My alkycontrol setup

#1

My alkycontrol setup

just bored, thought i would share my setup thats about to get started...although its not an rx7 i used to own one and a couple of rx7 guys will be helping me put some of this stuff together

my goal is to hit about 650ish whp on pump and meth

details of the build

328 block

m3 crank and head

cp 8.5 compression pistons

eagle h beam rods

custom tubular manifold

garrett t4/67mm, .68 a/r

aem ems, 3.5bar map sensor

details of the alky setup

alkycontrol progressive controller and pump

3 gallon foam fuel cell mounted in the trunk

custom discharge and alky lines by MIKE R

fitting welded into TB pipe with an m15 nozzle

the aem ems will be controlling the meth setup and activating it when it needs to but anyways just thought id share!!

but anyways just thought id share!!

ill try and take some pics of the alky stuff stuff but heres what car this is all goin on...

my goal is to hit about 650ish whp on pump and meth

details of the build

328 block

m3 crank and head

cp 8.5 compression pistons

eagle h beam rods

custom tubular manifold

garrett t4/67mm, .68 a/r

aem ems, 3.5bar map sensor

details of the alky setup

alkycontrol progressive controller and pump

3 gallon foam fuel cell mounted in the trunk

custom discharge and alky lines by MIKE R

fitting welded into TB pipe with an m15 nozzle

the aem ems will be controlling the meth setup and activating it when it needs to

ill try and take some pics of the alky stuff stuff but heres what car this is all goin on...

Last edited by mrmarsh; 07-01-07 at 11:19 PM.

#2

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

we appreciate the post as we are all just trying to gain as much AI knowledge as possible. it sounds like you'll have a good setup... i like my Alkycontrol system w two M10 nozzles.

keep us updated.

hc

keep us updated.

hc

#3

honestly im still new to this whole alky thing, i just went with what was recommended to me.... what advantages are there to running 2?

update...i sent my fuel cell and pump to alkycontrol, julio is a great guy to work with...he has been very helpful and asked me to please send him the pump to check it out since i bought it used (from a friend but still, a second opinion never hurts) he then told me to send my fuel cell to install a float device and low level sensor and told me to just paypal him however much the parts cost! and not to worry about anything else

he then advised me to relocate the position of the pump itself after sending him some pictures of the original owners install...i have some pics and ill post them later on, just got my pistons in the mail as well

update...i sent my fuel cell and pump to alkycontrol, julio is a great guy to work with...he has been very helpful and asked me to please send him the pump to check it out since i bought it used (from a friend but still, a second opinion never hurts) he then told me to send my fuel cell to install a float device and low level sensor and told me to just paypal him however much the parts cost! and not to worry about anything else

he then advised me to relocate the position of the pump itself after sending him some pictures of the original owners install...i have some pics and ill post them later on, just got my pistons in the mail as well

#4

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

i suggest you ask Julio re whether you should run one M15 or two M10s. he will ask you how much hp you plan to make... given your 600+ number you will be running two M10s. i run two M10s BTW.

i suggest you review the pics of my thread (sticky) "Optimised Installation." it might help you as to nozzle location.

BTW, my Alkycontrol system is working great in year 2.

good luck,

hc

i suggest you review the pics of my thread (sticky) "Optimised Installation." it might help you as to nozzle location.

BTW, my Alkycontrol system is working great in year 2.

good luck,

hc

#5

Given my experience, my suggestion is for 400rwhp and under, do a single M15, assuming 3/4 gasoline and 1/4 methanol while at 15+psi of boost. For anything over, go twin M10's. That'll yield enough nozzle for mid-high 500's to the wheels. Haven't done 600rwhp yet but I'd suspect an M15 and M10 pair of nozzles would be the next step up.

B

B

#6

with similar setups most people with my motor get about mid to high 400's without any meth, just pump fuel. julio got my package of stuff yesterday so ill give him a call and figure out what he recommends in terms of placement and nozzle size...i have one bug welded to a 90degree fitting on my TB pipe and that yielded almost 600hp on my buddys car...

thanks so far guys

thanks so far guys

#7

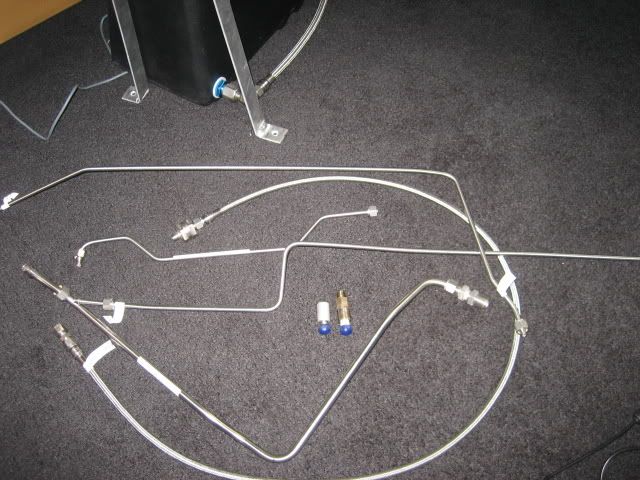

heres how the setup was installed on my buddys car, only change i will be making is mounting the pump on the underside of the trunk compartment and possibly changing to two m10's and changing up the aluminum fitting on one section...luckily my battery is mounted stock on the other side of the trunk so it makes things a bit easier

Trending Topics

#9

Am I correct in saying that vent line comes out right above the exhaust?? And I see you used hardline from the pump to the bay correct? Is it hardline all the way to the nozzle or did you switch to braided at some point along the way?

Chris

Chris

#10

Which brings me to another question, what kind of hardline would you want to run from the pump to the bay considering that the ss line is about 7 or 8 bucks a foot and hardline is less than half that. And it would make it a little more resistant to road debris. Would you want brake line tubing? What diameter? And then run the last foot and a half in braided, kind of like the fuel tank feed and return lines.

Chris

Chris

#11

a unmolested shurflo pump from the factory will put out 125 - 150 psig.

stainless steel tubing 1/4" OD

thin wall ~5000psig

thick wall ~10,000psig

polymeric nylon tubing 1/4" OD

thin wall ~500psig

thick wall ~900psig

SS tubing will for sure add the bling factor the system

I run my polymer line under the doorsill

stainless steel tubing 1/4" OD

thin wall ~5000psig

thick wall ~10,000psig

polymeric nylon tubing 1/4" OD

thin wall ~500psig

thick wall ~900psig

SS tubing will for sure add the bling factor the system

I run my polymer line under the doorsill

#12

Which brings me to another question, what kind of hardline would you want to run from the pump to the bay considering that the ss line is about 7 or 8 bucks a foot and hardline is less than half that. And it would make it a little more resistant to road debris. Would you want brake line tubing? What diameter? And then run the last foot and a half in braided, kind of like the fuel tank feed and return lines.

Chris

Chris

and yes the vent is about where my exhaust would be, heres a picture of all the stuf i gota piece together....already bent and labeled, even i couldnt mess this up lol

and yes the vent is about where my exhaust would be, heres a picture of all the stuf i gota piece together....already bent and labeled, even i couldnt mess this up lol

heres a picture(crappy) of the IC pipe near the throttle body where ive mounted one fitting so far for a nozzle...dont worry itll get cleaned up and everything will be powdercoated a black wrinkle finish to match the rest of the stock parts...only thing that will be visible in my engine bay are some ss lines, ha

just got my manifold in yesterday as well, had alot of issues getting one but im glad everything worked out

and i also got my aem ems, cdi, harness and various little things to go along with it...all goes well ill be dropping her off to have another fitting welded for the 2nd nozzle and the rest of the piping,exhaust and meth system installed before the motor build

noobish question here but i have one ss line that would hook up to the fitting thats on the TB pipe...but if i have 2 nozzles how would that work?

ive been searching around and i think i might be goin with 2 m10 nozzles instead of the single m15

#16

just got my pump and tank back from julio, apparently the foam in the cell had caused a seal to leak in the pump itself

-pump fixed and cleaned

-low level sensor installed with LED warning

-fittings on tank switched to brass

-foam removed and tank cleaned

-cap hardware replaced

-decided on two m10 nozzles

decided to keep pump in the trunk

cost a lil bit more than i expected but it had to be done, i guess, ha...all that is left to do is find some new hardware for the vent and line to the pump!!! so far so good

-pump fixed and cleaned

-low level sensor installed with LED warning

-fittings on tank switched to brass

-foam removed and tank cleaned

-cap hardware replaced

-decided on two m10 nozzles

decided to keep pump in the trunk

cost a lil bit more than i expected but it had to be done, i guess, ha...all that is left to do is find some new hardware for the vent and line to the pump!!! so far so good

Thread

Thread Starter

Forum

Replies

Last Post

eplusz

General Rotary Tech Support

15

10-07-15 05:04 PM

joel(PA)

Race Car Tech

0

10-01-15 11:25 AM