4-Rotor FC Build

#1577

Exhaust Manifold Leak

Nice line, but be careful as those look like high pressure fittings (meant for hydraulics), which are made to be strong and durable but not flow as much as they have a much smaller cross section as a alu An fitting of the same size. So if using these hose I would think -12 is the minimum for pieces where all the flow has to go trough.

I found out by using the exact same teflon hose and fittings on our renesis miata.

I found out by using the exact same teflon hose and fittings on our renesis miata.

#1578

That will also probably do just fine, but you can't really get oil in the engine's main and rotor bearings, and I have all the stuff I need to pressure fill it lying around the shop, so it doesn't really take a big effort.

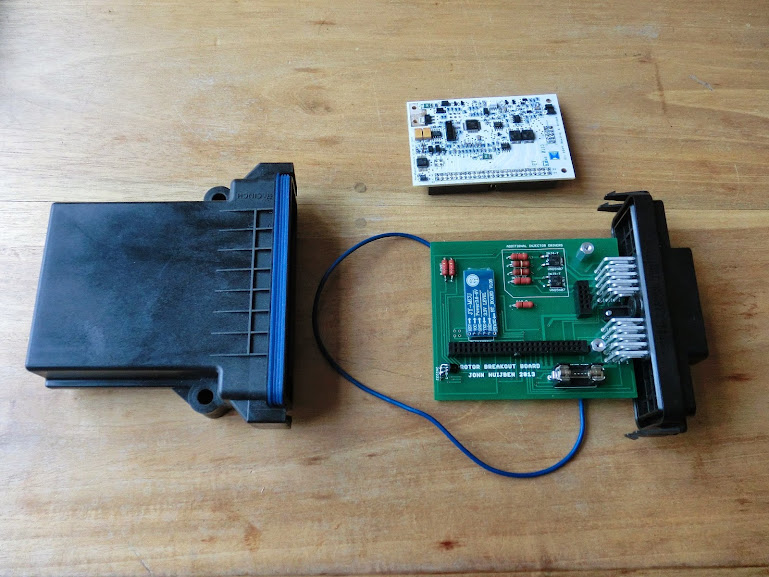

The center of it is a microsquirt 2.2 module, but I designed and assembled the breakout board to which the module mounts myself, which adds a few ignition and injection channels (so it does sequential injection), it also adds a few general outputs and bluetooth connectivity. I fitted everything in a small waterproof industrial enclousure.

I tested it in the car tonight and everything works! , all sensors are showing up nicely, outputs are working, all injectors are working, sparks are working so I'm happy

, all sensors are showing up nicely, outputs are working, all injectors are working, sparks are working so I'm happy  I did hit one snag though, the #2 trailing plug isn't sparking as strong as all the other plugs. The problem seems to be the external bosch igniter box. One of the channels does seem to be switching, but it's not completely switching to ground, when it switches there's still a resistance, so the coil doesn't charge so well. Kind of bummed, because apart from that it's really almost ready for it's first start!

I did hit one snag though, the #2 trailing plug isn't sparking as strong as all the other plugs. The problem seems to be the external bosch igniter box. One of the channels does seem to be switching, but it's not completely switching to ground, when it switches there's still a resistance, so the coil doesn't charge so well. Kind of bummed, because apart from that it's really almost ready for it's first start!

Yep, your right, these are hydraulic lines and fittings. The lines are -10an size, but they run in parallel. (the front iron is tapped, so there are 2 oil lines coming out of the engine) so combined the flow area is quite large. The fittings are indeed a lot thicker, I bored the fittings out on the lathe to make them thinner and flow more.

I tested it in the car tonight and everything works!

, all sensors are showing up nicely, outputs are working, all injectors are working, sparks are working so I'm happy

, all sensors are showing up nicely, outputs are working, all injectors are working, sparks are working so I'm happy  I did hit one snag though, the #2 trailing plug isn't sparking as strong as all the other plugs. The problem seems to be the external bosch igniter box. One of the channels does seem to be switching, but it's not completely switching to ground, when it switches there's still a resistance, so the coil doesn't charge so well. Kind of bummed, because apart from that it's really almost ready for it's first start!

I did hit one snag though, the #2 trailing plug isn't sparking as strong as all the other plugs. The problem seems to be the external bosch igniter box. One of the channels does seem to be switching, but it's not completely switching to ground, when it switches there's still a resistance, so the coil doesn't charge so well. Kind of bummed, because apart from that it's really almost ready for it's first start!Nice line, but be careful as those look like high pressure fittings (meant for hydraulics), which are made to be strong and durable but not flow as much as they have a much smaller cross section as a alu An fitting of the same size. So if using these hose I would think -12 is the minimum for pieces where all the flow has to go trough.

I found out by using the exact same teflon hose and fittings on our renesis miata.

I found out by using the exact same teflon hose and fittings on our renesis miata.

#1579

Full Member

May I ask what service you used for the board production and what enclosure that is? I've done some prototyping like that before, but never that cleanly.

And those are Bosch 227 modules right? I've never had any issues with poor spark strength in those, they're basically just 4 transistors in a box, not much to go wrong other than it just being fried. Thank goodness they're super common and not terribly expensive

And those are Bosch 227 modules right? I've never had any issues with poor spark strength in those, they're basically just 4 transistors in a box, not much to go wrong other than it just being fried. Thank goodness they're super common and not terribly expensive

#1580

May I ask what service you used for the board production and what enclosure that is? I've done some prototyping like that before, but never that cleanly.

And those are Bosch 227 modules right? I've never had any issues with poor spark strength in those, they're basically just 4 transistors in a box, not much to go wrong other than it just being fried. Thank goodness they're super common and not terribly expensive

And those are Bosch 227 modules right? I've never had any issues with poor spark strength in those, they're basically just 4 transistors in a box, not much to go wrong other than it just being fried. Thank goodness they're super common and not terribly expensive

The case is made by cinch (Cinch Connectors), I'm using their "ModICE® ME Enclosure" with a 30-pin connector. The enclousure is too small for use with a megasquirt board or something like that, but the microsquirt board just fits.

Yep, I'm using bosch 227's, I also didn't think they could go wrong, which is why I bought the 20$ no-name ones instead of the $100 bosch ones. You get what you pay for I guess. The module was acting wierd today, the one that failed yesterday was testing ok today, but another channel was showing up dimmed. Maybe my testing method isn't perfect. I'm using a 12v 2w bulb with 2 leads connected to it, one to 12V, the other to the igniter pin that normally connects to the coil -. Then I turn the coil output on at a 10ms interval with a dwell time of 3ms. Most of the time the bulb light up a bit, but with some outputs it looks more dimmed.

After messing a bit I said screw it and just went and tried to start the car, which sortoff worked

The engine jumped to life, and started plowing out big clouds of smoke

The engine jumped to life, and started plowing out big clouds of smoke  . I can't seem to keep the engine running though, it starts up very quickly but then dies just as quick. I think the amount of fuel thats being injected during cranking is enough to fire it up, but that the main fuel map is all wrong. I made a little datalog of a few efforts:

. I can't seem to keep the engine running though, it starts up very quickly but then dies just as quick. I think the amount of fuel thats being injected during cranking is enough to fire it up, but that the main fuel map is all wrong. I made a little datalog of a few efforts:Starting attempt datalog

#1582

Exhaust Manifold Leak

Nice, if it starts instant and runs for a sec its probaly running on the after start enrichement, what you can do it make kind of a slop in the fuel map, lets say what you bave now at 3000 rpm and ramp fueling up from there to about 1500 rpm, if you then start it and give light throttle you will see where can just stabilize the engine and the. You have a approx base point..

Tuning idle with alpha n is not so easy under alll conditions

Tuning idle with alpha n is not so easy under alll conditions

#1583

Full Member

Wait, I didn't read you were tuning with alpha-N. I'd definitely recommend the switch to speed-density if at all possible. As I'm sure you know, in principle, this gives you a much better idea of how much air (by mass) is moving through the engine at any given point in time.

#1585

Nice, if it starts instant and runs for a sec its probaly running on the after start enrichement, what you can do it make kind of a slop in the fuel map, lets say what you bave now at 3000 rpm and ramp fueling up from there to about 1500 rpm, if you then start it and give light throttle you will see where can just stabilize the engine and the. You have a approx base point..

Tuning idle with alpha n is not so easy under alll conditions

Tuning idle with alpha n is not so easy under alll conditions

Wait, I didn't read you were tuning with alpha-N. I'd definitely recommend the switch to speed-density if at all possible. As I'm sure you know, in principle, this gives you a much better idea of how much air (by mass) is moving through the engine at any given point in time.

Today I started by fixing a few water leaks that I found. One of the aluminium coolant pipes was dripping from one of the welds, the coolant filler neck connection was seeping, and the connection between the copper heater pipe and the heater hose was also seeping a little bit (So don't use 19mm hose there!), I drained the water, welded the coolant pipe, pressure tested both of the pipes, added an o-ring to the filler neck to seal it, and replaced the 19mm heater hose with smaller hose.

When I was putting it back together I noticed the fuel line started dripping gas. I still have the stock fuel tank, fuel pump and fuel lines underneath the car, and while they looked good on the outside (they were covered with car undercoating) It seems like they were rusty on the inside because the lines had been empty for so long. I brushed some of the undercoating away and the drip turned into a spray of gas. No really quick way of fixing it, both of the fuel lines just need replacing so I removed the lines and tank from the car, and will try to sort it in the next few days. Kindoff bummed that I couldn't continue trying to get the engine running, but I'm glad it started to leak while I was working on the car, This happening on the dyno or on the track could get pretty bad.

#1586

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 31,119

Received 2,786 Likes

on

1,972 Posts

booo i'm mad at your fuel line! (mine leaks from the same place actually, sometimes)

i wanna see this thing run

its also been my experience that tuning alpha N is no different than the MAP sensor... tuning is tuning. actually if you watch the MAP signal and the TPS signal they almost agree anyways, the transients are different, but that's about it

i wanna see this thing run

its also been my experience that tuning alpha N is no different than the MAP sensor... tuning is tuning. actually if you watch the MAP signal and the TPS signal they almost agree anyways, the transients are different, but that's about it

#1587

Full Member

Fair point, I hadn't really considered the lack of plenum. And I guess in the end tuning is tuning.

I recently had to drop the tank on my 7 too (for the same reasons), I feel your pain. Best of luck!

I recently had to drop the tank on my 7 too (for the same reasons), I feel your pain. Best of luck!

#1588

Oil Pressurization answer

Just jumping in here. Great build!

I saw you were concerned for oil starvation during start up.

an oil accumulator may be your answer.

Canton Racing Products 24-006K Canton Racing Accusump Oil Accumulators - Free Shipping on All Orders @ JEGS

With your skills you could probably make one.

Cheers

I saw you were concerned for oil starvation during start up.

an oil accumulator may be your answer.

Canton Racing Products 24-006K Canton Racing Accusump Oil Accumulators - Free Shipping on All Orders @ JEGS

With your skills you could probably make one.

Cheers

#1589

Rotary Enthusiast

iTrader: (2)

Join Date: May 2005

Location: E-L Netherlands

Posts: 1,165

Likes: 0

Received 0 Likes

on

0 Posts

Just jumping in here. Great build!

I saw you were concerned for oil starvation during start up.

an oil accumulator may be your answer.

Canton Racing Products 24-006K Canton Racing Accusump Oil Accumulators - Free Shipping on All Orders @ JEGS

With your skills you could probably make one.

Cheers

I saw you were concerned for oil starvation during start up.

an oil accumulator may be your answer.

Canton Racing Products 24-006K Canton Racing Accusump Oil Accumulators - Free Shipping on All Orders @ JEGS

With your skills you could probably make one.

Cheers

These oil accumulators deliver oil before starting eliminating dry-start scuffing (pre-oiling), and they discharge oil during low-pressure surges to protect against engine damage in demanding race conditions.

But shutting the engine off, will result in a low-pressure situation.

Would it not discharge because of that and rendering it useless for startup?

#1590

Description says:

These oil accumulators deliver oil before starting eliminating dry-start scuffing (pre-oiling), and they discharge oil during low-pressure surges to protect against engine damage in demanding race conditions.

But shutting the engine off, will result in a low-pressure situation.

Would it not discharge because of that and rendering it useless for startup?

These oil accumulators deliver oil before starting eliminating dry-start scuffing (pre-oiling), and they discharge oil during low-pressure surges to protect against engine damage in demanding race conditions.

But shutting the engine off, will result in a low-pressure situation.

Would it not discharge because of that and rendering it useless for startup?

I have heard of people having issues with them in that during a race scenario it really doesn't help as it makes the car rely on it (the tank has to recharge after every "use") While certainly nice for start up, an appropriately size oil pump is best.

#1592

I was just concerned about the first start. This engine holds about 13 litres of oil, and half of that isn't in the sump but in the lines, coolers filters and oil gallerys. If I were to just fill up the sump and start it up I wouldn't have any oil pressure for half a minute or so. These engines don't like running without oil, so I wanted to make sure everything was filled up before first start. I only have a crappy cell phone picture but it shows how I did it:

I used an air cylinder, fitted a hose to it, and fitted a quick connecter to one of the oil lines, then I loosened the fitting at the engines oil pressure outlet and started filling the lines and coolers, just hang the air hose in the barrrel, pull the piston rod, connect the line to the engine and push the oil in. After the lines and coolers were filled I did the same with the oil filters. When the filters were full I tightened everything up, removed a blind stop in the oil filter pedestal, hooked the line up there, and then I filled the air cylinder, and applied 5 bars of pressure to the topside of the air cylinder, which forced the oil in under pressure. This fills up the engines oil gallerys and bearings. I removed the plugs and cranked the engine with the starter, instant 1.5 bars of pressure with the starter, when the engine fired up later I intantly had about 6 bars.

I used an air cylinder, fitted a hose to it, and fitted a quick connecter to one of the oil lines, then I loosened the fitting at the engines oil pressure outlet and started filling the lines and coolers, just hang the air hose in the barrrel, pull the piston rod, connect the line to the engine and push the oil in. After the lines and coolers were filled I did the same with the oil filters. When the filters were full I tightened everything up, removed a blind stop in the oil filter pedestal, hooked the line up there, and then I filled the air cylinder, and applied 5 bars of pressure to the topside of the air cylinder, which forced the oil in under pressure. This fills up the engines oil gallerys and bearings. I removed the plugs and cranked the engine with the starter, instant 1.5 bars of pressure with the starter, when the engine fired up later I intantly had about 6 bars.

#1593

Fuel lines are fixed! Pretty easy and quick job really, I replaced the old pipes with 8x1mm hydraulic piping, and put in new hoses and clamps. Seems to do the job! Filled the coolant back up, and the water leaks seem to be fixed (knock on wood). So with all that done I figured it was time to try and start it up again. Hooked up the laptop, added a ton of fuel (the req. fuel number in megasquirt was set at 2.2, I increased it to 12). This time I was able to keep the engine running! But not all was well, it wasn't running on all 4's, I think it was only running on 2 rotors, so I figured it's just probably that ignition module that tested iffy a few days back. At that time I started hearing a sissling noise, so I stopped the engine and went to take a look to find quite a bit of oil on the floor. I removed the bumper and found this:

The damn thing just bursted right open! I don't think it harmed the engine, but I'm not 100% sure what caused this. Could just be a bad oil cooler, or could be something in the hydraulic system. I am using a stock FD rear pressure regulator, and the front one is the stock regulator with a shim. Oil pressure looked normal the times I looked at it. About 6 bars at 1000 rpm with a cold engine. Maybe I should try getting a pair of RX-8 coolers. They look like they would fit in about the same position, and they certainly are made for high pressure, the newer RX-8's run about 115psi!

The damn thing just bursted right open! I don't think it harmed the engine, but I'm not 100% sure what caused this. Could just be a bad oil cooler, or could be something in the hydraulic system. I am using a stock FD rear pressure regulator, and the front one is the stock regulator with a shim. Oil pressure looked normal the times I looked at it. About 6 bars at 1000 rpm with a cold engine. Maybe I should try getting a pair of RX-8 coolers. They look like they would fit in about the same position, and they certainly are made for high pressure, the newer RX-8's run about 115psi!

#1598

Not saying it isn't true, and obviously a used oil cooler always need be be flushed and checked before being used, but I wonder how an oil cooler could possibly get clogged up?

I would assume that the bearing stuff that gets in the oil from normal wear and tear would just pass through the oil coolers and end up in the oil filter. Unless the engine suffers catastrophic engine failure I didn't really think it happened, Especially since the particles have to pass though the filter screen in the oil pickup tube and the oil pump first.

I looked some more at my destroyed oil cooler and think the failure is caused by 3 things:

- Higher than normal oil pressure and flow rate

- No oil thermostat which means the cold and thick oil is being pushed through the oil coolers

- Cheap thin coolers

Using the RX-8 coolers (Or dual stock FC coolers, thats a do-able option aswell) would solve 2 of those things. I am also concidering removing the shims in the front oil regulator, and possibly fitting a different gear and chain set between the e-shaft and oil pump. The stock setup uses a 1:2 ratio, Mine uses a 1:1 ratio, but maybe it's a bit too much, maybe a 1:1.5 ratio will also suffice, and it will relief some strain from the oil pump aswell.

#1600

John......most of RX-8 we rebuild are run by customers till the very end, destroying bearings completely and when you remove oil pan, you do not get big pieces but rather something like copper paste :

Image Gallery | Fabrizio | 2 of 43 | IMG_1051.JPG

Thats something what will pass easily thru oil screen, into oil pump and from there straight to oil coolers.....and suprisingly its not caught by oil filters completely either......

Image Gallery | Fabrizio | 2 of 43 | IMG_1051.JPG

Thats something what will pass easily thru oil screen, into oil pump and from there straight to oil coolers.....and suprisingly its not caught by oil filters completely either......