rotor housings and E85

#1

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

rotor housings and E85

i recently disassembled three customer motors that had run on E85 in 2015.

all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals.

each was used a bit differently.

one was drag raced on the streets at night for serious money and has yet to be beaten. it dynoed at 614 SAE hp at 25.5 psi boost and was tuned by an excellent tuner, Nelson Severio. it ran slightly above 9000. Redline 2 cycle alcohol oil as premix at approx 3 oz. Goopy apex seals. GT4094r.

the second was a BREW in a FC and was dyno'd at slightly over 550 by Nelson. the turbo was a BW 63 FMW. it was not driven quite as hard but was raced. the premix was Benol at up to 3 oz. Rotary Aviation Super Seals.

the third BREW was in a ground up restoration RX3, was raced a bit and had a few less miles than the other two. it was also tuned and dynoed by Nelson and did around 550 w a BW S300 63. Atkins apex seals. Redline 2 Cycle Alcohol Oil as premix between 2 and 3 oz.

all 3 motors started w perfectly honed rotor housings from Goopy.

i was most interested in how much premix deposits were in the motors but it didn't take long for my interest to shift to the rotor housings.

all three had identical significant vertical wear on them and each had an amount of wear commensurate w the amount of usage and power.

all six housings will have to be re-honed.

the contact surface of all three apex seal brands (Goopy, RA and Atkins) were pitted and wear matched up w the housings.

if this is what to expect w E85 it is unacceptable to me.

perhaps if one were to run more pre-mix that might work. i did find the primary intake port walls were coated w a tarry deposit both from the Benol and Redline. the secondary ports did not have as much which would be as you would suspect.

another possible fix could be enabling the rotor housing lube ports. if i were to do it i would have my ECU control a pump and tank. i would want some lube being injected all the time.

each of my customers will have to make his own decision re fuel but i am going back to pump and 100% meth injection for the street and Q16 w meth AI for the track. (the meth is to lower IATs as Q16 works best under 140F).

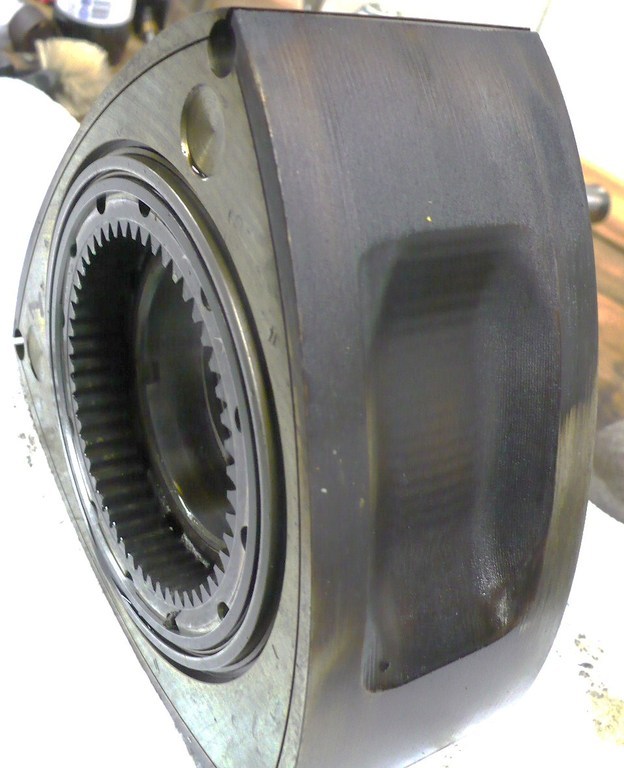

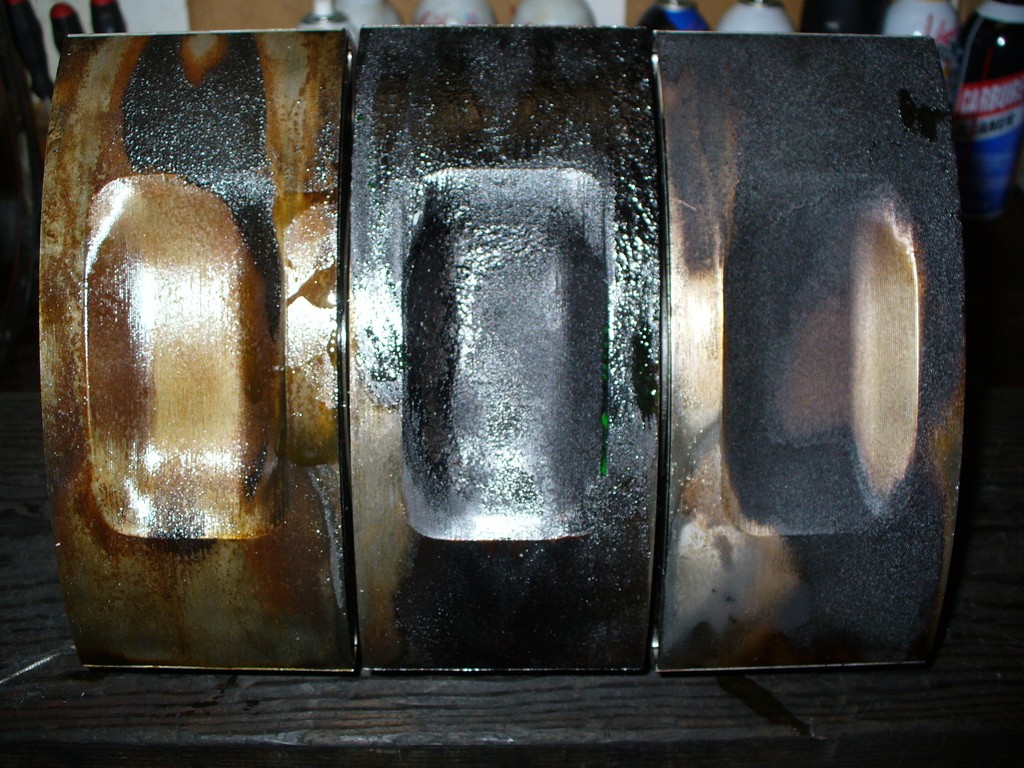

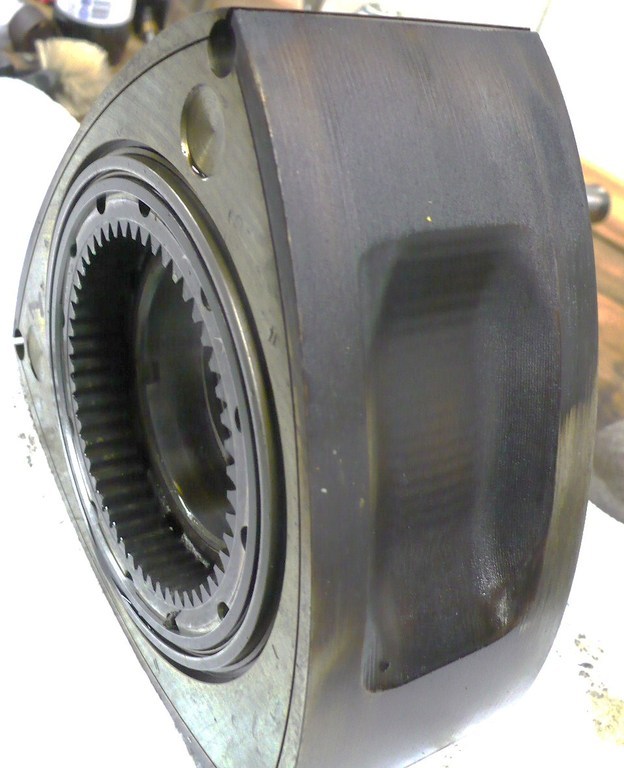

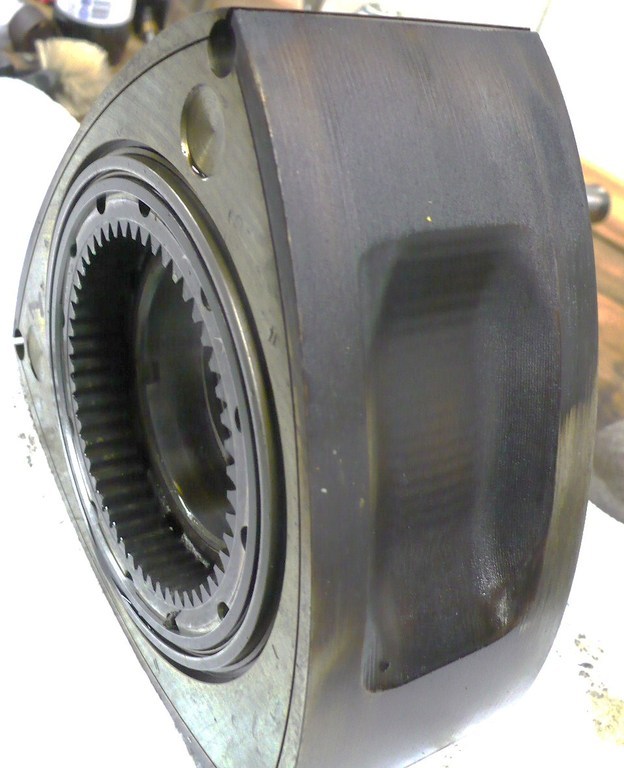

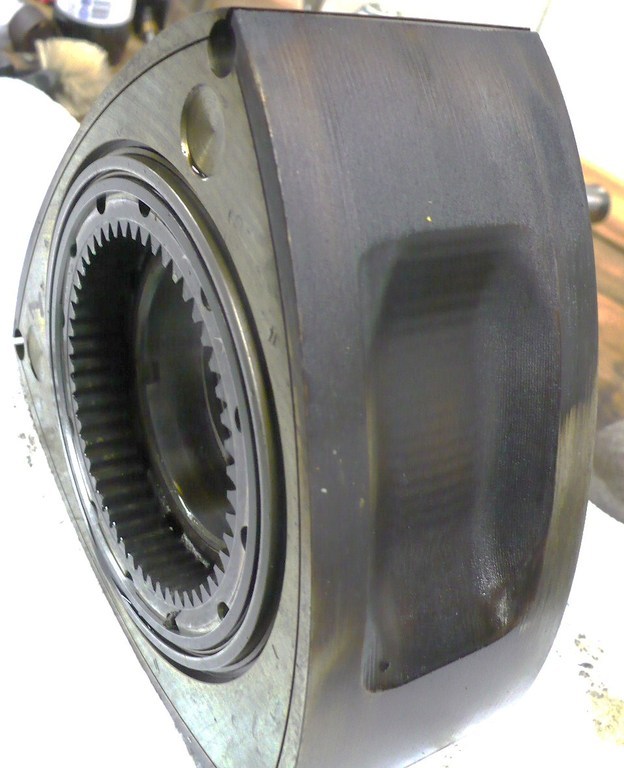

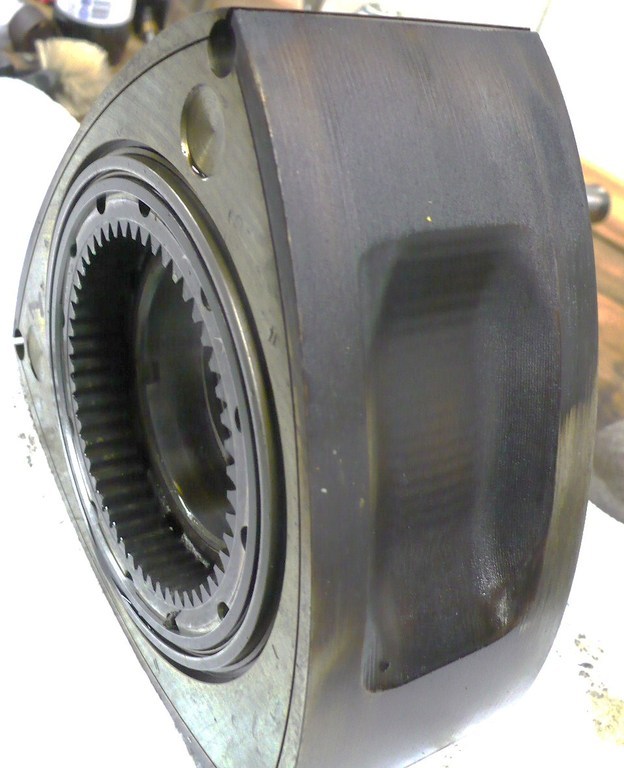

i ran on pump and meth for four years around 500 and disassembled my motor, which was still gaining compression after 4 years, just to check it out. here's a pic of one of my housings and rotors... 'quite different than the E85 motors. BTW, i did not touch the rotor or housing before taking the following pics:

[URL=https://imageshack.com/i/pl7VcWbmj] [URL]

[URL]

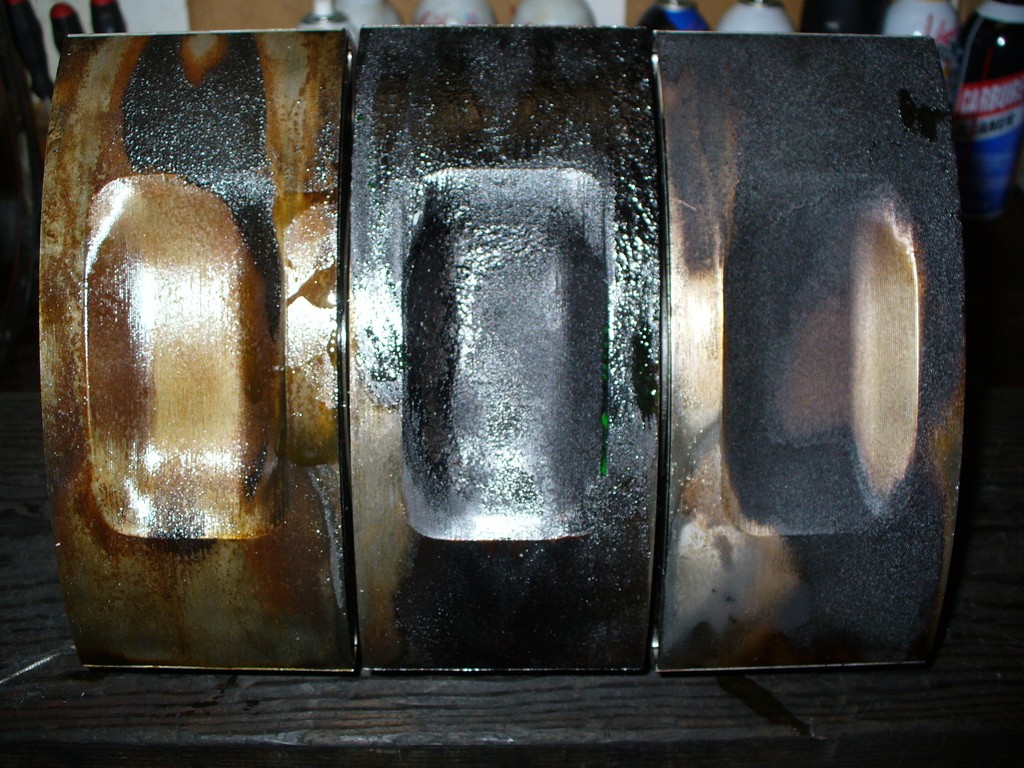

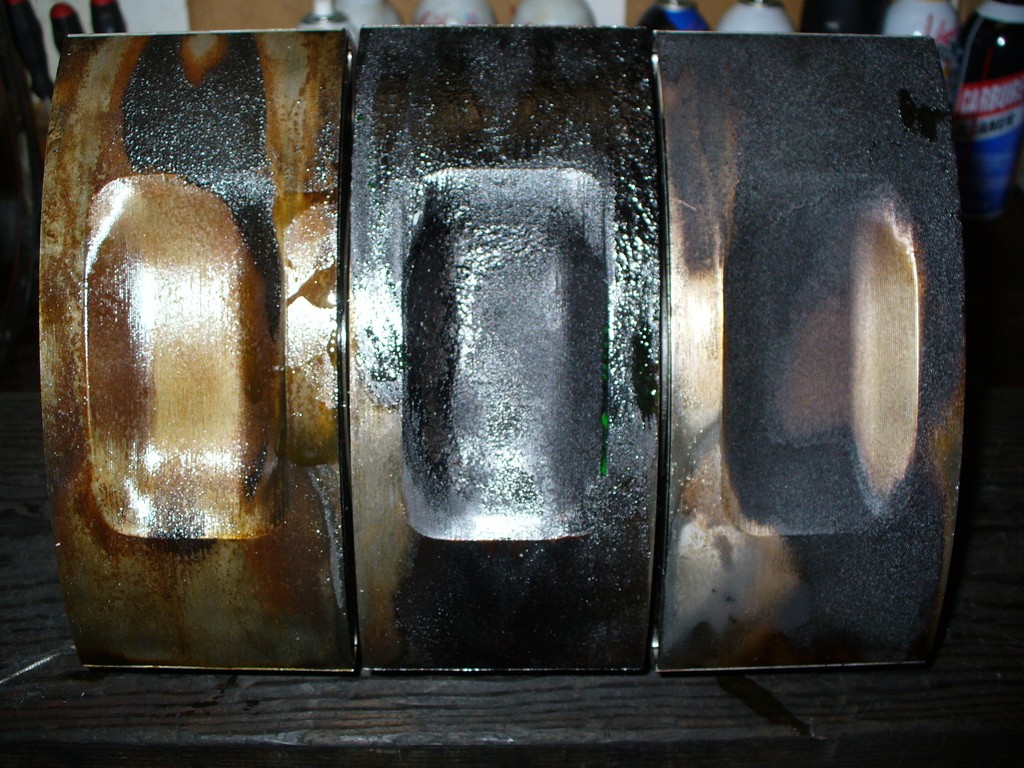

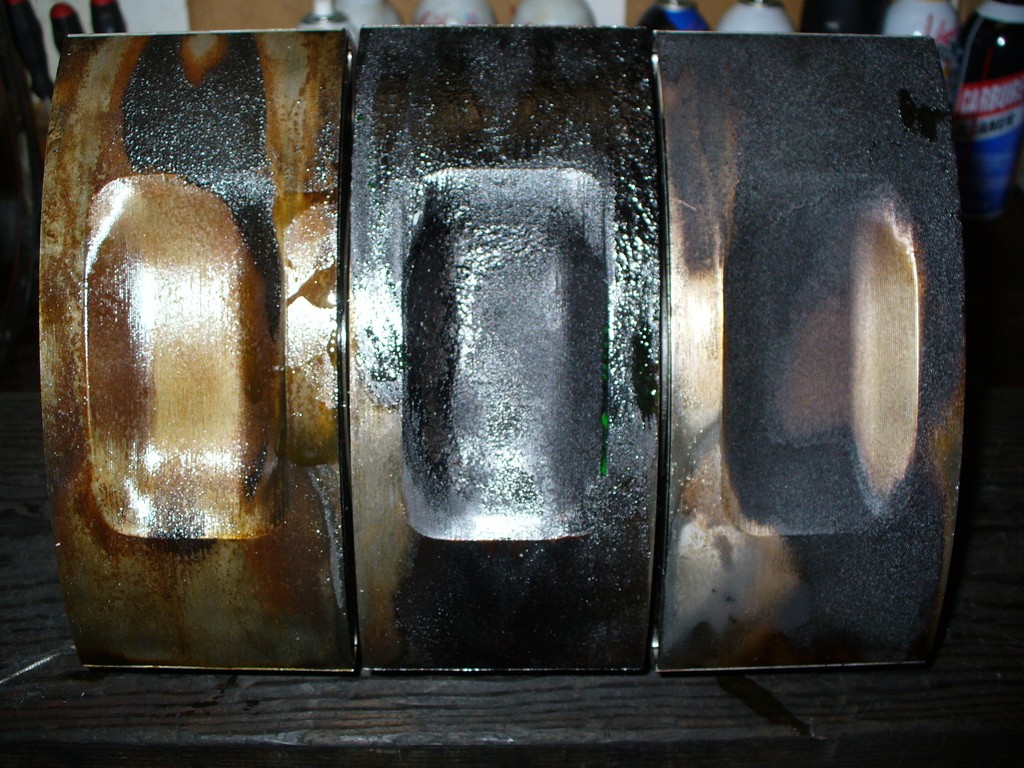

here's a pic of the 614 hp E85 rotor housings. i do realise that a 1.3 L rotary is making 472 rwhp per liter. to put in a comparative context this would equate to a 6.2 L LS motor making 2926 rwhp! there's a lot of combustion chamber pressure going on inside. (understatement)

another motor... less usage and a bit less power but same vertical striations.

we have been collectively looking for answers, have yet to come up w any. running more premix might work as would re-enabling the oil injection port. i do find it interesting that amongst the 3 motors we have 3 different apex seals, and two diff pre-mixes.

my Mcloed double disc is in and my motor is running so i will be dynoing this coming week. we have switched over to 93 pump and 100% meth. eventually we will switch to Q16 and perhaps try a 50/50 mix of Q16 and pump while continuing to use meth AI.

any input on this welcomed.

Howard

all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals.

each was used a bit differently.

one was drag raced on the streets at night for serious money and has yet to be beaten. it dynoed at 614 SAE hp at 25.5 psi boost and was tuned by an excellent tuner, Nelson Severio. it ran slightly above 9000. Redline 2 cycle alcohol oil as premix at approx 3 oz. Goopy apex seals. GT4094r.

the second was a BREW in a FC and was dyno'd at slightly over 550 by Nelson. the turbo was a BW 63 FMW. it was not driven quite as hard but was raced. the premix was Benol at up to 3 oz. Rotary Aviation Super Seals.

the third BREW was in a ground up restoration RX3, was raced a bit and had a few less miles than the other two. it was also tuned and dynoed by Nelson and did around 550 w a BW S300 63. Atkins apex seals. Redline 2 Cycle Alcohol Oil as premix between 2 and 3 oz.

all 3 motors started w perfectly honed rotor housings from Goopy.

i was most interested in how much premix deposits were in the motors but it didn't take long for my interest to shift to the rotor housings.

all three had identical significant vertical wear on them and each had an amount of wear commensurate w the amount of usage and power.

all six housings will have to be re-honed.

the contact surface of all three apex seal brands (Goopy, RA and Atkins) were pitted and wear matched up w the housings.

if this is what to expect w E85 it is unacceptable to me.

perhaps if one were to run more pre-mix that might work. i did find the primary intake port walls were coated w a tarry deposit both from the Benol and Redline. the secondary ports did not have as much which would be as you would suspect.

another possible fix could be enabling the rotor housing lube ports. if i were to do it i would have my ECU control a pump and tank. i would want some lube being injected all the time.

each of my customers will have to make his own decision re fuel but i am going back to pump and 100% meth injection for the street and Q16 w meth AI for the track. (the meth is to lower IATs as Q16 works best under 140F).

i ran on pump and meth for four years around 500 and disassembled my motor, which was still gaining compression after 4 years, just to check it out. here's a pic of one of my housings and rotors... 'quite different than the E85 motors. BTW, i did not touch the rotor or housing before taking the following pics:

[URL=https://imageshack.com/i/pl7VcWbmj]

[URL]

[URL]

here's a pic of the 614 hp E85 rotor housings. i do realise that a 1.3 L rotary is making 472 rwhp per liter. to put in a comparative context this would equate to a 6.2 L LS motor making 2926 rwhp! there's a lot of combustion chamber pressure going on inside. (understatement)

another motor... less usage and a bit less power but same vertical striations.

we have been collectively looking for answers, have yet to come up w any. running more premix might work as would re-enabling the oil injection port. i do find it interesting that amongst the 3 motors we have 3 different apex seals, and two diff pre-mixes.

my Mcloed double disc is in and my motor is running so i will be dynoing this coming week. we have switched over to 93 pump and 100% meth. eventually we will switch to Q16 and perhaps try a 50/50 mix of Q16 and pump while continuing to use meth AI.

any input on this welcomed.

Howard

Last edited by Howard Coleman; 02-26-16 at 09:00 AM.

#2

That is consistent with what I had experienced running Atkins seals with only 1oz/gallon premix.

I have since switched to 2oz/gal premix and the rotor housings look fine with a borescope through the exhaust ports. This is on gasoline, of course. And naturally aspirated, so much lower chamber pressures.

Given the additional amount of fuel required with E85, I'm frankly shocked that 3oz/gal is apparently not enough.

I am wondering what Mazda seals would do.

I have since switched to 2oz/gal premix and the rotor housings look fine with a borescope through the exhaust ports. This is on gasoline, of course. And naturally aspirated, so much lower chamber pressures.

Given the additional amount of fuel required with E85, I'm frankly shocked that 3oz/gal is apparently not enough.

I am wondering what Mazda seals would do.

#5

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

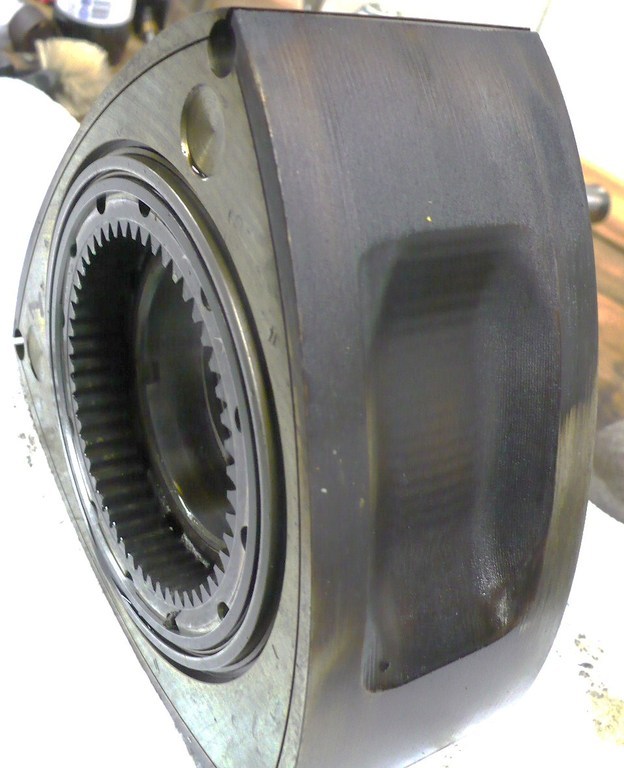

rotors from 3 CPR E85 motors

from left to right:

rotor one 550 hp lowest use of the three Redline 2 Cycle Alcohol Oil

rotor two 550/575 medium use some racing Benol

rotor three 614 hp lots of serious drag racing Redline 2 Cycle Alcohol Oil

each mixed at the same ratio (approx 2 oz) and tuned by Nelson Siverio.

all 3 motors were running perfectly at time of dis-assembly. not touched prior to picture.

compare to a pump gas w meth AI rotor from my motor after 4 years of use. Atkins apex seals. 1 oz SuperTech (Walmart) 2 cycle, 1.5 on dyno.

from left to right:

rotor one 550 hp lowest use of the three Redline 2 Cycle Alcohol Oil

rotor two 550/575 medium use some racing Benol

rotor three 614 hp lots of serious drag racing Redline 2 Cycle Alcohol Oil

each mixed at the same ratio (approx 2 oz) and tuned by Nelson Siverio.

all 3 motors were running perfectly at time of dis-assembly. not touched prior to picture.

compare to a pump gas w meth AI rotor from my motor after 4 years of use. Atkins apex seals. 1 oz SuperTech (Walmart) 2 cycle, 1.5 on dyno.

Last edited by Howard Coleman; 02-26-16 at 09:03 AM.

#7

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

"What did the side seals and side housing surfaces look like?"

side seals are fine and have the same .002 clearance as when built. irons are fine. as w all the other E85 motors i have looked at there is a premix deposit on the sides of both rotors that face the mid iron. there is nothing on the outer sides.

since the majority of time the premix is passing thru the primary port that checks out. the side of the rotor is facing the port flow when the port is closed and getting blasted w premix.

the premix is not getting by the sideseal at the cornerseal.

i just received the pair of rotor housings that had the most wear from Goopy. they did a magnificent job on them and they are ready to go back to work.

amazing.

Howard

side seals are fine and have the same .002 clearance as when built. irons are fine. as w all the other E85 motors i have looked at there is a premix deposit on the sides of both rotors that face the mid iron. there is nothing on the outer sides.

since the majority of time the premix is passing thru the primary port that checks out. the side of the rotor is facing the port flow when the port is closed and getting blasted w premix.

the premix is not getting by the sideseal at the cornerseal.

i just received the pair of rotor housings that had the most wear from Goopy. they did a magnificent job on them and they are ready to go back to work.

amazing.

Howard

Trending Topics

#8

rotor housings and E85

interesting because I just read a comment from a guy using pump e85 down here in nz on piston engines having abnormal bore marks and why he would be going back to pump and didn't recommend e85. I wrote it off as could of been bunch of reasons at the time I was reading it but does kind of match up with what you are saying...also damn that benol is nasty. I think it was Aaron's post possibly where it was all gunked up his intake so stopped using it.

#9

Very curious.

I've always run primary injector only and with premix only and I've never noticed any difference in deposits side to side. If anything, the only time I have noticed a difference is when I had an OE type manifold with a vacuum leak on the secondary side and dirt was finding its way into the engine, the gear side of the rotors saw significantly more wear on all rubbing surfaces involved. (Catastrophically so. I think the eccentric shaft and rotor housings were still usable.)

I've also not seen carbon deposits as being related to the amount of premix used.

So, my wonder is, what is in these ethanol-specific premix oils that is causing heavy deposits and poor lubricity? And my next wonder is, is the 15-30% gasoline content enough to carry a traditional 2 cycle oil? (I don't see why not, but I haven't tried it)

I've always run primary injector only and with premix only and I've never noticed any difference in deposits side to side. If anything, the only time I have noticed a difference is when I had an OE type manifold with a vacuum leak on the secondary side and dirt was finding its way into the engine, the gear side of the rotors saw significantly more wear on all rubbing surfaces involved. (Catastrophically so. I think the eccentric shaft and rotor housings were still usable.)

I've also not seen carbon deposits as being related to the amount of premix used.

So, my wonder is, what is in these ethanol-specific premix oils that is causing heavy deposits and poor lubricity? And my next wonder is, is the 15-30% gasoline content enough to carry a traditional 2 cycle oil? (I don't see why not, but I haven't tried it)

Last edited by peejay; 02-23-16 at 06:01 AM.

#10

i recently disassembled three customer motors that had run on E85 in 2015.

all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals.

each was used a bit differently.

one was drag raced on the streets at night for serious money and has yet to be beaten. it dynoed at 614 SAE hp at 25.5 psi boost and was tuned by an excellent tuner, Nelson Severio. it ran slightly above 9000. Redline 2 cycle alcohol oil as premix at approx 3 oz. Goopy apex seals. GT4094r.

the second was a BREW in a FC and was dyno'd at slightly over 550 by Nelson. the turbo was a BW 63 FMW. it was not driven quite as hard but was raced. the premix was Benol at up to 3 oz. Rotary Aviation Super Seals.

the third BREW was in a ground up restoration RX3, was raced a bit and had a few less miles than the other two. it was also tuned and dynoed by Nelson and did around 550 w a BW S300 63.

all 3 motors started w perfectly honed rotor housings from Goopy.

i was most interested in how much premix deposits were in the motors but it didn't take long for my interest to shift to the rotor housings.

all three had identical significant vertical wear on them and each had an amount of wear commensurate w the amount of usage and power.

all six housings will have to be re-honed.

the contact surface of all three apex seal brands (Goopy, RA and Atkins) were pitted and wear matched up w the housings.

if this is what to expect w E85 it is unacceptable to me.

perhaps if one were to run more pre-mix that might work. i did find the primary intake port walls were coated w a tarry deposit both from the Benol and Redline. the secondary ports did not have as much which would be as you would suspect.

another possible fix could be enabling the rotor housing lube ports. if i were to do it i would have my ECU control a pump and tank. i would want some lube being injected all the time.

each of my customers will have to make his own decision re fuel but i am going back to pump and 100% meth injection for the street and Q16 w meth AI for the track. (the meth is to lower IATs as Q16 works best under 140F).

i ran on pump and meth for four years around 500 and disassembled my motor, which was still gaining compression after 4 years, just to check it out. here's a pic of one of my housings and rotors... 'quite different than the E85 motors. BTW, i did not touch the rotor or housing before taking the following pics:

here's a pic of the 614 hp E85 rotor housings. i do realise that a 1.3 L rotary is making 472 rwhp per liter. to put in a comparative context this would equate to a 6.2 L LS motor making 2926 rwhp! there's a lot of combustion chamber pressure going on inside. (understatement)

another motor... less usage and a bit less power but same vertical striations.

we have been collectively looking for answers, have yet to come up w any. running more premix might work as would re-enabling the oil injection port. i do find it interesting that amongst the 3 motors we have 3 different apex seals, and two diff pre-mixes.

my Mcloed double disc is in and my motor is running so i will be dynoing this coming week. we have switched over to 93 pump and 100% meth. eventually we will switch to Q16 and perhaps try a 50/50 mix of Q16 and pump while continuing to use meth AI.

any input on this welcomed.

Howard

all three BREW motors were running perfectly at the time of disassembly. all 3 showed proper vacuum. the motors were taken down to install Elite Rotary Shop studs and two were being switched to Goopy apex seals.

each was used a bit differently.

one was drag raced on the streets at night for serious money and has yet to be beaten. it dynoed at 614 SAE hp at 25.5 psi boost and was tuned by an excellent tuner, Nelson Severio. it ran slightly above 9000. Redline 2 cycle alcohol oil as premix at approx 3 oz. Goopy apex seals. GT4094r.

the second was a BREW in a FC and was dyno'd at slightly over 550 by Nelson. the turbo was a BW 63 FMW. it was not driven quite as hard but was raced. the premix was Benol at up to 3 oz. Rotary Aviation Super Seals.

the third BREW was in a ground up restoration RX3, was raced a bit and had a few less miles than the other two. it was also tuned and dynoed by Nelson and did around 550 w a BW S300 63.

all 3 motors started w perfectly honed rotor housings from Goopy.

i was most interested in how much premix deposits were in the motors but it didn't take long for my interest to shift to the rotor housings.

all three had identical significant vertical wear on them and each had an amount of wear commensurate w the amount of usage and power.

all six housings will have to be re-honed.

the contact surface of all three apex seal brands (Goopy, RA and Atkins) were pitted and wear matched up w the housings.

if this is what to expect w E85 it is unacceptable to me.

perhaps if one were to run more pre-mix that might work. i did find the primary intake port walls were coated w a tarry deposit both from the Benol and Redline. the secondary ports did not have as much which would be as you would suspect.

another possible fix could be enabling the rotor housing lube ports. if i were to do it i would have my ECU control a pump and tank. i would want some lube being injected all the time.

each of my customers will have to make his own decision re fuel but i am going back to pump and 100% meth injection for the street and Q16 w meth AI for the track. (the meth is to lower IATs as Q16 works best under 140F).

i ran on pump and meth for four years around 500 and disassembled my motor, which was still gaining compression after 4 years, just to check it out. here's a pic of one of my housings and rotors... 'quite different than the E85 motors. BTW, i did not touch the rotor or housing before taking the following pics:

here's a pic of the 614 hp E85 rotor housings. i do realise that a 1.3 L rotary is making 472 rwhp per liter. to put in a comparative context this would equate to a 6.2 L LS motor making 2926 rwhp! there's a lot of combustion chamber pressure going on inside. (understatement)

another motor... less usage and a bit less power but same vertical striations.

we have been collectively looking for answers, have yet to come up w any. running more premix might work as would re-enabling the oil injection port. i do find it interesting that amongst the 3 motors we have 3 different apex seals, and two diff pre-mixes.

my Mcloed double disc is in and my motor is running so i will be dynoing this coming week. we have switched over to 93 pump and 100% meth. eventually we will switch to Q16 and perhaps try a 50/50 mix of Q16 and pump while continuing to use meth AI.

any input on this welcomed.

Howard

Dont see that you mentioned which apex seals were in the 3rd engine(rx3)? Either way the first two engines the wear is due to the seals. Its facts, every "unbreakable" seal eats housings faster. Pre-mix all you want, until the car smokes all the time and you will still see this wear. Doesnt matter the fuel, the tune etc. If someone says otherwise its because they are trying to sell you something. Your atkins motor looked that way because that is how all engines look with OEM or Atkins seal after 10k miles. However, we all know what can happen with those seals if detonation occurs.

With that said, I have "unbreakable seals" in my engine(newest E&J). If I get 10K miles out of the seals/housings and it doesnt destroy my EFR turbo I consider that a win. Its the reality of the situation. I'm sure the e85 can accelerate the wear but we all know the major cause of the wear you see on the housings. There is 15 years of evidence at this point.

Last edited by djseven; 02-23-16 at 11:17 AM.

#11

Your atkins motor looked that way because that is how all engines look with OEM or Atkins seal after 10k miles.

Its facts, every "unbreakable" seal eats housings faster.

This was my initial though as well and why I asked what seals were in the E85 engines since they look like my engines did on gasoline and RA seals.

However, Howard said the 3rd E85 motor (not pictured?) used Atkins seals and the housing chrome was also torn up on that one as well.

Its facts, every "unbreakable" seal eats housings faster.

This was my initial though as well and why I asked what seals were in the E85 engines since they look like my engines did on gasoline and RA seals.

However, Howard said the 3rd E85 motor (not pictured?) used Atkins seals and the housing chrome was also torn up on that one as well.

#12

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

after close inspection of the 3 motors, each w different apex seal brands, i conclude there was zero diff as to wear both on the housings and on the apex seals. i use a 10X loupe to look at seals and they all looked very similar after considering the power/usage.

same pitting of the crowns, very slight overhang and no flatted shoulders.

same pitting of the crowns, very slight overhang and no flatted shoulders.

#13

Your atkins motor looked that way because that is how all engines look with OEM or Atkins seal after 10k miles.

Its facts, every "unbreakable" seal eats housings faster.

This was my initial though as well and why I asked what seals were in the E85 engines since they look like my engines did on gasoline and RA seals.

However, Howard said the 3rd E85 motor (not pictured?) used Atkins seals and the housing chrome was also torn up on that one as well.

Its facts, every "unbreakable" seal eats housings faster.

This was my initial though as well and why I asked what seals were in the E85 engines since they look like my engines did on gasoline and RA seals.

However, Howard said the 3rd E85 motor (not pictured?) used Atkins seals and the housing chrome was also torn up on that one as well.

My rotor housings looked as they did when I put them in, after ~30k with Atkins and more oiling. (I can't say "correct", just "more" which is better than before) save for chrome flaking which you just have to live with on early rotor housings. I'll know if I ever get arsed to build a new engine so I can take this one apart... it's close to four seasons and maybe 50k miles and lots of overheating and it is now starting to drink a little coolant, makes cold start after a long time difficult until it blows the coolant out of the chambers.

Last edited by peejay; 02-23-16 at 02:38 PM.

#14

And that is what my rotor housings looked like after 60k with Atkins seals and insufficient oiling.

Ah, thanks for that information.

I had always heard Atkins seals are the only aftermarket steel seals that aren't hard on rotor housings.

I have little experience with Atkins as I assembled one of my motors with some 2mm and they all broke lengthwise like Cookie Monster took a bite out of them (but leaving intact the long piece corner where stock ones always break).

I do not blame the seals; the old rubber hose between new fuel pump and tank outlet had split open the first time I boosted...

The way Atkins have a habit of breaking lengthwise I would guess it has to do with their heat treatment process and they are probably harder than most aftermarket seals on the wear surface, but not as hard as stock.

Ah, thanks for that information.

I had always heard Atkins seals are the only aftermarket steel seals that aren't hard on rotor housings.

I have little experience with Atkins as I assembled one of my motors with some 2mm and they all broke lengthwise like Cookie Monster took a bite out of them (but leaving intact the long piece corner where stock ones always break).

I do not blame the seals; the old rubber hose between new fuel pump and tank outlet had split open the first time I boosted...

The way Atkins have a habit of breaking lengthwise I would guess it has to do with their heat treatment process and they are probably harder than most aftermarket seals on the wear surface, but not as hard as stock.

#15

I wouldn't say they were "hard" on the rotor housings, per se. They cleaned up with a minimal amount of manual sanding. (Although I do have an Idea for a better method of surface restoration besides laboriously doing it manually, along with a good way to do side housing lapping) It would be more fair to say that I was hard on the engine, as I was running it at high RPM and not giving it enough oiling.

Do they need more oil than stock seals? It's hard to say. Racing Beat will tell you that even with Mazda seals you may need to run 4-6oz/gallon of premix on ultra high output engines. Certainly because the seals don't have the surface hardness that Mazda seals do, they will wear more and more unevenly. I have seen Mazda sealed engines with the scoring, but it tends to be less pronounced.

Do they need more oil than stock seals? It's hard to say. Racing Beat will tell you that even with Mazda seals you may need to run 4-6oz/gallon of premix on ultra high output engines. Certainly because the seals don't have the surface hardness that Mazda seals do, they will wear more and more unevenly. I have seen Mazda sealed engines with the scoring, but it tends to be less pronounced.

#18

I missed that. Ive seen it with their 3mm seals but never with 2mm. Then again most 2mm atkins seals motors I tore down only had a couple thousand miles on them before detonation chipped a seal.

#21

Straight meth? Or 50/50 mix?

I was going to ask what brand of pre-mix, but it looks like your earlier post is edited to say Walmart brand, so I guess Ms. Croteau in 7th Grade was correct, reading is important!

I was going to ask what brand of pre-mix, but it looks like your earlier post is edited to say Walmart brand, so I guess Ms. Croteau in 7th Grade was correct, reading is important!

#22

Thread Starter

Racing Rotary Since 1983

iTrader: (6)

Joined: Oct 2001

Posts: 6,136

Likes: 564

From: Florence, Alabama

straight meth as AI.

after that motor i switched to a GT4094r and added 75 hp. i did some research and decided to up the lubricity of the premix and settled on Redline 2 cycle racing oil w my pump base fuel. the WalMart oil might have been fine... also a bit cheaper

after that motor i switched to a GT4094r and added 75 hp. i did some research and decided to up the lubricity of the premix and settled on Redline 2 cycle racing oil w my pump base fuel. the WalMart oil might have been fine... also a bit cheaper

Last edited by Howard Coleman; 02-27-16 at 09:35 PM.

#25

rotors from 3 CPR E85 motors

from left to right:

rotor one 550 hp lowest use of the three Redline 2 Cycle Alcohol Oil

rotor two 550/575 medium use some racing Benol

rotor three 614 hp lots of serious drag racing Redline 2 Cycle Alcohol Oil

each mixed at the same ratio (approx 2 oz) and tuned by Nelson Siverio.

all 3 motors were running perfectly at time of dis-assembly. not touched prior to picture.

compare to a pump gas w meth AI rotor from my motor after 4 years of use. Atkins apex seals. 1 oz SuperTech (Walmart) 2 cycle, 1.5 on dyno.

from left to right:

rotor one 550 hp lowest use of the three Redline 2 Cycle Alcohol Oil

rotor two 550/575 medium use some racing Benol

rotor three 614 hp lots of serious drag racing Redline 2 Cycle Alcohol Oil

each mixed at the same ratio (approx 2 oz) and tuned by Nelson Siverio.

all 3 motors were running perfectly at time of dis-assembly. not touched prior to picture.

compare to a pump gas w meth AI rotor from my motor after 4 years of use. Atkins apex seals. 1 oz SuperTech (Walmart) 2 cycle, 1.5 on dyno.

That looks like a Bad Tune and too much Premix on the rotors. One oz Per gallon is more than enough. And those housings are getting eaten up by Seals. E85 isn't necessary the issue. But over pre-mixing is. I'm also wondering why all 3 engines would be sent back to you if they were running perfectly fine at the time of dis-assembly?