Thoughts on eliminating the pressure tank while still sequential, Can it be done?

#1

Thoughts on eliminating the pressure tank while still sequential, Can it be done?

Ok here is what i'm thinking. I am running simplified sequential right now. I decided to relocate my solenoids over by the ABS while my engine is out. In effort to cut down on amounts of hoses running across my engine bay from the ABS spot i was looking at the pressure chamber set up. It only feeds one solenoid, the turbo control.

This solenoid is used to produce a quick transition by pressuring the turbo control actuator. This got me thinking... What if i just ran a hose to that solenoid with a check valve on it from the Y-pipe to the front nippl eof the turbo control solenoid? Immediately it looked like a legit idea but the more i think about it the more i wonder if i can do it. These are my concerns, feel free to add more or resolve them if you like...

1. Doe this solenoid constantly feed pressure to the actuator or does it just use a quick shot of pressure from the solenoid to make the transition? If it is constantly under pressure, not only when switching, then i would probably need a chamber to provide enough pressure over a long period of time as opposed to a somewhat long length of hose with a check valve.

2. The actuator test in the factory service manual to check its integrity requires around 15 PSI to move the actuator rod if i can remember right... This is a big area of concern. Does the presure chamber provide more pressure than what stock boost levels see? If i just ran a straight check valve would there enough pressure for a good transition or would i lose boost in a slow transtion?

3. assuming the transition would work if the above questions are resolved, i am wondering if a good transition would happen intermittenly. Once the solenoid was switched the pressure in the hose would eventually disappear if there wasn't a constant source, like the pressure chamber. Once you let off the gas would there be no pressure in the hose? probably not, especially if i shifted at transition, while the pressure in the hose was being depleted. (who shifts before rediline anyways ha ha but hypothetically speaking here). I think that this would be fine though seeing as how the primary turbo would spool up and provide presure back to the hose with the check valve in it before it was needed to make the shift into secondary boost. Also i guess while the scondaries are online the lost pressure in the hose would jsut be replaced, by more at the same moment yeah?

Does anyone see any flaws in this? i think it may boil down to whether the pressure chamber gives more pressure than 10 psi for the transition and if there needs to be a large constant amount of pressure being though the hose with the check vavlve, when when not in boost. I searched and didn't find anything on this topic or ideas related to eliminating the pressure tank without going ful non-sequential so feel free to make a discussion out of it guys. hopefully someone can help me figure this out.

This solenoid is used to produce a quick transition by pressuring the turbo control actuator. This got me thinking... What if i just ran a hose to that solenoid with a check valve on it from the Y-pipe to the front nippl eof the turbo control solenoid? Immediately it looked like a legit idea but the more i think about it the more i wonder if i can do it. These are my concerns, feel free to add more or resolve them if you like...

1. Doe this solenoid constantly feed pressure to the actuator or does it just use a quick shot of pressure from the solenoid to make the transition? If it is constantly under pressure, not only when switching, then i would probably need a chamber to provide enough pressure over a long period of time as opposed to a somewhat long length of hose with a check valve.

2. The actuator test in the factory service manual to check its integrity requires around 15 PSI to move the actuator rod if i can remember right... This is a big area of concern. Does the presure chamber provide more pressure than what stock boost levels see? If i just ran a straight check valve would there enough pressure for a good transition or would i lose boost in a slow transtion?

3. assuming the transition would work if the above questions are resolved, i am wondering if a good transition would happen intermittenly. Once the solenoid was switched the pressure in the hose would eventually disappear if there wasn't a constant source, like the pressure chamber. Once you let off the gas would there be no pressure in the hose? probably not, especially if i shifted at transition, while the pressure in the hose was being depleted. (who shifts before rediline anyways ha ha but hypothetically speaking here). I think that this would be fine though seeing as how the primary turbo would spool up and provide presure back to the hose with the check valve in it before it was needed to make the shift into secondary boost. Also i guess while the scondaries are online the lost pressure in the hose would jsut be replaced, by more at the same moment yeah?

Does anyone see any flaws in this? i think it may boil down to whether the pressure chamber gives more pressure than 10 psi for the transition and if there needs to be a large constant amount of pressure being though the hose with the check vavlve, when when not in boost. I searched and didn't find anything on this topic or ideas related to eliminating the pressure tank without going ful non-sequential so feel free to make a discussion out of it guys. hopefully someone can help me figure this out.

#3

1. Doe this solenoid constantly feed pressure to the actuator or does it just use a quick shot of pressure from the solenoid to make the transition? If it is constantly under pressure, not only when switching, then i would probably need a chamber to provide enough pressure over a long period of time as opposed to a somewhat long length of hose with a check valve.

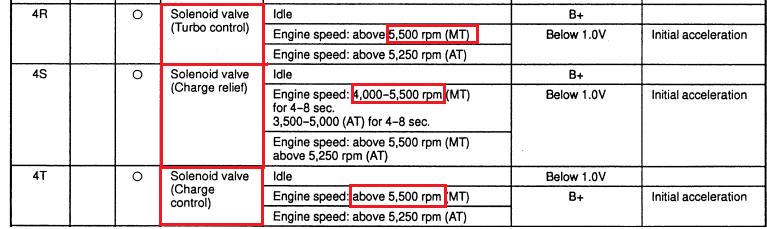

The two solenoids are both triggered from pin 4R. Before transition, the turbo control solenoids (which are normally closed) are OFF. At the point of transition, they both turn ON (ground is supplied from pin 4R) and the solenoids open to allow vacuum and pressure into both sides of the actuator. The solenoids stay open until rpm drops below the hysteresis point, regardless of manifold pressure.

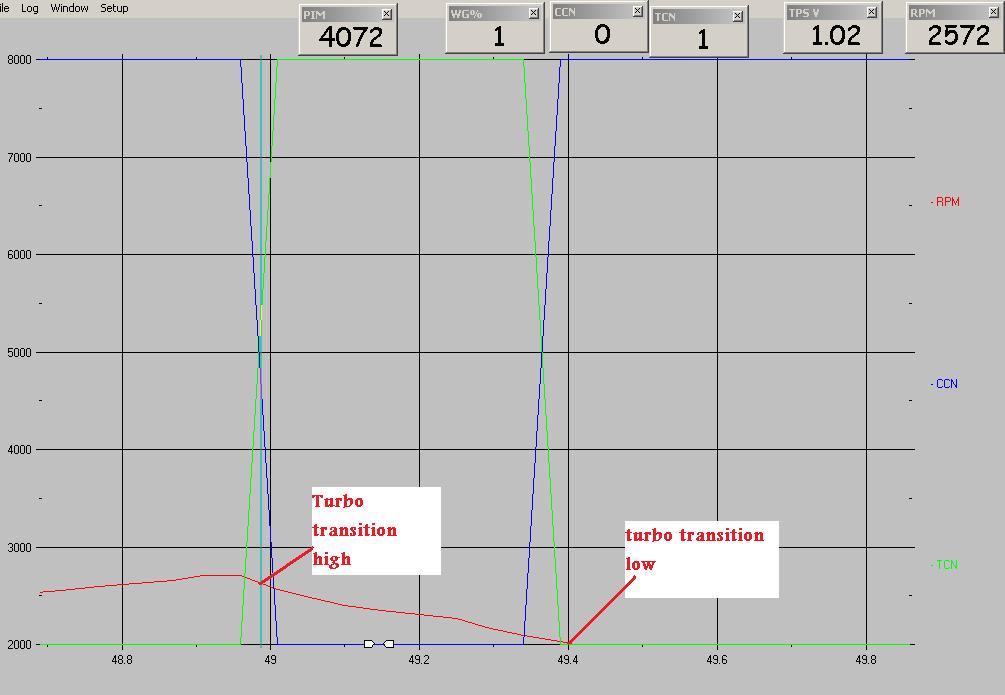

That point is 3000rpm but it can be changed if you have a Power FC and a Datalogit. In that log above I changed the "high" transition to 2500rpm and the hysteresis point ("low") point to 2000 rpm, just as a test. See post 31 of this thread https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

2. The actuator test in the factory service manual to check its integrity requires around 15 PSI to move the actuator rod if i can remember right... This is a big area of concern. Does the presure chamber provide more pressure than what stock boost levels see? If i just ran a straight check valve would there enough pressure for a good transition or would i lose boost in a slow transtion?

3. assuming the transition would work if the above questions are resolved, i am wondering if a good transition would happen intermittenly. Once the solenoid was switched the pressure in the hose would eventually disappear if there wasn't a constant source, like the pressure chamber. Once you let off the gas would there be no pressure in the hose? probably not, especially if i shifted at transition, while the pressure in the hose was being depleted. (who shifts before rediline anyways ha ha but hypothetically speaking here). I think that this would be fine though seeing as how the primary turbo would spool up and provide presure back to the hose with the check valve in it before it was needed to make the shift into secondary boost. Also i guess while the scondaries are online the lost pressure in the hose would jsut be replaced, by more at the same moment yeah?

3. assuming the transition would work if the above questions are resolved, i am wondering if a good transition would happen intermittenly. Once the solenoid was switched the pressure in the hose would eventually disappear if there wasn't a constant source, like the pressure chamber. Once you let off the gas would there be no pressure in the hose? probably not, especially if i shifted at transition, while the pressure in the hose was being depleted. (who shifts before rediline anyways ha ha but hypothetically speaking here). I think that this would be fine though seeing as how the primary turbo would spool up and provide presure back to the hose with the check valve in it before it was needed to make the shift into secondary boost. Also i guess while the scondaries are online the lost pressure in the hose would jsut be replaced, by more at the same moment yeah?

The old 2nd generation 87-88 cars had a turbo control actuator equivalent. It was the twin scroll actuator, which opened a second passage in the turbine housing at 2800rpm. That was controlled with a vacuum solenoid and a check valve.

#4

good information there arghx. i'm probably gonna agree with you on your last point that it couldn't bring any more performance gains or anything, and would maybe cause some laggy transition possible. that is all conjecture though from my side. I'm really just trying to eliminate extra hoses and not looking for any performance gains by this. not as many people are responding as i thought would. Maybe i'll just have to try it actually try it myself and experiment. Only thing is though it'll be a month or two before i can put my engine in, and then a thousand miles of break in after that before i can test the theory and see if it will still transition correctly without the tank.

#7

The purpose of the pressure tank is to make available positive pressure to the TCA via the solenoid switch at all operating phases of the engine. I suspect by eliminating the pressure tank there will be phases when the area of your re-routed hook-up in the Y-pipe will be experiencing negative pressure (vacuum) which will slow the operation of the TCA or cause sporatic function of the TCA and a poor transition to secondary turbo boost.

Trending Topics

#8

I've thought of making a pressure chamber from aluminum (same volume)

just to relocate it somewhere else in the engine bay, for a cleaner look.

And to get 1 more piece of plastic out of the engine bay

just to relocate it somewhere else in the engine bay, for a cleaner look.

And to get 1 more piece of plastic out of the engine bay

#9

#11

jd to rescue-

"The purpose of the pressure tank is to make available positive pressure to the TCA via the solenoid switch at all operating phases of the engine. I suspect by eliminating the pressure tank there will be phases when the area of your re-routed hook-up in the Y-pipe will be experiencing negative pressure (vacuum) which will slow the operation of the TCA or cause sporatic function of the TCA and a poor transition to secondary turbo boost."

wouldn't the only negative vacuum come when throttle is let off, all the other time the turbos would spool and provide pressure to the hose after the check valve, and thanks to this check valve no loss in that pressure or variation in air flow after the check valve, when the solenoid is not being grounded? and when it is being grounded wouldn't that pressure just be replaced by the turbos spooling? also another side thought. if that pressure is replaced and since it is a sealed system when the turbo actuator springs back under 3,000 rpms that would build that pressure even more in the hose since more air was packed in after the check valve during operation. that could be a positive, but also maybe somewhat bad for the solenoid to have to overcome that higher pressure when it is flipped off right? usually what goes bad on these solenoids is that when un-energized it has trouble closing that plunger over the pressure and slowly closes it. just a couple of random thoughts let me know what you think...

good input here guys. makes me wish i didn't have at least another month before i could try it myself

#12

also it seems that the primary turbo would provide the solid 10 psi needed for the solenoid every time, long before it is grounded and actually uses that pressure to control the transition right?

#14

Thread

Thread Starter

Forum

Replies

Last Post