rotor housings and E85

#26

It really isn't. Mazda was injecting roughly that much engine oil at full throttle... but they were also applying it directly to the housing surfaces/seals, where all of it would be used as lubricant. When you mix it with the fuel, most of it stays in the air and doesn't make it to the internal surfaces. So just by that alone you will need to premix more oil in the fuel than you would use with a metering pump.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

I found a paper regarding 2 stroke engines and premix ratios that found similar results (it was led me to experiment with using more oil) and one of the things that was noted was a lag time between changing oil premix and its effect. They would go richer and it would take several pulls before power improved, they would lean back out and it would take several more pulls before the power would decrease again. If this holds true for a rotary (and I don't really see why not) then 128:1 probably is sufficient for a car that sees light load all the time (where Mazda runs as lean as 400:1 with the oil droolers) and short bursts are acceptably dealt with before the oil film gets fully used up. For applications where heavy throttle is used frequently and for long periods, you will need more oil.

I have met "rotary experts" who have explained to me that the oil injection is bad for the engine and you should take it off, and premixing isn't needed at all. They also trailered their car to the drag strip and never drove it on the street.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

I found a paper regarding 2 stroke engines and premix ratios that found similar results (it was led me to experiment with using more oil) and one of the things that was noted was a lag time between changing oil premix and its effect. They would go richer and it would take several pulls before power improved, they would lean back out and it would take several more pulls before the power would decrease again. If this holds true for a rotary (and I don't really see why not) then 128:1 probably is sufficient for a car that sees light load all the time (where Mazda runs as lean as 400:1 with the oil droolers) and short bursts are acceptably dealt with before the oil film gets fully used up. For applications where heavy throttle is used frequently and for long periods, you will need more oil.

I have met "rotary experts" who have explained to me that the oil injection is bad for the engine and you should take it off, and premixing isn't needed at all. They also trailered their car to the drag strip and never drove it on the street.

Last edited by peejay; 02-28-16 at 02:46 PM.

#27

Looked for the article, found it, and read something interesting that may be especially relevant to this thread.

Article: http://edj.net/2stroke/jennings/oilpremix.pdf

(bolding mine)

Benol is castor based. Redline, apparently, is not, but I also have no personal experience with them as I always use Pennzoil or Lucas. (Or Speedway)

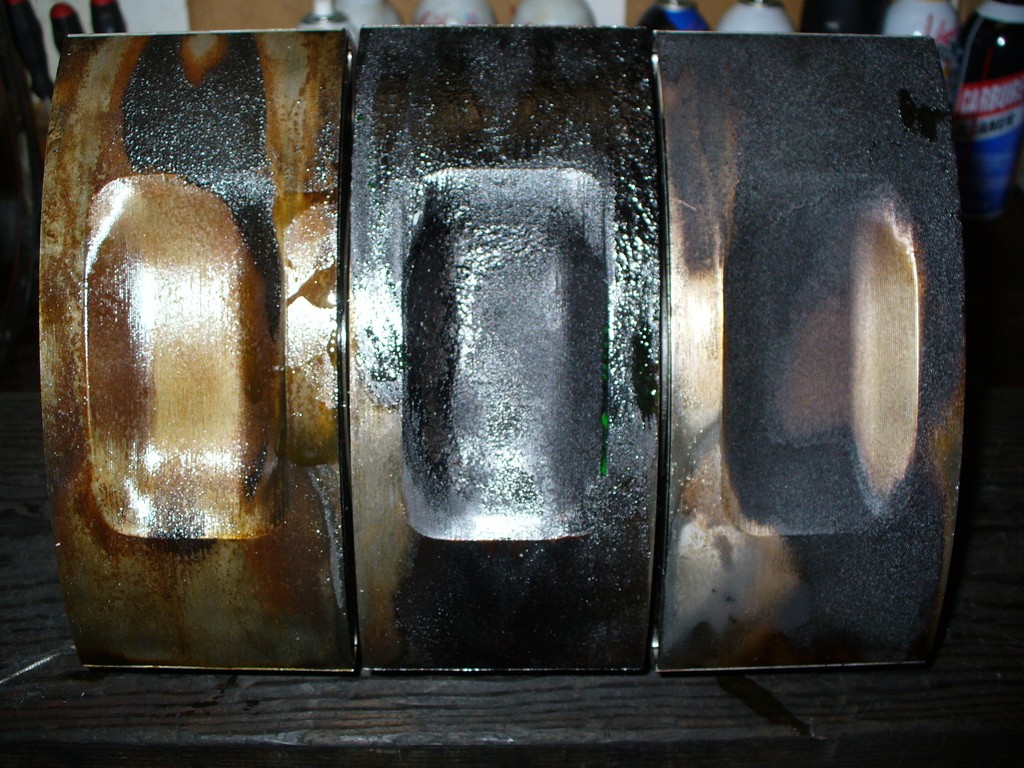

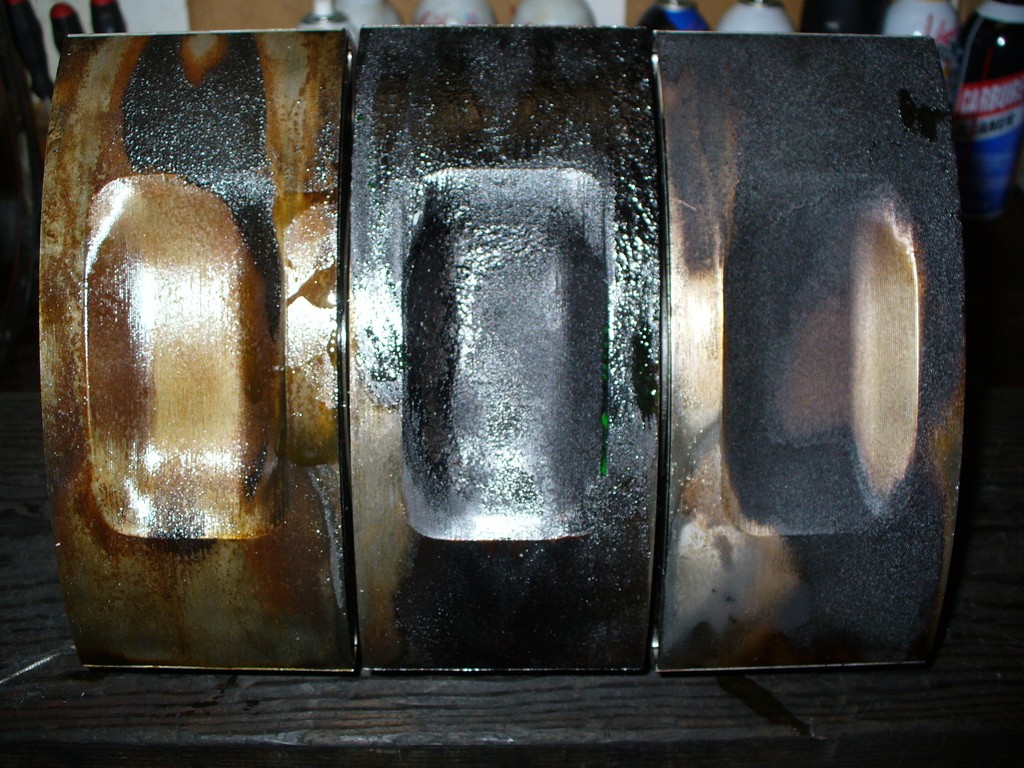

Without reading the text, can we guess which rotor was run with Benol, assuming the racer did not premix a new batch of oil every day he used it and dump the old fuel (like we all do, right? right? wait we don't?)

Article: http://edj.net/2stroke/jennings/oilpremix.pdf

"Also, most (but not all) of the petroleum and synthetic based "additive package" do not have castor oil's dangerously short shelf-life. Mix castor with gasoline and/or expose it to air, and its lubricating qualities quicky degrade; you can use today's batch of castor/gas premix for tomorrow's race but it's no good for the next weekend. Old castor premix will coat spark plugs with black, tar-like deposits, and its lubricating quality isn't worth zilch; which is why the Castrol people would really rather have you use their less-touchy, easier-to-live-with, and entirely adequate conventional additive-package oils.

Benol is castor based. Redline, apparently, is not, but I also have no personal experience with them as I always use Pennzoil or Lucas. (Or Speedway)

Without reading the text, can we guess which rotor was run with Benol, assuming the racer did not premix a new batch of oil every day he used it and dump the old fuel (like we all do, right? right? wait we don't?)

Last edited by peejay; 02-28-16 at 03:15 PM.

#28

It really isn't. Mazda was injecting roughly that much engine oil at full throttle... but they were also applying it directly to the housing surfaces/seals, where all of it would be used as lubricant. When you mix it with the fuel, most of it stays in the air and doesn't make it to the internal surfaces. So just by that alone you will need to premix more oil in the fuel than you would use with a metering pump.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

Yes, I would also like to add my own experience regarding premix.

I was using the RA Super Seals and it was already known they are "hard on housings" (incompatible material hardness leading to galling).

I kept my stock S4 OMP intact and with no slack and premixed 50:1 with Mercury Quicksilver (it resists smoking) on top of that.

The RA Super Seals still galled the rotor housing surface. I don't think any amount of lubrication can help incompatible materials.

In fact, I found the galling creates so much heat on the wear surface of the RA Super Seals that they get micro cracks along their lengths and break more easily than stock seals. This happens over time, I am not saying a fresh set of RA Super Seals are weaker than stock in fracture strength.

I just ended up using stock 3mm seals and breaking front and rear housings instead of seals after my experiences with 2mm and 3mm RA seals and RA Super Seals.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

Yes, I would also like to add my own experience regarding premix.

I was using the RA Super Seals and it was already known they are "hard on housings" (incompatible material hardness leading to galling).

I kept my stock S4 OMP intact and with no slack and premixed 50:1 with Mercury Quicksilver (it resists smoking) on top of that.

The RA Super Seals still galled the rotor housing surface. I don't think any amount of lubrication can help incompatible materials.

In fact, I found the galling creates so much heat on the wear surface of the RA Super Seals that they get micro cracks along their lengths and break more easily than stock seals. This happens over time, I am not saying a fresh set of RA Super Seals are weaker than stock in fracture strength.

I just ended up using stock 3mm seals and breaking front and rear housings instead of seals after my experiences with 2mm and 3mm RA seals and RA Super Seals.

#29

All that build up on the rotors is pretty normal when regular maintenance isn't done on higher Mile rotaries. If it's on a low mile engine, maintenance like plug changes and or a bad tune will cause that as well, when you throw over premixing into the picture... You would get the same. The wear on the housings is from incompatible seal materials mostly. Yes premixing lubricates, but Id point fingers at ill maintenance and the tune before saying premix did any of that.

It really isn't. Mazda was injecting roughly that much engine oil at full throttle... but they were also applying it directly to the housing surfaces/seals, where all of it would be used as lubricant. When you mix it with the fuel, most of it stays in the air and doesn't make it to the internal surfaces. So just by that alone you will need to premix more oil in the fuel than you would use with a metering pump.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

I found a paper regarding 2 stroke engines and premix ratios that found similar results (it was led me to experiment with using more oil) and one of the things that was noted was a lag time between changing oil premix and its effect. They would go richer and it would take several pulls before power improved, they would lean back out and it would take several more pulls before the power would decrease again. If this holds true for a rotary (and I don't really see why not) then 128:1 probably is sufficient for a car that sees light load all the time (where Mazda runs as lean as 400:1 with the oil droolers) and short bursts are acceptably dealt with before the oil film gets fully used up. For applications where heavy throttle is used frequently and for long periods, you will need more oil.

I have met "rotary experts" who have explained to me that the oil injection is bad for the engine and you should take it off, and premixing isn't needed at all. They also trailered their car to the drag strip and never drove it on the street.

In informal testing, I have found increases in engine power and compression by going as rich as about 50:1, at which point I stopped going further because the exhaust was starting to get visible. This with Mazda seals in a GSL-SE based engine.

I found a paper regarding 2 stroke engines and premix ratios that found similar results (it was led me to experiment with using more oil) and one of the things that was noted was a lag time between changing oil premix and its effect. They would go richer and it would take several pulls before power improved, they would lean back out and it would take several more pulls before the power would decrease again. If this holds true for a rotary (and I don't really see why not) then 128:1 probably is sufficient for a car that sees light load all the time (where Mazda runs as lean as 400:1 with the oil droolers) and short bursts are acceptably dealt with before the oil film gets fully used up. For applications where heavy throttle is used frequently and for long periods, you will need more oil.

I have met "rotary experts" who have explained to me that the oil injection is bad for the engine and you should take it off, and premixing isn't needed at all. They also trailered their car to the drag strip and never drove it on the street.

#30

One thing to keep in mind is that gasoline has some lubricity, while E85 is basically astringent. I would have to believe that to keep the apex seals and housings lubed correctly when running E85 you should keep the OMP and factory oiling method in place along with whatever level of premix is needed.

One other crazy question may be what type of air filtration did these high powered engines use? I have seen way too many highly boosted rotary engines running with absolutely no air filtration what so ever. You may need a huge air box with multiple cylindrical shaped filters to support those HP levels, but you absolutely must feed the beast with clean air - rotary, piston or otherwise.

One other crazy question may be what type of air filtration did these high powered engines use? I have seen way too many highly boosted rotary engines running with absolutely no air filtration what so ever. You may need a huge air box with multiple cylindrical shaped filters to support those HP levels, but you absolutely must feed the beast with clean air - rotary, piston or otherwise.

#31

IME dirty air also coincides with extreme side housing wear, which also leads to oil rings scraped completely flat. The dirt gets between the oil rings and side seals and never flushes back out, just keeps going around and around like lapping paste. Then the failed oil rings allow a lot of oil into the engine with disgusting results.

(Which is why I asked what the side housings and the sides of the rotors looked like - that one engine I built that ate itself in 400mi had rotors that looked just like that Benol-fed rotor. Disgusting.)

(Which is why I asked what the side housings and the sides of the rotors looked like - that one engine I built that ate itself in 400mi had rotors that looked just like that Benol-fed rotor. Disgusting.)

Last edited by peejay; 02-29-16 at 12:27 AM.

#32

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

i do consider this thread potentially very valuable but we aren't "there" yet...

valuable in the sense we have three motors all running E85 at fairly high power levels and all three suffering from the same serious problem.

and make no mistake here, when i say "running" i mean just that. prior to being disassembled they showed no sign of any problems as to low vacuum, lack of power etc. as i clearly stated in post one and will now restate as this was questioned in a prior post:

"all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals."

it probably doesn't need to be stated here but we have winter in Wisconsin (and Illinois where all 3 motors locate) which provides opportunity to refresh...

a 550+ hp rotary motor requires significant attention given 550 rotary is the same as a 2623 rwhp LS motor.

all 3 motors are going back together w Elite Rotary Shop studs as well as Goopy apex seals. two of the motors were running stock thrubolts.

another important consideration re the three motors is that they were running 3 different brands of apex seals.

the highest hp, most raced motor ran Goopy, the mid-use motor ran Rotary Aviation and the lighter used motor ran Atkins.

the wear on the housings mirrored, exactly, the wear on the apex seals. all three brands showed exactly the same kind of wear and only varied by degree which related to usage.

there certainly are differences in apex seal characteristics but they did not show up in this situation... primarily because there was no detonation in any of the motors.

tune has been mentioned as a possible consideration. all 3 motors were tuned by Nelson Siverio. Nelson doesn't do a copy and paste 30 minute tune. he appears to me to be highly professional. all 3 motors were happy and all made above 550 SAE and i was very impressed w the 614 number at only 25.5 psi w a GT4094r. show me a bigger number w that turbo at that boost please. the motor saw 32/34 psi boost when racing and revved to 9400.

i would like to have my 80+ CPR motors tuned by Nelson. check out his Facebook page to get a sense of his accomplishments...

https://www.facebook.com/RRRdynotuning/

so i don't think it is the tune.

maintenance:

two motors had obsessive maintenance, the other not as much. NGK BR10ES plugs changed every couple of weeks along w the oil. large air filters on two cars, a medium on the other.

as to premix ratio:

lots of opinions here...

i asked Goopy what ratio most of there high hp cars were running and it was approx 3 oz. this coincides exactly w someone on our board who i consider to be one of the most accomplished as to testing the engine limits on alcohol.... currently using 60% E85 and 40% meth in the 700 area. he says he gets housing wear but manages it.

one of the more interesting reads is the from the link Peejay provided... 5 pages single spaced w few pictures.

"Two Stroke Ratios, is less more?"

written by Gordon Jennings

from SuperBikePlanet.com on his death..

"Jennings authored the 1973 book (The) Two-Stroke Tuner's Handbook, which is considered one of the best layman's resource materials for two-stroke engines; it is highly sought after by collectors and tuners alike."

(i note it is available on Amazon for $495 a copy)

continuing on Jennings..

"He raced motorcycles, flew planes, raced cars and more often than not wrote about those experiences in Cycle, Car and Driver and in other magazines. Throughout his career he was the technical editor at Road and Track, the editor of Car and Driver, the editor at Cycle and also the technical editor at Cycle. His experience led him to be an expert witness after he left publishing."

Jennings was truly a giant in motorsports engineering and is on par w Carol Smith/"Tune to Win."

everyone running E85 and most running gasoline and premixing should spend a half hour on the linked article that Peejay references in post 27.

of course our motors are a bit different than the Suzuki PE250 but the fundamentals are the same. metal against metal, heat, stress and the need for something to reduce actual contact, i e, lubricity.

Gordon tested three ratios... Suzuki recommends a 5% (6.4 oz/gal) for the motor so Gordon tested both sides of center, 8.5 oz and 4.2 oz. he found that the richer side of center provided the most power. lots of supportive detail.

while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt.

the other interesting item related to the caster component as has been previously mentioned... according to Gordon:

castor oil's dangerously short shelf life, Mix caster with gasoline and/or leave it exposed to air, and its lubricating qualities quickly degrade; you can use today's batch of castor/gas premix for tomorrow's racing but it is no good for the next weekend. Old caster premix will coat spark plugs with black tar-like deposits, and its lubricating quality isn't worth zilch..."

note that the test and above comments refer to caster and gasoline. i wish at times i were a chemist so i could relate caster to alcohol but given Gordon's description of the "tarry" deposits it is probably a good bet that caster and ethanol work similarly to caster and gasoline.

the rotary is an unusual engine in that it is capable of creating HUGE combustion chamber pressures, it has a large swept area where the apex seal sweeps. this combo creates a major lubricating challenge especially as power climbs. i note Mazda has two oil injection ports on the un-turbo'd Renesis.

unless some fix magically appears re E85 i am on gas. i do think if i were to stay w E85 i would re-enable the oil injection ports and design my own system w my ViPEC controlling a pump injecting 2 cycle oil. (Nelson's suggestion)

i still love alcohol but it will only enter my engine in the form of 100% meth AI lowering my IATs.

valuable in the sense we have three motors all running E85 at fairly high power levels and all three suffering from the same serious problem.

and make no mistake here, when i say "running" i mean just that. prior to being disassembled they showed no sign of any problems as to low vacuum, lack of power etc. as i clearly stated in post one and will now restate as this was questioned in a prior post:

"all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals."

it probably doesn't need to be stated here but we have winter in Wisconsin (and Illinois where all 3 motors locate) which provides opportunity to refresh...

a 550+ hp rotary motor requires significant attention given 550 rotary is the same as a 2623 rwhp LS motor.

all 3 motors are going back together w Elite Rotary Shop studs as well as Goopy apex seals. two of the motors were running stock thrubolts.

another important consideration re the three motors is that they were running 3 different brands of apex seals.

the highest hp, most raced motor ran Goopy, the mid-use motor ran Rotary Aviation and the lighter used motor ran Atkins.

the wear on the housings mirrored, exactly, the wear on the apex seals. all three brands showed exactly the same kind of wear and only varied by degree which related to usage.

there certainly are differences in apex seal characteristics but they did not show up in this situation... primarily because there was no detonation in any of the motors.

tune has been mentioned as a possible consideration. all 3 motors were tuned by Nelson Siverio. Nelson doesn't do a copy and paste 30 minute tune. he appears to me to be highly professional. all 3 motors were happy and all made above 550 SAE and i was very impressed w the 614 number at only 25.5 psi w a GT4094r. show me a bigger number w that turbo at that boost please. the motor saw 32/34 psi boost when racing and revved to 9400.

i would like to have my 80+ CPR motors tuned by Nelson. check out his Facebook page to get a sense of his accomplishments...

https://www.facebook.com/RRRdynotuning/

so i don't think it is the tune.

maintenance:

two motors had obsessive maintenance, the other not as much. NGK BR10ES plugs changed every couple of weeks along w the oil. large air filters on two cars, a medium on the other.

as to premix ratio:

lots of opinions here...

i asked Goopy what ratio most of there high hp cars were running and it was approx 3 oz. this coincides exactly w someone on our board who i consider to be one of the most accomplished as to testing the engine limits on alcohol.... currently using 60% E85 and 40% meth in the 700 area. he says he gets housing wear but manages it.

one of the more interesting reads is the from the link Peejay provided... 5 pages single spaced w few pictures.

"Two Stroke Ratios, is less more?"

written by Gordon Jennings

from SuperBikePlanet.com on his death..

"Jennings authored the 1973 book (The) Two-Stroke Tuner's Handbook, which is considered one of the best layman's resource materials for two-stroke engines; it is highly sought after by collectors and tuners alike."

(i note it is available on Amazon for $495 a copy)

continuing on Jennings..

"He raced motorcycles, flew planes, raced cars and more often than not wrote about those experiences in Cycle, Car and Driver and in other magazines. Throughout his career he was the technical editor at Road and Track, the editor of Car and Driver, the editor at Cycle and also the technical editor at Cycle. His experience led him to be an expert witness after he left publishing."

Jennings was truly a giant in motorsports engineering and is on par w Carol Smith/"Tune to Win."

everyone running E85 and most running gasoline and premixing should spend a half hour on the linked article that Peejay references in post 27.

of course our motors are a bit different than the Suzuki PE250 but the fundamentals are the same. metal against metal, heat, stress and the need for something to reduce actual contact, i e, lubricity.

Gordon tested three ratios... Suzuki recommends a 5% (6.4 oz/gal) for the motor so Gordon tested both sides of center, 8.5 oz and 4.2 oz. he found that the richer side of center provided the most power. lots of supportive detail.

while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt.

the other interesting item related to the caster component as has been previously mentioned... according to Gordon:

castor oil's dangerously short shelf life, Mix caster with gasoline and/or leave it exposed to air, and its lubricating qualities quickly degrade; you can use today's batch of castor/gas premix for tomorrow's racing but it is no good for the next weekend. Old caster premix will coat spark plugs with black tar-like deposits, and its lubricating quality isn't worth zilch..."

note that the test and above comments refer to caster and gasoline. i wish at times i were a chemist so i could relate caster to alcohol but given Gordon's description of the "tarry" deposits it is probably a good bet that caster and ethanol work similarly to caster and gasoline.

the rotary is an unusual engine in that it is capable of creating HUGE combustion chamber pressures, it has a large swept area where the apex seal sweeps. this combo creates a major lubricating challenge especially as power climbs. i note Mazda has two oil injection ports on the un-turbo'd Renesis.

unless some fix magically appears re E85 i am on gas. i do think if i were to stay w E85 i would re-enable the oil injection ports and design my own system w my ViPEC controlling a pump injecting 2 cycle oil. (Nelson's suggestion)

i still love alcohol but it will only enter my engine in the form of 100% meth AI lowering my IATs.

#33

Another thing to keep in mind is the effect that burning E85 has on the oil in the crank case - nasty byproducts and added moisture. That is one of the reasons why API came out with SN rated motor oil in Oct 2010, to help deal with those nasty crank case combustion byproducts that occur when using E85 as well as to counter their effects on things like gaskets and seals.

I am not completely against using E85 - its just not a simple / quick change from running gasoline that a lot of people think - "Oh well, just swap in bigger injections, big fuel pump(s), maybe larger line sizes and then pour in the new fuel and re-tune the spark / fueling maps". You have to reconsider everything in the fuel system (due to materials incompatibilities as well as flow requirements from using the lower BTU per unit mass content fuel) and then you have to deal with new issues such as the loss of lubricity in the fuel itself and altered combustion byproducts.

I am not completely against using E85 - its just not a simple / quick change from running gasoline that a lot of people think - "Oh well, just swap in bigger injections, big fuel pump(s), maybe larger line sizes and then pour in the new fuel and re-tune the spark / fueling maps". You have to reconsider everything in the fuel system (due to materials incompatibilities as well as flow requirements from using the lower BTU per unit mass content fuel) and then you have to deal with new issues such as the loss of lubricity in the fuel itself and altered combustion byproducts.

#34

I have seen first hand at work the damage that ethanol can do in cars. Ethanol, as we know, absorbs moisture and leads to premature wear of aluminum and metal components. Almost all new cars sold run plastic fuel tanks and lines to mitigate this phenomenon. I was taking some classes on carbon buildup on newer GDI powered cars. The case studies we saw with the ethanol powered cars, in any concentration, was increased injector wear, more oil contamination, and high fuel injection pump wear.

It's not just E85 that doesn't have lubricity, even E10 you get at the pump has a lower lubricity. I worked on a Scion FRS that has a high pressure GDI pump that is cam driven by a plunger. I worked with the customer in a case study on the effects of ethanol in the fuel and the impact it had on carbon buildup and depositing in the oil. One thing I noticed right away was that even with Chevron branded Premium fuel in E10, the high pressure pump would chirp at idle. You couldn't really hear the chirp off idle, but the car was also fitted with an aftermarket turbo and 3" exhaust.

Later on, we ran the car down and refueled with non-ethanol Premium from a local Cenex station. The pump chirp went away and the oil depositing went down. My biggest concern with ethanol in any concentration is that it wears out rubber and metal components faster than straight gas, plus it has a shelf life. Another case study I took part in was on a Honda Civic driven by an older lady. It had a huge lack of power and the dealer that she was taking it to could not figure it out. We get it and the tank had 28% ethanol and the injectors were plugged with tiny salt particles. The injector screens have a small, I wanna say 10 micron screen that the salt plugged up.

I'm not necessarily against using E85 either, but the benefits of it are far outweighed by the problems that can be had. I don't think that E85 is a viable fuel for street use, unless you are changing your oil every 1500-2000 miles. That still doesn't address the housing wear, unless you run so rich on the oil premix that it may mitigate it. My other concern is that the larger amount of oil may foul out EGO sensors, so then you may be unable to accurately follow your fueling needs.

The way I see it, I would rather deal with AI and filling that vs the 33% loss of fuel economy AND the other corrosive side effects of E85.

It's not just E85 that doesn't have lubricity, even E10 you get at the pump has a lower lubricity. I worked on a Scion FRS that has a high pressure GDI pump that is cam driven by a plunger. I worked with the customer in a case study on the effects of ethanol in the fuel and the impact it had on carbon buildup and depositing in the oil. One thing I noticed right away was that even with Chevron branded Premium fuel in E10, the high pressure pump would chirp at idle. You couldn't really hear the chirp off idle, but the car was also fitted with an aftermarket turbo and 3" exhaust.

Later on, we ran the car down and refueled with non-ethanol Premium from a local Cenex station. The pump chirp went away and the oil depositing went down. My biggest concern with ethanol in any concentration is that it wears out rubber and metal components faster than straight gas, plus it has a shelf life. Another case study I took part in was on a Honda Civic driven by an older lady. It had a huge lack of power and the dealer that she was taking it to could not figure it out. We get it and the tank had 28% ethanol and the injectors were plugged with tiny salt particles. The injector screens have a small, I wanna say 10 micron screen that the salt plugged up.

I'm not necessarily against using E85 either, but the benefits of it are far outweighed by the problems that can be had. I don't think that E85 is a viable fuel for street use, unless you are changing your oil every 1500-2000 miles. That still doesn't address the housing wear, unless you run so rich on the oil premix that it may mitigate it. My other concern is that the larger amount of oil may foul out EGO sensors, so then you may be unable to accurately follow your fueling needs.

The way I see it, I would rather deal with AI and filling that vs the 33% loss of fuel economy AND the other corrosive side effects of E85.

#35

I wanted to run E85 specifically for the cooling benefits. Drag racers on methanol don't even have cooling systems a lot of the time, solid blocks and heads. Me, I want to keep coolant and oil temps down because I can feel the power falling away once the temps go past 190 and I've seen 230 on course.

#36

I wanted to run E85 specifically for the cooling benefits. Drag racers on methanol don't even have cooling systems a lot of the time, solid blocks and heads. Me, I want to keep coolant and oil temps down because I can feel the power falling away once the temps go past 190 and I've seen 230 on course.

#37

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

Neal,

there a a number of options and certainly E85 is one of them. back in the day... 1999-2002 i ran Brainerd's Ferrari Club of America event. at the time i had a modestly ported engine w the OE turbos, a Pettit flash tuned ECU and was making probably around 350.

on race gas.

as you know, Brainerd has one of the fastest straights, 6000 feet followed by turn one that is banked wide radius. you don't lift in turn one. i was on street tires, Toyo Proxes, had big brakes coil overs and had my suspension dialed in. no AI. no engine problems at 160 into turn one. for three or four years.

of course 350 is fairly modest these days.

i will be very interested in what i can do power-wise V E85 on gasoline.

93 pump w 100% meth ought to be able to handle Brainerd in the 450 area.

after a dyno run w 1200/1500 CC of meth as AI my UIM is cold to the touch. now that i have a thermocouple in the stock IAT location i will know exactly what IATs i am running.

w E85 my IATs were below 42 degrees F.

option 2 will be a 50/50 pump and VP Q16 with meth AI. Q16 really likes cold IATs, specifically below 140 F. the meth is onboard simply to lower IAT.

option 3 will be 100% Q16 and meth AI. expensive but given i will only be using it for a couple of half mile roll race events and the Oct Tex Mile not a big deal.

fuel choice is everything to our very very high combustion chamber pressure motors and we have many options.

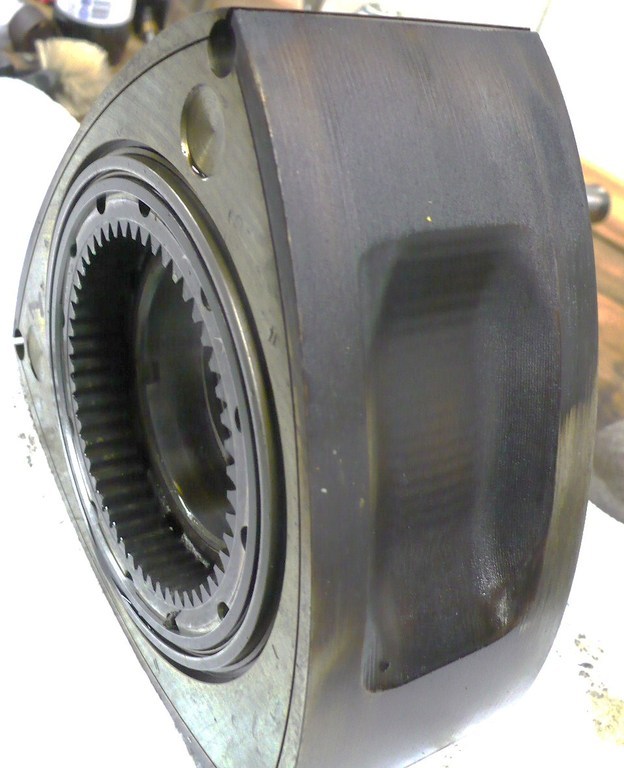

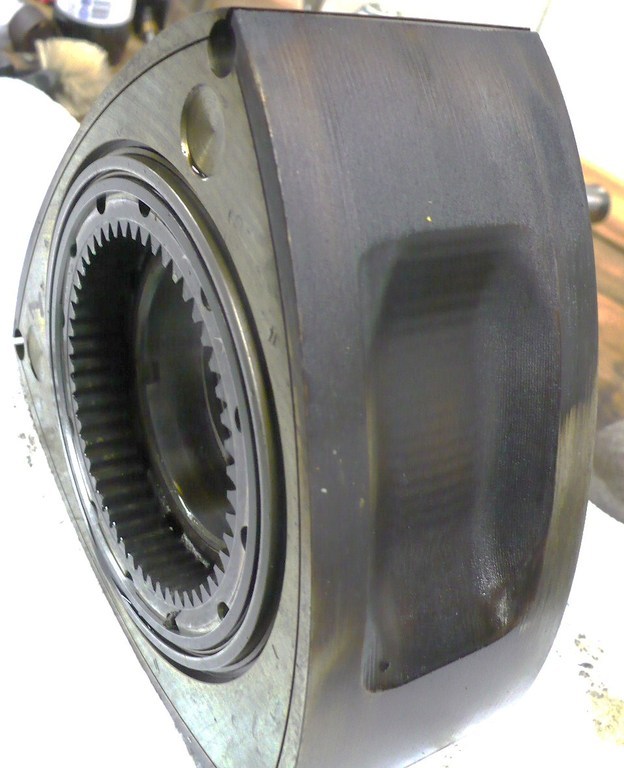

i want my rotors to look like this after 4 years so i am going gas with meth AI.

there a a number of options and certainly E85 is one of them. back in the day... 1999-2002 i ran Brainerd's Ferrari Club of America event. at the time i had a modestly ported engine w the OE turbos, a Pettit flash tuned ECU and was making probably around 350.

on race gas.

as you know, Brainerd has one of the fastest straights, 6000 feet followed by turn one that is banked wide radius. you don't lift in turn one. i was on street tires, Toyo Proxes, had big brakes coil overs and had my suspension dialed in. no AI. no engine problems at 160 into turn one. for three or four years.

of course 350 is fairly modest these days.

i will be very interested in what i can do power-wise V E85 on gasoline.

93 pump w 100% meth ought to be able to handle Brainerd in the 450 area.

after a dyno run w 1200/1500 CC of meth as AI my UIM is cold to the touch. now that i have a thermocouple in the stock IAT location i will know exactly what IATs i am running.

w E85 my IATs were below 42 degrees F.

option 2 will be a 50/50 pump and VP Q16 with meth AI. Q16 really likes cold IATs, specifically below 140 F. the meth is onboard simply to lower IAT.

option 3 will be 100% Q16 and meth AI. expensive but given i will only be using it for a couple of half mile roll race events and the Oct Tex Mile not a big deal.

fuel choice is everything to our very very high combustion chamber pressure motors and we have many options.

i want my rotors to look like this after 4 years so i am going gas with meth AI.

#38

I concure with you on this. I too want to run E85 when on the track. But what are the thought with today's technology of having a flex fuel sensor and changing between 91-93 and E85 weather on the track or street. Simply put the correct premix in with each fuel. (being that you have the supporting fuel components for it) would the 91 essentially keep the engine and fuel system clean for the times you run E85?

Sensors are like $50-100 depending on where you shop (Summit is easy button), wiring pigtail is a few bucks more, MS3Pro will natively do fuel, ignition, and boost table blending based off of a pure gasoline map and a pure E85 map and the results of the sensor, and we sell and install the systems where I work now, so this much of it is a no brainer for me. Which is good since my motto is, when it comes to spending money on the car, don't think too hard, just do what makes sense. (That way is almost always cheaper than trying to shave costs here and there!)

I think my MS2 system will also read a flex sensor but it won't do table blending, it will just alter the base fuel per cycle (the "req_fuel" in MS-land) based on that, so it changes fueling by a fixed percentage. Which works to run the same lambda with gasoline as E85 but it won't let you take advantage of E85's different lambda for best power.

Neal,

i will be very interested in what i can do power-wise V E85 on gasoline.

93 pump w 100% meth ought to be able to handle Brainerd in the 450 area.

after a dyno run w 1200/1500 CC of meth as AI my UIM is cold to the touch. now that i have a thermocouple in the stock IAT location i will know exactly what IATs i am running.

w E85 my IATs were below 42 degrees F.

option 2 will be a 50/50 pump and VP Q16 with meth AI. Q16 really likes cold IATs, specifically below 140 F. the meth is onboard simply to lower IAT.

option 3 will be 100% Q16 and meth AI. expensive but given i will only be using it for a couple of half mile roll race events and the Oct Tex Mile not a big deal.

i will be very interested in what i can do power-wise V E85 on gasoline.

93 pump w 100% meth ought to be able to handle Brainerd in the 450 area.

after a dyno run w 1200/1500 CC of meth as AI my UIM is cold to the touch. now that i have a thermocouple in the stock IAT location i will know exactly what IATs i am running.

w E85 my IATs were below 42 degrees F.

option 2 will be a 50/50 pump and VP Q16 with meth AI. Q16 really likes cold IATs, specifically below 140 F. the meth is onboard simply to lower IAT.

option 3 will be 100% Q16 and meth AI. expensive but given i will only be using it for a couple of half mile roll race events and the Oct Tex Mile not a big deal.

A tale of three engines, for you.

Engine 1 is a mild Grand National engine on pump gas with AI used to supplement the injectors. Small turbo. Ran out of injector at about the 450whp level, at safe and realistic ignition timing and methanol injection settings.

Engine 2 was a less mild engine, good heads and a much larger turbo, on C16. Engine made 565whp slightly more boost, ran out of injector at that point as well. Block limits coming up soon at that point so well enough was left alone.

Engine 3 was similar heads but a much stronger block and slightly larger turbo, and higher compression than engine 2, also on C16. 700+whp was reached. More interestingly turbo lag was all but nonexistent.

Engine 4 was engine 3 on E85 and no other changes but fuel system and tuning for the different fuel. 10% MORE horsepower than C16.

I want to try E85 on a stock-appearing turbo car, I really do.

Last edited by peejay; 02-29-16 at 09:07 PM.

#39

I'm really enjoying this thread and I'm interested to see where it goes.

I'm in the middle of converting to E85 and am using FD housings w/ OEM seals. I'll be interested to see how the housings end up, though I'm not planning on taking the engine apart for a long time to find out

I didn't realize people were using so much pre-mix... though I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly. The amount of fuel and therefore oil volume going into the engine is what needs to be tracked, not the premix ratio. The amount of oil an NA rotary running @ 13:1 AFR is getting is very different than a turbo running @ 30 psi @ 10:1 AFR. Yes more oil is needed, but is it 3 or 4 times as much oil? (to match fuel injector usage) probably not

This is compounded by the fact that you're using even more fuel with E85 which also increases the volume of oil going into the engine...

I'm in the middle of converting to E85 and am using FD housings w/ OEM seals. I'll be interested to see how the housings end up, though I'm not planning on taking the engine apart for a long time to find out

I didn't realize people were using so much pre-mix... though I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly. The amount of fuel and therefore oil volume going into the engine is what needs to be tracked, not the premix ratio. The amount of oil an NA rotary running @ 13:1 AFR is getting is very different than a turbo running @ 30 psi @ 10:1 AFR. Yes more oil is needed, but is it 3 or 4 times as much oil? (to match fuel injector usage) probably not

This is compounded by the fact that you're using even more fuel with E85 which also increases the volume of oil going into the engine...

#40

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

post 32

"while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt."

post 39

"I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly."

if you read my post carefully you will see i am not comparing ratios, rather am speaking to the dynamics of rich V lean ratios re power and lubricity. the dynamic effect of rich/lean should transfer between piston/rotary.... not the actual ratio.

empiricism rules the day and it is clear that at high 10 AFR ratios and 2.3% premix, about 40 to 1, 3 oz/gal, not enough premix was available to do the job above 500 hp.

as far as the varying amount of fuel and therefore premix going into the motor... i do agree that a motor running at 10.0 AFR has about 10% more premix going into it which helps but it also has 10% more alcohol which is the enemy of lubricity.

bottom line in my book, if you are running alcohol in any form as your base fuel lubrication is your main challenge.

"while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt."

post 39

"I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly."

if you read my post carefully you will see i am not comparing ratios, rather am speaking to the dynamics of rich V lean ratios re power and lubricity. the dynamic effect of rich/lean should transfer between piston/rotary.... not the actual ratio.

empiricism rules the day and it is clear that at high 10 AFR ratios and 2.3% premix, about 40 to 1, 3 oz/gal, not enough premix was available to do the job above 500 hp.

as far as the varying amount of fuel and therefore premix going into the motor... i do agree that a motor running at 10.0 AFR has about 10% more premix going into it which helps but it also has 10% more alcohol which is the enemy of lubricity.

bottom line in my book, if you are running alcohol in any form as your base fuel lubrication is your main challenge.

#41

I think Manny killer if he has any photos of his engine disassembly from the end of a season of motorsport use @ 400-500hp range could post some up. alot of revs etc. may just be helpful to have another example. and we all know and have seen how he uses and drives his car. also the fact he's used a couple of different premix oils. I think it could add some balance to this as I dont recall him being disappointed on pull down. and similarly his pull down wasn't out of necessity but rather a refresh for a new season.

#42

post 32

"while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt."

post 39

"I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly."

if you read my post carefully you will see i am not comparing ratios, rather am speaking to the dynamics of rich V lean ratios re power and lubricity. the dynamic effect of rich/lean should transfer between piston/rotary.... not the actual ratio.

empiricism rules the day and it is clear that at high 10 AFR ratios and 2.3% premix, about 40 to 1, 3 oz/gal, not enough premix was available to do the job above 500 hp.

as far as the varying amount of fuel and therefore premix going into the motor... i do agree that a motor running at 10.0 AFR has about 10% more premix going into it which helps but it also has 10% more alcohol which is the enemy of lubricity.

bottom line in my book, if you are running alcohol in any form as your base fuel lubrication is your main challenge.

"while the piston motor (apparently) requires more premix it is instructive that upping the premix from center helped and lowering the premix hurt."

post 39

"I think comparing a turbo rotary to any sort of two-stroke piston engine, or even a non-turbo rotary in terms of premix ratio is silly."

if you read my post carefully you will see i am not comparing ratios, rather am speaking to the dynamics of rich V lean ratios re power and lubricity. the dynamic effect of rich/lean should transfer between piston/rotary.... not the actual ratio.

empiricism rules the day and it is clear that at high 10 AFR ratios and 2.3% premix, about 40 to 1, 3 oz/gal, not enough premix was available to do the job above 500 hp.

as far as the varying amount of fuel and therefore premix going into the motor... i do agree that a motor running at 10.0 AFR has about 10% more premix going into it which helps but it also has 10% more alcohol which is the enemy of lubricity.

bottom line in my book, if you are running alcohol in any form as your base fuel lubrication is your main challenge.

If you recall in the article peejay posted they were using a premix requiring a higher oil ratio (castor oil). then mention that "new" (this article is from 1978) synthetic premixes are designed to run at 100:1 or possibly other ratios due to the additive packages, so the statement that piston engine apparently need more is somewhat unfounded, as is comparing 3 oz of castor oil to 3 oz of redline oil as being in any way the same

A while ago I emailed redline and asked them to clarify their comment on their site that reads "use at leaner ratios than with a gasoline two-stroke product"

This was their reply:

Originally Posted by redline

Thank you for contacting Red Line Oil, the mix ratio with alcohol is typically about half the oil need with gas as about twice the fuel is necessary with alcohol.

When using gas in a rotary race car a mix ratio of about 100:1 is typical, with E85 a mix ratio of 150:1 would be a good starting point, 0.85 ounces per gallon of fuel or 8.5 ounces per 10 gallons.

Regards, Dave

Red Line Oil

When using gas in a rotary race car a mix ratio of about 100:1 is typical, with E85 a mix ratio of 150:1 would be a good starting point, 0.85 ounces per gallon of fuel or 8.5 ounces per 10 gallons.

Regards, Dave

Red Line Oil

Howard,

Were all these engines running FD housings? there are changes to the housing coatings that may account for some of the additional wear, but I'm not sure if that coating survives goopy's refurbishing process...

Last edited by eage8; 03-01-16 at 06:16 PM.

#43

The FD housing coating is for break in only and is essentially gone after the engine has run for any length of time, per Mazda.

Also, I found the blurb per Racing Beat:

So, they say they run over 4oz/gallon on a two rotor engine making ONLY 600hp... far less than the above examples. On gasoline...

Also, I found the blurb per Racing Beat:

The requirement for turbo engines in racing is high enough that use of a metering oil pump is impractical. Therefore, we premix up to 22 oz of oil to 5 gallons of fuel in a 600 HP 2-rotor. If you are not pressing your engine this hard, you can use proportionally less oil.

#44

I don't have any experience with goopy's housing refresh, but would that have any effect on the total

wear? And with any refresh, would it be wiser to run a much richer, say 6oz/gal initially then back

down to 2-4oz/gal?

wear? And with any refresh, would it be wiser to run a much richer, say 6oz/gal initially then back

down to 2-4oz/gal?

#45

Also, I found the blurb per Racing Beat:

Quote:

The requirement for turbo engines in racing is high enough that use of a metering oil pump is impractical. Therefore, we premix up to 22 oz of oil to 5 gallons of fuel in a 600 HP 2-rotor. If you are not pressing your engine this hard, you can use proportionally less oil.

So, they say they run over 4oz/gallon on a two rotor engine making ONLY 600hp... far less than the above examples. On gasoline...

Yeah, that is what got me mixing a quart of premix per fill-up.

Makes a good smoke show on start up when you drive it only once a month to race (premix settles to bottom of tank).

I wouldn't try that much premix pushing the limits of 91 like everyone on this forum insists on doing with the rotary.

Quote:

The requirement for turbo engines in racing is high enough that use of a metering oil pump is impractical. Therefore, we premix up to 22 oz of oil to 5 gallons of fuel in a 600 HP 2-rotor. If you are not pressing your engine this hard, you can use proportionally less oil.

So, they say they run over 4oz/gallon on a two rotor engine making ONLY 600hp... far less than the above examples. On gasoline...

Yeah, that is what got me mixing a quart of premix per fill-up.

Makes a good smoke show on start up when you drive it only once a month to race (premix settles to bottom of tank).

I wouldn't try that much premix pushing the limits of 91 like everyone on this forum insists on doing with the rotary.

#46

I don't get "pushing the limits"... the Audi guys seem to love seeing how lean they can run under high boost. Like, sacrifice timing so EGTs shoot to the moon so they can run 12:1 at 18psi because you make more power at 12:1. Well, maybe for a few seconds, but the EGTs hurt the exhaust valves or kill the turbo.

But then I like to build things so they last a long while, make power where the percentages are good. You bet your *** I don't tune turbo cars to run at 12:1 except at very low boost levels. Endurance racing turbo engines run as rich as 8-9:1, basically just lean enough for stable combustion, because an engine that lasts is better than a fast engine that is broken.

But then I like to build things so they last a long while, make power where the percentages are good. You bet your *** I don't tune turbo cars to run at 12:1 except at very low boost levels. Endurance racing turbo engines run as rich as 8-9:1, basically just lean enough for stable combustion, because an engine that lasts is better than a fast engine that is broken.

Last edited by peejay; 03-01-16 at 05:57 PM.

#47

I don't either.

Race car.... race gas.

Its pretty simple to me, how many other such HUGE class granted advantages do you give up when racing?

C16, your engine will thank you.

If you don't think you need that much protection from detonation you can even mix in your quart of premix into 5 gallons of 116 leaded, put it in your tank and fill up on 91 and you will have 99 octane.

Race car.... race gas.

Its pretty simple to me, how many other such HUGE class granted advantages do you give up when racing?

C16, your engine will thank you.

If you don't think you need that much protection from detonation you can even mix in your quart of premix into 5 gallons of 116 leaded, put it in your tank and fill up on 91 and you will have 99 octane.

#48

OEM seals have the best material selection and wear characteristics of any seal. Looks like we continue to learn this over and over again.

Also looks like more lube and running an OMP is the best thing to do. I have ra super seals from the previous owner who decided to run them. I will run that till they need replacement, but stock 2 piece seals for sure for me.

Also looks like more lube and running an OMP is the best thing to do. I have ra super seals from the previous owner who decided to run them. I will run that till they need replacement, but stock 2 piece seals for sure for me.

#49

Interesting read. I have been pondering on the idea that diesel fuel lubricants may be the ticket. Lubricants such as Optilube could be a solution as they are touted to have far superior lubrication properties to 2 cycle oils. However I have not contemplated how this lubricant will perform in E85, as alternative fuels are a new interest to me.

The link to my previous thread with links to research data, emails to the manufacturer, etc.

https://www.rx7club.com/rotary-car-p...ative-1081114/

The only thing I would add to my original post is to note that not only are the fuel additives good at preventing injector pump wear. they're great for the cylinder walls. In our case, rotor housings.

The question now, in my mind, is 1. Will it mix without separation in ethanol blends the way it mixes with diesel and gasoline. 2. If when mixed, will it retain its lubricating properties.

The link to my previous thread with links to research data, emails to the manufacturer, etc.

https://www.rx7club.com/rotary-car-p...ative-1081114/

The only thing I would add to my original post is to note that not only are the fuel additives good at preventing injector pump wear. they're great for the cylinder walls. In our case, rotor housings.

The question now, in my mind, is 1. Will it mix without separation in ethanol blends the way it mixes with diesel and gasoline. 2. If when mixed, will it retain its lubricating properties.

Last edited by R_PROWESS; 03-05-16 at 08:58 PM.

#50

I'll be using Redline this season. Here is a pic of their Gasoline Pre-mix. Huge difference in viscosity on first look....especially compared to Benol and Motul. The Redline stuff isn't nearly as thick. The Alcohol Safe Pre-Mix is on the way...I'll post pics of the stuff when I get it.