My Latest , Greatest and Last !!!

#51

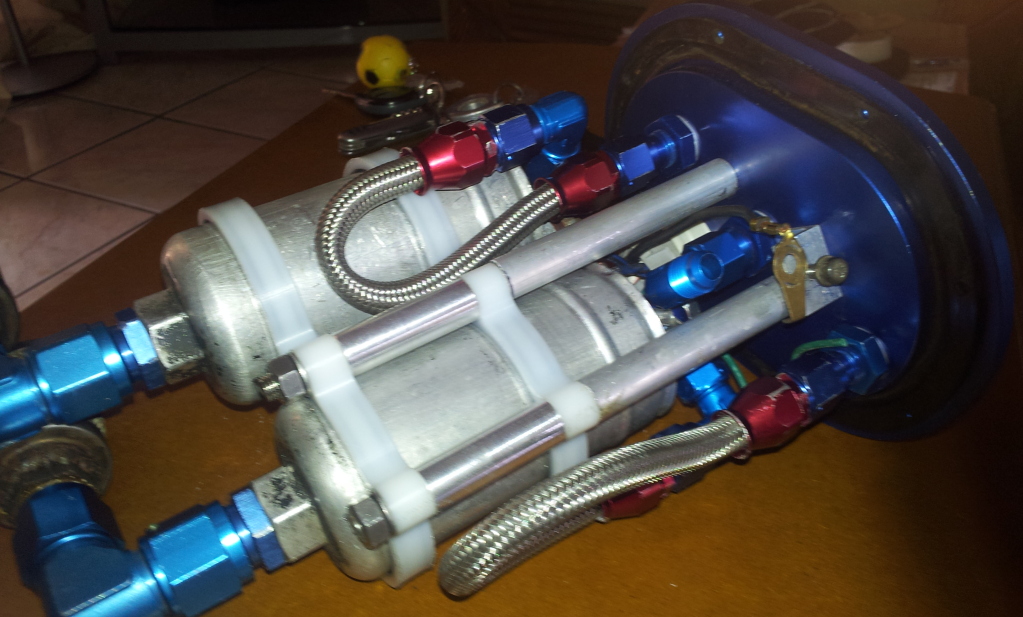

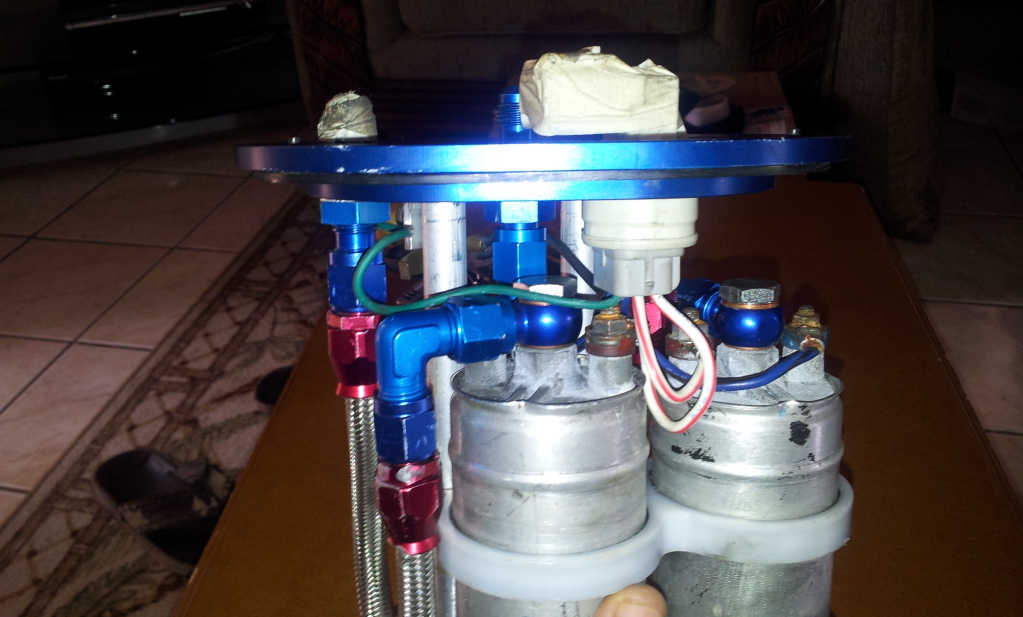

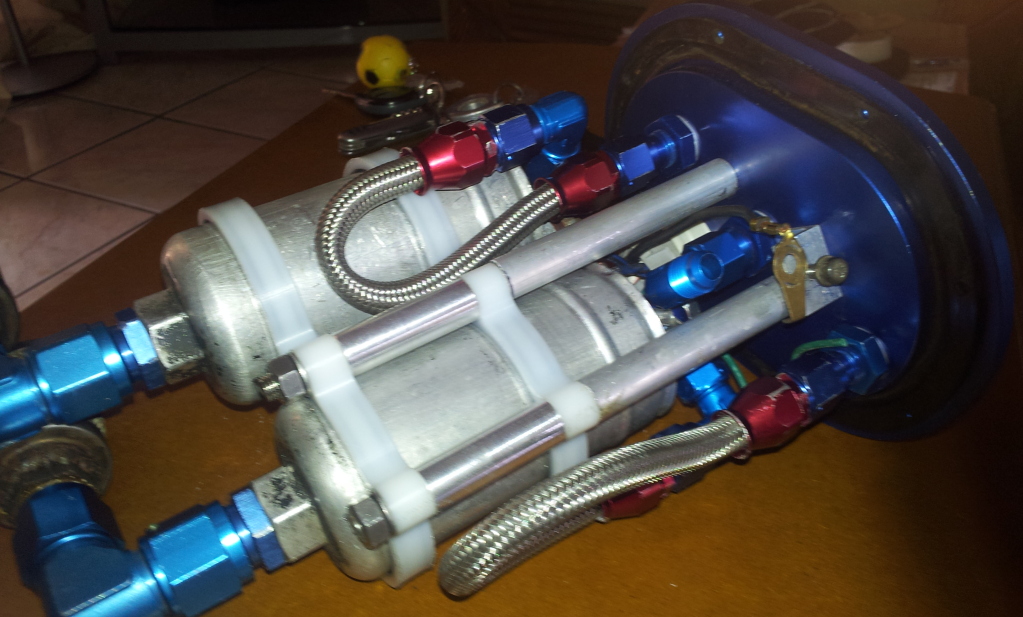

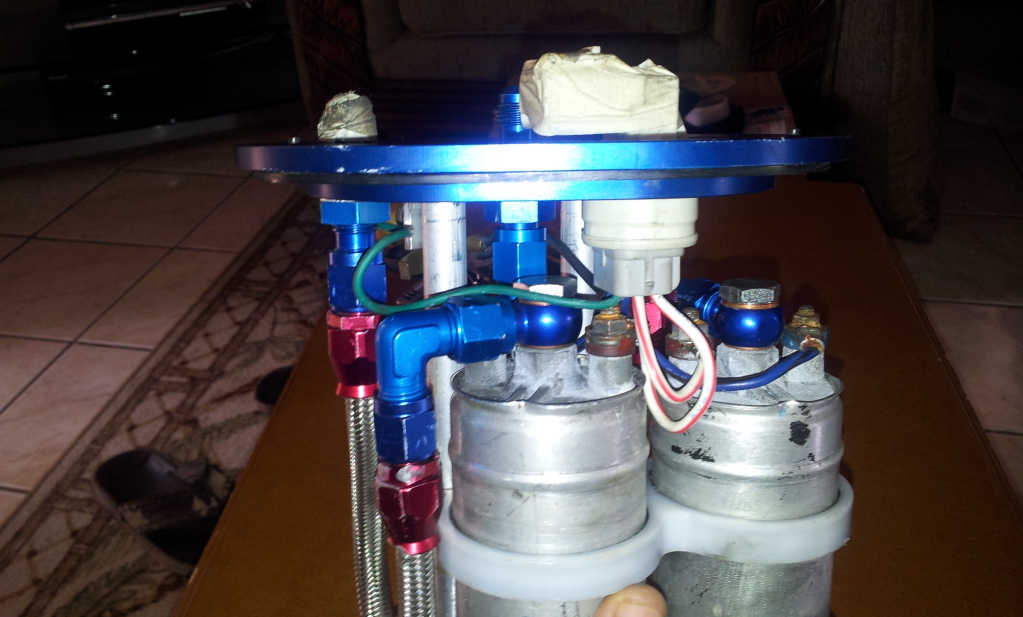

Did some work on my fuel pumps today , because I am not comfortable with any of the filters available for the 044 for intank use I made my own. This made me have to shorten the assembly to get it to fit ...but it does fit . Now to install them and put up the fuel tank!

#53

as much as i love speedflow, those check valves will fail, and will give you grief, do away with them if you can. great build i'd love to do a semipp for my next motor, probably go with the revolution LIM kit myself

Brad.

Brad.

#54

#56

#57

As you can see it simply a spring and a plug , just two moving parts,

The reversing fuel pressure holds the plug in the shut position whilst the opposite happens when the fuel flow is forward . The plug seals against the valve body via a viton 'O' ring , this is the only possible point of failure I can see and this is ONLY if the wrong 'O' ring is used , to avoid this they supplied another which is alcohol compatible.

So I am comfortable with the design and operation of the valve ......so in it goes!

Thanks for the heads up though .

PS : I have a similarly designed check valve on my oil system , I have a CANTON ACCUSUMP pre oiler installed , and it has never missed a beat !

#58

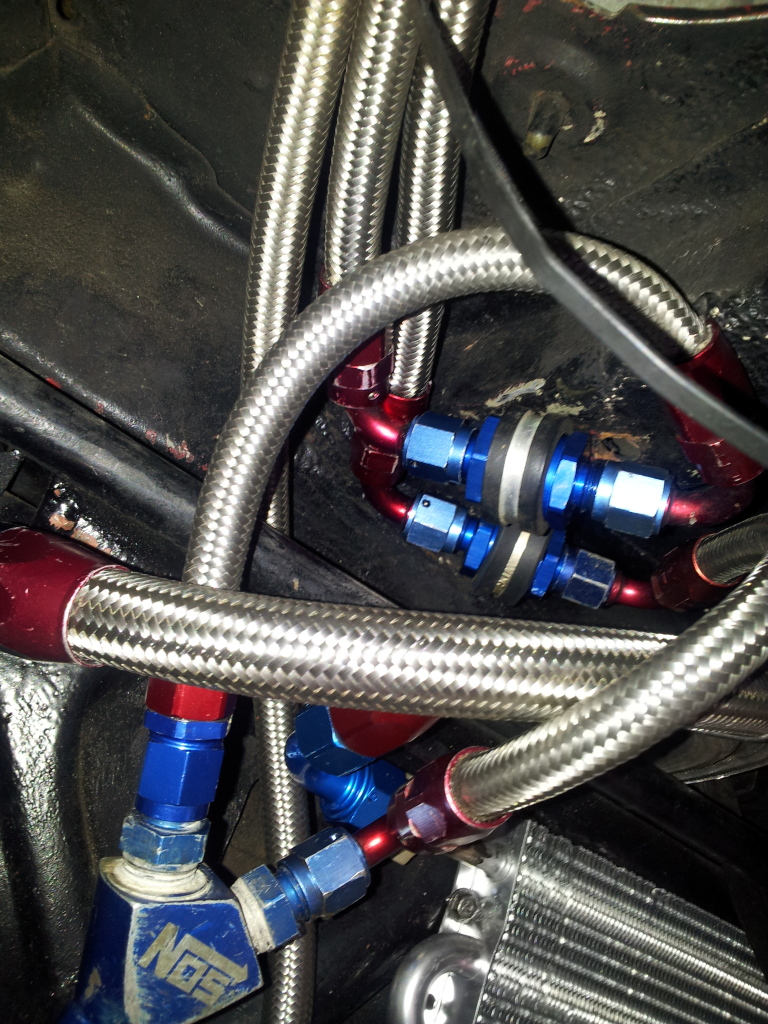

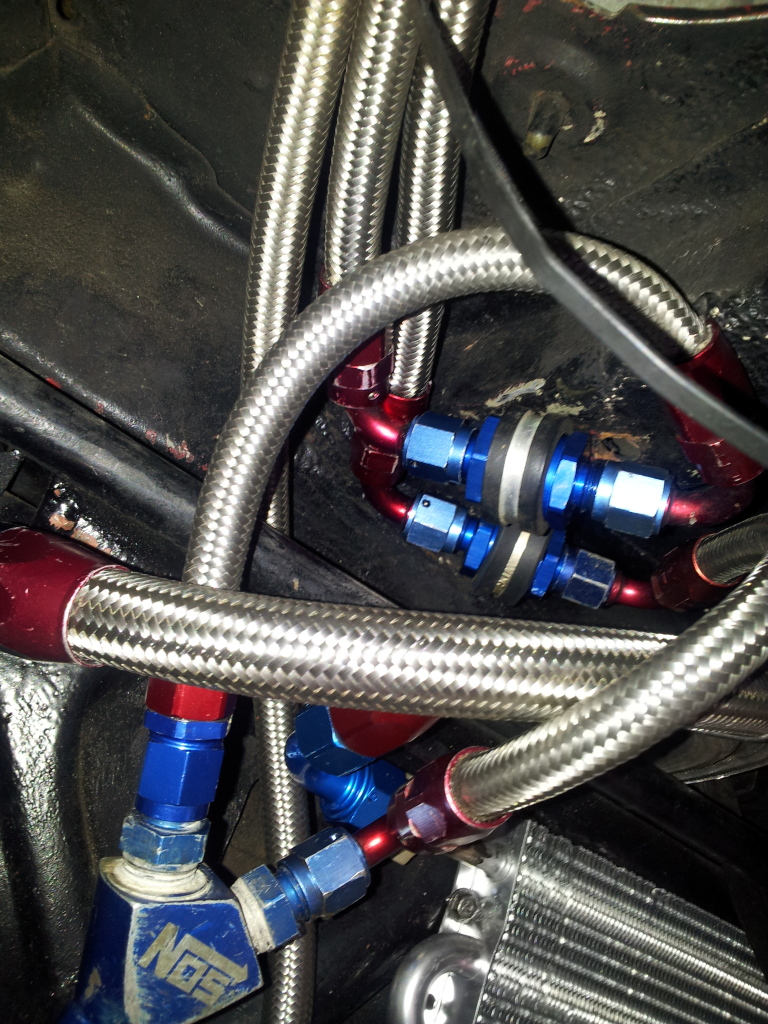

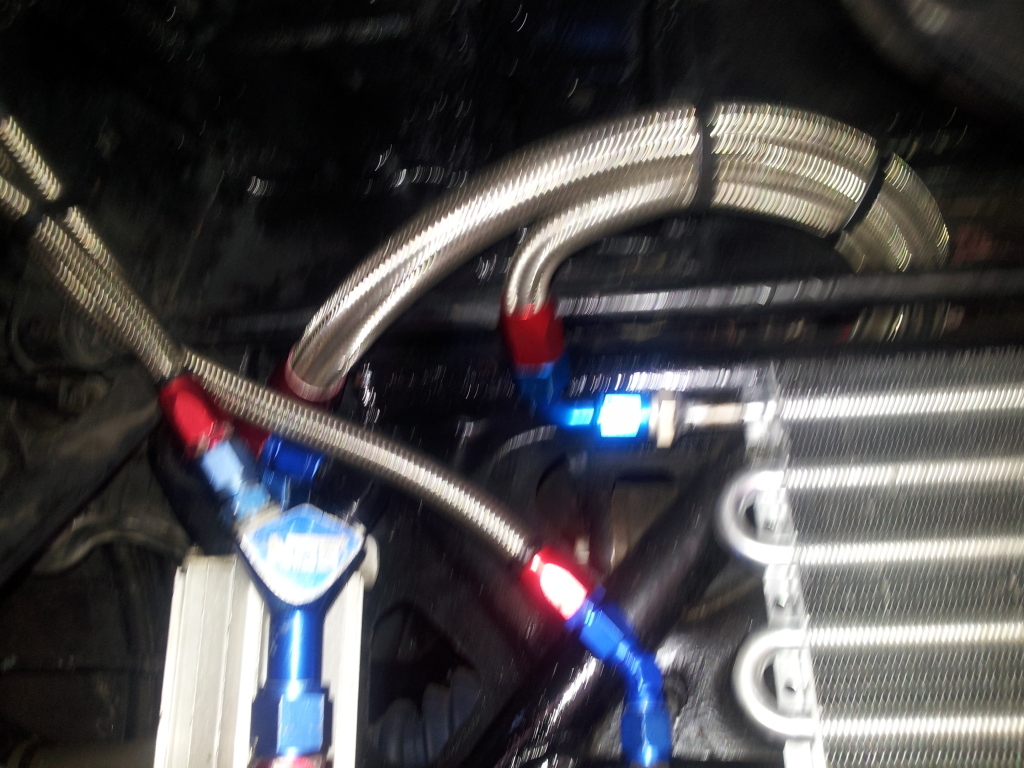

Sooooo, I completed the fuel supply and returnlines at the back of the car ,the supply circuit is the one with the NOS Y allowing the discharge from each fuel pump to join there .Each circuit also has its own cooler the smaller of which is actually a filter /cooler combo. located on the supply line and the larger on the return line.

Fuel coolers

Check valves installed.

Because it is soo much easier to access the exhaust system under the car when the fuel tank isn't there , I decided to hold off on mounting it so that I can wrap and install the exhaust system when I finally get the LAVA wrap I ordered two f@#%in weeks ago !!!! .

Fuel coolers

Check valves installed.

Because it is soo much easier to access the exhaust system under the car when the fuel tank isn't there , I decided to hold off on mounting it so that I can wrap and install the exhaust system when I finally get the LAVA wrap I ordered two f@#%in weeks ago !!!! .

#60

*pic of Racepak dash display*

Any reason you added a separate volt meter and fuel gauge? The racepak can display both, you just need a module for the fuel level but voltage is just a configuration away. You have 4 screens you can toggle through.

Btw, Please do not take this the wrong way, but don't you think there is a better way to run those fuel lines so it just does not look so hacked together? You have so many expensive and quality parts and IMO you are taking away from that by doing work that looks like that.

BTW, I like the fuel cooler, I will be adding one to my setup this winter as those dual 044's definitely will add some heat to the fuel.

Any reason you added a separate volt meter and fuel gauge? The racepak can display both, you just need a module for the fuel level but voltage is just a configuration away. You have 4 screens you can toggle through.

Btw, Please do not take this the wrong way, but don't you think there is a better way to run those fuel lines so it just does not look so hacked together? You have so many expensive and quality parts and IMO you are taking away from that by doing work that looks like that.

BTW, I like the fuel cooler, I will be adding one to my setup this winter as those dual 044's definitely will add some heat to the fuel.

#61

Btw, Please do not take this the wrong way, but don't you think there is a better way to run those fuel lines so it just does not look so hacked together? You have so many expensive and quality parts and IMO you are taking away from that by doing work that looks like that.

BTW I am open to sugestions!

BTW I am open to sugestions! !

!

#62

What kind of benefit will you get out of the fuel coolers? I know cooler fuel is obviously better, but there are several people making well over 600whp without fuel coolers. Yes, they are using auxilliary injection (water or meth), or race gas to help get that high, but I'm guessing you'll have auxilliary injection too. Seems like a lot of extra spots for failure for not much of a benefit.

#63

the fuel was boiling and vaporising in the pump. The fix was to simply direct the return flow away from th pumps suctionbut a cooler would have been a lot better since the system was still circulating hot fuel.! Ever wonder why the intake air temperature compensation map never works right ? its because the temperature of the fuel (which also gets hotter ) isnt considerd .After tuning my own car I had to go re-tune after just adding a cooler since the whole entire map went two points richer. Try feeling your fuel tank after a run , youll see how hot it gets , this isn't good for a couple 300LPH pumps that are on recycle 80% of the time.

#65

The Racepack model I have is the display only unit, it communicates directly to the ECU via a module ,so to get fuel levet on it I will need to connect the sender to one of the computers analog inputs , that in itself would be too complicated and all my analog volt inputs are used up anyway, the gauge was just $40.

No offence taken I am always open to constructive critisism . I did try 100 times to get it looking neater but the space back there is just too tight , I may have a go at it again but I dont think the routing would be changed much.Maybe its because I am not too **** about things like this ,with me function always takes precident to form BTW I am open to sugestions!

BTW I am open to sugestions!

Cool , nice to know i've influenced at least one person on here !

!

No offence taken I am always open to constructive critisism . I did try 100 times to get it looking neater but the space back there is just too tight , I may have a go at it again but I dont think the routing would be changed much.Maybe its because I am not too **** about things like this ,with me function always takes precident to form

BTW I am open to sugestions!

BTW I am open to sugestions!Cool , nice to know i've influenced at least one person on here

!

!

The easiest way to do that would be to run one of our USM modules. Part number 230-vm-usm $199. This is a 4 port box that allows you to wire in your own sensors. IT can be calibrated through the software for different type sensors. This will plug into your V-net port on the back of the dash. If you don’t have anything plugged into that at the moment you will need a v-net extension cable. The price depends on the length you need. We have lengths from 6inches to 18ft. Let us know if you have any further questions.

Although to add it now would be a waste of money as it would be expensive for the additional equipment to show exactly what you have already.

Re: the fuel lines, perhaps a different selection of fittings to route the lines a bit differently or a different component location to help make the lines route differently.

Also, what I think twinchargedrx7 is refering to failure points is a fitting coming loose or something like that as you have added many into the fuel system

BTW, you did not influence me; I had the idea for a fuel cooler for a few months now

Last edited by RENESISFD; 10-09-12 at 04:33 PM.

#66

That is just one way to do it, the other way is shown below...

The above was taken from the racepak forum Racepak.com • View topic - fuel level post #2.

Although to add it now would be a waste of money as it would be expensive for the additional equipment to show exactly what you have already.

The above was taken from the racepak forum Racepak.com • View topic - fuel level post #2.

Although to add it now would be a waste of money as it would be expensive for the additional equipment to show exactly what you have already.

As for the hoses , I'm already looking at my options, thanks.

and for the cooler , I guess great minds think alike

#67

I have personnaly withessed an FC suffering from overheated fuel , after a couple minutes of normal running it would begin to miss , buck , loose power,show unstable fuel pressure and be very difficult to re- start after stopping. When checked the fuel pump couldn't be touched ! obviously

the fuel was boiling and vaporising in the pump. The fix was to simply direct the return flow away from th pumps suction.

the fuel was boiling and vaporising in the pump. The fix was to simply direct the return flow away from th pumps suction.

Failure ? how does a cooler fail if it isn't over pressured ? have you ever seen a cooler fail ? I've never ......I'll take the chance , after all I have twin oil coolers , twin water coolers for my AW inter cooler and a water filled AW intercooler ! in the scheme of things its a small risk

#68

I still don't see why a fuel pump would ever run that hot, I've run big pumps and haven't had that problem. I'm not knocking it, cooler fuel is obviously better, but it just seems like a ton of extra work without much of a benefit. But if your pump is getting too hot to touch, then you obviously need to do something about it.

I just meant new places for something to spring a leak. That's a lot of fittings, they don't usually come loose on their own unless its user error, but thats still more fuel connections than I'd like to have

I just meant new places for something to spring a leak. That's a lot of fittings, they don't usually come loose on their own unless its user error, but thats still more fuel connections than I'd like to have

,word of advice............. DO NOT LEAVE YOUR FUEL SYSTEM SITTING FOR A YEAR WITH GAS IN IT !!!!

,word of advice............. DO NOT LEAVE YOUR FUEL SYSTEM SITTING FOR A YEAR WITH GAS IN IT !!!!

#69

On the fuel system check valves, remember pretty much ALL gas out there is 10% ethanol, it's getting hard (and more expensive) to find pure gas. It's possible the ethanol could be killing those O-rings.

EDIT: I see you're not in the US, so that might be a different case where you are. But still worth thinking about.

Dale

EDIT: I see you're not in the US, so that might be a different case where you are. But still worth thinking about.

Dale

#70

If I'm not mistaken, while the Bosch 044 pump is both incredibly reliable and high flowing it does have the reputation for heating the fuel. I think running the coolers is a great idea for your setup.

Fantastic build! What is the car going to be primarily used for?

Fantastic build! What is the car going to be primarily used for?

#71

On the fuel system check valves, remember pretty much ALL gas out there is 10% ethanol, it's getting hard (and more expensive) to find pure gas. It's possible the ethanol could be killing those O-rings.

EDIT: I see you're not in the US, so that might be a different case where you are. But still worth thinking about.

Dale

EDIT: I see you're not in the US, so that might be a different case where you are. But still worth thinking about.

Dale

Thanks ! It is primarily a street machine , but I do have a passion for drag racing.

#72

I think a great improvement was made , THANKS again!

#74

Found a stainless steel ANACONDA in my back yard !........

LOL its just my custom 4 " exhaust before wrapping, the barrel shown is a 5" BORLA XR1 ,not shown at the back there is a pair of 4" XR1's for high flow and minimum noise (i'm getting a bit too old for that now

LOL its just my custom 4 " exhaust before wrapping, the barrel shown is a 5" BORLA XR1 ,not shown at the back there is a pair of 4" XR1's for high flow and minimum noise (i'm getting a bit too old for that now  ) , the're a bit banged up after serving previous duty under the car. I plan to paint them black with VHT header paint for my own custom NOIR system ,i'll put up pics when I'm done restoring them, .

) , the're a bit banged up after serving previous duty under the car. I plan to paint them black with VHT header paint for my own custom NOIR system ,i'll put up pics when I'm done restoring them, .