it that bad

thewird

I see that area as useful space so I will use it but maybe I will curve it instead. Will really come down to when I actually do it and see how the runner leads up to it. I'll post pics for those that are interested.

I thought about Semi-pp but I don't think its right for me. Besides I can always do it later when I get a tranny. You know most of the semi-pp drag cars have bridge + semi-pp right. I would still do it if you want it that bad

thewird

#114

Joined: Mar 2010

Posts: 569

Likes: 0

From: Mississauga Ontario

! love this build thread! Keep up the awesome work

! love this build thread! Keep up the awesome work

JDK

Looking good..... Can't wait to see it on the track, should be lots of fast RX7's this year . Good luck with the build.

!

! Best regards Pat

#117

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

Ok, so I finally scribed my timing onto my 20b irons. However I can't decide to curve the bottom part or not. I included the difference in the picture, open to suggestions/opinions haha. Now for the secondary port, pretty much finalized, however I'm debating an extra mm of opening timing. I then moved to the exhaust ports and then pretty much said **** this because I still haven't decided if I'm going to do square or curved ports.

Building something for yourself is so much more complicated because you get so picky, jesus LOL.

thewird

Building something for yourself is so much more complicated because you get so picky, jesus LOL.

thewird

#118

4th string e-armchair QB

iTrader: (11)

Joined: May 2005

Posts: 2,745

Likes: 0

From: North Bay, Ontario

Hey, do you have a cut open rotor to scribe the side seal tracks? What I did for my last streetport porting template was to scribe the leading and trailing tracks of the side seal onto the template itself, and then ported as far open as possible leaving 1mm or less for the leading edge of the side seal to ride on for both primary and secondary. The trailing sideseal edge just drops in to the port regardless, and as long as you have a bevel and/or a steep enough angle on the closing face of the port to allow the side seal to "scissor" back onto the iron, you're good to go.

Now, when it comes to streetports, you really can't open them too early IMO. Earlier opening really doesn't affect drivability much/at all, and you actually gain torque, or at the very least lose none in the whole RPM range. The closing edge has more effect on drivability and the shape of the power curve in general.

You already know how I feel about the bottom of the port. lol

Now, when it comes to streetports, you really can't open them too early IMO. Earlier opening really doesn't affect drivability much/at all, and you actually gain torque, or at the very least lose none in the whole RPM range. The closing edge has more effect on drivability and the shape of the power curve in general.

You already know how I feel about the bottom of the port. lol

#119

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

I have a template that is made all the way to the side seal track. That is why I say I can go another mm which means more intake/exhaust overlap. Drivability/idle is not a concern with this engine. It needs to work 5k-8.5k, the rest I do not care about. I do believe that more opening reduces torque though which is why I'm debating just how much mid I want to sacrifice for more top.

thewird

thewird

#121

I say, leave a mm of meat on those ports for now. And don't take too much off the bottom either. Because, once it's gone, it's gone for ever.

Once the 20B is put together and you run it hard for a while, it will eventually need a re-build. Then you will have an opportunity to re-size the ports.

Don't over do it (all at once).

Once the 20B is put together and you run it hard for a while, it will eventually need a re-build. Then you will have an opportunity to re-size the ports.

Don't over do it (all at once).

#123

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

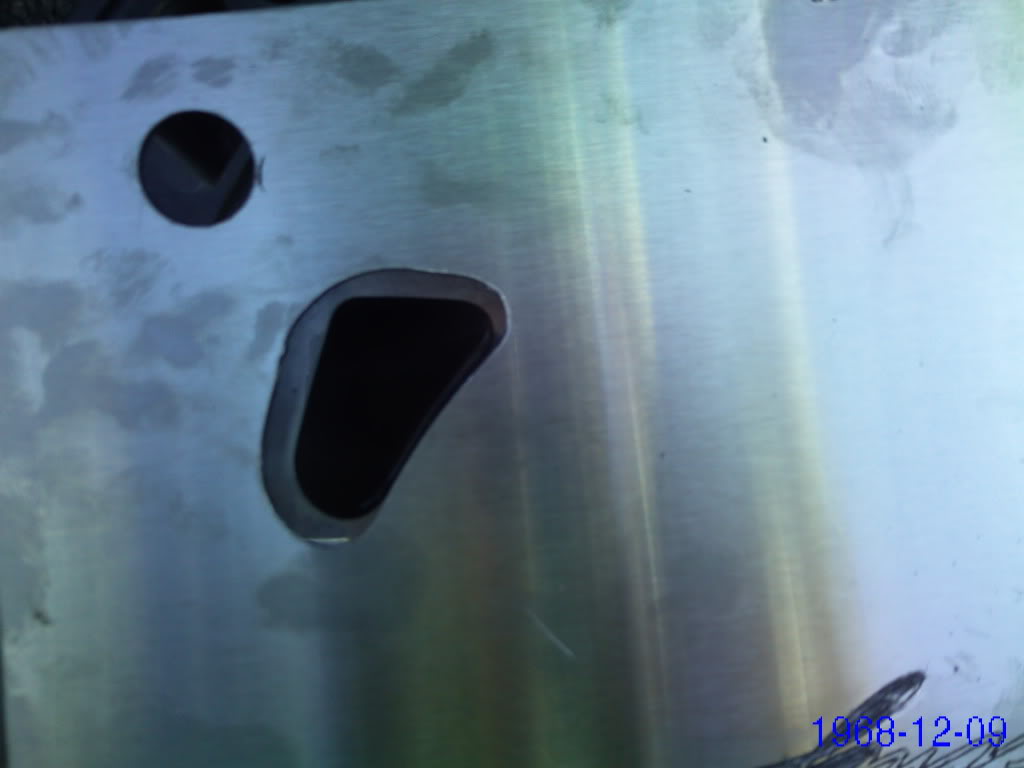

Mr. Trots*88TII-AE*, what do you think about this... Rough cut with a shitty picture LOL. I think I might try this since I never did before. I freehand ported it down to the runner.

thewird

thewird

#124

those are my pineapple racing templates, they have it sloped more to the bottom inner corner like you were planning.

the pics are of my s5 ports but i did the same on my fd.

ran 11.42@122mph with thoe ports and a S5 hybrid turbo

#125

Thread Starter

Lives on the Forum

iTrader: (8)

Joined: Oct 2006

Posts: 6,597

Likes: 11

From: Toronto, Canada

The pineapple medium port timing is targeted more for the midrange. They don't add a lot of closing timing. I'm targetting my powerband 5-8.5k which is why I went aggressive on the closing side. The bottom part of the port is just more volume and Trots has me second guessing myself on that part LOL.

thewird

thewird

. Good luck with the build.

. Good luck with the build.