Warning: Aeroquip socketless hose not for FD3s rx7

#1

Warning: Aeroquip socketless hose not for FD3s rx7

A few months back, I had a socketless aeroquip -8AN hose for a second oil cooler popped off on me while I was idling at a light.

I thought it might have been the penetrating oil I used so I went out and bought another 10 feet of the Aeroquip socketless hose but used 10W40 oil this time.

Today I moved away from the light, heard a loud pop and saw a cloud of smoke in the rear view mirror. Pulled over and sure enough, the hose had popped off. Had the car towed home. I called up a local aviation hose shop. They told me that the socketless hose type are not designed for engine with high oil pressure. Well, our FD runs 80-120 psi cold and 60-80 psi warm.

I thought it might have been the penetrating oil I used so I went out and bought another 10 feet of the Aeroquip socketless hose but used 10W40 oil this time.

Today I moved away from the light, heard a loud pop and saw a cloud of smoke in the rear view mirror. Pulled over and sure enough, the hose had popped off. Had the car towed home. I called up a local aviation hose shop. They told me that the socketless hose type are not designed for engine with high oil pressure. Well, our FD runs 80-120 psi cold and 60-80 psi warm.

#2

Did the hose tear or pop off of the fitting? The hose is supposed to be good up to 250psi, so it sounds like it may have been a problem with the fitting, especially if it popped off during idle.

I've been running the Aeroquip stuff for quite some time now without any problems. When installing the hose I soaked it in hot water to soften it, and used motor oil for lubrication.

I've been running the Aeroquip stuff for quite some time now without any problems. When installing the hose I soaked it in hot water to soften it, and used motor oil for lubrication.

#4

I'm using socketless hose for all but one oil line.

It sees 120+ PSI pretty regularly during autox and track events, and have had no issues with the hoses.

In fact I had to pull a couple of connectors back off when I was installing the hoses (oops!) and they are just about impossible to remove without cutting.

Sounds like you may have some other issue with them, though I don't have a good suggestion as to what that might be.

Got a pic of the failed hose?

It sees 120+ PSI pretty regularly during autox and track events, and have had no issues with the hoses.

In fact I had to pull a couple of connectors back off when I was installing the hoses (oops!) and they are just about impossible to remove without cutting.

Sounds like you may have some other issue with them, though I don't have a good suggestion as to what that might be.

Got a pic of the failed hose?

#6

Did the hose tear or pop off of the fitting? The hose is supposed to be good up to 250psi, so it sounds like it may have been a problem with the fitting, especially if it popped off during idle.

I've been running the Aeroquip stuff for quite some time now without any problems. When installing the hose I soaked it in hot water to soften it, and used motor oil for lubrication.

I've been running the Aeroquip stuff for quite some time now without any problems. When installing the hose I soaked it in hot water to soften it, and used motor oil for lubrication.

I'm going to get aircraft type hoses made instead of messing with the braided lines.

#7

I'm using Summit's Twist-tite hose ends and hose which is their version of socketless fittings & hose. I used them for a second oil cooler as well and have been running them on my FD since November. I used Earl's assembly lube to put them together and so far theyre holding up well with no leaks as far as I can tell. Fris from lucky7racing has some socketless fittings on his track miata and hasnt had any problems either. I think his are the Summit brand as well.

Was it the same fitting that kept popping the hose off or was it a different fitting each time? Did you replace the fitting along with the hose? Maybe you have a bad fitting (assuming its the same one popping the hose off)?

I had to redo one of my lines as well to make it a little shorter and I couldnt pull the hose off without cutting it. So far my car has seen 1 track day and some daily driven action since installing the hoses. I'm going to inspect them as soon as I get a chance and see if theres any signs of them failing.

Was it the same fitting that kept popping the hose off or was it a different fitting each time? Did you replace the fitting along with the hose? Maybe you have a bad fitting (assuming its the same one popping the hose off)?

I'm using socketless hose for all but one oil line.

It sees 120+ PSI pretty regularly during autox and track events, and have had no issues with the hoses.

In fact I had to pull a couple of connectors back off when I was installing the hoses (oops!) and they are just about impossible to remove without cutting.

Sounds like you may have some other issue with them, though I don't have a good suggestion as to what that might be.

Got a pic of the failed hose?

It sees 120+ PSI pretty regularly during autox and track events, and have had no issues with the hoses.

In fact I had to pull a couple of connectors back off when I was installing the hoses (oops!) and they are just about impossible to remove without cutting.

Sounds like you may have some other issue with them, though I don't have a good suggestion as to what that might be.

Got a pic of the failed hose?

Trending Topics

#8

lol you put motor oil on the barbs before you tried to put on the hose? seriously were did it tell you to do that? Thats where you messed up, they will just slide off when you slobber them in oil. Use some force and push em on dry, mine hold like a champ.

#9

If they slide off it is due to the fittings and hoses being incompatible. In addition, if a "pushlok type" hose requires a clamp to stay in place, either the hose or fitting or both are not designed to be pushlok.

#10

Either works.

I also put the sockets in the freezer for 10 minutes, and plunge the end of the hose in some hot water for a minute.

Even then these aren't terribly easy to install.

No way a cars oil pressure is going to pop these off except under extraordinary circumstances.

Something like 50w oil and revving a cold engine to 8k might do it.

Oil filters have been exploded that way, so it might just pop off a hose.

The cure for that is, don't do that.

Could be the hose and socket are mis-matched.

If you can install the socket into the hose by hand without causing the veins in your arms and forehead to bulge, they are probably mismatched.

... or you spend way too much time in the gym.

#13

Anyone else have problems with these? Mine have been holding up well since November and I'm using the cheaper Summit brand fittings and blue hose. Are any of you with failures mixing fitting manufacturers with different hose manufacturers (Aeroquip fitting w/summit hose for example)?

#14

Anyone else have problems with these? Mine have been holding up well since November and I'm using the cheaper Summit brand fittings and blue hose. Are any of you with failures mixing fitting manufacturers with different hose manufacturers (Aeroquip fitting w/summit hose for example)?

Dave

#15

I used the Aeroquip hose with Summit fittings without any problem. The Summit stuff is actually about the same price as Aeroquip or Mocal.

Anyone else have problems with these? Mine have been holding up well since November and I'm using the cheaper Summit brand fittings and blue hose. Are any of you with failures mixing fitting manufacturers with different hose manufacturers (Aeroquip fitting w/summit hose for example)?

#17

I used them and had no problems with them  I also used a little bit of engine oil to slide them on. I doubt you can pull them off without cutting them, unless you are superman. Ask me how I know, haha

I also used a little bit of engine oil to slide them on. I doubt you can pull them off without cutting them, unless you are superman. Ask me how I know, haha

I also used a little bit of engine oil to slide them on. I doubt you can pull them off without cutting them, unless you are superman. Ask me how I know, haha

I also used a little bit of engine oil to slide them on. I doubt you can pull them off without cutting them, unless you are superman. Ask me how I know, haha

#18

Good article from Grassroots Motorsports on the topic of hoses and such:

http://grassrootsmotorsports.com/articles/hose-heaven/

http://grassrootsmotorsports.com/articles/hose-heaven/

#19

sorry to bump this terribly old thread, but i just randomly came across it and wanted to share my experience:

last year i helped a friend assemble a -6 aeroquip push lock type fuel system (all aeroquip hose and fittings) and we've had zero problems with it.

we put all the fittings in the freezer, and dipped the hose into boiling water for about 30 seconds before slipping it onto its fitting. this works like a charm, but make sure you have them marked and do it right the first time or you will absolutely not be able to get the hose off of the fitting. we messed one up and literally had to cut it off.

i used this same tactic for my -10 oil drain and it worked perfectly, and it is super tight.

this is not coming off... of course this is my 0 psi oil drain, but i have a hard time believing that a good fitting will let a hose shoot off at under 250psi...

i personally wouldn't recommend using motor oil for assembly, as the freezer / boiling water way seems to work very well.

last year i helped a friend assemble a -6 aeroquip push lock type fuel system (all aeroquip hose and fittings) and we've had zero problems with it.

we put all the fittings in the freezer, and dipped the hose into boiling water for about 30 seconds before slipping it onto its fitting. this works like a charm, but make sure you have them marked and do it right the first time or you will absolutely not be able to get the hose off of the fitting. we messed one up and literally had to cut it off.

i used this same tactic for my -10 oil drain and it worked perfectly, and it is super tight.

this is not coming off... of course this is my 0 psi oil drain, but i have a hard time believing that a good fitting will let a hose shoot off at under 250psi...

i personally wouldn't recommend using motor oil for assembly, as the freezer / boiling water way seems to work very well.

#20

My hoses and fittings have been working great since I installed them and havent had any issue with them leaking or popping off. I didnt freeze the fittings or dip the hose in hot water either. I just used a little bit of Earl's assembly lube to put them together and havent had issues since I first replied to this thread.

#23

half ass 2 or whole ass 1

iTrader: (114)

Joined: Nov 2011

Posts: 3,425

Likes: 481

From: okinawa to tampa

i had my aeroquip line pop off of push on fitting once. this was after install and on the first start up. i think it was because i hadnt pushed the line all the way down to the base of the fitting. i double checked the rest of the lines and sure enough there was another one that hadnt been pushed all the way to the base.

after that, it never happened again. i think the case from the op may have been user error or just one of those 1 in a million situations....

after that, it never happened again. i think the case from the op may have been user error or just one of those 1 in a million situations....

#24

guys,

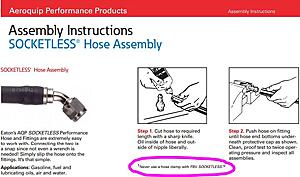

i recently did a dual oil cooler install (well, i added an rx8 cooler to the passenger side) and double-checked the oetiker clamps concept, and this is what i came across:

and also this excerpt from the aeroquip FAQ about their hoses:

Q: Should I use a clamp with the FBV (SOCKETLESSTM) hose and fittings?

A: No. In fact, the use of a clamp has been known to cause premature hose failure at the point of the fitting. This hose and fitting are designed and manufactured to work to the indicated specifications without a socket or clamp.

i recently did a dual oil cooler install (well, i added an rx8 cooler to the passenger side) and double-checked the oetiker clamps concept, and this is what i came across:

and also this excerpt from the aeroquip FAQ about their hoses:

Q: Should I use a clamp with the FBV (SOCKETLESSTM) hose and fittings?

A: No. In fact, the use of a clamp has been known to cause premature hose failure at the point of the fitting. This hose and fitting are designed and manufactured to work to the indicated specifications without a socket or clamp.

#25

guys,

i recently did a dual oil cooler install (well, i added an rx8 cooler to the passenger side) and double-checked the oetiker clamps concept, and this is what i came across:

and also this excerpt from the aeroquip FAQ about their hoses:

Q: Should I use a clamp with the FBV (SOCKETLESSTM) hose and fittings?

A: No. In fact, the use of a clamp has been known to cause premature hose failure at the point of the fitting. This hose and fitting are designed and manufactured to work to the indicated specifications without a socket or clamp.

i recently did a dual oil cooler install (well, i added an rx8 cooler to the passenger side) and double-checked the oetiker clamps concept, and this is what i came across:

and also this excerpt from the aeroquip FAQ about their hoses:

Q: Should I use a clamp with the FBV (SOCKETLESSTM) hose and fittings?

A: No. In fact, the use of a clamp has been known to cause premature hose failure at the point of the fitting. This hose and fitting are designed and manufactured to work to the indicated specifications without a socket or clamp.

I've built numerous cars in SCCA each with 20+ AN fittings most of which are socketless and I've never had a problem. I also use this bad boy:

KOUL tools 409: EZ-ON Hose Press Includes: -4 thru -16 Adapters | JEGS

Its well worth the investment if you're making more than a couple hoses.