eage8's SSM/HPDE FC Turbo

#1

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

eage8's SSM/HPDE FC Turbo

So I've decided to make a build for my car thus far... and to keep track of it going forward.

I bought the car in 2004 while I was a freshman in college... it was more or less completely stock a black/black S5 TII covered in primer...

Started modding it and quickly blew the turbo (3" exhausts on stock waste gates will do that...)

I seem to have lost all my earlier pictures, so here it is a few years later after I changed the wheels, exhaust, and put coilovers on it:

since then it's slowly turned into this:

I've been racing it mainly in SCCA's Solo SSM class which is pretty wide open. But lately I've started doing HPDE's in my corolla and have been working to get the RX7 capable of handling them as well.

I bought the car in 2004 while I was a freshman in college... it was more or less completely stock a black/black S5 TII covered in primer...

Started modding it and quickly blew the turbo (3" exhausts on stock waste gates will do that...)

I seem to have lost all my earlier pictures, so here it is a few years later after I changed the wheels, exhaust, and put coilovers on it:

since then it's slowly turned into this:

I've been racing it mainly in SCCA's Solo SSM class which is pretty wide open. But lately I've started doing HPDE's in my corolla and have been working to get the RX7 capable of handling them as well.

#2

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Suspension...

Suspension:

Coilovers:

After starting with JIC FLT-TARs, I bought a set of very second hand double adjustable tri-point konis... then after discovering how bad I was at tuning double adjustable dampers I sold them and made a set of custom bilstein coilovers based on Josh18_2k's:

https://www.rx7club.com/suspension-wheels-tires-brakes-20/[fc]-bigass-budget-baller-bilstein-build-thread-955929/

based on bilstein 3000GT strut inserts and GC camber plates:

In my friend's garage making stut housings:

done:

rears for some reason I don't have a picture of either... but they're AWR valved bilsteins with remote reservoirs based on AK7108 off-road shocks:

So far I like them a lot.

Front Suspension:

Delrin control arm bushings

cusco lower arm bar

mazdatrix 3 point strut bar

whiteline 27mm sway bar with spherical endlinks

AWR roll center adjusting ball joints

Custom tie rods to correct bump steer

Rear suspension:

A while ago I dropped the rear subframe and pretty much replaced everything .

AWR Spherical bearings for the outer bushings with cam bolt deletes

AWR individual camber adjusters (later replaced with MMR adjusters)

TCS subframe link (just for the solid bearings, not for adjustment)

Delrin upper triaxial hub bushing

Delrin DTSS eliminator bushings

UHMW Solid subframe bushings

AWR adjustable toe links

removed the rear sway bar at the same time

cusco strut bar

I'm currently running my MMR camber adjusters with no bearing spacers. Josh18_2k recommended this and they work a lot better (the rear suspension doesn't bind) I greased the bolt it slides on and double nutted it so it doesn't loosen up.

more in a bit...

Coilovers:

After starting with JIC FLT-TARs, I bought a set of very second hand double adjustable tri-point konis... then after discovering how bad I was at tuning double adjustable dampers I sold them and made a set of custom bilstein coilovers based on Josh18_2k's:

https://www.rx7club.com/suspension-wheels-tires-brakes-20/[fc]-bigass-budget-baller-bilstein-build-thread-955929/

based on bilstein 3000GT strut inserts and GC camber plates:

In my friend's garage making stut housings:

done:

rears for some reason I don't have a picture of either... but they're AWR valved bilsteins with remote reservoirs based on AK7108 off-road shocks:

So far I like them a lot.

Front Suspension:

Delrin control arm bushings

cusco lower arm bar

mazdatrix 3 point strut bar

whiteline 27mm sway bar with spherical endlinks

AWR roll center adjusting ball joints

Custom tie rods to correct bump steer

Rear suspension:

A while ago I dropped the rear subframe and pretty much replaced everything .

AWR Spherical bearings for the outer bushings with cam bolt deletes

AWR individual camber adjusters (later replaced with MMR adjusters)

TCS subframe link (just for the solid bearings, not for adjustment)

Delrin upper triaxial hub bushing

Delrin DTSS eliminator bushings

UHMW Solid subframe bushings

AWR adjustable toe links

removed the rear sway bar at the same time

cusco strut bar

I'm currently running my MMR camber adjusters with no bearing spacers. Josh18_2k recommended this and they work a lot better (the rear suspension doesn't bind) I greased the bolt it slides on and double nutted it so it doesn't loosen up.

more in a bit...

#5

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

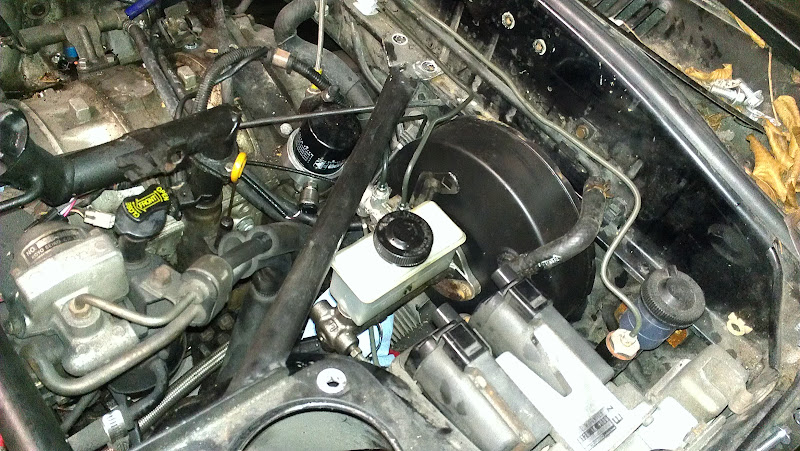

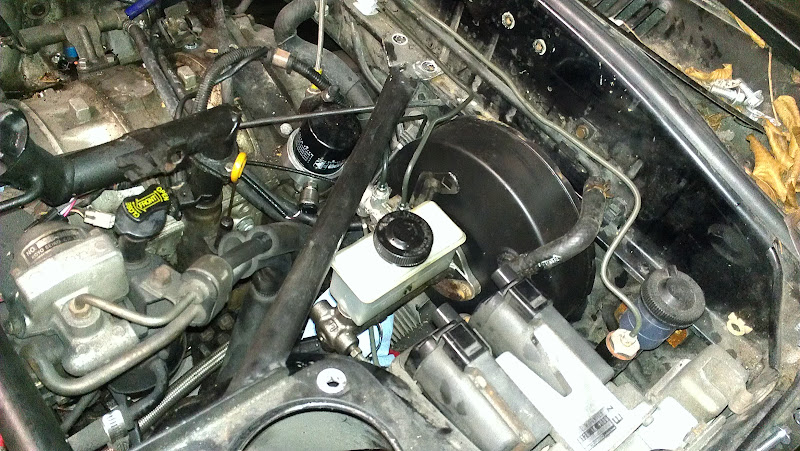

Drivetrain

Most of my engine mods have been to get the car reliable... but when I do that I normally upgrade things which make other parts less reliable... apparently I have no good pictures of my engine bay recently haha, so you get this one until I can take a better one lol:

quick over run of my engine:

I bought the car with a freshly mazda reman'ed S5 TII engine which is still in the car

BNR stage2 turbo @ 12 psi

megasquirt 3 + 3x board w/ sequential injection

LC1 wideband

greddy profec b spec 2 boost controller (soon to be switched over to MS controlled solenoid)

ID injectors 750cc primaries, 2200cc secondaries

racingbeat 85 psi oil pressure regulator

pineapple racing oil bad w/ baffles

mazdacomp engine + trans + diff mounts

no emissions

AC removed

apexi bov

custom 3" intake with a universal apexi filter

3" racing beat exhaust (yup, it's heavy)

ACT prolite flywheel

ACT extreme PP w/ a street disc clutch

mazdatrix short shifter

I originally put an AWR (mazdacomp) radiator in the car... but the center bolt backed out on my fiero GT fan and my fan ate it... after running a stock radiator again for a while (you don't really need fancy radiators for autocross) I picked up a godspeed radiator for a track day last november that I was trying to get the car ready for... I ended up taking the corolla instead (which blew up it's brake master cylinder) but I've been using it for autocross and it's held up surprisingly well:

after running a stock radiator again for a while (you don't really need fancy radiators for autocross) I picked up a godspeed radiator for a track day last november that I was trying to get the car ready for... I ended up taking the corolla instead (which blew up it's brake master cylinder) but I've been using it for autocross and it's held up surprisingly well:

here it is with no fan:

Diff:

I started with an S5 viscous, which sucked.

When I rebuilt my rear subframe/suspension I swapped in an FD Torsen with S4 stub shafts which was a lot better

recently I went all out and rebuilt the whole diff with an OS Giken and 4.3 gears and it's awesome so far I've only done a few cold autocrosses on it though

I've only done a few cold autocrosses on it though

I had the car dyno'd a long time ago (2010?) and it made 270 whp @ 12 psi on a dynopack I haven't changed a lot since then, so it's still probably around that. I have the dyno sheet somewhere... I'll post it if I find it.

Most of my engine mods have been to get the car reliable... but when I do that I normally upgrade things which make other parts less reliable... apparently I have no good pictures of my engine bay recently haha, so you get this one until I can take a better one lol:

quick over run of my engine:

I bought the car with a freshly mazda reman'ed S5 TII engine which is still in the car

BNR stage2 turbo @ 12 psi

megasquirt 3 + 3x board w/ sequential injection

LC1 wideband

greddy profec b spec 2 boost controller (soon to be switched over to MS controlled solenoid)

ID injectors 750cc primaries, 2200cc secondaries

racingbeat 85 psi oil pressure regulator

pineapple racing oil bad w/ baffles

mazdacomp engine + trans + diff mounts

no emissions

AC removed

apexi bov

custom 3" intake with a universal apexi filter

3" racing beat exhaust (yup, it's heavy)

ACT prolite flywheel

ACT extreme PP w/ a street disc clutch

mazdatrix short shifter

I originally put an AWR (mazdacomp) radiator in the car... but the center bolt backed out on my fiero GT fan and my fan ate it...

after running a stock radiator again for a while (you don't really need fancy radiators for autocross) I picked up a godspeed radiator for a track day last november that I was trying to get the car ready for... I ended up taking the corolla instead (which blew up it's brake master cylinder) but I've been using it for autocross and it's held up surprisingly well:

after running a stock radiator again for a while (you don't really need fancy radiators for autocross) I picked up a godspeed radiator for a track day last november that I was trying to get the car ready for... I ended up taking the corolla instead (which blew up it's brake master cylinder) but I've been using it for autocross and it's held up surprisingly well:here it is with no fan:

Diff:

I started with an S5 viscous, which sucked.

When I rebuilt my rear subframe/suspension I swapped in an FD Torsen with S4 stub shafts which was a lot better

recently I went all out and rebuilt the whole diff with an OS Giken and 4.3 gears and it's awesome so far

I've only done a few cold autocrosses on it though

I've only done a few cold autocrosses on it thoughI had the car dyno'd a long time ago (2010?) and it made 270 whp @ 12 psi on a dynopack I haven't changed a lot since then, so it's still probably around that. I have the dyno sheet somewhere... I'll post it if I find it.

#6

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Wheels and tires and stuff:

I'm currently in the process of swapping all my wheels and tires (more on that later)

but I've been autocrossing on a 245/275 Hoosier A6 stagger up until this point:

17x8 + 30 in front 17x10 +30 in the back (including spacers)

I later switched to 17x9 +25 in the front... didn't help my understeer issues as much as I had liked.

the car has ARP studs which makes spacers nice and easy 3.25" front 2.5" in the rear (the brakes and hub are a lot thinner back there)

since the FN01R-Cs got stolen for A6 duty, I've been running my stock wheels on the street with some 225/50/16 star specs on them:

I'm currently in the process of swapping all my wheels and tires (more on that later)

but I've been autocrossing on a 245/275 Hoosier A6 stagger up until this point:

17x8 + 30 in front 17x10 +30 in the back (including spacers)

I later switched to 17x9 +25 in the front... didn't help my understeer issues as much as I had liked.

the car has ARP studs which makes spacers nice and easy 3.25" front 2.5" in the rear (the brakes and hub are a lot thinner back there)

since the FN01R-Cs got stolen for A6 duty, I've been running my stock wheels on the street with some 225/50/16 star specs on them:

#7

Nice build.

Quick question. When you guys made the strut fit the front, did you just use some tubing similar in diameter, weld the ears/mounting points on, then slide the housing over the strut? Or did you weld the ears directly on the strut?

Quick question. When you guys made the strut fit the front, did you just use some tubing similar in diameter, weld the ears/mounting points on, then slide the housing over the strut? Or did you weld the ears directly on the strut?

Trending Topics

#9

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

I used these for the coilover collars:

Originally Posted by MaczPayne

Have ya corner balanced the car yet?

I'm about 160 lbs so the car with 1/2 a tank is ~2720 lbs. I've since changed quite a bit... I'll have to corner balance it again when it's all finished in a month or 2.

#10

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Interior:

In preparation for track duty I installed an autopower race roll bar:

and a set of Sparco sprint Vs:

I mounted the driver side with just some 1/4" steel bar on the stock rails to the bottom mount holes in the seat and it's ok, just a little high. the passenger side I attempted to bottom mount to a planted seat bracket and it's WAY too high... pretty much just for decoration at this point... I'll have to remount it. eventually. luckily I'm already int he advance HPDE group from going to a few track days in teh corolla so I don't need to fix it before then. (you don't need an instructor in advance group)

I also installed schorth 6 point harness at the same time so I removed my S5 automatic seat belts. In total it was 24 lbs of weight reduction.

I recently added some more gauges to my center gauge pod:

left to right, top to bottom it goes:

oil pressure

oil temp

dual EGT (one for each rotor)

wide band AFR

coolant temp

and I have a boost gauge on the a-pillar

The pod was bought on hear a while ago as a 3 gauge + 1 DIN. when I added the oil gauges and made a the extra plate to mount the new gauges in which mounts to to the same holes behind the new plate. I think it came out pretty well.

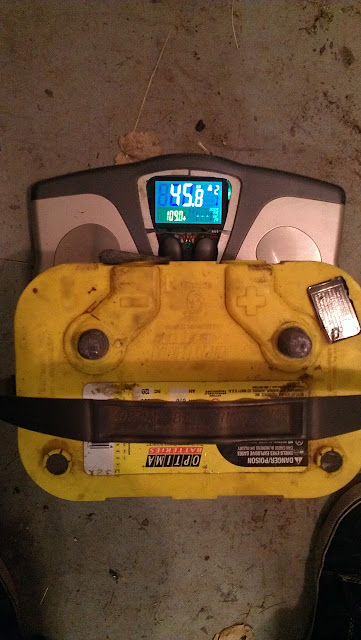

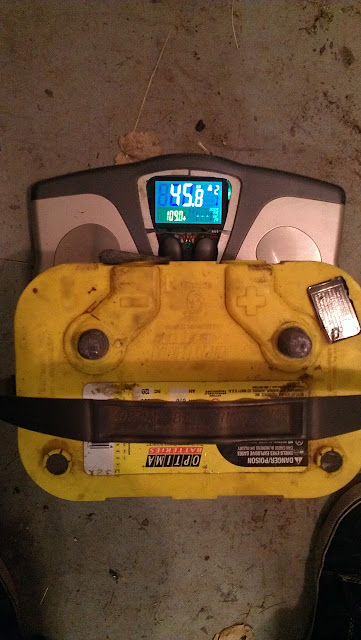

I also recently took the 46 lb yellow top out of the passenger side bin (which I admit, was mounted semi-sketchily)

and put in a 16 lb yousa motorcycle battery (YTX24HL) on a modified improved mount. 30 more lbs or weight reduction = totally offsetting my 50 lb roll bar

In preparation for track duty I installed an autopower race roll bar:

and a set of Sparco sprint Vs:

I mounted the driver side with just some 1/4" steel bar on the stock rails to the bottom mount holes in the seat and it's ok, just a little high. the passenger side I attempted to bottom mount to a planted seat bracket and it's WAY too high... pretty much just for decoration at this point... I'll have to remount it. eventually. luckily I'm already int he advance HPDE group from going to a few track days in teh corolla so I don't need to fix it before then. (you don't need an instructor in advance group)

I also installed schorth 6 point harness at the same time so I removed my S5 automatic seat belts. In total it was 24 lbs of weight reduction.

I recently added some more gauges to my center gauge pod:

left to right, top to bottom it goes:

oil pressure

oil temp

dual EGT (one for each rotor)

wide band AFR

coolant temp

and I have a boost gauge on the a-pillar

The pod was bought on hear a while ago as a 3 gauge + 1 DIN. when I added the oil gauges and made a the extra plate to mount the new gauges in which mounts to to the same holes behind the new plate. I think it came out pretty well.

I also recently took the 46 lb yellow top out of the passenger side bin (which I admit, was mounted semi-sketchily)

and put in a 16 lb yousa motorcycle battery (YTX24HL) on a modified improved mount. 30 more lbs or weight reduction = totally offsetting my 50 lb roll bar

#11

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Exterior:

So when I got the car is was primered... the PO's brother was going to paint it, and assured me he'd paint it for me, but that never happened....

so it spent a while in primer.

about 3 years ago I had a friend of mine who owns a restoration shop paint it for me in SEM's hot rod black. I think it turned out pretty well.

went from this:

to this:

I started off transporting my r-comps in my car... which was a bit crowded:

I recently installed a trailer hitch:

which made things a lot easier when I picked up a used, already built, tire trailer for $100:

So when I got the car is was primered... the PO's brother was going to paint it, and assured me he'd paint it for me, but that never happened....

so it spent a while in primer.

about 3 years ago I had a friend of mine who owns a restoration shop paint it for me in SEM's hot rod black. I think it turned out pretty well.

went from this:

to this:

I started off transporting my r-comps in my car... which was a bit crowded:

I recently installed a trailer hitch:

which made things a lot easier when I picked up a used, already built, tire trailer for $100:

#17

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

Bump Steer:

So when I installed the AWR RCA balljoints I kind of guessed at the spacing on my tie rod ends to try to fix the bump steer. I used a digital level and just spaced them out so they were more or less the same...

and I got to this spacing:

a few months later I aquired a long acre bump steer measuring tool:

Longacre Racing - Online Catalog: Electronic Wheel Scales, Gauges, Pyrometers, Chassis Setup and More!

and measured my front bump steer and it was terrible....

droop:

-1" -0.09"

bump:

1" 0.077"

2" 0.131"

3" 0.195"

that's 1/5" of toe in at 3" of compression.... on each side. granted I don't think my front suspension compressed that much with a tire on it, it still sucks.

after removing one of the spacers I got:

droop:

-2" -0.0345"

-1" -0.0125"

-0.5" -.0075

bump:

1" 0.0" awesome

2" -0.0085"

3" -0.0285"

much better

later I realized this was without realigning the car, so when I did realign the car the length of the tie rod changed... so I have to redo it. I also want to get some thinner shims to see how much better I can get it.

I also tested the rear at the same time:

droop:

-1" 0.004"

-0.5" 0.004"

bump:

0.5" -0.005

1" -0.004

1.5" -0.001

2" -0.006

yeah... I don't need to touch that at all.

So when I installed the AWR RCA balljoints I kind of guessed at the spacing on my tie rod ends to try to fix the bump steer. I used a digital level and just spaced them out so they were more or less the same...

and I got to this spacing:

a few months later I aquired a long acre bump steer measuring tool:

Longacre Racing - Online Catalog: Electronic Wheel Scales, Gauges, Pyrometers, Chassis Setup and More!

and measured my front bump steer and it was terrible....

droop:

-1" -0.09"

bump:

1" 0.077"

2" 0.131"

3" 0.195"

that's 1/5" of toe in at 3" of compression.... on each side. granted I don't think my front suspension compressed that much with a tire on it, it still sucks.

after removing one of the spacers I got:

droop:

-2" -0.0345"

-1" -0.0125"

-0.5" -.0075

bump:

1" 0.0" awesome

2" -0.0085"

3" -0.0285"

much better

later I realized this was without realigning the car, so when I did realign the car the length of the tie rod changed... so I have to redo it. I also want to get some thinner shims to see how much better I can get it.

I also tested the rear at the same time:

droop:

-1" 0.004"

-0.5" 0.004"

bump:

0.5" -0.005

1" -0.004

1.5" -0.001

2" -0.006

yeah... I don't need to touch that at all.

#19

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

brakes:

When I bought the car one of the few mods was the PO had removed the ABS block and installed a mazdatrix ABS bypass because the block had been leaking. I didn't really mind, I never owned a car with ABS until semi-recently and have heard the FC ABS isn't any good anyway...

I installed stainless steal lines but all the extra tubing and the rubber line in the mazdatrix bypass always bugged me.

so about a year ago I replaced all the lines with non-ABS lines along with a stock single stage brake and non-abs brake master cylinder. brake feel got way harder, but this is probably mostly due to the single stage brake booster.

lots of old lines:

mazdatrix bypass:

new OEM lines from mazdaspeed (new rear line not shown):

new single stage non-abs brake booster (freshly painted... fancy)

rebuilt non-abs 7/8" BMC:

I've always had difficulty modulating the FC's brakes at the limit with both systems... not really sure what to do about that.

recently I installed a level zero motorsports BMC brace also, but I don't have picutres of it.

after flatspotting 2 (very dead anyway) front A6s at the last autocross (it was also ~40* so it wasn't entirely my fault ) I ordered a wilwood brake proportioning valve from flyin miata:

) I ordered a wilwood brake proportioning valve from flyin miata:

Flyin' Miata : Chassis : Brakes : Complete adjustable brake proportioning kit

I'll get that installed and hopefully it'll help me improve the cars braking a bit which i've never been satisfied with.

the current pads are Hawk HPS. For the track I have a set of Hawk DTC60/HT10 stagger sitting on the shelf.

I've also started on some brake ducting for HPDEs. I have some AWR ducts on my hubs (you can see in earlier pictures)

before I take the FC on the track I have some of these I'll be isntalling where the foglights used to be and connecting up my brake ducts:

Plastic Single Race Car Bumper Duct

When I bought the car one of the few mods was the PO had removed the ABS block and installed a mazdatrix ABS bypass because the block had been leaking. I didn't really mind, I never owned a car with ABS until semi-recently and have heard the FC ABS isn't any good anyway...

I installed stainless steal lines but all the extra tubing and the rubber line in the mazdatrix bypass always bugged me.

so about a year ago I replaced all the lines with non-ABS lines along with a stock single stage brake and non-abs brake master cylinder. brake feel got way harder, but this is probably mostly due to the single stage brake booster.

lots of old lines:

mazdatrix bypass:

new OEM lines from mazdaspeed (new rear line not shown):

new single stage non-abs brake booster (freshly painted... fancy)

rebuilt non-abs 7/8" BMC:

I've always had difficulty modulating the FC's brakes at the limit with both systems... not really sure what to do about that.

recently I installed a level zero motorsports BMC brace also, but I don't have picutres of it.

after flatspotting 2 (very dead anyway) front A6s at the last autocross (it was also ~40* so it wasn't entirely my fault

) I ordered a wilwood brake proportioning valve from flyin miata:

) I ordered a wilwood brake proportioning valve from flyin miata:Flyin' Miata : Chassis : Brakes : Complete adjustable brake proportioning kit

I'll get that installed and hopefully it'll help me improve the cars braking a bit which i've never been satisfied with.

the current pads are Hawk HPS. For the track I have a set of Hawk DTC60/HT10 stagger sitting on the shelf.

I've also started on some brake ducting for HPDEs. I have some AWR ducts on my hubs (you can see in earlier pictures)

before I take the FC on the track I have some of these I'll be isntalling where the foglights used to be and connecting up my brake ducts:

Plastic Single Race Car Bumper Duct

#20

FYI - my MMR camber adjusters developed some play after not-too-long. I could do the 'wheel bearing" test and feel clicking. my final (hopefully) soluton was to just shorten OEM dogbones.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

#21

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

I usually only go to SCCA events at FedEx feild, but capitaldrivingclub has a nice program for people newer to autocross also.

#22

Thread Starter

1308ccs of awesome

iTrader: (9)

Joined: Sep 2003

Posts: 6,189

Likes: 17

From: Woodbine, MD

FYI - my MMR camber adjusters developed some play after not-too-long. I could do the 'wheel bearing" test and feel clicking. my final (hopefully) soluton was to just shorten OEM dogbones.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

I might have my friend with a CNC machine (same guy that helped make my strut housings) try and replicate the adjusters that John Huijben made:

https://www.rx7club.com/build-thread.../#post11320822

I might be able to convince him to make a few sets I'll let you know if you're interested.

#23

#24

FYI - my MMR camber adjusters developed some play after not-too-long. I could do the 'wheel bearing" test and feel clicking. my final (hopefully) soluton was to just shorten OEM dogbones.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

here's what I did (no pics of course..):

1. set camber with adjusters

2. pull adjusters, mark left/right

3. set adjusters on metal table, weld bolts to the table to set eye-eye length for each side

4. cut OEM dogbones in half

5. grind dogbones down until they fit over bolts butted together

6. chamfer and TIG weld. many many short tack+quench cycles to try and not melt the plastic in the dogbone :-P

I did this at the beginning of the 2012 season, and so far so good. No play in either wheel. Hoping I didn't ruin the bearings with heat..

It's on my agenda to see if I can make af few male-female rodend pairs that are just cut to various lengths, then mix 'n match to change camber (bottom out the male thread into female to get a fixed link). Easier than welding, but not as cheap.

The problem with the AWR adjusters is that they eliminate a degree of freedom in the rear suspension. So they will always eventually break. They also wear out.

Awesome fix. Not too adjustable, but better than the alternatives